Advantages of monolithic brick housing construction

Monolithic construction allows you to reduce the time for constructing a building (the speed of construction is faster than even the construction of brick-and-block houses) and significantly reduce financial costs. The advantages of building from monolithic concrete can also be noted, such as a long service life (up to 100 years), lack of settlement (glazing and doors can be inserted immediately after the concrete hardens), fire safety, good resistance to strong winds and climatic disasters. For a long time in Russia, only industrial enterprises - factories, warehouses, etc. were built in this way, but now the construction of residential buildings has expanded widely. And over the past few years, monolithic construction has gained popularity in the construction of country cottages.

Stages of monolithic construction

Monolithic construction, like any other, has its stages.

- As at the beginning of any construction, to begin building a house in accordance with monolithic technology, the construction site is cleared and prepared for the construction of the building. The construction area is calculated based on the size of the building itself, as well as the area that needs to be allocated for storage and delivery of building materials. A distinctive feature of monolithic construction is the fact that concrete for construction is prepared directly at the site of construction of the building, which can significantly reduce the cost of preparing and delivering concrete, and as a result, save on the final cost of construction.

- Next, the reinforcement frame is installed. This stage is extremely important in monolithic construction technology, which allows you to build a highly economical house in the shortest possible time. Depending on the shape of the reinforcement frame, the shape of the future building is formed. The reinforcement frame gives the building walls additional reliability and strength.

- Then the formwork is installed. After preparing the area and installing the reinforcement frame, construction approaches the stage of erecting special panel structures, into which concrete will be poured a little later.

- Concrete is poured. To build a house, an ordinary concrete mixture is used, which is responsible for forming the walls of the future building.

- Warming up the concrete. This need arises only when construction takes place in the winter so that the concrete hardens better. However, if construction takes place in the summer, then there is no need for this procedure.

- Curing. Removing formwork. In order for the concrete to harden, it is left for several days. After the concrete has hardened, the formwork is removed and construction approaches the finish line.

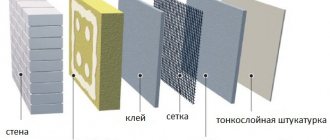

- Exterior decoration of the house. This stage is considered the final stage of construction. Since concrete has high insulation properties, monolithic buildings do not require additional work on laying hydro-, heat- and sound-insulating materials. There is also no need to level the walls, so all finishing work tends only to perform facing work. To decorate the facade of a monolithic building, you can use any known decorative materials that are only used today for exterior finishing work. The most commonly used materials are panel cladding materials, facing bricks, decorative plaster and many others. Here architects can give free rein to their innovations and at the same time take into account the taste preferences of the customer as much as possible.

Peculiarities

The peculiarity of monolithic brick construction is that when constructing a beam foundation for a building, it does not end before the first floor, but continues until the very roof of the house. Also in this type of construction it is necessary to use the method of temporary formwork, which is made for several floors at once, while construction on the next floor begins only when the concrete on the previous one has hardened. During accelerated construction, work is carried out simultaneously, one team erects load-bearing structures, and at the same time another team lays brick walls. In parallel with pouring concrete, reinforcement is also being built up. The reinforcement runs from the very foundation of the house to its top.

External walls and load-bearing partitions are made of aerated concrete blocks, which allows noise to be blocked out and heat to be conserved; these blocks also reduce the overall weight of the structure. Subsequently, these walls are finished with insulation. Polystyrene foam is mainly used as insulation. At the final stage, facing bricks are laid on top of everything. The entire building is finished with this material, and outwardly the house looks like a structure made entirely of brick.

Today, the Ufa residential real estate market is represented by brick, panel, monolithic and mixed types of apartment building structures. And when choosing an apartment, the buyer already has to take into account not only the location of the house, the floor, the layout of the apartment, but also figure out what is better: a monolith or a panel, a brick or a block. Let's look at the advantages and disadvantages of each type of design separately....

Monolith.

Monolith is a construction technology in which a liquid concrete mass is fed into the formwork and the wall is solid, without a single seam.

