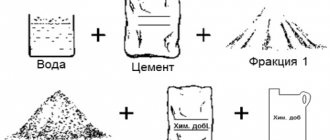

Concrete mix components

To obtain a high-quality result, first of all, it is important to choose the correct composition of the solution for the foundation, the most important of which are cement and water . In addition, the concrete mixture includes aggregates: sand and crushed stone, gravel or pebbles. Each of these components has a number of requirements that must be met if you want to lay a strong foundation.

Concrete composition:

- cement;

- water;

- sand;

- crushed stone or gravel;

- special additives to obtain certain properties of concrete.

Cement is a component that binds all the components of the solution into a single conglomerate. It is better to buy it immediately before the start of construction work. The fact is that cement is a very hygroscopic , capable of absorbing moisture even from the air, turning into hard stone.

If a bag of binding material has been stored for a long time in a warehouse or even at your home, then when you open it, you may see solid lumps instead of powder. In the case when they are small in size and crumble in the hands, cement is still suitable for use. Otherwise, the entire package will have to be thrown away. To prevent this from happening, in a store or warehouse, pay attention to the manufacturing date on the packaging. At home, binders should only be stored in a dry place and not for long.

Component Properties

To obtain concrete with the properties you need, the brand of cement is also important . Most often, M300, M400 or M500 grades are used to fill the foundation. The numbers are compressive strength, which is measured in kilograms per square centimeter.

Water is a component without which the solution will not turn into solid stone. Mixing it with cement is called mixing. The water must be clean , without unnecessary salts and contaminants.

Ideally, it should be added to the solution as much as is necessary for chemical interaction with cement. However, in this case a very hard mixture is formed, which is very difficult to lay.

If you add too much water, the concrete will flow well. When dry, the liquid will evaporate, leaving pores in the foundation material. This will reduce the strength of the finished product.

When mixing, a chemical process occurs that results in the formation of a hard stone, which will shrink and crack over time. In order to relieve internal stresses, increase strength and reduce the cost of concrete, large and small aggregates are added

Sand must meet two basic requirements: be clean, free of clay and organic matter, and have a certain grain size - from 0.14 to 3-5 mm. River sand, washed by the current, is best suited for construction. Quarry contains admixtures of clay, which significantly impairs the strength of concrete.

Crushed stone or gravel is classified as coarse aggregates. They are subject to the same requirements as sand: purity and grain size. The maximum size of individual elements should be no more than a quarter of the width of the foundation. It is important to use crushed stone or gravel with different grain sizes. In this case, there are fewer voids, which reduces cement consumption.

The brand of coarse aggregate should also be taken into account. The fact is that the strength of ready-made concrete doubles over time, but the strength of stone remains the same. For this purpose, the grade of aggregate should be twice that of ready-made concrete.

Mortar for brick foundations

Cement mortar is used to fill the foundations.

In addition to foundations made of monolithic concrete, foundations made of brickwork are often used in construction. Most often they are made in the form of basement walls and are technologically no different from conventional masonry.

Mortar for brickwork can be of several types:

- lime;

- cement-lime;

- cement.

Lime

Making such a solution is quite simple - no cement is required for its preparation. Its composition includes sifted sand and slaked lime in proportions of 3 to 1. However, this composition is much inferior in strength to cement. Therefore, it is not recommended to use it for foundation construction.

Cement-lime

In addition to lime and sand, it also contains cement. In this case, the lime is soaked, producing lime milk. On it you should knead a dry mixture of sand and cement, bringing it to the consistency of a thick dough. Lime makes the solution much more flexible and easier to use.

But at the same time, it somewhat reduces the strength indicators. Therefore, cement-lime mortar is not used for laying load-bearing foundation elements. As a rule, it is used when filling openings of columnar or pile foundations with bricks.

Cement

This is the most durable type of masonry mortar, widely used in construction. To prepare it you will need cement, purified sand or construction chips (screenings) and water. The proportions of the dry mixture may vary depending on what brand of solution needs to be prepared. So, for grade 50, cement and sand are taken in a ratio of 1 to 6.

In order to properly make a stronger mortar for the foundation, it is necessary to change the proportions towards increasing the mass fraction of cement. For laying load-bearing walls of the ground floor or basement, a mortar of grade M150-M200 is used. The ratio of sand and cement in this case is 1:3.

Brick laying is always done on a concrete base - a grillage or pad. Direct contact of bricks with the ground is also undesirable - brick foundations must be equipped with waterproofing.

Watch the video on how to properly make concrete for further pouring with your own hands.

"Skinny" concrete

Another common type of foundation, often used in the construction of both large objects and private houses, is block foundation. It is mounted from standard FBS concrete blocks, fastened together with cement mortar. The blocks are laid on a sand or gravel bed, which is often secured with so-called “lean” concrete. It is also often used to fasten concrete blocks together, sealing the end holes of adjacent blocks.

A feature of “lean” concrete is a significant reduction in the proportions of water and cement in the total mass of the solution. Because of this feature, this type of foundation mortar got its name. “Skinny” concrete is used where adhesion strength is not so critical. This allows significant savings during construction on the most expensive component of concrete - cement.

To prepare “lean” concrete, sand, gravel and cement are taken. Moreover, cement makes up only 5-10% of the total mass of the finished mixture. The proportion of water is also low, so the consistency of “lean” concrete is more reminiscent of damp earth.

All of the above types of foundation mortar should be used exclusively where it is regulated by SNiP standards. Only if these standards are observed and the proportions are observed, it is possible to produce a high-quality solution for pouring the foundation and build the strongest possible foundation for any house.

