Provide standard strength of concrete products. Using mixtures, high-quality pouring of foundations and monolithic building structures is performed. Concrete of any grade can withstand tests and the maximum number of quality checks for cement and fillers, in mixtures and finished structures.

We offer mortars and concrete from the manufacturer with standard indicators that meet the requirements of GOST. Strict compliance with standards is ensured by the use of special additives and plasticizers that meet the requirements for water resistance, frost resistance, etc. But is it possible to assess the quality of concrete during pouring or during setting without laboratory testing?

How to find out the quality of concrete before pouring

It is possible to accurately find out certain characteristics of a mixture only in a laboratory that operates at every large enterprise. After all, concrete M350 or M400 looks almost the same as M100. When ordering a batch, the client is forced to trust the passport and documents for the ordered delivery, which are presented by the mixer driver. To do this, you need to carefully review the certificates provided.

Next, you should pay attention to the brand indicated by the manufacturer, as well as the time when the invoices were issued. After all, a vehicle makes many trips per day, and the documents presented for unloading may not correspond to the shipment actually delivered to the construction site. There are also signs by which experienced craftsmen can roughly evaluate the brand.

How to visually determine the grade of concrete?

- Pay attention to the shade of the mixture. Light brown indicates an excess of sand, reddish indicates slag additives or the presence of clay. The solution should be a uniform, gray shade. However, the change in color of the mixture may depend on the presence of various additives.

- The quality of concrete can be determined by casting a portion into a separate container (bucket, wetted mold). No puddles of water should appear on the solution.

- When pouring, no delaminations or cracks should form on the surface.

- If the concrete falls like a cake, and cement laitance is poured separately, this can be considered a sign of poor quality of the mixture provided.

But a concrete mixture can only be accurately tested in a specialized laboratory, and most often after it has gained strength. Therefore, when pouring the main foundation, it is necessary to cast cubes measuring 100x100x100 mm and leave to harden under standard conditions. After full ripening (28 days), samples should be sent to the laboratory for testing.

How to properly prepare a sample?

The correct quality control of concrete depends on compliance with the rules for the manufacture and storage of standard samples. It is necessary to remember that:

- The design strength of the solution is achieved in 28 days.

- In 7 days, 70% of the design strength is achieved. This can be used when conducting accelerated tests. For example, concrete m200 will show an average strength of 140 kgf/sq. cm.

- Samples must be stored at a temperature of about 20 ᵒC and a humidity of 90–100%. Maintaining a certain level of humidity is necessary for the concrete to properly gain strength and undergo the so-called “hydration process.”

The obtained samples should be protected from mechanical damage and freezing.

High humidity is an important factor in the manufacture of building structures made of concrete. To do this, during the first five days they are either watered with water or covered with waterproof material.

For those cases where it was not possible to cast preliminary samples, it is possible to conduct studies of the quality of already hardened concrete directly on the construction site using special non-destructive measurement methods.

How to determine the quality of concrete after hardening

To evaluate the quality of the resulting product, there are several methods that experienced builders know.

- Carefully inspect the resulting surface of the product or foundation. High grade concrete must have a smooth surface, without pores or layers. If pouring work was carried out at low temperatures in winter, characteristic patterns should not appear on the surface, which indicate freezing of the mixture. The presence of patterns indicates freezing during pouring; they lower the concrete grade by 70-100 points (from M300 to M200-250);

- Using a hammer that weighs no more than 500 g, tap the foundation after reaching 70% of the strength characteristics. The sound should be clear. If, with a ringing sound during an impact, hammer marks remain on the surface, this indicates that the density of the concrete is 150-200 kg/cm2. A dull sound indicates a low grade of the mixture, and indicates that the strength does not exceed 100 kg/cm2. And if, upon impact, cracks form on the surface or the material crumbles, it is recommended to re-fill.

By hitting the chisel with a light-weight hammer (300-400 grams), you can also find out the quality of the concrete. It is necessary to evaluate how and to what depth the chisel plunges into concrete during impacts of average force.

- If the tip plunges deeply and easily without hitting crushed stone or gravel, the grade is below M70.

