Features of constructing a polycarbonate greenhouse

Rational use of material significantly reduces money and time costs. Experts advise following the rules:

- For arched structures, arcs of 6 and 12 mm are made.

- All joints must be on the profile. It is better to make the arcs and frame solid to increase strength.

- For a gable greenhouse, the wall and roof are oriented to the size of the sheet. Each plate must be divided without leaving any residue.

- Gaps of about 2-3 mm are made between the frame and the sheets. This is done to allow polycarbonate to expand freely when heated. For the same purpose, the holes for the bolts are made slightly larger than the stated diameter.

- In places where bolts are attached, it is preferable to use rubber washers to soften expansion. This way the cracks will not appear.

- It is better to cover the external ribs with a vapor-proof film or profile. Provides moisture protection and eliminates clogging. The inner edges are left as is to allow condensation to drain freely.

In this way, savings are achieved without loss of greenhouse productivity.

During transportation, polycarbonate is laid flat in the body. Positioning on the edges deforms the sheets. Plates up to 8 mm must fit completely into the machine to avoid breakage. Thicker ones can be left suspended for 0.5-1 m. Thin flexible options can be rolled into a half roll and secured with tape.

The material is stored in a dry, closed room away from open sun. A barn or garage is great. On the street, it is better to stack the blanks on top of each other without packaging (UV layer up) and cover with an awning.

Non-aggressive means are used to clean the walls of the greenhouse. The best option for washing is soapy water and damp cloths. After cleaning, the walls are wiped dry to maintain better transparency.

A wise choice and work with polycarbonate is the key to a long service life of the greenhouse, a good harvest without harm to the plants.

Polycarbonate is an impact-resistant polymer that retains heat well. Compared to glass, it is less fragile: if it breaks, it will not result in dangerous fragments. Also, unlike glass greenhouses, polycarbonate structures are resistant to vibration and temperature changes. The flexibility of the material allows you to create round-shaped greenhouses. It is easier to install the greenhouse due to the light weight of the sheets.

Polycarbonate is an impact-resistant polymer that retains heat well

Compared to polyethylene film, polycarbonate is more expensive, but it is much more durable. If high-quality sheets are selected, then with proper operation the greenhouse will last 15–20 years.

Polycarbonate greenhouses are installed in the Far North and are used year-round, since the material retains heat well and is not afraid of frost

It is only important to choose sheets of the required thickness and strength so that the roof does not deform under the weight of the snow cover

Classification of polycarbonate

The material is made in two types:

Monolithic

Solid sheets of different sizes and thicknesses.

The monolithic version resembles cloudy glass. It has a noticeable weight, an aesthetic appearance, is very durable, but it is also more expensive. This polycarbonate is easy to install without additional frames. Meanwhile, monolithic sheets practically do not retain heat. In such a greenhouse, sensitive plants will freeze.

Cellular

Two or three sheets connected by a layer of numerous ribs. The structure resembles a honeycomb, hence the name.

Cellular cells scatter light better and evenly distribute the temperature inside the structure. The seedlings will not get burned or suffer from overheating or hypothermia. This material is much cheaper. In addition, cellular polycarbonate is more flexible. It is attached to the frame even in the form of arches. Lightweight series with thin ribs are available.

For the construction of greenhouses and hotbeds, cellular polycarbonate is predominantly used.

What polycarbonate do you choose?

Cellular

Monolithic

UV protection

Transparent plastic is exposed to intense sunlight during operation. The processes of photoelectric destruction, triggered by the ultraviolet part of its spectrum, lead to the formation of microcracks on the surface, which grow over time and lead to brittleness and gradual destruction of the panel.

A special coating is applied to the outer layer of cellular polycarbonate to protect against these processes. The technology of coextrusion—the mutual introduction of materials—allows us to eliminate the separation of the protective layer from the base.

This coating is applied to most types of material only on one side. To inform the user, a mark is placed on the packaging film, which indicates the order of installation of the panel.

Certain types of polycarbonates are produced with a photostabilizing coating on both sides of the sheet. Such panels are used for noise-absorbing screens or outdoor advertising structures, which are installed near populated areas along major roads. For the construction of a greenhouse, their use does not make sense, since in this case only one side is exposed to ultraviolet radiation.

Manufacturers offer polycarbonate without a light-stabilizing layer. Such panels are used only for interior work; they are not suitable for greenhouses. After just a year of operation, such panels are destroyed as a result of destructive processes.

Experts recommend using high-quality cellular polycarbonate from well-known manufacturers with one-sided UV protection for greenhouses. Such sheets are covered with a film indicating the side on which there is a protective layer.

When choosing polycarbonate, you should always pay attention to quality. Well-known manufacturing companies value their reputation and produce products of higher quality

High-quality products must bear the manufacturer's mark. It is usually located on the front side.

The marking contains information about the manufacturer, sheet dimensions, thickness, grade of material and production date. The light barrier layer is always on the front side and should always be on the outside when installed. Lightweight brands are designated “Light”; the sheet thickness (3-4 millimeters) may not be indicated on them at all.

The surface of the sheets must be flat, smooth, without kinks or scratches. They are covered on both sides with a thin film with the company logo printed on the front side of the sheet. The material should not contain bubbles, opaque cloudy areas, or other inclusions.

Even an experienced craftsman is not always able to visually distinguish cheap fakes from high-quality polycarbonate. Before purchasing, be sure to read the documentation for the product.

Hoping for excessive gullibility of buyers, unscrupulous companies sometimes sell low-quality polycarbonate, indicating on the packaging the logos of brands that do not supply products to Russia. The seller is required to provide a certificate of conformity for the product.