One of the advantages of a monolithic house is good sound insulation of apartments. However, you need to immediately make a reservation that thanks to the continuous construction of the vertical walls, you will be able to perfectly hear the hammer drills of all your neighbors right up to the top floor. This lack of monoliths is felt especially well due to the fact that repairs in monoliths, as a rule, can last for months. Another advantage of a monolithic structure is the fact that such a building gives a uniform settlement, which in itself prevents the formation of cracks. As a rule, the size of apartments in monolithic buildings is larger than in panel buildings, and therefore, even with the same price per square meter, apartments in monolithic buildings will always cost more than in panel structures. Also among the disadvantages is the timing of construction of a monolithic house. The time spent on the construction of such a structure is usually 2-3 times more than on the construction of a panel house and almost the same as on the construction of a brick one. In addition, the construction of such a house can always be “frozen” for an indefinite period.

Panel

The most important advantage today is the low cost of apartments in such a building. Another advantage of a panel house is the speed of construction. Typically, such a house is built from 3 to 12 months, in contrast to monolithic and brick ones, where the construction time ranges from one to two years. In the new series of panel houses, the distance between the load-bearing walls is increased and is 4.2 m (unlike the “old” ones, where this distance is 3.3 m). The height of the ceilings has also increased, now it reaches 3 meters. Most of the new series include glazing of loggias and balconies; the apartments have two bathrooms and spacious kitchens. Improved thermal protection. It is worth talking especially about the quality of the panel of the new series. The production of house components is carried out in a factory environment by skilled workers under constant supervision. The quality of panel houses is always predictable and unchanged, since the construction technology is quite simple and has been proven for a long time. Among the disadvantages of panel houses is still poor sound insulation. You will still be able to hear the sounds that accompany the activities of your neighbors. This inconvenience can only be eliminated by covering the walls with a soundproofing coating. Also among the disadvantages is the standard layout of apartments.

Brick

The main advantage of a brick house is determined by the composition of the brick itself. Let's remember what a brick is? Brick is fired clay, an environmentally friendly product. An optimal microclimate is created in a brick house: in summer, residents can enjoy natural coolness, and in winter, warmth. It is also worth noting that the walls of such a house “breathe”; this quality of a brick house prevents the appearance of problem areas on the walls and corners where microorganisms develop that can harm health. Living in a brick house will allow its owner to save on heating, since such a house, as we said above, retains heat well. Brick houses take too long and therefore are expensive. The cost of an apartment in a brick house is significantly higher than in a panel house. Usually they build mixed ones: monolithic brick. Their characteristics and quality are almost the same as those of monolithic houses. Since the 90s, the number of monolithic brick houses being built has been steadily increasing, while the number of panel houses has been decreasing. Real estate agency “Expert” on Teatralnaya, together with Uralsib Bank and Construction Trust No. 3, are holding a free seminar on the topic: “How to profitably sell an old apartment, buy a new one and benefit from a mortgage?”, which will take place on March 20 (Wednesday) at 7 p.m. :15 at the address: Ufa, st. Pushkina, 94, in the House of Actor building. Details and registration for the seminar by phone: 273-72-12, 294-73-21.

Let’s dot the i’s on the issue of the eternal confrontation between house construction technologies. Pros and cons of each type of construction.

BRICK HOUSES

- What are they built from?

When building brick multi-storey buildings, two types of bricks are usually used - ceramic and silicate. More expensive ceramic bricks have excellent performance properties - they are quite durable and have high thermal and moisture resistance. Sand-lime brick is much cheaper, but does not tolerate temperature changes and high humidity, so it is practically not used for the construction of high-rise buildings. Increasingly, hollow bricks - slotted and porous - are used in construction. Their main advantages are lightness and excellent thermal insulation (due to the presence of air cavities in the structure). However, working with hollow bricks requires special care - if the mortar gets into the voids, all the useful properties of such a brick will come to naught.

- How quickly are they built?

Brick houses are built slowly because they require highly skilled masons - after all, even minimal masonry errors can ruin the facade. Construction deadlines are usually lengthy, and compliance with them depends on many factors, ranging from weather conditions to the availability of masons. Therefore, today they often prefer to build monolithic brick houses, which can be erected faster.

- Durability

Ceramic brick is one of the most durable materials; the standard service life reaches 150 years.

- Comfort

Brick houses are considered the most comfortable - they have maximum heat resistance, hygroscopicity and sound insulation, as well as the highest score for environmental safety (zero background radiation). Modern apartments in brick houses have a good layout and high ceilings (up to three meters). They are suitable, for example, for creating two-level apartments or individual redevelopment.