- With an immersion depth of up to 5 mm, we can assume that the grade is equivalent to M70-M100.

- For concrete grades M100-M200, when a chisel hits the surface, only small thin layers are separated.

- If there are no marks left from the chisel at all or there is a shallow mark and there are no peelings at all, we can assume that the grade of concrete is higher than M200.

However, all these methods provide only a rough estimate. Only laboratory tests can accurately determine the quality of poured concrete and the reliability of the structure. In this case, special equipment, measuring devices and tools are used. In addition to testing cast control samples (a cube with an edge of 10 cm), there are many non-destructive methods for checking the quality of the mixture - ultrasonic, shock-pulse, and other instruments and control methods. The methods listed above are “folk” and do not claim to be highly accurate. In addition, the reliability of the determination depends on the experience of the master who is trying to determine the grade of concrete.

Analytical method

It is divided into 2 types. The first, with the help of special formulas, is available to those who have received a special construction education.

The second one is accessible to everyone and is most often used in practice. Take a very small piece of concrete, a hammer weighing about half a kilo and a chisel. The chisel is placed on a piece of concrete, and a hammer is lowered onto it with medium force. The hammer bounces off; there is no need to release it again. Remove the chisel and look at the diameter. If the concrete is not damaged, then these are the best types of concrete - from B 25 and above. If the concrete is slightly damaged (up to five millimeters), then these are medium grades of concrete - from B 10 to B 25. But if the concrete is damaged up to a centimeter, then these are relatively weak grades - from B 5 to B 10.

This method of measuring the strength of concrete is suitable for everyone, it is easy to remember, but it is also worth remembering that this method is only suitable for small construction projects - when constructing official large buildings in which enterprises will be located or people will live, concrete must be assessed using invited experts and industrial formulas and installations.

Even if you, say, are repairing the roof of a private house, you will need to evaluate the strength of the concrete support structures on which this roof will be supported.

Contents

Concrete is one of the most popular materials in construction; its quality and strength characteristics affect the integrity of the entire structure. Under the influence of external factors and deformation loads, the design strength usually does not coincide with the actual results. There are several methods for diagnosing the quality of concrete. The chipping method has become widespread in practice, but experts also use other testing methods.

How to check concrete performance in the laboratory

If, when producing a mixture at an enterprise, the technology and proportions are strictly followed, the components are selected, and there are no low-quality fillers, the quality of the finished product will undoubtedly be ideal. But just in case, it is recommended to prepare samples for subsequent control. They will be tested in a laboratory using the compression method and an expert opinion will be issued.

In order to fully accurately determine the quality of the finished concrete and its compliance with the specifications, it is necessary to pre-make formwork in the form of cubes with an edge size of 100 mm. After the concrete has matured, the samples need to be delivered to a laboratory, where they know exactly how to check the grade of concrete. This procedure is carried out after compaction (vibration) and drying under the same conditions in which general filling was carried out.

Checking and clarifying the brand of the resulting concrete, as well as issuing a certificate, must be carried out after the mixture has fully matured, after 28 days.

The correct selection and quality control of concrete is the key to the strength, durability and safety of the future structure. It is worthwhile to approach the issue of choosing a supplier, the method of delivering concrete and the use of concrete mortar very carefully.

Method for checking the quality of concrete using a hammer and chisel

To check concrete, you will need a hammer weighing 500-800 grams and a steel chisel.

Place the chisel on the surface to be tested at an angle of approximately 180 degrees and hit it with medium force. For a more accurate check, a similar operation must be done in different places in the structure. We evaluate the impact mark:

- The mark is barely noticeable - high quality concrete corresponding to grade B25;

- The mark is very noticeable - concrete grade B15-B25;

- Strong depressions were formed. The concrete began to be painted - concrete grade B10;

- The chisel penetrated more than 10 mm into the material - concrete grade no more than B5.

During ongoing construction, it makes sense to determine the quality of concrete before pouring begins. To do this, you need to fill a sample with dimensions of 100x100x100 cm. Until the concrete has set, you should pierce it with a concrete rod to release air.