The quality of construction largely depends on the choice of consumables for the sheathing and the correct installation. To prevent the panels from cracking due to thermal compression and expansion, the diameter of the bolt or screw should be slightly smaller than the holes for the fasteners.

The panels are mounted on a special H-shaped profile. To prevent foreign particles and moisture from entering the sheet, all open edges of the material are covered with a special vapor-permeable profile. The bottom edge of the sheet is left open, through which the resulting condensate drains.

We advise you to study - Types of fireplaces by fuel type, installation method, construction and design

The advent of polycarbonate has significantly simplified life for summer residents and owners of large agricultural companies. This material is superior to its closest competitors and glass in many respects, but the expansion of its range has led to difficulty in choosing and an increased risk of purchasing a low-quality product. Today, both those who build a greenhouse with their own hands and those who prefer to buy a ready-made structure are equally concerned about the question of how to choose polycarbonate for a greenhouse so that the material will last for many years and ensure normal conditions inside the structure. Looking ahead, we note that it is worth considering a lot of nuances

, but a careful approach will be rewarded with high durability of the greenhouse and minimal repair costs.

Polycarbonate for a greenhouse - which is better?

Experts recommend using cellular polycarbonate for greenhouses. Which is the best of those on the market? Let's consider the main material parameters that should determine your choice.

Thickness of polycarbonate for greenhouse

It would seem that the thicker the sheet, the stronger it is; accordingly, the greenhouse will be more durable and resistant to damage. But when it comes to growing vegetables, you cannot adhere to only this point of view. The fact is that the thickness of the sheets determines their light transmittance. Evaluating this parameter allows you to determine what thickness of polycarbonate is best to use for the greenhouse.

| Sheet thickness in mm | 4 | 6 | 8 | 10 | 16 | 20 | 25 |

| Light transmittance in % | 85 | 81-83 | 80 | 79 | 62 | 61 | 60 |

As can be seen from the table, the light transmittance of the material decreases as its thickness increases. At the same time, it is unacceptable to use panels that transmit only 60 percent of solar energy in agriculture, since this is critically low for plants.

The thinnest plastic for greenhouses demonstrates the maximum level of light transmission. But in this case, it will not satisfy the buyer’s needs, since its strength is not enough to cover large horizontal surfaces exposed to snow loads.

Therefore, the recommended thickness of polycarbonate for a winter greenhouse is from 6 to 10 mm. It may be advisable to use the strongest material where the load is greatest. That is, install thinner sheets, 6 mm thick, on the walls, and the strongest ones, 10 mm, on the roof.

Polycarbonate for greenhouses – which color is better?

The choice of color can be a pressing task first and foremost when designing a decorative structure. Is there any fundamental importance in choosing the color of the material for the greenhouse roof? And what color of polycarbonate is best to use for a greenhouse?

Experts are confident that in this matter it is important to understand the only point - the coloring of the polymer is carried out by introducing tinting dye particles into its structure. Therefore, for example, blue polycarbonate creates a shading effect on a sunny day, as it cuts off part of the solar spectrum.

It is rational to use this property for arranging canopies and canopies. However, for a greenhouse it is important to use panels with maximum light transmission. Only transparent sheets have this. Therefore, in the question of which polycarbonate for a greenhouse is better, you should focus exclusively on colorless transparent panels.

Polycarbonate with UV protection

Another point that buyers often don’t think about is the level of protection of the material from sunlight. Like any plastic, polycarbonate itself is defenseless against ultraviolet radiation.

Under the sun, processes of destruction increase in its structure. Visually, this is manifested by an increase in the number of microcracks, the surface becomes noticeably cloudy and yellow. Dust gets clogged into microcracks and prevents the passage of sunlight. As a result, not only the light transmittance of the material decreases, but also its strength. Under the weight of snow, the roof of the greenhouse will burst in the first winter.

Light stabilization technology allows you to protect the material from destruction by the sun. It involves introducing UV filters into the structure of sheets or applying UV filters to their surface. The most effective today is coextrusion - a technology for applying a UV protective layer to the surface of the sheet, which allows you to obtain truly durable polycarbonate for greenhouses. You can buy it with a guaranteed service life of up to ten years.

Material without UV stabilization is not intended for outdoor use; it can only be used indoors. Such polycarbonate is not suitable for installing a greenhouse, as it will become unusable within one year.

The price of carbonate for greenhouses with UV protection is higher than without it. However, it is important to remember that the service life of such material is much longer. In addition, when choosing protected panels, you can focus on the most budget option, because manufacturers offer sheets with one-sided and double-sided protection.

The latter are intended for use outdoors, provided that each side is illuminated by the sun. Double-sided protection is relevant when polycarbonate is used to install noise-insulating screens or stop pavilions. When it comes to a greenhouse, you can choose a cheaper material with one-sided protection, since its reverse side will not be exposed to the sun.

Which brand of polycarbonate is better?

There are many brands on the market offering cellular polycarbonate. Manufacturers from Europe, Russia, and China sell products at completely different prices. And the buyer is always tempted to pay less, because, at first glance, everyone’s products are the same.

This is fundamentally wrong. There are four criteria by which the quality of polycarbonate panels is determined.

- What are they made of? Granulated raw materials are used for production. First of all, the quality of the finished product depends on it. The quality of raw materials varies among different manufacturers. The world's leading producers of granulate are BAYER and SABIC. In Russia, the only manufacturer of such products is. If the panels are made from high-quality raw materials and exclusively primary ones, without additives, we can say that the first criterion meets the ideal.