Proportions for preparing concrete

To ensure high-quality concrete and a reliable foundation, it is important not only to select components that meet all requirements, but also to choose the right proportions. In ready-mixed concrete, which is produced in factories, cement, sand, crushed stone and water are in a volumetric ratio of 1: 2: 4: 0.5. For private construction, the proportions will depend on the planned grade of concrete (usually M 200 - M 300 is sufficient for a foundation) and the characteristics of its components.

If there is more cement in the mixture, the concrete will be very hard and difficult to place. If there is an excess of sand or crushed stone, the solution will not set well. Excess water, as mentioned above, will lead to increased porosity of concrete. That is why maintaining proportions is a mandatory requirement.

Concrete grades for foundations

Already at the design stage, the question arises: what brand of cement mortar is best to use for the future foundation? It seems to many that there is not much difference between brands of cement mortar.

When choosing a brand of concrete, you need to rely on the weight of the future house

However, this is far from true - the choice of one or another type of concrete is influenced by a number of factors:

- Features of the soil of the site: groundwater level, freezing depth, etc.

- Design and type of future foundation: monolithic, in the form of brickwork, made of FBS blocks.

- Dimensions of the future house. The greater the specific gravity of the structure, the higher the strength of the concrete foundation should be.

For example, to fill a strip or column foundation, you will need a mixture that includes cement, crushed stone (gravel), sand and water. This is a concrete solution of grade M300 or M400 - the exact proportions for preparing such a mixture are regulated by SNiP construction standards.

To make a brick base, use regular masonry mortar. It can also be used for installing foundation blocks. However, in the latter case, so-called “lean concrete” is often used. It got its name due to the small proportion of cement in the total volume of the concrete mixture.

To obtain a high-quality solution, it is necessary to strictly follow the recommended proportions of all components.

Ways to improve the quality of the solution

- Even if all the requirements for the components of a concrete solution are met, sometimes its quality needs to be improved. For example, various plasticizers and superplasticizers allow you to increase strength and ductility while reducing the amount of water. The most famous of them is s-3.

- Water repellents attract many air bubbles into the solution, thereby slowing down the setting process.

- In cold weather, it is better to mix the cement mixture not with clean water, but with salt solutions. There are many other additives that change the properties of concrete.

The quality of the finished concrete is also affected by the method of its placement. The most reliable, durable foundation will be obtained if the solution is subjected to vibration . It will allow you to lay the concrete as tightly as possible, without unnecessary air chambers. In the absence of professional devices, the most primitive method is to rotate a steel rod immersed in a newly poured foundation.

Self-preparation of concrete mortar

As you can see, making homemade concrete is not that easy. If you count all the costs for materials and their delivery, then even in the absence of hired labor and a concrete mixer, the amount you will get is no less than what you would spend on purchasing ready-mixed concrete.

In addition to the fairly high cost, there are other disadvantages of preparing the solution yourself. For example, a person without experience is unlikely to be able to correctly determine the water-cement ratio, taking into account the moisture content of the sand and the size of the crushed stones. Subsequently, this will greatly affect the strength of the structure.

Self-production of concrete is justified only in cases where very little of it is needed (less than one cubic meter), or the construction site is located in a place where it is difficult for a car to reach. In other situations, it is better not to take risks and purchase concrete produced at a concrete concrete plant. The main thing is to choose a trusted manufacturer. In this case, you will save yourself from unnecessary expenses and unjustified loss of time, and your home from destruction associated with the quality of the foundation.

Producing concrete yourself

As a rule, on the site where construction is taking place, there is always a sufficient amount of sand and fine crushed stone. After all, these materials are used for backfilling, laying pipes and even laying paths. Therefore, in most cases, it will be enough just to purchase additional Portland cement to prepare a concrete solution for a monolithic foundation for a private wooden or brick house that is small in size and weight.

To produce concrete mortar with your own hands, you will need a concrete mixer, electric or mechanical, or an ordinary deep trough. You need to pour all the ingredients into the container in the required ratio, add water and mix evenly by hand or with a mixer connected to a drill. After the solution reaches the desired consistency (thick sour cream), pouring is carried out. The prepared solution must be used strictly within two hours after preparation.

If wet sand is added to the solution or the weather outside is wet and humid, then significantly less water must be spent on preparation. The solution should be of medium viscosity, not too thick and not runny. Cement must be purchased immediately before starting work. Work on installing the foundation of the house should be done only in warm, dry weather.

Recommendations for self-filling

To make concrete, use a concrete mixer, a wooden box, an iron bath or wood flooring. It is important to ensure that no debris or other impurities get into the solution. To begin with, pour in the dry ingredients - sand, crushed stone, cement, mix them thoroughly to obtain a homogeneous composition. Then slowly add water, stirring until evenly moistened. And only after that they start pouring.

Photo: prepared solution

Keep in mind that cement does not store for long; over time, its grade decreases under the influence of moisture. After the first month, about 10% of strength is lost, after 3 – 20%, in six months this figure reaches 30-40%.

When pouring a foundation, the most popular unit of measurement is a bucket, so few people accurately observe the correct proportions. It is not recommended to stir the mixture with a shovel, as the concrete will be inhomogeneous. Thus, losses may occur and eventually the M 100 grade will be released. But this will be enough to build a small house or gazebo.

Even if you deviate greatly from the standards for pouring a foundation, it will still be durable and will withstand heavy loads, so it will be suitable for building a house. But, according to official standards, you should take cement M 300 or M 400 to get a grade of 200 or more.

Pour the foundation in warm weather; negative temperatures provoke some difficulties. For example, you will have to heat the water and the composition itself, since they may freeze before hardening begins. And when hardening begins, without heating the concrete will begin to freeze due to the water contained in it, and the resulting ice crystals will begin to destroy the foundation from the inside.