Quality control of concrete and reinforced concrete on construction sites and in precast concrete plants

| March 30, 2010

The head of the construction inspectorate explained that based on the results of inspections in the Republic of Tatarstan, a unified register of construction industry enterprises that produce high-quality products should be created. Next they will be accredited by the State Tax Service of the Republic of Tajikistan. Holders of accreditation certificates will be “posted” on the website of the SSN RT.

The head of the department of KSASU, Vladimir Izotov, specifically focused on the quality of concrete used in monolithic construction. He noted that out of 34 laboratories in the Republic of Tatarstan, only one (!) is capable of conducting a full analysis of the quality of this building material. As a result, the solution often contains the cheapest, and therefore low-quality, components. Naturally, this has a negative impact on quality: it leads to delamination of buildings and further to a decrease in the strength and durability of buildings.

To the question of the BUSINESS Online portal about how manufacturers of building materials were left practically without state supervision, the Minister of Construction, Architecture and Housing and Communal Services of the Republic of Tatarstan Marat Khusnullin answered:

– Unfortunately, we have such a gap in the legislation. It seems that at the federal level the state strictly prescribed control over construction, but the production of industrial building materials remained uncontrolled. Concrete, for example, is an essential component. Concrete builders may be professional, but concrete - who knows what quality it is? Unfortunately, the state construction supervision inspection does not have the function of checking industrial building materials. It seems that there should be certification, a quality laboratory should work at the enterprise, but at the same time - how does it work, who accredited it? Therefore, we are now raising the issue at the legislative level in order to eliminate this gap. Because we can build a beautiful building today, but if the concrete is of poor quality, then this building may collapse!

For comments on the current situation, the editors of the magazine “Reinforced Concrete Products and Constructions” turned to Alexey Stepanovich Semchenkov, director of the Research Institute of Reinforced Concrete Concrete Products named after. A.A. Gvozdeva:

In monolithic housing construction, ensuring the proper quality is a very difficult task. During construction, there are violations associated with premature removal of formwork and early loading of structures. Also, in order to reduce construction time, acceleration of the strength gain of concrete is used, associated with the introduction of additives into it or the supply of thermal energy. The process of gaining strength by concrete is accompanied by technological breaks, which cannot be used to combine work on the site. This condition causes many violations, both technological and safety.

Concrete quality control, advanced training of construction personnel - this issue is fundamental and is resolved or not resolved in its own way in each specific organization. The quality of individual works, and then of the entire construction, depends not only on the quality of the materials and structures used, but also on the qualifications of the construction engineers and workers. Concrete quality control at a monolithic construction site must be present during the work continuously and provide real support to production. This means that control authorities should not conduct inspections, visiting facilities in order to identify possible flagrant violations and subsequently clarify the circumstances, but carry out continuous monitoring and, having the necessary knowledge and technical equipment, not only record emerging deviations, but also give timely recommendations on them elimination.

At the moment, technical control is poor; the quality of reinforcement and concrete mix is not checked before their use upon arrival at the construction site. The slump of the concrete mixture cone is not determined, and an insufficient number of control cubes are prepared. As a rule, not professional, but cheap labor with a low level of construction culture is hired to carry out work, which further aggravates the situation. Thus, workers and foremen do not know the construction specialty and do not know the language. There are no line workers, foremen, foremen, or foremen. Subsequent quality control of concrete by non-destructive methods is carried out in an unacceptably small volume and illiterately, after it has gained strength.

An additional problem of monolithic housing construction is the imperfection of the regulatory framework for quality control.

There are certain standards for factories that guarantee the quality of structures. To do this, every enterprise that produces construction products must have laboratories and quality control departments.

Laboratories should:

– check compliance with standards for aggregates, cement, water, modifiers;

– select the optimal compositions of concrete mixtures;

– hammer concrete cubes and test them at different ages;

– carry out testing of reinforcement samples to determine compliance of their physical and mechanical characteristics with the requirements of the standards.

Chief Technologist Department:

– exercises control over the preparation and tension of reinforcement, compliance with the welding regime of reinforcement products, preparation of components for the concrete mixture, preparation and laying of the concrete mixture;

– monitors incoming technical documentation and its compliance with the capabilities of the factory technological equipment;

– in agreement with the authors, introduces changes proposed by factory technologists into the working documentation of manufactured structures and products;

– orders the authors of standard series to process reinforcement products and change the characteristics of concrete in accordance with the supply of materials (reinforcement, cement, aggregates, additives) and the capabilities of technological equipment.

