Many people are accustomed to the fact that concrete is gray in color. But you can still diversify it and make it shine in a wide variety of shades. Thanks to modern technologies, it is possible to produce pigments for coloring cement.

They are mainly used for paving slabs, paving stones, curbs, side stones and many other elements that are used to decorate any yard and street. But how to make paint yourself? This is a serious decision that should be taken with special responsibility.

First of all, you need to find out what types of dyes exist, and only after that you need to familiarize yourself with all the specifics of manufacturing.

Which pigment dye is best to choose for painting concrete with your own hands?

Cement dyes or pigments are powdered additives that impart different colors to cement or mortar.

Once dry, these components do not dissolve and are not exposed to water, oils or other liquids. Also, if they are of good quality, they are not exposed to sunlight or rain.

Dyes for cement must have the following properties:

- High level of coloring ability. It is imperative that the pigment can transfer its color to the cement;

- It must cover the color of the item to which it is applied;

- Dispersity. Thanks to this property, the color coverage properties and dyeability are increased;

- High level of oil absorption. This property consists of the ability of paint particles to retain oil on the surface of the product;

- High light fastness. This property is to retain color even under strong exposure to sunlight.

But what pigment dye to choose for coloring concrete products is quite a difficult task. Therefore, you first need to consider the types of pigments that are used for cement products.

Acid dyes for concrete

Acid dyes are the most popular method for painting concrete products.

This dye has a powdery composition that has a transparent structure. It does not have a harmful effect on the environment and does not harm human health. When painting, it reacts with the cement and turns it into the desired color.

Acrylic dyes for concrete

Acrylic-type pigments are used for painting cement products in areas where long-lasting paint retention is required.

Therefore, it is an ideal option for painting floors and walls. The required color is selected directly on site in the store. The choice of colors is quite wide. In addition, there are no problems during mixing. This paint can be applied to surfaces both inside and outside the house. The dye has no harmful effects and dries quickly.

Dry dyes for concrete

Dry dyes are great for those who want to add a pop of color to their yard. The range of these dyes offers a huge selection of colors. By the color of the powder you can immediately guess what color the concrete products will be painted.

Features of dry dyes:

- The color tolerates any weather conditions well. Does not collapse under the influence of rain and sunlight;

- Dry paints are best used for new concrete that has not previously been subjected to any treatment;

- Only the surface of the product should be painted with the dry mixture;

- The composition contains substances that ensure long-term retention of the mixture on the surface and strengthen the structure of the cement.

Remember that the powder does not dissolve in water. To dissolve, use a special professional solvent.

Colored additives for concrete

These components are used to produce colored material. Additives can be either in liquid or powder form. They are added to the raw cement solution. The shades of these additives mainly come in light and bed tones.

Cement structures to which color additives have been added are painted throughout the entire structure. For this reason, the paint does not deteriorate under the influence of rain and sunlight. It is not afraid of damage, deformation, or potholes. The color will last as long as the product itself lasts.

Application of acid dye

The concentration of the tint composition on the plane depends not only on the proportion of the pigment, but also on the method of applying the mixture. When working, a plastic spray gun is used, from which a solution is sprayed under pressure. The power tool must be suitable for working with acidic compounds. To achieve a rich, thick shade, paint is applied with a brush. After it, traces of strokes remain noticeable, so you need to go over the surface being treated again using a pump sprayer until they completely disappear.

To achieve the “marble” effect, the concrete slab is placed at a slight slope and paint is liberally applied. As a result, self-distributed acid dyes for concrete form an irregular pattern, imitating an expensive material. To form a natural pattern with veins, two mixtures are used:

- strong concentration - a rich, bright color is obtained;

- weak concentration - a light, bleached shade is obtained.

Which cement to choose for making colored concrete with your own hands?