Next, the sample is dried at an ambient temperature of 20-25 degrees Celsius and after 28 days it is taken to a specialized laboratory for analysis. Thus, you can obtain the most accurate technical characteristics and grade of concrete.

Assumption! If construction deadlines are tight, the sample can be transported 7-14 days after pouring. In this case, the laboratory should indicate the exact holding time.

In addition to determining the quality of concrete using improvised means, there are the following methods that require special tools, devices and installations:

- Determining the strength of concrete using a Fizdel hammer;

- Determining the strength of concrete using a Kashkarov hammer;

- Ultrasonic method: determining the quality of concrete by determining the propagation time of the sound wave and its speed using special equipment.

The correct selection and quality control of concrete is the key to the strength, durability and safety of the future structure. It is worthwhile to approach the issue of choosing a supplier, the method of delivering concrete and the use of concrete mortar very carefully.

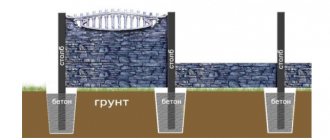

Concrete bases

The main load-bearing element of the entire building is the foundation. It is divided into different types. There are pile or block foundations, but most often when constructing private houses, strip, column or combined structures are used. At the same time, the quality of concrete used for the construction of foundations is very important. This method is very popular due to its affordability, ease of construction and high strength of the resulting structures.

The choice of concrete grade is very important; the strength of the structure depends on it. For private houses, you can use concrete from grade 200. However, the fact that you ordered concrete of the brand you need does not mean that this particular solution will be delivered to you. Less important indicators when using concrete are the degree of compaction, the conditions of laying and setting.

Should you pour the foundation yourself or turn to professional builders?

In the case of building a private house, when pouring a strip foundation, you can get by with household concrete mixers and mix it yourself from dry building mixtures. But you need to clearly understand that this is a very responsible and labor-intensive process, which will require a team of at least three people and it is not clear what grade of concrete will be obtained. There are two options - the first is to order the construction of a foundation from construction professionals with a guarantee, a contract and a concrete passport. The second is to order concrete yourself with delivery: the quality and price of which varies from “terrible” to “excellent” depending on the manufacturer. The purpose of this article is not to analyze concrete manufacturers, so we will give a couple of tips for the average buyer so that he can determine how good ready-mixed concrete he has purchased.

How to choose a supplier

Conscientious manufacturers always control the concrete manufacturing process, its composition and the quality of components. But how to choose such a supplier? There are several ways:

- You can contact companies that supply large construction projects with concrete. You can find their contacts from the superintendents at such facilities.

- Owners of newly built houses can also help make the choice of concrete for the foundation. At the same time, you should study the condition of their foundations. If you notice defects in the form of salt, cracks and peeling, this indicates low quality concrete.

- When choosing suppliers’ websites, pay attention to those that have not only a contact phone number, but also organizational addresses, information about the company, registration information, etc.

- When buying concrete, ask for a product passport with stamps. Moreover, it must go to each machine separately. The grades for strength, mobility, frost resistance, time and day of shipment must be specified there. It is better not to take handwritten passports without stamps. It is advisable to buy Gostov concrete, not commercial concrete.

- It is also necessary to preserve supply agreements. This way you can make a claim against the manufacturer.

But the quality of concrete must be checked in any case.

Transportation can affect the mobility of the mixture and its consistency. If the car moves over potholes at high speed, the homogeneity of the solution may be compromised. As a result, large elements of concrete will settle to the bottom, and the liquid will rise. This solution cannot be used. Of course, the solution can be mixed, but it is better not to take it at all. The same should be done when transporting in an open state.

The choice of concrete should be made taking into account the time spent on transportation. If this time is exceeded, the concrete may delaminate. It should be within 2-3 hours. And to save time, it is better to unload directly into the formwork.

Concrete quality control

It can be done in several ways. The visual method is as follows:

- When delivering concrete, the composition must be of uniform consistency.

- You can do a test pour. Concrete should not either flow with water or fall out in clumps. This indicates its heterogeneity.