Technical control department (QC) to ensure the required quality and strength of manufactured concrete and reinforced concrete structures and products:

– monitors the compliance of reinforcement products, protective layers of concrete in structures with working drawings;

– carries out periodic and selective testing of structures and products in accordance with the standards using non-destructive and destructive testing methods and coordinates test results with the authors of standard series projects;

– carries out quality checks and acceptance of finished products according to working drawings, strictly observing the requirements (in terms of control operations and scope of control) of current regulatory documents, using the results of control carried out by the laboratory;

– accepts finished products in batches, from which excludes products manufactured with deviations from the design, in violation of the normal technological process or with obvious defects, and the possibility of using such products is decided by the design organization.

Consequently, manufactured reinforced concrete products can be sent to a construction site only after they have been accepted by the technical control department of the enterprise, labeled and a passport has been drawn up for the batch or individual reinforced concrete products.

Thus, it becomes obvious: in the current situation, the easiest way to improve the quality of buildings and structures is to build them from products of maximum factory readiness.

You can leave comments on this article by registering.

Any publication of this material must include reference to the source of information.

www.gbi-magazine.ru

Concrete and reinforced concrete work on a construction site. Concrete quality control.

Concrete and reinforced concrete work includes 3 processes:

1. procurement – production of concrete, reinforcement, formwork;

2. transport process;

3. main – installation of formwork, reinforcement inside the formwork, laying concrete and its compaction, care of concrete, stripping.

Transportation of concrete mixture can be carried out:

1. concrete mixer trucks: They can transport both ready-mixed concrete and dry concrete. L = up to 70 km.

2. concrete truck. L = 40 km;

3. dump trucks. L = 10 km.

Before starting, work must be completed, documented in a hidden work report: - preparation of the foundation; — waterproofing; — reinforcement and its welding;

— installation of embedded parts and bolts.

The following must also be completed: - correct installation of formwork; — placing geodetic marks on the formwork; — preparation of mechanisms and devices;

- preparation of old concrete - cleaning it, etc.

Concrete is obtained as a result of hardening of a properly selected, homogeneously mixed and compacted concrete mixture consisting of cement, water, aggregates, and, if necessary, special additives. The composition of the mixture must ensure the design class of concrete within the given time frame, and, if necessary, meet special requirements regarding frost resistance, water resistance and a number of other properties.

Laying the concrete mixture: The concrete mixture is supplied to the structure to be concreted using various cranes in buckets or belt conveyors, concrete pavers, concrete pumps, pneumatic injection, link trunks and vibrating trunks.

Compaction of the concrete mixture: During preparation, a significant amount of air enters the concrete mixture. If the trapped air is not removed, the concrete may become porous and of reduced strength.

Removal of trapped air and compact arrangement of components is achieved by compacting the concrete mixture. The strength and durability of a concrete structure depend on the quality of compaction. Most often, concrete mixture is compacted by vibration. As a result of vibration, the concrete mixture becomes fluid, i.e. acquires increased mobility, and the particles, moving, tend to take a more stable position under the influence of gravity. The concrete mixture fills all the spaces between the reinforcement bars and between the reinforcement and the formwork, the air contained in it is displaced, and the mixture is significantly compacted.

Concrete quality control.

Concrete quality control consists of checking the compliance of its physical and mechanical properties with the project requirements. It is mandatory to check the compressive strength of concrete. Concrete testing for axial tensile strength, bending tensile strength, frost resistance and water resistance is carried out as required by the project. These tests are carried out on control samples made from concrete mixture samples taken after its preparation at a concrete plant, as well as at the site of concrete work.

Quality control of concrete in structures and structures is carried out at the request of the project or special regulatory documents, in cases where there are concerns that the quality of the laid concrete for some reason does not meet the requirements of the project or the physical and mechanical indicators of control samples are lower than the design ones. Quality control of concrete in structures is carried out by testing the strength, frost resistance and water resistance of drilled cores, as well as non-destructive methods for determining strength.