- How much do they weigh? A 4 mm thick polycarbonate sheet from the manufacturer can weigh 0.65 - 0.8 kg per square meter. At the same time, the optimal weight is exactly 800 grams, while lightweight versions are always savings and not entirely reasonable. A reputable manufacturer must mark the reduction in the volume of raw materials in the finished sheet with a special marking, for example, Light, that is, lightweight. If the manufacturer does not do this, he is deliberately deceiving the consumer.

- Are you protected from the sun? We have already discussed the need to protect panels from the sun above. Let us only repeat that the thickness of the protective layer on the surface should be 35-60 microns. The thickness of the coating on a sheet can only be checked in a laboratory, so you should only buy polycarbonate whose brands are recognized by specialists in the areas of application. Along with this, the declared properties and characteristics of a material of a particular brand must be documented by relevant test reports.

- What equipment were they made on? Another point that remains a secret “behind seven locks” for the end consumer. Let us only note that modern, technological equipment is very expensive; only leading brands can “afford” its purchase. By trusting the brand name, you are more likely to buy quality material.

In Russia, polycarbonate that meets all quality standards is represented by products of several brands.

- European - Polygal, Lexan, Makrolon (BAYER). The companies are recognized as world leaders in the production of high-quality polycarbonate.

- Russian – Novattro, Kazansky, Actual Bio. The products of these brands are manufactured in Russia and today provide worthy competition to European market leaders.

Choose products from leading polycarbonate manufacturers who guarantee their high quality. Using inexpensive and durable sheets, you can install a greenhouse of the required size for year-round use.

No. 2. Selecting the thickness of cellular polycarbonate

Thickness is a determining factor when choosing polycarbonate for a greenhouse

In this matter, it is important to take into account a lot of factors and choose a material that is not too thin, but not too thick: in the first case, strength decreases, in the second, light transmission deteriorates.

The main factors that influence the choice of polycarbonate thickness:

- climate of the region

, especially the height of the snow cover and its weight, which determines the maximum load on the material; in the region; - frame material

. A metal frame has better load-bearing capacity and can withstand higher loads than a wooden one; - sheathing step

. The closer the greenhouse frame elements are located to each other, the more durable the structure will be and the less thick the polycarbonate may be needed; - seasonality of use

. If the greenhouse will be used only in the autumn-spring period, then thinner polycarbonate can be chosen. For year-round greenhouses, the material chosen is significantly thicker, because it must withstand not only snow and wind, but also retain heat; - type of

construction If you plan to build an arched, dome or teardrop-shaped greenhouse, you need to think in advance whether it will be possible to bend the polycarbonate in a certain way. The thinner the material, the higher the bending radius.

How to choose the optimal thickness taking into account all these factors? To get the most accurate value, you can turn to professionals. The second option is to buy, the kit already includes polycarbonate of optimal thickness (the type of construction and climatic features are taken into account). An alternative solution is to try to choose the required polycarbonate yourself: complex calculations are not needed, since you can be guided by the practice of using the material, the main parameters of polycarbonate sheets of different thicknesses (in the table below) and data on the climate of the region, which is also easy to obtain on the Internet.

Optimal parameters for thickness

When choosing the thickness of sheets for a greenhouse, it is necessary to take into account several decisive parameters: climatic conditions of the region, frame material, lathing pitch, seasonality of use, what plants will be grown, type of construction:

- Thickness 4 mm. Suitable for arranging non-professional greenhouses, it bends easily, is easy to process and install, and lets in more light. The main advantage is the low price. But it should also be taken into account that such polycarbonate will not withstand heavy rainfall and strong winds. To increase stability and strength, you will need a large number of ribs and regular cleaning. This design is not suitable for regions with harsh winters.

4mm thick monolithic polycarbonate is an inexpensive but unsustainable solution - Thickness 8–10 mm. A greenhouse made of such polycarbonate is much stronger and stronger; under certain operating conditions it can be used in winter. Due to the thickness, the strength of the material and thermal insulation increase, but at the same time its weight also increases. Transmits light well, easier installation and fastening. However, the cost of such polycarbonate is much higher than thin polycarbonate, which not everyone can afford.

- Thickness 15 mm. The most expensive type of material with a high degree of frost resistance and thermal insulation. Excellent resistance to precipitation pressure and sudden gusts of wind. Suitable for greenhouses with the possibility of artificial lighting, winter gardens.

Some manufacturers produce sheets with a thickness of more than 15 mm. But their use for greenhouses is unprofitable.

Why is the density of cellular polycarbonate important for greenhouses?

Density means the mass of 1 square meter of material. If the density is 0.8 kg, then 1 meter weighs 800 g.

For example, a polycarbonate sheet measuring 3x5m. density 0.8 kg. will weigh 12kg. The same sheet with a density of 0.6 kg. weigh 9kg. In terms of cost, the second option will be 25% cheaper, but it is not suitable for greenhouses.

What is the advertisement lying about?

Often on websites, the descriptions of greenhouses include epithets: reinforced, impact-resistant, reliable. The following are inflated figures that do not coincide with the values in the material passport and warranty card. The main load on the greenhouse is snow. Depending on humidity, 1 cube of snow weighs about 300 kg, which means that:

- with a maximum load on the greenhouse according to the passport of 100 kg, it will withstand a layer of snow of 33 cm. Such a greenhouse will have to be cleaned regularly.

- if according to the passport the largest load is 250 kg, the greenhouse will withstand 75 cm of snow. It can be cleaned a couple of times during the winter.

- when the maximum permissible load starts from 300 kg, the greenhouse does not need to be cleaned even in a snowy winter.

