Despite the stereotype developed over the years that container houses are ordinary construction sheds or primitive structures for temporary housing in the country, in practice these buildings are modern structures that amaze with their external, quite presentable appearance and the comfort and coziness they create.

The use of these structures for housing construction in Europe and America allows us to see in practice how good buildings are that are built with high quality and according to good designs.

History of container structures

house made of two containers, covered with wood

The idea of such an unusual container house project does not have an author. Not surprising. There is nothing new in this. What is more important is a creative approach to buildings, design and finishing work applied. Adam Culkin was the first to successfully use containers as building blocks. His stunning modern and beautiful house surprises with its appearance, which is hardly traced by its primitive construction.

a simpler one-story version of a container house

Having received significant savings through the use of a used sea container, the talented architect managed to create a full-fledged house, monolithic on the outside, consisting of many rooms on the inside. The building required three blocks. Such an architectural technique as the use of identical panoramic windows united the containers into a single structure.

Projects of houses from sea containers

The undoubted advantage of a container house is its ability to be placed on a site of small size and non-standard shape. In addition, the container can be upgraded to a state suitable for permanent residence in various climatic conditions.

Nevertheless, in Russia such houses are quite rare, while overseas and in Europe such structures are widely used.

House projects from 1 high 40 foot container

The most affordable and prefabricated house consists of a single 40-foot-long container. As a rule, you need to pay from 2 to 2.5 thousand dollars for a container of this size. Therefore, if you want to increase the area of your home, and your financial capabilities allow it, then installing 2-3 containers nearby will not be difficult.

The purchase of three containers will cost from 6 to 7 thousand dollars, and the usable area of the house will reach 85.2 square meters with a length of 12 and a width of 7.1 meters.

These dimensions will be slightly reduced when the walls of the house are insulated, which is necessary for comfortable living in the Russian climate. As a rule, insulation and finishing of the walls, ceiling and floor of a structure takes about 0.2 meters on each side of the house. The cost of such finishing depends on the materials used and can double the owner’s costs. However, building a house and a container is still significantly cheaper than other construction methods.

When planning a structure consisting of several floors, the savings compared to other types of buildings increase even more.

To heat a container house, you can use either a gas boiler or a simple wood stove. For the area of one container this will be quite enough. In order to ensure that there is never smoke in the house, the firebox should be placed on the outside of the building.

Project of a house from two adjacent containers

To design and install a country house that does not require a large area, it is enough to purchase a couple of containers. There are several options for their layout.

As an example, let's look at the following container house projects:

Two-story version of a country house made of containers

This option is most suitable for use on a site with limited area. In this case, the containers are installed one on top of the other; the high-quality material from which the containers are made provides the necessary strength and rigidity of the structure. Depending on the owner’s wishes, the floors are connected by stairs, or part of the floor of one container and part of the ceiling of another are eliminated. This achieves a two-level structure.

Prefabricated project from several blocks

If there is significant free space on the site, the owner can assemble an individual house by installing several containers in different orders. The result can be a real multi-room house. If desired, a garage can be attached to such a structure or a second floor can be added. The possibilities here are truly endless.

In the conditions of the Russian real estate market, a house made of containers can become optimal for many categories of the population. For example, for families for whom purchasing an apartment seems too expensive a purchase, or for those wishing to move from an apartment to their own home.

Features of building houses from containers

Thanks to different combinations of colors and designs, a container house is a great place to live and relax

The idea of building a building from blocks is not new. The child builds similar structures from cubes. This is exactly what the home in question looks like:

- Stacked containers are combined into multi-story buildings.

- The adjacent structures form a large one-story building.

- You can try to somehow shift the containers, position them in an unusual way relative to each other and get an original structure that will claim to be unique.

Both railway and sea containers made of steel are used for housing. The height of the room, equal to the width, is small, just over 2.3 m; for American houses this is not considered a low ceiling. The length can be 6 or 12 meters, depending on the container.

small house with a flower terrace on the roof

The peculiarity of such houses is the corrugated surface of the container, which has high strength characteristics. This allows you to cut out large panoramic windows and huge doors without loss of strength and without deformation.