At the place where the concrete mixture is placed in the structure, systematic monitoring of its workability should be carried out.

cyberpedia.su

DETERMINATION OF CONCRETE STRENGTH OF MONOLITHIC STRUCTURES

6.1. A batch of monolithic structures includes structures made from the concrete mixture of one batch.

6.2. The strength of concrete is determined by the results of testing samples in accordance with GOST 10180 and GOST 28570 or by non-destructive methods in accordance with GOST 17624 and GOST 22690 or by proven and approved methods (for example, when installing concrete and reinforced concrete monolithic structures in winter conditions according to SP 70.13330).

6.3. Concrete strength testing by indirect non-destructive methods is carried out with the mandatory use of calibration dependencies established in accordance with the requirements of GOST 22690 and GOST 17624.

6.4. When installing concrete and reinforced concrete monolithic structures in winter conditions according to SP 70.13330, the strength of monolithic concrete should be monitored according to ST-NP SRO SSK-04.

6.5. Control samples made at the construction site for monitoring and assessing the strength of concrete in batches of monolithic structures according to 4.5 must harden under the conditions specified in the technological documentation for the production of monolithic concrete and reinforced concrete structures for this construction project.

6.6. When monitoring the strength of concrete of monolithic structures at an intermediate age, at least one structure of each type (column, wall, ceiling, crossbar, etc.) from the controlled batch is controlled using non-destructive methods.

The result of the control is a permit for subsequent work (removing formwork, loading structures, etc.) with a corresponding entry in the general work log.

6.7. When monitoring the strength of concrete of monolithic structures at design age using non-destructive methods, continuous non-destructive testing of the strength of concrete of all structures of the controlled batch is carried out. In this case, the number of controlled areas must be at least:

- three for each grip - for flat structures (walls, floors, foundation slabs);

- one per 4 m length (or three per grip) - for each linear horizontal structure (beam, crossbar);

- six for each structure - for linear vertical structures (column, pylon).

6.8. Actual strength of concrete in batch R

m is calculated using the formula

| (3) |

6.9. When testing using samples, the average strength of samples made from one BSG sample is taken as a unit value of concrete strength to control one type of standardized strength.

6.10. During continuous strength testing using non-destructive methods, the average strength of the controlled section in characteristic places of the structure is taken as a unit value of concrete strength:

- for foundation slabs - one measurement per 1 m3 of concrete, but not less than 3 measurements;

- for flat structures (walls, floors) - 1 measurement per 3 m2 plane, but not less than 3 measurements;

- for linear horizontal structures (beam, crossbar) - 1 measurement for every meter of flat surface, but not less than 3 measurements;

- for linear vertical surfaces (columns, pylons) - 1 measurement for every meter of flat surface, but not less than 3 measurements.

Note

. For complex surfaces of concrete structures different from the above, the number of measurements should be determined in the organizational and technological documentation.

Quality control and consumer properties of concrete mixture

Currently, during the construction of a building or structure, there is practically no comprehensive system for managing the quality of concrete, starting from the production of a concrete mixture and ending with monitoring the strength and other characteristics of concrete in the finished structure. While such a quality management system should include close interaction between designers, concrete mix producers and contractors (builders).

To ensure the durability of concrete in a monolithic structure, it is not enough for the work contractor to have at his disposal only the concrete indicators specified in the project. Achieving these indicators must be supported by requirements for the technological characteristics of the concrete mixture supplied to the construction site.

The quality indicators of the concrete mixture and concrete must meet the requirements of the main standards: - GOST 26633-91 “Heavy and fine-grained concrete. Technical conditions" - GOST 7473-94 "Concrete mixtures. Technical conditions" - GOSTR 53231-2008 "Concrete. Rules for monitoring and assessing strength",

— European standard EN 206-1: 2000 “Concrete. General technical requirements, production and quality control."

The design for a building or structure specifies requirements mainly for the class of concrete compressive strength. Depending on the type of structure, concrete grades for water resistance and frost resistance may also be specified.

Meanwhile, when assigning design requirements, the purpose of the structure, its dimensions (to assess the effect of heat generation during cement hydration and minimize the adverse effects of temperature deformations and stresses), the level of aggressiveness of the operating environment of the structure, aesthetic requirements for the surface of the finished structure, must be taken into account. ensuring the required thickness of the protective layer of concrete and ensuring high-quality concreting of densely reinforced areas and thin sections of the structure (indicating the maximum size of the aggregate size), etc.