Nuances of choosing cellular polycarbonate

The huge variety of cellular polycarbonate on the building materials market confuses the average person. Questions immediately arise: how to choose high-quality material at an affordable price, which characteristics are important in the first place, and which are secondary. We will try to give some practical advice on how to choose polycarbonate and what to look for when purchasing it.

Before delving into the technical specifications, you should decide why the material is being purchased. Most often in private construction, polycarbonate is used for greenhouses, canopies, gazebos, and fences. Depending on the functions that the polycarbonate will perform, the appropriate characteristics will be selected. So, pay attention to the following characteristics:

- thickness and structure.

The thickness of polycarbonate sheets can be 4, 6, 8, 10, 16, 20, 25, 32, 40 mm. Lightweight versions with thicknesses of 3.2 and 3.7 mm are available. For greenhouses that are not dismantled for the winter, sheets with a thickness of 6-8 mm are more suitable. Thicker ones will transmit less light, which is so necessary for plants. Sheets with a thickness of 3.7-4 mm are suitable for greenhouses with a milder climate and the absence of heavy snowfalls. It is better to make small canopies and gazebos with a material thickness of 6-8 mm; for roofing it is better to use a thickness of 16 mm or more.

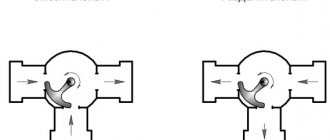

According to the structure, one-, two-, four- and six-chamber cellular polycarbonate is distinguished. They differ in the number of layers connected by jumpers. In addition, different arrangements of jumpers are possible (H-shaped and X-shaped), which also affects resistance to impacts and other mechanical influences.

- density.

The strength of the material and the ability to withstand negative weather influences (snow, wind, hail) depend on this indicator. The density value varies between 0.52-0.82 g/cm3. Sheets of the same thickness can have different densities, this depends on its structure (number of jumpers). Logically, the denser the sheet, the heavier it is.

- weight.

Weight directly depends on the density of the sheet. Accordingly, the lighter the sheet, the less dense and less impact resistant it is. Some manufacturers produce lightweight versions of polycarbonate sheets, but they must be marked with a special word, for example, Light. In world practice for the production of this material, the following indicators are considered to be the standard weight of a sheet of 1 m2: 4 mm - 0.8 kg; 6 mm – 1.3 kg; 8 mm – 1.5 kg, 10 mm – 1.7 kg.

- UV protection.

Without protection from UV radiation, polycarbonate begins to deteriorate after exposure to sunlight after 2-3 years. Therefore, manufacturers apply a special protective layer to increase service life. The service life of polycarbonate with UV protection is more than 10 years. Depending on the protection application technology, this period can be up to 30 years. The presence of a protective layer is reflected in special markings.

- minimum bending radius.

This characteristic is important when using sheets for the installation of curved structures (arched greenhouses, canopies, gazebos). This indicator depends on the thickness and structure of the sheet and is 0.6-2.8 m. It is advisable not to exceed the permissible bending radius so as not to disturb the structure of the sheet and the UV protective layer.

- light transmittance.

This parameter depends on the thickness of the sheet, its color and transparency. For different manufacturers, this parameter for transparent polycarbonate 4 mm thick varies from 80 to 95%. The thicker the sheet, the less light transmission.

Having found out what you should pay attention to when purchasing this material, you can begin to choose. We have presented to your attention the best manufacturers of polymer materials and their brands of cellular polycarbonate.

Quality criteria

Choosing high-quality polycarbonate for arranging a greenhouse structure is not difficult. It is enough to be guided by basic recommendations that take into account the quality criteria of this covering material.

- Retail chains offer a huge selection of polycarbonate, but high-quality coatings are produced under the brands of well-known brands that have proven themselves well, judging by consumer reviews.

- A lightweight type of plastic is suitable for greenhouse structures installed in warm regions of our country. This material has thin walls and partitions, which does not allow it to withstand low temperatures. In addition, the lightweight version does not allow the structure to be given the necessary rigidity and durability.

- The compliance of the material with production standards also requires attention. Given the declared thickness, it is advisable to double-check the information and measure this parameter yourself.

- High-quality and original polycarbonate has a mark on the surface that confirms the application of a protective UV film.

- High-quality plastic is easy to process, and when drilling or cutting it does not form cracks or chips.

Before purchase

Before purchasing, carefully study the inscriptions on the protective film. Many sellers often present lightweight and cheap polycarbonate under the name of a leading brand.

Correct manufacturers always indicate in their labeling that this is a lightweight option. And you may not find anything at all in cheap Chinese products.

If you receive an offer to buy material much cheaper than the manufacturer sells, this should alert you. And you can immediately think whether you are rich enough to change polycarbonate for the next season.

Determining quality

The future material for covering the greenhouse is responsible for obtaining the harvest. The strength and stability of the structure and its ability to influence the external environment depend on it.

Therefore, it will be useful to learn some tips that will help you choose a quality product:

- There is a large amount of low-quality material in the retail trade. Therefore, it is better to pay attention to brands that have proven themselves well. You can read reviews on the Internet;

- Many offer lightweight polycarbonate. In most cases, it is intended for use in countries with warm climates, and is not suitable for use in our conditions. Produced with a thin wall and thin partitions. Does not withstand temperature changes well. Does not create the required structural rigidity and is not durable;

- Pay special attention to production standards. If I suggest you purchase polycarbonate with a thickness of 4 mm. Measure it, if in fact it turns out to be 3.5, you shouldn’t linger near such material. This is a fragile and low-quality material;

- Determining the weight of the sheet will also help in choosing a panel for the greenhouse. The weight of a standard sheet should be 10 kg, its lightweight counterpart weighs 8.5 kg (may weigh less). Lightweight and costs less than normal. But it does not have high wear resistance;

- High-quality material always has a mark on its surface, which indicates the application of a protective film from ultraviolet rays. A person must know how to attach the material

- High-quality plastic is well processed and is quite soft. Poor, can chip during processing, and crack when bending.

