Foundation blocks for foundation 200x200x400

The production of concrete products is aimed at different areas of application. Small foundation blocks replace heavy elements when installing strip and column foundations, and are also used in hard-to-reach places. With the help of a manual foundation block, work is carried out without heavy equipment, which significantly reduces construction costs. Both customers and contractors are interested in this approach. The manufacturer of concrete products can only offer an assortment of mini-foundation blocks to speed up the construction of buildings and structures at any time of the year.

Features and advantages of foam blocks

This material is becoming increasingly popular in the construction market. It has its own technical characteristics and special qualities.

The main advantages of foam blocks:

- Reliability

. Foam blocks are not subject to any external influences. They have truly stone strength and can be used for a long time, maintaining the internal structure. - High heat resistance

. This property can significantly reduce heat loss in winter. In summer, in hot weather, the size of the foam block and its structure make it possible not to allow high temperatures to pass through. Thus, an even microclimate is created inside the building and the required level of air humidity is maintained. - Environmental friendliness

. In this parameter, foam blocks are second only to wooden structures. If we take the environmental coefficient of wood as one, then for a foam block it will be 2, for sand-lime brick - 8, for ceramic brick - 10. - Quick installation

. Due to their low density and light weight, foam blocks are laid many times faster compared to the same volume of brickwork. One cube of foam blocks weighs much less than 1 m3 of brick. This process is further simplified, since the dimensions of the foam blocks for building a house are precisely measured. Thus, the speed of masonry work directly affects the total cost of construction and installation work. - Soundproofing

. These products are capable of high-quality sound absorption. According to this parameter, the size of foam blocks for partitions is almost twice as effective as brick or conventional reinforced concrete. - Fire safety

. Foam blocks are non-flammable materials. They reliably localize fires. The tests carried out allowed us to assign this material the first degree of fire resistance.

The process of laying foam blocks is not much different from laying ordinary bricks

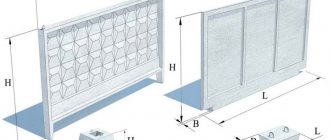

Technical parameters of foundation blocks 200x200x400

The production facility launched a vibrocompression line producing foundation-tape blocks. They are solid (FBS) and hollow (FBP). Special cutouts are often made in solid elements for laying communications, resulting in a small foundation block under the FBV brand.

Standard foundation blocks comply with the requirements of GOST 13579-78:

- Class not lower than B7.5;

- Frost resistance from 50 cycles;

- Thermal conductivity 1.1-1.2 W/m0C.

A solid foundation block of 200x200x4000 mm, which weighs only 32 kg, is considered convenient. This product does not need iron hinges for movement, like large elements. Some types are made with special recesses for gripping.

The manufacturer ensures the production of the foundation block in whole batches due to automation of the process. During production, semi-dry vibrocompression is used on machines or using a vibropress. The technology makes it possible to obtain a durable monolithic element, without cracks or air cavities inside.

Advantages of foundation blocks 20x20x40

The production of products that meet technological standards is possible only on factory equipment. FBS fully meets the quality standards:

- They have low water absorption, without accumulating ground moisture inside;

- Resistant to low temperatures;

- Withstand mechanical loads according to strength class;

- They have a uniform structure, smooth walls and clear geometric lines;

- Dimensions 400x200x200 easily fit into any installation scheme;

- The size range numbers rounded by 10 mm (390x190x188) allow you to take into account the thickness of cement-sand mortar joints;

- The weight of one product is designed for manual labor.

It is possible to lay out the foundation, ground and basement floors of the house in blocks 400 mm long even on swampy soil, making additional waterproofing and a drainage system.

Areas of application for foundation blocks 40x20x20 cm

Due to the strength and frost resistance of concrete elements, they are used to create the foundation for low-rise buildings, outbuildings, industrial hangars, etc. The work can be carried out in a short time, in any weather. Such a foundation does not require long-term exposure at positive temperatures. The main thing is to follow the installation diagram, adhering to technological standards.

FBS are great for:

- Tape and column structures;

- Arrangement of basements and basements;

- Support posts for fences.

Low-rise buildings are built on a strip foundation, which does not require additional thermal insulation. To reduce costs, hollow foundation blocks 40x20x20 in Moscow are often used as partitions and fences in the monolithic construction of high-rise buildings.

Installation of foundation block 400x200x200

At the construction site of the building, markings are carried out according to the architectural design. Then they dig trenches to lay the foundation. If you plan to equip basements and basements, dig a foundation pit. The strip foundation is laid according to the following scheme:

- Compact the soil in the trench and cover it with sand to a depth of 5-10 cm;

- According to the breakdown, corner foundation blocks are installed;

- Beacon blocks are placed at a distance of 15 mm;

- Stretch the wire between the beacon and the corner, installing intermediate elements along it;

- Each block is leveled vertically using a leveling rod.

On heaving, swampy, peaty soils, a columnar foundation is built:

- Make a depression below the freezing point;

- Fill in a layer of sand up to 10 cm, level and compact;

- Concrete foundation blocks are laid out in 3-4 rows in height.

This foundation option is ideal for wooden and frame buildings.

Light weight

The lightest building material today is foam block. This quality of material is of great importance in insulation and construction. Relatively quiet thermal conductivity makes it possible to make walls thinner than in construction with other materials.