- Checking for excess water is done as follows: when pouring a small part of concrete into the pit, a cake should form without cracks or layers. If the composition looks like lumps in a liquid substance, then it is of poor quality.

- Good concrete is gray in color. Brown color indicates an excess of sand, red indicates poor aggregates. However, when plasticizing additives are used, the color of the concrete may differ from gray. Uneven coloring should also alert you. It is better to refuse such a composition.

The test can also be performed by a concrete quality testing laboratory:

- To do this, you need to pour the delivered concrete into a soaked wooden box. Compact the composition by puncturing it with reinforcement. Place the box in a room with a given level of humidity and standard temperature. After 28 days, the sample is taken for testing.

- Don’t forget that you need to take a sample and pour it into molds to check the quality of concrete directly from the machine. The driver is also required to sign the sample collection certificate.

- The laboratory uses a special device to test the quality of concrete.

Is it possible to check the quality of concrete before placing it in formwork?

Question:

Asks Oleg from Rostov: “Hello! The foundation will be poured soon. We will order concrete from the factory. The question is whether it is possible to determine the quality of concrete when it is delivered to the construction site. It’s clear that it’s impossible to determine for sure without a laboratory, but at least approximately visually you can see a low-quality product?”

Answer:

The issue of checking the quality of concrete for the foundation before laying it inside the formwork is very relevant for private developers. In the absence of a laboratory, special instruments and chemical reagents, the characteristics of this structural material can be roughly assessed by several indirect signs:

- color - a bluish tint indicates a normal amount of cement, brown color most likely indicates the predominance of sand;

- cement laitance - in 85% of cases, the yellowness of this product indicates harmful impurities of clay, which is extremely dangerous for reinforced concrete structures, however, in the remaining 15% of cases, some harmless slags give exactly the same color;

- consistency - commercial heavy concrete must be mixed by RBI employees according to exact recipes on industrial equipment, therefore the water-cement ratio W/C is always lower (the mixture is thick and inactive) than when using a household concrete mixer, plasticity is ensured by special additives, the formation of cement stone (hydration) occurs faster;

- uniformity - the mixture should not contain particles of crushed stone or lumps of sand that have not been rolled in cement laitance.

How to pour the mixture

The choice of concrete class is as important as the correct placement of the mixture. It is done this way:

- First you need to check the base in the hole. The bulk base must be dust-free and clean. To do this, before pouring the mixture, the bottom of the pit is cleaned with air pressure.

- Before pouring, the entire formwork is moistened with lime milk or emulsions. This will protect the concrete from strong adhesion to the formwork and make it easier to dismantle.

- The filling must be completed in full in one day. This is necessary to obtain a continuous monolithic structure. At large sites, work is carried out by several teams from different machines at the same time.

- A 1.5 m long chute is used to supply concrete. It must move to different points of the foundation tape, otherwise you will not be able to evenly distribute the concrete along the tape. In order for the fluidity of concrete to be good, it is very important to make the right choice of cement for concrete. But if you cannot move the gutter along the belt, you will have to increase its length. This way you can move the end of the gutter to the desired location.

- The easiest way to pour the mixture is with a concrete pump. The consumption will be higher, but the productivity will increase. Moreover, the unit can supply the solution over a length of 50 m. Thus, from one machine it is possible to fill at different points of the base.

- The distance over which the mixture is thrown should not be more than 200 cm.

- Concreting is done in layers of 5-10 cm without interrupting the pouring.

- After pouring, the concrete is compacted. You can find out how to choose a vibrator for concrete in our other article.

- It is best to compact concrete using a deep-hole device. Choosing an internal vibrator for concrete will help increase the strength of the structure. In this case, the device is immersed in each layer separately, moving it inside the layer. It is not necessary to buy such a unit; you can rent it or order a tamper from a specific company.