The construction of container houses continues confidently. Unusual hotels and popular cafes have already been built based on such projects. Containers were used in the construction of restaurants and offices. The technology is in demand for the construction of garages and buildings in the far north and Antarctica. It is considered important to show imagination and give the building an unusual, original look.

What are we building?

offers various options for outbuildings and residential buildings made from block containers. The most popular of them are:

- one-room block containers, economy version;

- country blocks with kitchen and bathroom;

- residential buildings made of block containers (winter version);

- country blocks with toilet and shower.

Interior and exterior decoration is made from high quality materials that are safe and create comfortable living conditions. The block containers are equipped with PVC windows, insulated metal doors, heat and vapor insulation. To connect heating and household appliances, installation of basic electrical equipment is provided.

The delivery package of the residential unit may include sleeping places and plumbing equipment. By agreement with the customer, it is possible to install water pipes.

Choose one of the standard options for a residential block from the catalog on the website or order the development of an individual project from our specialists. Houses made from modular containers from offer comfortable living, excellent functionality and a reasonable price.

Advantages and disadvantages of houses for the construction of which containers are used

Container houses benefit from construction time compared to traditional construction

Container structures are becoming more and more in demand and are used not only as temporary housing, but also for permanent residence. The reasons for its popularity are quite understandable:

- The container has a low weight of only a few tons, which requires the construction of a small foundation.

- The construction of a house is carried out very quickly due to the formation of the premises using ready-made spaces.

- The design is highly durable and reliable, which is significantly reduced and reduced by large windows.

- The house is very easy to transport, disassemble and reassemble.

- The design operates well in unfavorable seismic and metrological conditions.

- The buildings are of low cost. This is due to the low price of the used frame and low foundation costs.

- The structure obtained from containers is distinguished by its unique design and originality of construction.

- Containers are easily combined with all building materials, placed on several floors, and used as temporary and permanent housing.

Using ordinary containers you can get an original home design

But not everything is so simple with such building structures. Existing shortcomings do not allow housing to lead among buildings. Among the shortcomings, we note the most significant:

- Containers were originally designed for transporting goods; their surfaces are treated with toxic compounds to protect them from weathering. Living in the house is possible only after complete removal of traces of treatment.

- The containers are made of metal, which easily heats up to high temperatures and does not retain heat at all. Living in a house is only possible if good thermal insulation is created on both sides.

- The ceiling height in the room is less than 2.4 m, which is lower than the standard and usual for our everyday life.

- To protect the container from weathering and corrosion, it is necessary to use special means.

Features of buildings made from block containers

The basis of a modular building is a block container. It is a durable but lightweight structure on a metal frame, which can be assembled and installed in a matter of days. The ability to combine a group of modules into one allows you to build houses from block containers of any area with a height of one or two floors. A significant advantage of the construction of such structures is the reduction in foundation costs due to their low weight.

Buildings based on block containers have a number of advantages. The main one is a simplified scheme for obtaining a building permit, since such housing is temporary. In addition, the advantages of modular construction are:

- significant savings on construction costs;

- short installation time;

- safety and reliability of structures;

- easy installation and dismantling;

- environmental friendliness;

- high quality of materials used in construction and finishing.

The low weight of houses made from block containers allows them to be easily moved from place to place. Perhaps in the future there are plans to build a permanent residential building on your site. In this case, the block container can be easily converted to suit any household needs: rearranged and used as a shed or workshop.

Project and design

two-story container house with a large panoramic window

The purpose of the building and its purpose are determined based on the layout. There are a sufficient number of standard projects, but the peculiarity of such construction is most often that the buildings are original and individual projects are required for their construction.

You should not neglect design work and rely on your intuition when constructing a building. Modular construction requires strength calculations, it is necessary to calculate the loads and calculate the dimensions of the foundations. In addition to these calculations, the design documentation determines the amount of building materials and the appearance of the structure.

Types of layouts

compact house made of containers with round and square windows, covered with profiled sheets

Depending on the placement of containers relative to each other and their quantity, the resulting rooms vary in layout and area:

- It is often used to place several containers in a row under one roof, with their long sides touching. In this case, by organizing openings inside the room, the rooms are connected and united. An interesting option and successful from a safety point of view is when one of the walls turns out to be foldable and is used as an adjoining space. And the inner part of the wall consists of panoramic windows.