For example, if we compare a foam block with a brick or cinder block, then for 1 m2 of a brick wall you will need 190 pieces. With a weight of each product of 5 kg, the mass of the wall is 950 kg. To construct the same foam block wall, you will need 21 kg of foam block. The mass of the wall will be 600 kg.

Even with this example, it can be determined that the foam block is much lighter than other materials, and, therefore. when it is necessary to load the structure to a minimum, foam concrete is the most suitable material. The foam concrete product is lightweight and convenient for construction; the excellent processing of this material is the result of its porous structure. This material is processed on the construction site; blocks can even be cut with a simple hacksaw. Almost everyone claims that the mass of the foam block is small, but only a few know exactly what it is, and then, probably, professional builders.

How to determine the weight of a concrete product?

If you need to determine the mass of a foam block, but there is no measuring equipment nearby, then you can use certain actions. The mass of a concrete product depends directly on the density value. It turns out that we find out the density of the material - we calculate its mass. If you do not take into account the moisture content of foam concrete, then the density of this product will be equal to the mass of its cubic meter. The density of a concrete product depends on its composition: cement, water, sand. All these ingredients are contained in 1 m3 of foam block. Let's look at the product labeling. For example, in a foam block product marked D300, it is precisely indicated to us that 1 m3 weighs 300 kg, D500 - 500 kg.

To calculate the weight of concrete, you need to multiply its density by its volume. Let's calculate the weight of a product marked 600x250x100 using an example. First, let's calculate the volume of one product; to do this, convert the dimensions into meters and multiply our values 0.6x 0.25x 0.1. We get the result - 0.015 m³. We determine the weight by multiplying 0.015 * 400. The mass of our material is about 6 kg. This calculation will be correct if the material is dry; it is worth considering that the product can, having absorbed moisture, increase up to 20%. For example, if a dry D600 block weighs 22 kg, then in a wet state the value will increase to 25 kg. If we calculate the most standard option with the marking 600x300x200 using this principle, we will get the mass of one block - 22 kg, 600x250x50 - 4 kg, 600x250x75 - 7kg, 600x400x300 - 28 kg.

This calculation will be useful when the product is non-standard. The mass of models with standard sizes has already been calculated by the manufacturer. For example:

- D400 – material weight 15 kilograms;

- D700 - weight 27 kilograms;

- D1200 – weight 47 kilograms.

You can determine the mass of the product differently, simply by taking into account the mass of a cubic meter of material and the number of foam blocks included in it. Sometimes it is still easier to ask about the mass of the purchased material from the seller or manufacturer, because production is different, the mass may not match, even if everything has been theoretically justified correctly.

Different manufacturers have different weights of blocks, despite the same dimensions.

If we consider the density characteristics, then the blocks can be thermal insulating and structural. Depending on the brand of material, the weight of the product will also change.

For example, if you find out the characteristics of a foam block with the D300 brand, then in the wall version the weight of one block of size 600x300x200 will be close to 11 kg, for a partition block with a size of 100x300x600 - 5 kg.

Technical characteristics have allowed foam concrete to take a leading position among other materials in construction. The foam block construction of the wall allows you to make the temperature in any room comfortable. A house made of a modern concrete product retains heat in the winter, and in the summer it works like an air conditioner, preventing heat from entering the room.

Foam concrete blocks have a high degree of thermal insulation and strength. Depending on the density of the building material, it is used both for the classical construction of houses and for thermal insulation work. Understanding how much a foam block weighs is very important when designing a house, as it allows you to correctly calculate the design weight of the walls and the load they create.

Structural characteristics of foam blocks

When finished, foam blocks have the appearance of a porous stone, similar to cellular concrete. For the manufacture of products, a special mixture is used, which includes cement, sand, water and pre-prepared foam. All components are thoroughly mixed together mechanically. When solidified, through pores are formed in structures, giving the material all the necessary properties.

By changing the proportions of the components, you can achieve different technical characteristics. For example, by reducing the amount of sand, the strength of the foam block increases. This allows you to create structural elements used for various purposes.

The process of laying foam blocks is faster than laying conventional building bricks when building a house

Main types of foam concrete blocks:

- Structural

. They have the greatest strength and are used for constructing foundations, plinths and laying load-bearing walls. Their main brands are D1000, D1100, D1200. They correspond to strengths of 50, 64 and 90 kg/cm2. The density of such foam blocks ranges from 1000 to 1200 kg/m3. The weight of a foam block of this type is 39-47 kg, a half-block will weigh 19-23 kg. - Structural and thermal insulation

. They have average strength, suitable for laying walls and partitions. These include grades D500, 600, 700, 800 and 900 with corresponding strengths of 13, 16, 24, 27 and 35 kg/cm2. The density indicator for these products is from 500 to 900 kg/m3. Each such foam block has a weight of 1 piece 23-35 kg, and a half-block - 11-17 kg. - Thermal insulation

. Structures with minimal strength are used to create thermal insulation for external walls. They are represented by grades D300, 350 and 400. For the first two grades, the strength is not calculated, but for D400 it is 9 kg/cm2. The average weight of such a block is 11-19 kg, half-block - 6-10 kg.

Non-standard structurally porous foam blocks with increased strength, grades D1300-1600, are produced separately.

Non-standard structurally porous foam blocks attract with their strength