Professionals advise checking the documentation for the material.

High-quality products always have accompanying documents that indicate the manufacturer, weight, dimensions, contain complete information about UV protection and detail the warranty.

The packaging of the panels is done with high quality, the products are placed in polyethylene. A marking is always made on the UV-protected side; such a marking must also be located on the edge of the material elements. Without such marking, you should not buy the offered material.

High-quality sheets are packed in film without any swelling or irregularities. If the packaging is made of transparent material, the bluish side on which the UV coating is applied will be visible to the light. There can be no scratches or foreign bodies on this surface.

When is it used?

People often start choosing greenhouses from the wrong direction. Of course, the frame, material and coating also play a huge role, but all this matters only if you decide on the seasonality of the greenhouse’s operation. This is where we propose to start. The most common use is when the greenhouse is not dismantled for the winter, but plants are grown only in the summer.

Summer use of the greenhouse

Another method of operation is winter, when the greenhouse is not only not dismantled for the winter, but also continues to perform its direct function of growing plants. The third option is prefabricated greenhouses; they are light and compact, so before the onset of cold weather they are disassembled and stored in a garage or shed.

With heating: 2 harvests per year, vegetables all year round. Without heating: growing greens, no heating required

In the absence of heating, only greens can be grown in winter greenhouses: lettuce, dill, parsley and green onions. When equipping a greenhouse with a heating system, mushrooms (oyster mushrooms and champignons), eggplants, tomatoes and even some types of flowers are added to this list.

Collapsible design

What type of polycarbonate is best for greenhouses?

To make an informed decision on this issue, it is necessary to understand the properties and technical characteristics of this material. The industry produces two types of polycarbonate: monolithic and cellular, the latter is precisely used for the construction of greenhouses. In terms of their parameters, such panels best meet all the requirements for roofing materials for such structures.

Before the appearance of cellular polycarbonate on the market, silicate glass and polyethylene film were used for these purposes.

The use of cellular polycarbonate has a number of advantages over the above materials:

1. Low specific gravity of the sheet.

Depending on the type of panel, its mass is no less than an order of magnitude lower than that of a glass sheet of the same size.

2. High mechanical strength.

When struck, cellular polycarbonate does not crumble into separate fragments like glass and is not prone to tearing like polyethylene film.

3. Resistance to climatic conditions.

High resistance of the material to climatic influences: significant temperature fluctuations, rain and snow.

4. Low thermal conductivity.

Low thermal conductivity and, as a result, excellent insulating properties, which significantly reduces the cost of heating the greenhouse.

5. Light transmission and UV protection.

Excellent light transmission of panels in some types is over 86% and reliable protection from harsh ultraviolet radiation.

We advise you to study - How to choose doors for the bathroom and toilet, taking into account the features of these premises

6. High plasticity of the material.

Plasticity of the material: during installation, it can bend to a certain diameter and remains in this position for a long time.

Cellular polycarbonate is durable; provided the panels are selected and installed correctly, the service life is 10 years or more without significant changes in properties.

An important factor in favor of choosing cellular polycarbonate as a material for greenhouses is the financial side of the matter. It is much cheaper than glass, and given its high durability, its use is more profitable than using polyethylene film. In addition to the direct effect of choosing cellular polycarbonate as a material for greenhouses, there are also side effects.

The use of these panels allows the use of load-bearing frames with a smaller margin of safety, which will save considerable money when constructing such structures. Due to its unique technical characteristics, cellular polycarbonate is becoming increasingly widespread in the construction of greenhouses.

The best cellular polycarbonates 4 mm thick

Main area of use: cellular polycarbonate for greenhouses and greenhouses. The products are recommended for use in creating canopies with an area of up to 50 sq.m. taking into account recommendations on the frequency of sheathing. Used for glazing balconies, terraces, gazebos and garden pavilions. The low price makes this category popular among summer residents and owners of country houses. We compared the properties of products from 7 brands and recommend buying one of the three types presented. These brands have good strength and can withstand increased loads.

Borrex

The sheets are characterized by increased strength and good light transmittance, which is 84%. The increased density has a positive effect on shock resistance. The bending radius is only 70 cm, which makes the polymer the best material for arranging small greenhouses and greenhouses with an arched structure.

When producing polycarbonate, ultraviolet blockers are introduced into the composition, which provide reliable protection against destruction under the influence of UV radiation. The manufacturer provides a 15-year warranty on its products. The brand’s assortment also includes monolithic cellular polycarbonate 4 mm thick, which is highly resistant to aggressive substances, but has increased weight.

Advantages:

- Good elasticity;

- Minimum water absorption;

- Heat resistance;

- Two sheet sizes;

- Wide palette.

Flaws:

- Overcharge.

Will Premium reinforced

Reinforced polycarbonate with an additional diagonal partition that helps cope with high static loads. Density 850 g/sq.m. makes plastic convenient for installation, increases resistance to mechanical stress. Technical parameters allow the use of sheets in the construction of canopies, canopies, and gazebos.

A UV layer is applied to the marked side, blocking hard ultraviolet radiation, preventing the destruction of the plastic. A good bending radius makes the sheet convenient for the construction of arched structures.