When making colored concrete, any type of cement can be used. But it is still worth taking into account the following nuances:

- It is advisable to use high-quality cement;

- It is worth paying attention to the color of the cement, because the initial color affects the shade after it is painted;

- Remember that the gray color of cement has a muting effect on the tone, thereby making it dirty and reducing brightness;

- It is best to use white cement. When stained with this concrete, the color will be bright and crisp.

To avoid problems when painting, use the following recommendations:

- It is advisable to do preliminary mixing and filling;

- If a large amount of pigment is introduced into the cement mixture, cracking may increase in the future;

- In addition, cracking can occur due to the high absorption of water by the cement powder. Therefore, plasticizers and water-retaining additives should be added to the mixture.

We independently create the desired color of the tile at the stage of its manufacture

You can create a dye for paving slabs with your own hands. To do this, you should take the chosen paint and add a certain amount of pigment to it, which, in your opinion, will improve the original color. It happens that the purchased paint does not live up to expectations and requires a slight change in shade. Solving this problem is simple if you know that the pigment chosen for correction will dissolve well in the base composition and will allow you to achieve the intended goal.

Paint for paving slabs, which you create yourself, can be placed in a cement-sand mixture at the stage of its preparation or applied to a ready-made surface. In the first case, you will need to create several copies of the tile, into which different amounts of coloring pigment are placed. Actions of this nature are carried out in order to understand which option will be optimal. The greater the amount of pigment, the brighter your products will look. Some experts suggest that it is more economically feasible to buy unpainted tile material and bring it to the desired condition yourself. For these purposes, it is recommended to choose acrylic paint that has a varied palette of shades.

Back to Contents

The procedure for placing paint in concrete mortar

When starting to paint the colorless composition of the future tiles, you should:

- dissolve the pigment in water, the volume of which depends on the saturation of the desired shade;

- carefully pour this solution into the cement-sand mixture;

- Mix the ingredients thoroughly.

You should try to obtain a mass that is uniform in color, since the final result of your work depends on this.

Back to Contents

Subsequent stages of making colored tiles

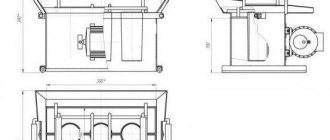

The finished mixture is poured into molds in the prescribed manner and subjected to vibration using a special table. In this way, all components are compacted, obtaining a smooth surface of the product. After drying, the tiles acquire their final color and can be used for their intended purpose.

There are no unique recipes that accurately describe the consumption of pigment required to create paving slabs. The ratios of the ingredients of the coloring composition depend solely on individual wishes.

Back to Contents

Preparation of concrete mixture with dye

An important condition when coloring cement is the uniform distribution of the dye throughout the entire structure of a particular product.

Therefore, the following recommendations must be followed:

- The dye must be added at the very stage of preparing the solution;

- The pigment should be distributed evenly throughout the entire base of the solution. The more carefully this is done, the faster the coloring matter will be distributed;

- The main indicator of readiness is the uniform distribution of color throughout the cement structure;

- It is important to maintain proportions. If the proportions are maintained correctly, this will ensure the same level of coloration of the concrete mixture from batch to batch. If the dye is used irrationally, this may lead to a change in the final color of the concrete and cause additional costs.

In addition, it is important to observe the proportions of the components of the concrete mixture:

- Cement – 1 measure;

- Sand – 2.5 measures;

- Fine gravel - 4.5 measures;

- Water – 1.4 measure;

- Dye – measure (by volume of mixture).

Remember, it is best to use white cement and white sand for the mixture. This will ensure a good and bright color. It is advisable to dilute it with water before adding the dye to the solution, and then pour it into the solution in diluted form.

How to make concrete dyes with your own hands?

Acid dyes are used to color cement. It is worth noting that dyes can flow along the walls and this will lead to poor coloring of the cement base. To solve this problem, you can use an acidic gel dye for cement mixtures.

To prepare an acid dye, you need to use the following means:

- Solvents;

- Adhesive components;

- Special coloring pigment;

- Various additives that are designed to consolidate the result.

All these components should be mixed well until a homogeneous consistency is obtained.