- If you don’t want to buy a tamper, you can simply pierce the concrete in different places with reinforcement. However, this is very difficult, since you need to poke into the concrete almost every square centimeter

- To protect the solution from external factors after pouring, it is covered with a film. But for uniform drying, you will need to remove the film and water the concrete 4 times a day. This is done for the first three days, then for another three days the procedure is carried out three times a day. However, instead of watering, you can choose a steam generator for steaming concrete, it is more efficient.

- Installation of walls begins after the concrete has completely set (after four weeks). By this time, the strength of concrete will be maximum, as can be judged from the test results.

Quality control after pouring

You already understand how to choose the grade of concrete for the foundation, but it is also worth learning about ways to control the hardened foundation. For this purpose, ultrasound or sclerometer can be used.

You can do this check yourself. To do this, you will need a chisel and a hammer weighing between 300-800 g. The procedure is carried out as follows:

- The chisel is placed at 90 degrees to the base and hit on it.

- If the chisel easily enters the base, then a solution of grade 70 or even lower was used.

- When the tool is deepened by 3-7 mm, we can say that the grade of concrete used was in the range of 70-100.

- Small chips with a depth of 2-3 mm indicate a concrete grade of 100 or 200.

- When using a 200 or higher grade loaf, the impact will leave a small mark.

To make the result more accurate, such tests are carried out on different parts of the base.

Standards

The brand of concrete composition affects the strength of the base after the solution has completely set. This indicator is marked with the letter M and a digital indicator ranging from 50 to 500. It is measured in kgf/cm3. The indicator shows the compressive strength of concrete. For small structures, foundations of grade 100-150 are sufficient. For individual houses, concrete grade 200-300 is needed. High grade concrete is used for the manufacture of load-bearing reinforced concrete structures.

The correct choice of plasticizer for concrete will increase its frost resistance. This indicator indicates the total number of freezing and thawing cycles that the solution can withstand. It is marked with the letter F and a digital indicator in the range of 50-500. Concrete with average frost resistance is suitable for our latitudes.

Another important indicator is water resistance. It is marked with the letter W and is in the range of 2-12 kgf/cm2. The number indicates the concrete's ability to withstand water pressure. For foundations for an individual house, you can use concrete with a W index of 2-4. When constructing swimming pools, concrete with a water resistance rating of 8-12 is used.

The choice of crushed stone for concrete should be made taking into account the loads on the structure

To avoid unnecessary problems in the form of unnecessary costs, including financial and moral ones, it is worth understanding the material with which you are going to build your house, bathhouse or any other work of construction art. That is, you need to know how to determine the brand of concrete.

Since the basis of everything is a strong, reliable foundation that would not let us down with cracks and subsidence, we should learn to understand the methods for determining its strength. It will depend on how much weight it can bear without breaking.

Correct determination of its strength will help to avoid mistakes.

Concrete grade is a number indicating the compressive strength of a 28-day cured concrete cube with a side of 20 cm, expressed in kg/cm².

Concrete grades M300-400 are the most suitable for individual housing construction

. M100-250 have a minimum degree of strength and are used as an auxiliary material. It is difficult to find grades above 500 on sale, and it is unlikely that you will need heavy-duty concrete with special additives.

The correct option, of course, is to study the accompanying documents (concrete quality certificate) from the supplier or manufacturer. It is necessary to pay attention to whether the mixture has separated during transportation.

Non-destructive method

The advantage of this method is that the sample remains intact and can be used for repeated studies. Using laboratory equipment, the following is recorded:

- The size of the slope.

- Tearing off.

- Impact magnitude of the impulse.

- Soft deformation value.

- Chipping.

- The result of simultaneous tearing and chipping.

Depending on how much the depth of immersion of the striker into the mass changes, a conclusion is drawn about the strength of the material. To do this, laboratory hammers are used, with the help of which plastic deformation of the concrete surface is carried out. After hitting the sample, a hole appears. Its diameter is measured and a conclusion is made about the strength parameters. Strength measurements using this method are carried out in several stages:

- Cleaning surfaces of paint, putty and plaster.

- Applying 10 blows of medium force on the control surface. The blows are applied strictly along the marks with an interval of 50 mm.

- Using a caliper, determine the dimensions of the holes with an accuracy of 0.1 mm.