To fulfill the design requirements, it is necessary to develop a work execution plan (WPP) directly for a specific construction site. The PPR must indicate the following information: - concrete strength class (average class strength at Vn = 13.5%); — waterproof grade (if necessary); — frost resistance grade (if necessary); — the required mobility of the concrete mixture at the construction site, depending on the method of supplying the mixture to the formwork and the method of its compaction; — preservation of the mobility of the concrete mixture depending on the type of structure, the volume of the concrete mixture within one grip; — types of structures (column base slab, internal walls, floors, etc.); — time for removing formwork depending on the type of structure;

- the value of stripping strength either in absolute value in MPa, or as a percentage of the average strength of the class with a coefficient of variation of 13.5% (not lower) for each type of structure.

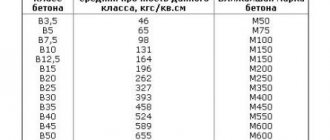

When developing a PPR, many factors must be taken into account that can affect the quality of concrete in the finished structure: the time of transportation of the concrete mixture from the supplier to the construction site, the method of supplying the mixture to the formwork, methods of its compaction and subsequent care of the laid concrete. Fulfillment of design requirements significantly depends on the quality of work performed. It should be borne in mind that many characteristics of concrete are interdependent. These are, first of all, indicators of the concrete class for strength and grade for water resistance. A change in one indicator entails a change in another. For example, concrete of class B20 and waterproof grade W12 cannot be produced. Approximately the following ratios can be accepted: B20 - W2; B22.5 - W4; B25 - W6; B30 - W8; B35 - W12; B40 - W14; B45 - W 14–16, etc. This pattern is confirmed by data obtained in the concrete laboratory of the Research Institute of Reinforced Concrete Concrete, and is supported by the requirements of SNiP 2.03.11-85 “Protection of building structures from corrosion” and the Guidelines for the selection of compositions of heavy concrete (Moscow: “Stroyizdat ", 1979).

Production concrete compositions should be developed for each specific type of structure. Thus, for a foundation slab with a height (thickness) above 500 mm, the following concrete composition can be recommended: - cement with PC additives - D20 or slag Portland cement;

- chemical additives - water-reducing/plasticizing, hardening retarders, which increase the time of mobility, as well as stabilizing ones, reducing water and solution separation. The mobility of the concrete mixture is recommended grades P4–P5 (16–20 cm - 21 cm and above).

For a column, the concrete composition with dense reinforcement should be developed using crushed stone of fraction 5–10, and chemical water-reducing/plasticizing and stabilizing additives are required. The mobility of the concrete mixture is recommended grade P5 (21 cm and above). The concrete composition for wall structures can be developed using crushed stone of a fraction of 5–10 mm (crushed stone of a fraction above 10 mm is no more than 1–2%). When developing production compositions, the amount of required stripping strength. With the same class of concrete, but with different values of stripping strength, the compositions will be different. The design of production concrete compositions for specific buildings and structures should be carried out at the batching plant in advance, before the start of deliveries of the main volumes of concrete.

An agreement should be concluded for the supply of concrete mixture after the necessary control tests in accordance with the requirements of the PPR for a specific concrete.

All of the above PPR requirements must be included in the contract between the BSU and the customer-builder. The contract should specify the standards to which concrete should be produced. First of all, GOST 26633, GOST 7473 and GOST 18105. The contract must be supplemented with the requirement that concrete should be supplied with an average strength class with a coefficient of variation of 13.5%. The need for this requirement is dictated by the fact that the BSU, when receiving Vn below 13%, delivers a concrete mixture with a design concrete strength approaching the class indicator, for example, for B25 the average strength is 327 kg∙s/sq.m. cm at Vn = 13.5%, and at Vn = 7% the average strength of concrete will be 270 kg∙s/sq. cm. With such supplies of concrete, the structure will obviously lack the specified design strength of 327 kg∙s/sq. cm.