Also, for further painting work you will need the following tools:

- Work clothes;

- Tassels;

- Scotch;

- Paint tray;

- Protective glasses;

- Ladder;

- Latex gloves.

Painting Tips:

- When painting concrete surfaces, it is best to use several color pigments;

- Since acid dyes do not have a large selection of colors, dyes of different colors should be mixed to achieve the desired effect;

- The first step is to mix all the dry ingredients, and then add the liquid;

- Products must be coated with a solvent, and the dye should be applied to an already cleaned surface;

- Also, the surface must be dried with a special spray or an acid-resistant brush without metal elements;

- Because this paint contains acid, it can cause serious harm. Therefore, all work must be carried out wearing gloves and protective clothing;

- After 6 hours, all paint and acid residues must be washed off with water;

- Drying is then carried out for 24 hours;

- The result is a perfectly painted base.

- For 1 m2 of surface to be painted, 0.25-0.35 liters of diluted dye solution will be required.

Working with pigment

Three types of pigments help make concrete colored:

- Metal oxides;

- Pigments from minerals and mining products;

- Chemical complex compounds.

A special feature of working with any coloring components is the difficulty of choosing a shade: each base color can have a wide range from saturated to pale, and pigments can also be combined with each other.

Dyes for tinting concrete are dry powders that are dissolved in water. The intensity of their manifestation depends on several conditions:

- Type of binder used. To obtain a pure color solution, it is advisable to use colored cement or pure white - it will not give a gray tint to the background, unlike ordinary Portland cement.

- The amount of pigment and its quality determine the intensity of the color and the duration of its preservation. Different compositions require a special approach when diluting and carrying out concrete work (temperature, humidity).

- The quality of the main components of the concrete solution - cement, sand, coarse filler (crushed stone, colored glass can be added, there may be no major incidents at all). Their purity and basic parameters must comply with GOST 26633-2012;

- The amount of water affects the color intensity and strength of the finished stone, so you should not deviate from the technology and recipe. Excess liquid will make the mixture workable, but the products most likely will not last long, and the color will wash off quickly.

The technology used to produce colored concrete is no different from mixing a regular mortar, with the exception that pigment is added to the water.

At home, you cannot do without an autonomous concrete mixer for mixing components - only with its participation can you dissolve the paint and achieve its complete distribution throughout the entire volume.

How to make colored concrete:

- Pour 7-8 liters of water into the concrete mixer;

- Pour the pigment into the water according to the instructions;

- To impart plasticity to the solution in water, it is also necessary to dissolve a plasticizer. This must be a special agent that increases the elasticity of concrete. As for the use of soap and any detergents with surfactants, opinions on the advisability of their use are controversial. In industrial construction, the use of such a component is impossible and is not considered; in private practice, many craftsmen actively use surfactants;

- Now cement and sand are added to the solution in a ratio of 1:3 (it is convenient to measure in units, 4 buckets of dry substances will require 7-8 liters of water). At the same stage, a large filler is introduced.

The technology for mixing colored masonry mortar is presented in the video; the process for making concrete is similar.

After mixing is completed, the mass is placed in a mold, applied to the wall or laid, depending on the purpose of the solution.

Colored cement is also sold ready-made, mixed with pigment. In this case, the kneading is carried out using conventional technology.

Penetrating painting of concrete surfaces

This painting method is the same as regular painting of products. But it is worth considering that during hardening, the cement composition retains its moisture absorption properties. This property is used for additional protection of the cement surface and for its coloring.

Painting recommendations:

- For coloring, you should use bases with deep penetration, capable of being absorbed to a depth of 5 mm;

- Water-based impregnations are not suitable for cement products. This is because these components have low penetration levels and will leach out over time;

- When choosing dyes, be sure to carefully read the composition. Mixtures must be designed specifically for penetrating coloring. You can also use varnishes and cement impregnations for the base;

- It is advisable to use this coloring for products that are not subject to significant loads.