- Containers located in a checkerboard pattern relative to each other leave a lot of scope for the designer. In this case, an interesting internal layout of the housing is obtained.

- The option of parallel arrangement of containers at a distance from each other is used.

- A widely used layout is when one container is located above another and together resemble dresser drawers.

- When containers are arranged in a structure resembling the letter P, a small and cozy patio is formed that can be well decorated and used for spending time with the whole family.

How much does a container house cost?

In order to estimate the cost of constructing a container house, it is necessary to determine the required area and, based on this data, the number of containers used. As an example of costing of work, we can consider a one-story house, for the manufacture of which two 40-foot containers are used.

The total area of the structure is about 55 square meters. Three square windows with a side of one meter and one large window 2.5 by 1 meter were cut into the walls. A standard entrance door has dimensions of 2.1 by 1 meter.

Containers

The purchase of two used containers will cost the buyer $2,600-2,700.

Foundation

Option 1. A columnar structure made of ceramic bricks consists of 23 pillars. This is quite enough to provide reliable support for the house. The pillars are located at a distance of two meters from each other and rise four rows above the ground. The masonry goes underground in five rows. To build such a foundation, 359 bricks are required for a total cost of $130.

Option 2. A strip foundation will cost much more. With a tape size of 700x300 mm (depth 400 mm, above ground 300 mm) and a length of 46.3 meters, the cost will be about $1,500.

Wooden frame on external walls

To make the frame, timber with a cross-section of 100x50 mm is used. The slats are packed at intervals of one meter from each other and subsequently covered with clapboard. The total amount of material is 34 bars, each 2.6 meters long (0.442 m3) and 240 lining boards measuring 12.5x96x3000 millimeters (69 m2). The cost for cladding the exterior walls is $290.

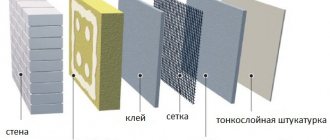

Insulation on external walls

Mineral slabs are used as insulation. The total surface area is 69 square meters and costs $413.

Wooden ceiling

The same timber is used as a frame as for the walls in the amount of 26 pieces. The assembled frame is sheathed with fiberboard measuring 1700x2745x3.2 millimeters. The total cost of the material is $140.

Roof insulation

A mineral slab with a thickness of 10 cm and an area of 55 square meters will be quite enough to insulate the roof. You will need to pay $330 for the material.

Wooden floor

The design of the floor frame does not differ from the ceiling and wall frames. For a floor area of 55 m2, 26 slats are required. A board measuring 100x40x2500 millimeters is laid on the floor. Total cost for flooring is $513.

Floor insulation

The mineral plate used as a heat insulator is absolutely identical to the ceiling one. The cost is also the same and is $330.

As a result, the total cost of materials needed to build a small house with an area of 55 square meters is $6,346, which is a fairly budget option. When using hired force, costs will increase approximately 2 times. If the owner wishes, the house can be improved and made more convenient and comfortable. The costs will increase even more.

It is worth noting that the cost of a house made from shipping containers is given as an example and may vary depending on the price of the material and the region where the house was built.

Construction safety

It is enough to arrange several containers asymmetrically to get a unique design

For the home and its environment, not only rodents and bacteria pose a serious danger. Robbers cause even more harm and damage. Container houses are no exception. In order to avoid uninvited guests and protect themselves from their presence, special technological and design techniques are used:

- To increase security, a frame wall with a regular door opening is installed in the container immediately behind the door. When the owners leave for a long period of time, they close the usual burglary-resistant door from the container.

- The second way to maintain security, despite its costly nature, is very reliable and convenient. One of the walls is equipped with a lifting wall. A glass wall is installed behind it, which allows the building to be filled with sufficient light. It is advisable to make the lifting wall from a material such as wood and use it as a cozy terrace while the owners are present.

two-story container house with large stained glass windows

For the convenience of residents, windows and doors can have different shapes and sizes. This will not affect the reliability of the structure, but will diversify the design of the room. In order to enter a room and cause damage to it, it will take a lot of time and require the use of special equipment and tools. Fortunately, criminals do not always have it.