- Relative cost

The level of prices per square meter in new brick buildings is usually impressive - luxury housing, as a rule, is built of brick. The cost of apartments in brick houses of the old pre-revolutionary building, “Stalin” and “Brezhnevka” buildings is less.

When buying a secondary home, it makes sense to carefully inspect the walls and look for cracks in them - those that fan out or run parallel to each other are especially dangerous.

What is a monolithic house: advantages and disadvantages

What is a monolithic house: advantages and disadvantages

The name speaks for itself, “monolithic houses” is an adjective formed from two words: mono and casting, which in total means uniformly (whole) filled. But this does not mean that the house is simply poured from concrete, no, it is poured, maybe only a frame, and the walls themselves between the columns are built up with other materials: brick, stone and others.

By the way, FC "Respect Stroyinvest" is ready to offer apartments on Saltovka, in the fifteen-story new building under construction in the Slobozhansky Quarter residential complex.

Monolithic blocks can be ready-made or made at the construction site by pouring concrete or mortar into formwork. It is also worth noting that there are 2 types of formwork:

- removable - usually made of wooden boards and dismantled after the concrete has hardened,

- non-removable - made of wood, steel, aluminum, plastic and other similar materials, this type of formwork is not dismantled and remains part of the monoblock, acting as additional heat-noise insulation.

It is worth noting that monolithic houses are the most common in the construction business. When making blocks, technologies are used that make it possible to make the block lightweight; the weight of the block is much less than the weight of masonry of the same size.

Advantages of monolithic houses

- One of the first advantages is the convenience and speed of construction, since monoblocks are either poured from concrete mortar or simply installed ready-made. Weight, due to the low weight of the structure, due to lightweight monoblocks, it is much easier to build such a house, because virtually any soil will be suitable for its foundation.

- Strength, thanks to the mono structure, the building has a minimum number of construction seams, which increases strength.

- The price of building a monolithic house is almost a third cheaper than building the same house from stone or brick, which is facilitated by savings on consumables, labor and equipment.

- Unlimited, since the role of load-bearing buildings is performed by external walls, the building can be raised to any height, and the internal layout can be made in any architectural style. Additional space, monoblocks are already made of stone and brickwork, which saves on average 7-8% of space compared to similar buildings made from the above-mentioned materials.

- Waterproof, concrete has good water resistance, such houses are not afraid of floods.

- Resistance to vibrations; due to the small number of seams, the building can withstand an earthquake with an amplitude of 7-8 points.

- Durability, monolithic houses are quite durable and, in temperate climate zones, can withstand more than 100 years without major repairs.

- The profitability of this building is simply off the charts; not only have we already saved time on construction thanks to the ease of installation, but the shrinkage of this building allows us to move on to interior decoration almost immediately after the completion of the main cycle.

Disadvantages of monolithic construction

It is difficult to work in cool weather; at temperatures below +5°C, the concrete mixture must be heated or additional frost-resistant mixtures must be used, which will increase the cost of work. Heat-sound conductivity, concrete conducts heat well, as a result of which an additional heat-sound insulating layer will be required.

But as you understand, these disadvantages are not significant, and the advantages are much greater than the disadvantages of a monolithic structure.

Which house is better: brick or monolithic?

Panel house

Panels in construction today are not very common: new construction of panel housing in large cities ranges from 4 to 7%. We consider exclusively panel houses, and not housing built using frame or monolithic technology, where the panels act as a curtain wall. If these categories are combined, you get about 20% of the new buildings market.

Houses using classic panel technology are record holders for the speed of construction.

At specialized factories they are able to manufacture entire rooms. A car arrives at the site with (yes, yes!) a ready-made room. Then it’s up to the tower crane and the welder-installer.

The panels have special steel hinges and at the initial stage of installation they are attached to each other using welding tacks. The building is assembled like a construction kit in 4-10 months; the number of floors has a major influence on the time frame.

All these absolute advantages are complemented by one more: 1 m2 of space in such a house has the lowest cost of all possible. Therefore, it should not be surprising that cities in regions where the income of the population is low are 80% built with panel houses.

Law of life: cheap cannot be the best

. The panels are criticized for their low thermal and sound insulation. Corner rooms may suffer from excess air humidity. All this entails the need to install heating devices of greater power than in rooms of similar size with good thermal insulation. Accordingly, during the heating season, utility bills increase significantly. Because of this, Soviet-built panel houses are subject to sanitization, insulating the facades and reducing the load on the heating system.