Advantages:

- Scatters light well;

- Service life up to 20 years;

- Resistance to aggressive chemicals;

- Light weight reduces the load on the frame.

Flaws:

- It is necessary to use components from other manufacturers during installation.

Actual

The sheets have a low density and good elasticity, which makes them easy to roll. Light weight reduces stress on the frame. High strength is ensured by an additional partition; the reinforced structure resists static and shock loads well. The building material is fire resistant.

Plastic is well protected from the destructive effects of solar ultraviolet radiation and has a service life of at least 15 years. It has good light transmittance, evenly scatters light, creating good conditions for the development of plants in greenhouses.

Advantages:

- Low price;

- Smooth surface;

- Protection against condensation;

- Good thermal characteristics.

Flaws:

- Available in one sheet size.

Which form should I choose?

It is usually said that content is more important than form; with greenhouses the opposite is often true. The structures can be arched, pointed (cone-shaped), with a pitched roof, etc. The arched type is universal, it is suitable for summer and winter use. For a summer greenhouse, film or polycarbonate is used, in winter - only polycarbonate. It will not be possible to bend glass into an arched shape.

Distribution of snow load in greenhouses of various shapes

The lancet greenhouse has an additional stiffening rib, which strengthens the structure; snow also rolls off better in winter. A greenhouse with a gable roof can be considered a “classic”. This is the only option that is suitable for glazing. Also, such a design is easier to reproduce during independent construction. Gable greenhouses are well suited for growing tall plants.

If a gable greenhouse will be installed all year round, you need to seriously think about eliminating the snow load or strengthening it, since the entire weight of the snow cover will be concentrated at only two points.

Location of the wall greenhouse

Wall-mounted greenhouses are good in areas with a lack of free space. They allow you to use the wall of the house as a support. It is convenient if a separate exit is made from the building to the greenhouse. The structure should be located on the south side; from the north, the plants will always be in the shadow of the house.

Which cellular polycarbonate is better

The material is used for the construction of industrial greenhouses with gable roofs and small greenhouses with a semicircular profile. The sheets are used in the construction of small canopies over the balcony and installation of awnings, under which several cars can be hidden. All this requires materials with different technical characteristics. The choice is also influenced by the amounts planned in the project estimate. For these reasons, our experts did not choose universal plastic, but suggest choosing the following types, depending on the planned work:

- Skyglass – for industrial glazing and the production of noise-insulating screens;

- Woggel yellow – for designer partitions and light-transmitting structures;

- Greenhouse-Nano – for home greenhouses and small farms;

- Volya Premium reinforced - for country greenhouses and hotbeds.

All polycarbonate offered has a service life of more than 15 years and can withstand high loads. Only such material has the right to be called the best in its category.

Color and honeycomb matter

When choosing cellular polycarbonate, you should pay attention to its structure - it also has a significant impact on its strength, light transmittance and overall quality. There are three types of honeycombs

There are three types of honeycombs.

- Rectangular.

The type of polycarbonate with such honeycombs is used most often. This polycarbonate has low strength, but at the same time it transmits light well and is perfect for creating small greenhouses. Polycarbonate with rectangular honeycomb - Square.

Polycarbonate with this type of honeycomb is stronger than the previous type. Typically used for fairly large structures. Square Honeycomb Polycarbonate - Hexagonal.

Material having honeycombs of this shape is the strongest and is not afraid of winds and snowfalls. But it transmits light much worse. Typically used in the construction of roofs, it is rarely used as a covering for greenhouses. Cellular polycarbonate with hexagonal cells (top)

In order not to spend extra money, it is worth clearly weighing all the requirements for the future structure. There is no point in installing a polycarbonate greenhouse with hexagonal honeycombs in a warm and windless region - these will be unjustified costs. And such material transmits light less well, which means it is not suitable for plants, especially light-loving ones, so you will have to spend money on additional lighting.

The color of cellular polycarbonate is also of great importance. In pursuit of fashion, manufacturers now offer material in almost any color - not only yellow, green, red, but even black. But when choosing polycarbonate by color, you should first of all think not about the design, but about the plants that will live in the greenhouse. It is worth carefully familiarizing yourself with the light transmittance of each type, and the lighting should be as close as possible to the natural level - only in this case will the representatives of the flora in the greenhouse be comfortable.

Types and colors of polycarbonate

Not all colored sheets meet this requirement. For example, blue polycarbonate absorbs 40% of solar radiation, and bronze – all 60%. It is also worth remembering that colored polycarbonate often transmits only a certain part of the spectrum, and there is no guarantee that it will only block the type of radiation that is dangerous to plants.

Light transmission of cellular polycarbonate

Based on the above, we can conclude that the optimal polycarbonate should be transparent and have a square honeycomb. This will be the optimal solution in combination with a material thickness of 8 mm.

Which option is best for building a greenhouse yourself if you have no experience?

To build a greenhouse yourself, it is better to choose transparent honeycomb material with a thickness of 6–8 mm. When purchasing, you need to check the quality of the sheets: from information about the manufacturer and dimensional data to the presence of UV film

It is also important to inspect the packaging for damage and the sheets themselves. High-quality polycarbonate has no cracks or bubbles, the stiffeners are not bent

To build a greenhouse yourself, it is better to choose transparent honeycomb material with a thickness of 6–8 mm

Polycarbonate sheets with a width of 2.1 m can be 6 and 12 m long. It is better for novice builders to work with six-meter sheets.