Container house projects

Housing made from sea containers can be called unusual and interesting. The easiest way to improve the appearance of a module is to equip it with hinged doors and stained glass windows. And if you want to arrange the house in some unusual way, you can create a small canopy over its facade. This allows you to keep the doors open during rain without fear of water entering the room. Polycarbonate sheets are well suited for arranging such a canopy.

To keep the interior warm, it is recommended to cover it with wood panels. With the help of such elements it is possible to turn the container into a comfortable place for relaxation and living. For greater coziness, you can create flower beds around the living container and plant your favorite flowers.

Projects of container houses are different. Those who want to get a cottage should take a closer look at multi-level buildings. The designs of Adam Kalkin, an architect who was one of the first to appreciate the capabilities of containers and began to use them as full-fledged housing, are popular. His interesting idea is the construction of one house inside another. This can be achieved due to the fact that smaller elements are placed inside a large structure, which can be considered as separate rooms. And to connect all the modules together, large sliding doors are well suited.

Such houses can be called exquisite and unusual. They easily accommodate a living room, a kitchen, as well as several bathrooms and bedrooms.

The projects of another talented architect, Marcio Kogan, are no less popular. According to his idea, the modules are installed on top of each other, and then the building is expanded by attaching additional modules.

To achieve the goal - building a dream home - containers of different sizes can be used. From the latter it is possible to create residential buildings, as well as public facilities. A striking example of this is the Starbucks coffee house. This cafe has an unusual design, due to which it arouses increased interest among visitors.

The modules can also be used for the construction of office buildings. With their help you can get an object of any style, but they are especially suitable for lofts. The concept of this direction implies a certain roughness and pristine forms, therefore, to maintain it, serious transformations of the containers will not be required.

Home construction

Construction of a house begins with the foundation. In this respect, building houses from containers is no different from conventional construction.

Construction of the foundation

foundation preparation

This is exactly the foundation on which the building is built, and on the quality of which the strength characteristics and durability of the building depend. Construction of the foundation is expensive. Container houses do not require a strong foundation due to the light weight of the structure. For a one-story building, it is enough to use foundation blocks and bury them in the ground. But designer structures and multi-story buildings require a high-quality reinforced strip foundation.

container installation

To install a strip foundation, a foundation pit is prepared according to the design data. The formwork and reinforcement cage are installed, and the concrete mixture is poured. When forming the foundation, concrete is compacted using special equipment. Then a technological pause begins, time is given for the foundation to finally harden, this is at least 22 days.

Anti-corrosion treatment

To protect against weathering and prevent corrosion, it is necessary to carry out anti-corrosion treatment at the very beginning of construction work. Iron and then lead lead are used as protective compounds. On top you should use paint that retains its properties well at high temperatures.

Home construction

After installing the container, window and door openings are cut out

Installation of the modules is carried out using special equipment; otherwise the container cannot be installed on the foundation. Next, the elements are fastened together and the foundation by welding, and a single structure is obtained. The next stage of construction includes internal work on installing partitions, cutting openings for windows and doors.

Roof structure

Container houses do not require roof construction

Despite the fact that the container has an upper surface, in order for it to have a decent appearance, work is being done to build a roof. This is a rather complex process and its stages do not differ from the construction of the roof of an ordinary residential building. A distinctive feature of containers is their high strength characteristics, so any material can be used as a roof covering. Even a structure of several floors can easily withstand it.

Insulation of the house

example of wall insulation with foam plastic

The work on insulating a container is no different from the usual insulation of a house. First, the sheathing is installed and filled with insulation. Mineral wool, polystyrene foam and other materials are used as insulation. When building this type of housing, especially if a significant part of the time is expected to be spent in it, you should not skimp on insulation; it is better to do it with a certain reserve.

using mineral wool to insulate the external walls of a house

The facade can be finished with decorative brick, simply plastered and painted, or covered with natural stone. When applying paint and varnish coatings, special paints are used that are resistant to high and low temperatures and their differences.

By using siding or siding panels to cover the exterior of a building, buildings can be further insulated. These materials available in the retail chain can be painted in different colors and differ in quality. These qualities make it possible to ideally select materials so that the building fits well into the landscape design and matches the style chosen by the architect.