- The arithmetic mean of the print diameter is measured.

- A calibrated curve based on measurements of standards is used. Based on the average result obtained, the strength grade is determined.

We have described only one non-destructive testing method; there are others. In any case, you need to use a calibration chart to determine the strength based on the diameter of the print. If you do not have samples, use special devices - sclerometers. They work on the principle of elastic rebound. Rod firing guns can also be used. Its scale shows a digital value depending on the reaction of the striker. The combined strength testing method involves tearing and simultaneous chipping. A special anchor device is installed into the concrete mass. The device presses on the controlled area and shows its strength.

Visual definition

It is possible to determine concrete by color: the better and stronger the mixture, the bluer the color. If yellowness appears in the liquid (cement milk), then this indicates clay impurities or other slag additives. The thicker this liquid fraction, the higher the grade of concrete. But, in general, the color also depends on the manufacturer’s specifications and on the additives that were used during production. A well-prepared mixture should not contain impurity grains that are not covered by the solution. A denser solution should resemble moistened soil.

Return to contents

Checking strength by contact

You can test concrete for strength using a special device - a sclerometer. The purpose of the device is to determine strength using the shock pulse method. A sclerometer costs from 11 to 35 thousand rubles. They are mechanical and electronic. It is unlikely that an ordinary buyer would want to buy such an expensive device for one-time use.

Another option is to send a concrete sample to a specialized laboratory to determine and check the degree of strength. To do this, you need to build a wooden box measuring 15 cm² and moisten it with water. The form is wetted with water so that dry wood does not draw water from the concrete mixture, worsening the process of hardening (hydration) of concrete. Since only good interaction between cement and water affects strength. Next, pour concrete into the prepared form. needs to be compacted. This can be done by several blows with a hammer on the sides of the box; also, for this purpose, the mixture is pierced with a piece of reinforcement to release the existing air. The cube should be left to cure for 28 days, at a humidity of about 90% and an average temperature of 20°C. 28 days is the period during which the concrete sets and gains strength.

You can send a concrete cube for laboratory testing at intermediate stages of hardening, these are the 3rd, 7th, and 14th days after the mold is made.

The strength of concrete can also be determined by impact testing. To carry out the test, you will need a chisel and a hammer weighing from 400 to 800 g. A chisel is placed on the surface of the hardened concrete, and it is struck with a hammer with medium force. If the chisel is driven to a depth of more than 1 cm, then the strength class is B5 (grade M75), if less than 0.5 cm, then B10 (M150). Leaves a small mark - B25 (M350), a small dent - B15-B25 (M200-250).

Construction is a rather labor-intensive process. To eliminate unnecessary costs and not waste time, you should take good care of the quality of materials. First of all, you need to think about how to check the brand of concrete mix.

The ordered solution does not always correspond to the characteristics specified in the document. If the added raw materials for making concrete do not meet the proper proportions, the quality of the solution automatically changes. To accurately recognize the brand, it is necessary to conduct a quality assessment.

Concrete grade is an indicator showing the compressive strength. Grades M300-400 are suitable for construction. M100-250 have minimal strength and are suitable only for auxiliary work. Much depends on the chosen supplier. It is worth looking for trusted companies with a good reputation that can provide the necessary documents for the products offered. If for some reason you doubt the integrity of the supplier, you should think about further research of the solution to determine whether it matches the specified brand.

Determining the grade of concrete can be done using different methods:

- Laboratory examination;

- Ultrasonic method;

- Self-check.

Each method varies in accuracy percentage and has certain subtleties.

Contact verification methods

Contact testing is carried out using two methods. The first is with the help of professional equipment - a sclerometer. The device determines strength using a shock pulse. The sclerometer can be mechanical or electronic, and its price ranges from 10 to 35 thousand; a purchase for one-time use is simply not rational for the average buyer.