GOST 18105 “Strength Control Rules” was developed at a time when the main task was to save cement, so the main entry of this standard is: “If the actual average strength level is higher than the minimum permissible value of the actual strength of concrete in a batch (with a certain homogeneity), then measures must be taken to reduce the strength of concrete and reduce cement consumption.” In GOST 18105, as amended in 2008, the same requirements for assigning actual strength remain. We suggest that this standard should be used today to monitor the performance of ready-mix concrete or precast concrete production and adjust concrete compositions to consistently provide average strength at Vn = 13.5%.

In some cases, at the request of the customer, quality control or individual points of the Technical Requirements should be carried out according to the European standard EN 206-1:2000.

To ensure the required quality of concrete in the finished structure, it is necessary to systematically monitor the following indicators at the stage of preparing the concrete mixture, i.e. at a ready-mixed concrete plant or batching plant: - mobility of the concrete mixture; — density of the concrete mixture; — intermediate (stripping) strength, preferably at 3 days of age, based on samples hardening in a normal hardening chamber;

— design strength at 28 days of age for samples hardening in a normal hardening chamber, since this is the strength specified in the design.

At the construction site, representatives of the on-site laboratory must accept the supplied concrete mixture. In this case, it is necessary to control the following indicators: - mobility of the concrete mixture at the construction site (if this indicator is 4-5 cm lower than required, this delivery should be sent back to the plant);

- the strength of concrete in a structure at an intermediate age (monitoring is carried out using non-destructive methods - a sclerometer, using ultrasound or using temperature curves; the relationship between the temperature of concrete and its strength is checked; the temperature in the body of concrete is usually measured using thermocouples).

The design strength of concrete at the age of 28 days can be assessed using control samples - by the destructive method - or by the non-destructive method - using a sclerometer, ultrasound, as well as a peel test.

An important condition for ensuring the quality of concrete is the care of concrete after it is placed in formwork and compacted. At any time of the year, it is necessary to cover the concrete structure with heat and waterproofing. To determine the type and thickness of thermal insulation, a calculation must first be performed.

With constant interaction between the designer, the concrete mix manufacturer and the builder-contractor, the quality and durability of concrete in monolithic structures will be ensured.

So, the durability of concrete is determined by three components: the quality of the project, the quality of the concrete mixture and the quality of the work.

| Author: S. A. Podmazova Date: 12/06/2010 Stroyprofil magazine 8-10 Heading: concrete and reinforced concrete: technologies, equipment |

"" back

stroyprofile.com

INPUT CONTROL AND ACCEPTANCE OF CONCRETE MIX BATCHES BY CONCRETE STRENGTH

5.1. A batch of BSG should include BSG of the same nominal composition in accordance with GOST 27006, prepared using the same technology.

5.2. The duration of laying one batch of BSG can be from one day to one week.

5.3. When carrying out the incoming control of BSG for concrete strength, at least two samples of BSG are taken randomly from each batch and at least one sample of BSG laid in a structure within one day.

5.4. The number of control samples in one batch is accepted according to GOST 10180, but must be at least four.

5.5. Control samples made at the construction site during incoming inspection of BSG batches for concrete strength should harden under normal conditions at a temperature of 20 ± 3 ° C and a relative air humidity of 95 ± 5%.

5.6. Tests of control samples are carried out in accordance with GOST 10180.

Documents drawn up based on test results (reports, protocols, etc.) must contain information about the actual (average) strength of the concrete of the BSG batch at the design age and the minimum unit strength value.

5.7. BSG batches are accepted based on the strength of concrete at the design age.

5.8. BSG batches are subject to acceptance based on concrete strength if the actual concrete strength in the batch is R

m is not lower than the required strength

R

T, and the minimum unit value of strength

R

imin is not less than the value (

R

T - 4) and not less than the standardized strength class of concrete:

| R m ≥ R T; | (1) |

| B ( | (2) |

5.9. In formula 2 of clause 5.8 of this standard, the minimum unit value of strength R

imin and the value of the required concrete strength

R

T must be substituted in MPa. The conversion factor from kgf/cm2 to MPa is 0.098.

5.10. Values of required concrete strength R

T BSG must be indicated in the document on the quality of BSG batches in accordance with GOST 7473.

5.11. The results of the BSG input control for concrete strength must be documented in the concrete work log, laboratory control and (or) section 3 of the general work log.