Internal insulation and finishing of premises

finishing the walls and ceiling with plasterboard followed by painting

For interior decoration, you can use plasterboard, plywood, and USB boards. It would be more correct to mount them on a rigid metal frame. For insulation, the inside is coated with polyurethane. Stretch ceilings, plasterboard, and Armstrong can be used as ceiling coverings. You can simply paint the wood.

The same materials that are used for ordinary houses are used as wall coverings: wallpaper, plasters. The floor is covered with linoleum, parquet, tiles.

Heating and connection to utilities

A small foundation implies a cold floor. A good type of heating for container houses is a heated floor system. With good thermal insulation of walls and roofs and low ceilings, houses will have a comfortable temperature for living.

container house with spacious veranda

The proposed heating is supported by the fact that the containers are hermetically sealed, there are no drafts in them, and after insulation, these problems do not bother the residents at all. This type of housing is well heated by solar panels, which can easily be placed on the roof.

When defining a house made of containers as housing for permanent residence, it is worth paying attention and providing for the connection of the building to utilities: water supply, sewerage, electricity and gas supply.

a container house will fit perfectly into any landscape

The possibility of connecting to water supply and sewerage is determined at the stage of design work. In the absence of a centralized water supply, the issue of building a well and supplying water to the house using a pump is considered. The lack of centralized drainage is compensated by the construction of a cesspool.

Ventilation of frame houses

Frame housing is characterized by a high degree of tightness of the modules. This is considered one of the important disadvantages of such structures. In order to eliminate this problem, a special system of forced or natural ventilation is created.

When building a house from containers, special attention is paid to ventilation

Interior design

Furniture and the style of interior design are determined by the owner of the house and have no major restrictions.

The exceptions are the Baroque and Classic styles, the design of which is characterized by massive furniture that is difficult to fit into the low, small space of the container. When choosing a design style for interior spaces, it is necessary to take into account the low height of the rooms. For decoration, you should avoid dark gloomy tones. To visually expand the area, it is good to use light pastel colors, including white. Mirrors are well suited for the same purpose; they always visually enlarge the space.

ceiling typical for frame houses

Large panoramic windows will help make the rooms brighter. The rigid corrugated structure of the container contributes to such structural elements. Large windows decorate the house and allow it to look beautiful, almost floating in the surrounding vegetation.

Stages of building a house from containers

The main point from which any construction begins is determining the required area of the building. If the living space does not initially meet the needs, it will definitely need to be expanded, as a result of which the costs will become unreasonably high.

As a rule, when developing and implementing a project to build a residential building from containers, several mandatory stages of work are performed:

- Preparation of a construction project;

- Preparing the trench and building the foundation;

- Switching containers into a single structure;

- Adding strength to load-bearing structures;

- Thermal insulation of the external or internal side of the room;

- Decorative finishing of the finished building.

If you have enough experience and the necessary skills, building a house will not take much time.

Drafting

When developing a project, the main attention should be paid to the layout of the room. It is necessary to provide for the availability of residential and office premises, as well as ease of movement between them. The building plan can be absolutely anything. This is one of the advantages of a container home. The owner can build his dream home himself or experienced architects can do it for him.

The number of living rooms is limited by the number of containers used during construction. As a rule, one container houses one room, bedroom or living room.

Foundation for container houses

Since the container is made of durable, often alloyed, steel, its weight can be quite large. Therefore, a house made from a sea container should be mounted on a high-quality strip foundation.

The foundation design does not differ from a standard strip monolith. Metal reinforcement is installed in the prepared ditch. Formwork made of boards is installed along the perimeter, which is necessary to raise the foundation above ground level.

Concrete B15 is most suitable as a foundation material. You can prepare such a mixture yourself using a concrete mixer, or you can order a ready-made mixture at the enterprise.

If the quality of the soil allows, as an alternative, you can use a columnar foundation, the costs of which are significantly lower than for a strip foundation. Connecting containers and strengthening load-bearing structures

Sea containers are made of durable steel, so the most acceptable way to connect them together is welding. During the assembly process of a multi-container structure, metal fasteners such as angles or channels are used.

During the process of assembling the house, window and door openings are cut out using a grinder. After the operation, the edge of the cut should be carefully treated with special means.