For rational use of materials and effective installation, professionals advise:

- in arched structures, the arcs must be equal to the length of the sheet so that there are no transverse joints;

- when calculating the parameters of the greenhouse, it is necessary to ensure that the joints of the slabs fall on the frame metal profile to increase strength;

- all sheets must be mounted in one direction;

- When creating gable greenhouses, it is better to distribute the polymer coating without cutting or residue.

In hot weather, this material expands with every degree, and in cold weather it decreases in size. This must be taken into account when attaching the sheathing to the frame. The mounting holes should be slightly larger than the diameters of the screws. This will help avoid cracking. Also, to avoid deformation due to temperature changes, you need to place a rubber washer or a special thermal nut under the fastener head.

Video about installing a polycarbonate greenhouse

When choosing a material, pay attention to the size and quality of the sheet. You shouldn’t save money and buy cheap and low-quality material, because it will last very little

If all installation rules are followed and the right choice is made, the greenhouse coating will serve for a long time and reliably.

Modern greenhouses can significantly increase the growing season of any plant. Similar structures can be found throughout our country - from Sochi to Sakhalin. An important component for such a huge popularity of greenhouses is the ease of installation and the high-quality material from which they are made. As a result, these two vectors affect the cost of the object and its service life. If everything is done according to the rules, a polycarbonate greenhouse can last at least seven years. In recent years, this material has been in unprecedented demand.

Cellular polycarbonate 4 mm Skyglass (Green, 12 x 2.1 m)

Photo: https://beru.ru

Good quality cellular polycarbonate for greenhouses has the highest light transmittance and thermal insulation properties, which helps increase the volume of crops grown. Only high-quality industrial equipment is used in production, granulates are made only from primary raw materials. Sheet thickness 4 mm, dimensions 2.1 by 12 m, green. All polycarbonate is coated with a protective UV layer.

Cellular polycarbonate 4 mm Skyglass (Green, 12 x 2.1 m)

Advantages:

- ease of installation

- aesthetics

- thermal insulation

- light transmittance

- improved light diffusion

- sound insulation

Flaws:

- not detected

How to choose the right polycarbonate

What type and thickness of polycarbonate to choose for building a greenhouse depends on how it will be used. The larger the building area, the thicker the coating should be. You should also take into account the pitch of the frame sheathing, possible snow and wind loads, and the varieties of plants that will grow in the greenhouse.

We advise you to study - Which windows to choose - wooden or plastic

Polycarbonate greenhouse

Which polycarbonate is better - cellular or monolithic?

When deciding which polycarbonate is needed for a greenhouse, you should understand the differences between the types of this material. With the same chemical composition, cellular and monolithic polycarbonate have completely different physical characteristics.

Monolithic consists of transparent sheets with a thickness of 1 to 12 mm. The main properties of this material:

- light transmittance up to 90%;

- flexibility;

- impact resistance.

Monolithic sheets

However, monolithic sheets retain heat very poorly and sag under snow cover and gusts of wind. Therefore, it is advisable to use such a coating only for small temporary structures such as greenhouses. Monolithic panels are not suitable for a permanent greenhouse.

Most often, cellular polycarbonate is used to build greenhouses. It is a layered material with stiffening ribs that form voids. Cellular coverage characteristics:

sheet thickness from 4 to 32 mm; light transmittance up to 86%; light weight compared to glass or monolithic panels of the same thickness; low thermal conductivity due to the cellular structure, which is especially important in the construction of greenhouses; service life from 10 to 20 years.

Honeycomb panels

Before choosing polycarbonate for a greenhouse in a store, you need to make sure that the coating has quality certificates, since cheap fakes shorten the service life of the building and also reduce its energy efficiency.

Sheet thickness standards

The answer to the question of what thickness of polycarbonate is best to use for a greenhouse depends on several factors:

- size of the structure - the larger the building, the thicker the coating should be;

- roof type - flexible sheets of 4-6 mm are used for arched ceilings, while for roofs with one or two slopes, material 6-10 mm thick is used;

- expected loads - in areas with snowy winters, they install material that can withstand the weight of the snow cover;

- operating conditions - the energy efficiency of honeycomb panels directly depends on their thickness, so for winter growing a coating with a thickness of at least 6 mm is used, and for spring greenhouses sheets of 4 mm are suitable.

Greenhouse house

For the average greenhouse on a personal plot, it is better to choose polycarbonate brands with a thickness of 4 to 8 mm. This is quite enough for growing most plants in the middle zone.

Material density value

When figuring out what thickness of polycarbonate is best for a greenhouse, it is necessary to take into account that this material has another important technical characteristic - specific density. The specific gravity value indicates how much stronger one sheet is than another for the same thickness.

For example, a standard sheet measuring 2.1 by 6 meters and 4 mm thick with a density of 0.5 kg/m² will weigh 6.5 kg, and with a density of 0.7 kg/m² its weight will increase to 9 kg. The denser and heavier the material, the greater the load it can withstand. For greenhouses, the optimal specific density is 0.7 kg/m².

Specifications

Polycarbonate color for greenhouse

On the market, structured plastic is presented not only in the form of transparent panels. You can often find sheets of a wide variety of colors: red, blue, green, yellow, bronze. What color of polycarbonate to choose for a greenhouse? First of all, you should remember that most plants can develop normally only with good lighting.

It is also important which components of the spectrum of sunlight fall on the leaves.

A good coating should allow 80 to 90% sunlight to pass through. Only transparent panels have such light transmission ability, which is why they are most often used in greenhouse construction. In the southern regions, it is permissible to choose lightly colored yellow panels that transmit about 70% of the light flux.