The second method involves sending the sample to a laboratory. First you need to carry out a number of manipulations:

- Prepare a wooden box with a volume of 15 cm³;

- Pour the purchased solution into the mold directly from the concrete mixer tray, pre-moisten the box with water. Compact the poured solution by making several punctures with reinforcement;

- Place the sample for 28 days in the same conditions as the main structure;

- The frozen sample is taken to the laboratory for testing. Evaluation can be made at intermediate stages of setting (3, 7 and 14 days).

The examination will issue a conclusion on the study of a sample of this brand and its compliance with established standards.

Testing samples in the laboratory

Ultrasound technique

Ultrasonic devices, in addition to strength testing, are used for flaw detection. The speed of propagation of ultrasound in concrete reaches 4500 m/s.

The calibration relationship between the speed of sound propagation and the compressive strength of concrete is fixed in advance for each mixture composition. In the case of using 2 dependencies for concrete of alternative or unknown compositions, inaccuracy may arise in determining the strength. The “strength-ultrasound speed” relationship is affected by a number of factors, the fluctuations of which in this case must be taken into account when using ultrasonic testing:

- Method for producing concrete mortar;

- Quantity and grain composition;

- Change in cement consumption by more than 30%;

- Possible cavities, cracks and defects in the finished structure;

- Concrete compaction level.

Ultrasonic testing is suitable for mass testing of structures of any shape, as well as for continuous monitoring of strength gain or loss. The disadvantage of the method is the error in the transition from acoustic to strength indicators. Ultrasonic equipment should not be used to check the quality of high-strength grades; the permissible range is limited to classes B7.5...B35 (10-40 MPa), in accordance with GOST 17624-87.

Self-check methods

Testing in a laboratory or using special means does not always pay off. This applies to cases where a small building is being built on private property. The poured and hardened solution can be checked at home in several ways. If it does not meet the necessary requirements, you can use a paid examination and recover damages from the supplier.

Smoothness check

Carefully examine the frozen structure. It should be smooth; the presence of patterns indicates non-compliance with the filling rules. Such a solution would most likely freeze, which would significantly reduce its strength. In fact, concrete grade M300 will have the same properties as M200-250.

Voice test

You can check by the sound of the impact. To do this, take a hammer or a piece of metal pipe weighing no more than 0.5 kg. The ringing tone when striking is important here. A dull sound indicates low strength and poor sealing. And if cracks or crumbs appear, it is necessary to completely or partially replace the structure.

Visual assessment

The method involves checking the characteristics of the solution upon acceptance. The following points can be highlighted:

- Color - a high-quality mixture is gray with a bluish tint; if yellowness is clearly visible in the cement laitance, the mixture contains clay impurities or slag additives. A brown or red color is characterized by an excess of sand or aggregate in an unacceptable amount; it is wiser to avoid a solution with an uneven shade altogether;

- The correct consistency is homogeneous, without lumps or clots and resembles moistened soil;

- Excess water is determined by pouring a small amount of the mixture into the pit; the result should be a cake without layers or cracks;

- A purchased solution of poor quality begins to separate during transportation; the mixture cannot be removed with a shovel or fed through a hose.

If a mixer is delivered, the quality of concrete can only be determined without inspection using the documents provided. In this case, everything depends on the integrity of the seller.

Checking concrete with a hammer and chisel

A hammer and chisel are the simplest answer to the question of how to check the quality of poured concrete. To do this, an impact test is carried out using a hammer. A chisel is placed on the surface of a completely dried foundation and a blow is struck with medium force. If the resulting dent exceeds 1 cm, strength class B5 (M75), less than 0.5 cm - B10 (M150). A small dent remains on B15-25 (M200-250), and a minor mark appears on B25 (M350).

It is necessary to take a hammer weighing 300-400 grams.

All the methods described have their advantages and disadvantages; to ensure the accuracy of the result, you should seek help from specialists. Laboratory, ultrasound and shock-impulse studies are more reliable and comprehensive. Quality directly depends on the characteristics of the constituent components, compliance with proportions, storage and transportation conditions. Therefore, you can protect yourself by choosing a trusted supplier with a good reputation, this will significantly reduce the risk of problems in the future.