But that's not all the surprises. The construction of a panel house requires low costs, but the cost of the panel is in a very wide range. The fact is that simple single-layer panels are very rare. Now manufacturers have the opportunity to produce multilayer “sandwich” panels with insulation from various materials. Such panels are much better. Thus, depending on the type of insulation and the thickness of the panel (150-400 mm), the cost may differ several times.

And lastly: a panel house is not suitable for those who like redevelopment.

Almost all the walls in them are load-bearing, with the exception of partitions between the kitchen, toilet and bathroom. So you need to familiarize yourself with the layout of the apartment in advance; you won’t be able to change anything.

Brick house

Modern brick houses can be divided into two categories. In 3% of cases, the load-bearing walls of the house and partitions will actually be made of brick; all other houses can be called brick. Their supporting structures are made using monolithic technologies, and the façade is hidden behind facing brickwork. The characteristics of the first type of houses are much better.

You can understand the builders: brickwork is a very expensive method of building a house. Expensive materials, labor and the longest construction period - up to three years. But there are companies that are not going to leave this market. There are plenty of people who want to live in a real brick house.

This is the most expensive and durable housing of all. Many people are afraid of the impossibility of finishing work; shrinkage occurs within 2 years after the construction of the house. Just don’t invest in expensive repairs - do cosmetic ones that are livable, and 2 years will fly by. By the way, this is the only obvious disadvantage of a brick house compared to all the others.

Load-bearing walls 2.5 bricks thick have good heat and sound insulation. The advantages include the unique ability of brick to absorb and release moisture. Concrete is incapable of this. And if there is increased air humidity in the region, those who say that it is easier to breathe in a brick house are not exaggerating at all.

And with redevelopment in brick houses, things are better: partitions between rooms can be moved as desired.

Monolithic house

Experts have calculated that the share of monolithic housing construction ranges from 75-80%.

Many factors come together here: the speed of construction is not much inferior to a panel house, the house can be faced with brick, any materials can be used for internal structures, and such houses can be built at sub-zero temperatures

.

Monolithic houses can be divided into two types: monolithic frame and monolithic. The first type is a structure made of support columns and floor slabs, which is the load-bearing frame of the building. The second type is a one-piece monolithic structure.

A special feature of monolithic frame houses is that 70% of housing built using this technology is faced with brick; the emotional attachment of consumers to this type of material is very high. But in fairness, let us note what good it is if it is just an element of decoration, and the outer walls in such houses are constructed mainly from gas silicate blocks.

One of the advantages of monolithic construction is the fact: there are practically no seams in a monolithic building, and this increases heat and sound insulation

. The use of multilayer “sandwich” panels for monolithic frame houses as a curtain façade further enhances these characteristics.

Monolithic construction has a very large localization. It is enough to place a concrete production station on site and work can be carried out day and night, regardless of weather conditions. Monolithic houses have a mass 25-30% less than brick ones. Accordingly, they have less foundation costs.

Unpretentiousness in construction equipment, the use of simple formwork and a small number of workers allowed monolithic construction to take a well-deserved first place in terms of cost per 1 m2 of area.

For those who cannot come to terms with the layout that the designers have developed, a monolithic house is a dream come true. You buy a “clean field” and are free to decide where and what material you will use as partitions. The only thing is that it is better not to change the connection of the bathroom and kitchen to the sewer and water supply risers.

Monolithic houses: pros and cons

What are the pros and cons of monolithic construction, we will try to dwell on this topic in detail. What’s interesting is that in private construction, customers, as a rule, combine these two types. That is, it turns out to be a concrete frame, externally finished with a brick wall. One point can be highlighted as to why this type is so popular. Construction companies before construction carry out comparative characteristics of different types of materials, and so the monolith, despite its disadvantages, is completely covered by a large number of positive aspects.

What is a monolith

What is this material? So, the simplest definition is a building made of poured concrete, with a frame designed inside to ensure the reliability of all elements of the structure. Due to the fact that such a system is used in a dependent connection with other elements, the houses are obtained without seams, that is, “solid cast”.