Material in blue and turquoise shades is absolutely not suitable for growing plants. The fact is that these colors absorb exactly those components of the spectrum that are necessary for the full development of plants. You should also refrain from using saturated red, brown and green shades, because they transmit only a third of the light that hits them.

Not all coating colors are suitable for growing plants

Which polycarbonate is better for a greenhouse - cellular or monolithic?

To create an optimal temperature regime and maintain the required humidity in a greenhouse, polycarbonate profiles are ideal. However, the question may arise as to what type of PC is most suitable for creating a greenhouse.

To answer this, you should consider the parameters that determine the differences between these material options:

- With the same sheet thickness, a cellular PC has less weight, which is necessary for creating frameless structures and covering large areas.

- The cellular version is more energy efficient; it retains more heat due to the air layer between the sheets.

- The price of a cellular profile is lower than a monolithic one.

- The honeycomb profile allows for more diffused light, which has a positive effect on the development of plants and their productivity.

Based on this, experts recommend using cellular polycarbonate for the construction of greenhouses.

Comparative characteristics of popular polycarbonate manufacturers

Today, the Russian market is distinguished by a wealth of choice among manufacturers of various levels. The most famous of them are SafPlast Innovative, Bayer material science, Poligral or PlastiLux. The products of these manufacturers are approximately comparable in terms of quality and price; the choice is largely related to customer preferences.

If we analyze the reviews of consumers who have purchased products from various polycarbonate manufacturers, and not only Russian ones, we can draw a number of conclusions:

- panels of the Sunnex brand, popular in our country, last no more than 4 years, although the manufacturer claims 7-8 years of operation;

- Poligral products, provided the panels are installed correctly, can last for 10 years;

- SafPlast Innovative panels are slightly inferior in this regard, but they can also last at least 8 years;

- Makrolon panels, which have the longest service life - 12 years, have proven themselves best.

Application of material depending on thickness

If you need cellular polycarbonate for any work, which manufacturer is better, the information presented above will help you understand. But you can make the right choice not only taking into account the reputation of the supplier company, but also being guided by the sheet parameters that determine the area of use of the material. For example, 4 mm cellular polycarbonate is used to form canopies and greenhouses. A thickness of two millimeters more is used for the construction of small greenhouses with a small area. If you add another 2 millimeters to the above value, the material can be used for the construction of medium-sized greenhouses and greenhouses.

If large vertical surfaces need to be covered to form a continuous deck, 10mm polycarbonate should be used. Sheets with a thickness of 16 mm can be used for large spans that can withstand impressive loads. Quite often, material with such parameters is used for the construction of large complexes of greenhouses and greenhouses. Summer residents who want to build a greenhouse should be aware that the best material density for this will be 800 grams per square meter.

Greenhouse made of cellular polycarbonate

The material has a number of advantages.

- Light weight. Lightweight polycarbonate for greenhouses allows you to install lightweight structures without a foundation. This significantly speeds up and reduces the cost of work.

- Sufficient transparency. According to this indicator, the material is not inferior to ordinary glass.

- Low thermal conductivity. Due to the presence of air in the “honeycomb”, polycarbonate plastic for greenhouses forms a stable heat-insulating layer, which eliminates intense heat transfer, which is characteristic of glass to a greater extent and monolithic polycarbonate to a lesser extent. In addition to the main function of “sheltering” crops, the material maintains a stable temperature in the greenhouse more effectively than its analogues. This allows you to reduce heating costs if the greenhouse is used for crop production all year round.

- No lens effect. Glass and monolithic panels allow direct sunlight to pass through. In this case, a “lens effect” is created, that is, the sun’s ray is focused on some point (usually a drop of dew or water on the leaves or stems of plants) and directs its energy specifically to it. As a result, the surface of the crops is not only unevenly illuminated, but also creates areas subject to intense heating. Cellular polycarbonate for a greenhouse does not create a lens effect due to its multilayer structure. It scatters sunlight, allowing it to evenly penetrate the greenhouse and illuminate the crops not only in their upper part, but throughout their entire height.

Cellular polycarbonate for a greenhouse, due to the diffusion of light and uniform illumination of plants over the entire height, stimulates the process of photosynthesis. As a result, crops grow and develop better, and the intensity of vegetation and fruiting increases.

Specifications

Polycarbonate sheet for greenhouses has the following technical characteristics:

- impact resistance – 2.1 J;

- service life – at least 10 years;

- weight - 0.72 to 1.27 kg per square meter of area (depending on the thickness of the sheet);

- transparency – at least 86 percent;

- heat transfer coefficient – 3.7 W/m2.оС;

- thermal conductivity coefficient – 0.14-02 W/m.K;

- operating temperature range - -45…+120оС.

In terms of impact resistance, the material is forty-two times faster than glass, while weighing almost ten times less. And its thermal conductivity coefficient is significantly lower than that of most transparent analogues. This makes a transparent roof covering made from it a universal and justified choice for use in a greenhouse complex.

Light transmittance

It is known that transparent cellular polycarbonate perfectly transmits sunlight. In terms of light transmittance, it is only slightly inferior, literally by one or two percent, to a monolithic one. However, the type of solar energy that the panels direct into the greenhouse is different from what glass allows through.

Cellular polycarbonate for greenhouses transmits a total of 86 percent of solar energy. Moreover, most of this volume (at least 90 percent) is short-wave spectrum and only 10 percent is long waves. Moreover, it is the long waves that constitute ultraviolet radiation, which is destructive for all living things. The polycarbonate covering for greenhouses “filters” the light of the sun, allowing only those rays that will be beneficial for plant crops to penetrate inside.