Since the container design does not imply the presence of holes, its rigidity is significantly reduced when preparing window and door openings. The supporting structure is strengthened by welding channels or pipes along the entire perimeter of the opening. In this case, the stiffening ribs should extend from floor to ceiling. The elements of the supporting structure should be welded together using a continuous seam. Spot welding is suitable for connecting stiffeners and the container body. To connect the stiffeners and the container body, it is worth using the services of an experienced welder who can withstand the angles and inclinations of welding. Otherwise, the subsequent installation of the hanging elements may be performed poorly. At the end of the work, it is necessary to weld the main doors of the container and carry out high-quality treatment of the container against corrosion.

If the design involves the installation of several floors, then all load-bearing walls should be additionally strengthened by welding channels of sufficient thickness.

How to insulate a container house?

In the harsh climate of many Russian regions, insulation of residential premises becomes of primary importance. Reliable insulation made from high-quality materials can significantly increase indoor comfort and also reduce heating costs. It should be noted that to preserve heat, it is necessary not only to use the best materials, but also to minimize sources of heat loss. As a rule, the following design flaws may be such reasons.

- Crevices. One of the main sources of heat leakage. Poor quality assembly of the structure will negate all efforts to insulate the house. All the heat will go into the cracks, even with the best heating and thermal insulation.

- Bridges of cold. Sea containers are made of metal with excellent thermal conductivity. Therefore, the main heat exchange passes through them. The container body is a so-called cold bridge – a source of room cooling. If you do not take responsibility for insulating the outer part of the structure, the house will always be cold.

- Elements with increased thermal conductivity. These elements include surfaces that are not subject to additional insulation, such as windows and doors. If the thickness of the glass unit is insufficient or the door insulation materials are of poor quality, heat loss will be higher than normal, and the room will cool down much faster.

Insulate from the outside or from the inside?

The choice of insulation method depends on the specifics of the area in which the house is assembled, as well as on the desires and capabilities of the owner. To make the final choice of insulation method, you should pay attention to the properties of the material from which the container is made. Steel is a homogeneous, dense composition, has high thermal conductivity and is susceptible to corrosion. The choice of material and method of insulation must be made based on these characteristics. In principle, a container house can be insulated both inside and outside.

The peculiarity of steel is its homogeneous composition, therefore, moisture cannot enter the metal structure. Thus, corrosion is possible when moisture forms on the surface of the housing from inside or outside the building. It is quite easy to protect the outside of the house from the damaging effects of dampness. To do this, it is enough to cover the surface with a protective layer, for example mastic or paint. The inside is a much more vulnerable place in the room. Evaporation and condensation can accumulate on the surface and are the main cause of metal corrosion and dampness in the room.

Insulating the outside is an excellent option for solving the problem of damp walls, but only if the house is used for permanent residence and is heated daily. If the container is installed as a country house, then in winter it will freeze to subzero temperatures. When the heating is turned on, the steel walls will begin to thaw, and all the moisture will flow onto the floor. The owner of such a house will immediately receive all the delights of seasonal use of a metal house, such as the appearance of mold, swelling of floors, and short circuits in electrical networks.

But even in the case of seasonal use, a container house can be protected from such negative consequences. This requires high-quality thermal insulation, which prevents the air in the room from coming into contact with metal walls, that is, with internal insulation of the walls. In this case, all the energy released by the heater will be used to warm the room, and not to heat the metal. The metal container will work like a thermos and act as a supporting structure, while the thermal insulation will be responsible for maintaining an acceptable temperature.

How to properly insulate from the inside?

Insulating a metal container differs from the same procedure performed in a standard building. The most appropriate option for the initial sheathing of the surface, made of wooden blocks. The thickness of the stuffed sheathing can be 5 or 10 cm. Thermal insulation is achieved by spraying a material with low thermal conductivity, such as polystyrene foam or polyurethane foam. Insulation of ceilings and walls is mandatory, and excess insulation is removed.

The second layer of sheathing is a vapor barrier coating, which is secured to the sheathing with a construction stapler.

The third layer is decorative. The walls are covered with clapboard, chipboard, and other types of coverings.