How to check the quality (strength) of concrete and concrete mixture yourself

Everything is important in construction, but special attention, of course, should be paid to the load-bearing structures of the building. We have already written about ways to check brick (stone) masonry, but now it’s time to talk about concrete structures and checking their quality.

The quality of this type of structure largely depends on the quality of the concrete used during construction and the correctness of its installation. Its indicators indicate the strength and durability of buildings and structures. If you have been supplied with bad concrete or it has been laid incorrectly, the most severe consequences are possible, including the destruction of structures. Therefore, it is important to check the quality of the resulting structure, especially the quality of the foundation.

Concrete structures are most often found outdoors. As a result, with poor-quality compaction or poor-quality concrete mixture, a large number of pores remain in the structure through which moisture enters the structure. Moisture will enter the structure, freeze, and destroy the microlayer of concrete. This is a serious defect, so the quality of the concrete of the supporting structures must be of the best quality.

To control (check) concrete, you can invite a specialist from our center to the site or try to carry out the research yourself using available tools according to the rules and tips described below.

If construction is just beginning, it makes sense to determine the quality of concrete before it begins to be laid.

Checking the concrete mixture before laying

First you need to make sure what color the concrete mass is: It should be clean, gray, uniform. If the shade is brown, most likely the concrete contains too much sand and the concrete is of poor quality.

It is important to distinguish between the brown tint of concrete caused by sand and the possible brown tint due to various additives.

Its next indicator is homogeneity in composition. If it is not like that, this is also a big drawback and problems during the construction process. The mixture should flow and not fall in chunks. Its consistency should be slab-like, but at the same time, if it is liquid, this is also not good. This type of concrete is also not of high quality.

At this stage, we strongly advise you to take samples of the delivered concrete when pouring important load-bearing structures.

To do this, you need to make cube-shaped molds from boards for pouring concrete samples. The dimensions are small - 100x100x100 mm.

The poured concrete mixture must be compacted using a rod (layer by layer) or vibrating. These samples are then dried. The ambient temperature should be between 20-25 degrees Celsius.

After 28 days, this sample is taken to a specialized laboratory. Here it will be analyzed for strength. The analysis procedure is standard. As a result of this study, you will receive the most accurate values and characteristics of the concrete supplied to you.

The ideal would be to draw up an act of pouring samples and ask the driver who supplied you with the concrete mixture to sign it.

Checking the quality of concrete of the finished structure

First you need to carefully inspect the surface. It should be smooth. If it was poured in winter, then there will be no patterns on the concrete. If there are any, most likely it froze during the pouring period, and this is bad. As a result, the strength of the structure decreases within 50-100 kg/cm2. (i.e. if you poured M300 grade concrete, the actual concrete of the structure will be M200-250 grade).

1) Checking the quality of concrete by impact sound

To check the quality of the finished structure, you must use a hammer (or a piece of heavy, thick iron pipe) weighing at least 0.5 kg.

The research principle is similar to the “Schmidt hammer” and “Kashkarov hammer” devices.

You need to evaluate the ringing tonality. If the sound is dull, then the concrete has poor strength, and its compaction is quite poor and of poor quality. This study is suitable for structures made of concrete grade M100 and higher.

2) Checking the quality (strength) of concrete using a chisel

The strength (class, grade) of concrete of a finished structure can be determined using a chisel by the impact of an average hammer blow on it, weighing 300-400 grams.

- If the chisel is easily immersed (hammered) into concrete, it is necessary to prevent it from getting into the filler (crushed stone, gravel, etc.) - concrete grade below M70

- If the chisel is immersed in concrete to a depth of about 5 mm. – then most likely the concrete grade is M70-M100

- In the case when thin layers are separated from the concrete surface upon impact, the grade of concrete is in the range M100 - M200

- Concrete grade M200 or more, if the chisel leaves a very shallow mark or none at all, and there are no peelings.

All these methods, with the exception of laboratory tests of manufactured samples, give a general idea. For more accurate values and confidence in your design, it is better to use the services of a specialist with specialized measuring tools. After all, there are a large number of methods for non-destructive testing of concrete (ultrasonic testing of concrete, shock-pulse method, etc.).