As for the foundation, for such structures it has a common structure, that is, the foundation slab itself is connected to the walls. For this purpose, a slab about a meter wide is used, which is additionally reinforced with reinforcement.

To be honest, it is no coincidence that this construction has now received a new impetus. Indeed, in history, the first mentions of such a construction came from the times of the Roman Empire. By the way, the famous Pantheon was built according to this principle; scientists proved this back in the middle of the 20th century. Interestingly, the first mentions of the practice of using a monolith in Russia indicate that the famous palace of the Empress and a weaving factory in St. Petersburg were built using exactly this technology.

Over the next almost two hundred years, various architects made a lot of changes to the technology, trying to reduce the number of disadvantages, bringing the design itself almost to ideal. Now, despite the most advanced developments, it is not possible to achieve perfection, but still the technology has many more positive aspects compared to others.

Today there is not a single technology that allows you to build problem-free houses. When choosing a technology, be prepared that ideals do not exist; each has its own nuances and must be taken into account.

Monolith houses: pros and cons

- The technology itself allows you to create a variety of design ideas.

- Speed, incredibly high pace of construction.

- Resistance to earthquakes (up to 8 points).

- The design ensures shrinkage evenly and you will not experience any cracks. Also, it becomes possible to immediately begin finishing.

- Strength is high, given the seamless nature.

- There are no point loads, the load is distributed evenly, which makes it possible to significantly reduce and lighten the foundations.

- Possibility of using lightweight formwork, without the use of complex structures and machines.

- Price. The cost of construction is lower than that of similar brick ones.

- There is room for the imagination of designers, planners, and customers. Buildings can have completely different floors, architectural forms, varied layouts, etc.

- Due to the fact that the thickness of the walls is less, this gives a noticeable increase in area.

- Taking into account the fact that this is a solid structure, floods are not terrible; water simply cannot penetrate the monolith.

Negative sides

After the advantages given above, the disadvantages listed below may seem insignificant, but they should not be neglected. Minuses:

- Greater labor intensity of work compared to other types.

- All engineering networks, ventilation, must be thought out from the beginning, because it may not be possible to make changes in the future.

- The pouring process is allowed only in warm weather; the temperature should not be below 5 degrees. In winter, it is rare that anyone decides to pour, due to the fact that heating and sweeping are required, which in turn leads to a decrease in the quality of the solution, as well as to an exorbitant increase in cost.

- To form a single monolith and ensure better strength characteristics, pouring must be carried out continuously, and from several directions at once.

- It is necessary to ensure that the mixture is compacted, otherwise all the advantages will turn out to be disadvantages.

- Concrete walls have a very high level of thermal conductivity, which affects thermal insulation.

The monolith itself does not protect the room from noise, especially impact noise. Therefore, as a rule, the sound insulation of such houses is poor.

As you can see, the last two drawbacks seriously undermine the popularity of such houses. But, nevertheless, the possibility of additional insulation and sound insulation solves this problem. However, another problem arises; the cost increases significantly. At the moment, manufacturers are trying to be pragmatic about this, using polystyrene foam structures as formwork. The use of such elements at the initial stage comes down to a technological aspect, but after successful pouring, this structure is not removed, it remains and serves as a reliable heat and sound insulator.

As we can see, today no problem-free technology has yet been invented; each type of construction has its own disadvantages, which can be partially covered by advantages. In principle, nothing distinguishes a monolithic private house, pros and cons, from the listed characteristics. Both multi-storey construction and private construction imply the same work procedure. But, still, if you compare the price ratio, monolithic houses in the private sector are slightly inferior to their main competitors.

Construction technology

The sequence of construction and installation work and the technology of erecting a building with a monolithic frame base imply certain types of work. The construction of a cottage is based on the construction of the skeleton of the structure, followed by filling the wall openings and laying the internal partitions.

We pay special attention to load-bearing columns. Their concreting is carried out using technologies using heavy concrete grades M300, M350. Such measures are necessary to ensure reliable and stable support for the reinforced concrete belt.

To fill the walls we use gas blocks or bricks. When finishing the walls, we additionally insulate them with an outer thermal insulation layer. This solution will ensure that the internal temperature of the room is maintained during subsequent stays in the house. Columns, ends of interfloor ceilings, and belts can become weak points in the thermal insulation of a house. These elements require careful insulation. To solve the thermal insulation problem, we use mineral insulation or expanded polystyrene.