Floor insulation is practically no different from similar operations with walls. As an addition, the floor is sometimes covered with screed. Polystyrene foam boards are suitable for insulation, which, unlike mineral wool, do not have the ability to retain moisture.

External and internal finishing

All work to give the walls a finished appearance should be carried out only after removing rust stains and applying an anti-corrosion coating. The walls are insulated by stuffing the sheathing and then applying a thermal insulation coating. At the end of the insulation process, the surface is covered with plywood or OSB.

The final stage of exterior finishing is the application of one of the following types of coatings:

- Natural or artificial stone;

- Plaster decorative mixture;

- Block house;

- Plastic panels or siding.

Each of the materials mentioned has a right to exist and is good in a certain situation. The installation of such structures is not very difficult; with a little experience, anyone can handle it.

Construction cost

The cost of building modular housing is several times less than traditional conventional buildings. Most of the costs, about a third, fall on internal work, installation of utilities, and remuneration of workers. The cost of transporting a container is comparable to its price or slightly higher.

facing external walls with bricks

The costs that need to be spent on insulating housing and purchasing thermal insulation are high. When using two or more structures to build, savings are achieved through the use of a combined wall that does not require thermal insulation.

In any case, regardless of the layout used or the chosen design, container houses allow you to save money, and you get continuous benefits from their construction.

bold design solution

With the help of imagination, you can change the appearance of the container beyond recognition, give it completely different shapes, add a veranda, awnings. In this case, it will be difficult to find traces of a modular structure under a beautiful modern building. In our country, such structures are rarely used as permanent housing. There is an opinion that housing should be of good quality construction. But in Europe and America, container houses are popular and in demand.

Building a house from a container (140 photos)

The foreign fashion for container houses has reached us. Houses from containers began to be built in port cities, where a used sea container (6 or 12 meters long, i.e. 20 and 40 feet) could be found on sale for pennies (or even for nothing). Such housing could be built in a hurry, especially if the climate is warm. And don’t forget a ready-made container house is the same real estate; it’s even easier to sell than a plot. The price will drop by thirty percent, no more, but the quality will not suffer. Building a house from a container is in our selection.

Glass foyer Two containers Two-story house House in the forest Construction

Container lifting

Blocks on a rack

House like cubes Evening Bedroom House with balcony

Hanging room House by the river Crane

Glass wall Construction has begun Green house

Small rooms

House with a veranda Lonely Second floor Four-story mansion Overlooking the river Container house

With a shaggy friend

Blue Container House with Swimming Pool

Steps to the house

Blue House Triton

Two-story With a platform on the roof Strict style Chaotic construction

Moderate style House with a balcony Small castle Pipes Near the forest Interior decoration Large windows

Evening look Small cafe

Showcase window Windows are closing The sky is reflected in the windows

High-rise building Plantings

House in the forest Colorful house

Black and white In the mountains Container on container House with roof Garage

/var/www/funik/data/www/funik.ru/wp content/uploads/2019/10/d540e14de88242e996e3 1

Roof Yard Approach to the house

House with veranda Recreation area

Green area Window

Spouses Large house with roof Containers

Chamomile glade Veranda for relaxation

Small house with a roof. Large windows. Umbrella in front of the house. White container on black.

Baby walking Original roof

Tree on the roof Stormy sky Cloudy day

Small house Large display windows House installation

Bedroom Blue-yellow-green

Transparent room One door is open Bright house All doors are open House on legs Playground

House in a pine forest Large living room Kitchen

container house Huge living room

Blind wall Area in front of the house Minihotel Construction of a house Blue House

Landscaping of the site Empty containers Near the Microdistrict river

Table on the street Yellow Garage

Street

Red House

Stairs to the second floor Lawn and dogs

Simple house

Installation of doors and windows Staircase Great hall upstairs

Tree near the house

Side view Three entrances One container Installation of blocks Hanging balcony In light colors

Street staircase Large door Lifebuoy Roof over containers Interior decoration Cladding Design

Wall room Canopy Family

Unusual house Construction site

Black pipe

Beautiful lighting

Exterior decoration Door open Crane holding container Gray house Narrow windows House in a quiet place Colorful containers

Upvote this post!

( 3 ratings, average: 3.67 out of 5)

Photo gallery - container houses:

S