A lintel is considered a structural element that lies above door and window openings and carries the load of brick walls. If pressure acts on the masonry above the openings, then reinforced concrete partitions should be used.

When there is no impact or load on the bricks outside the opening, then it is permissible to use non-load-bearing reinforced concrete or brick structures; a prerequisite is the use of high-quality mortar and reinforcement between the rows of bricks.

Jumper

It is convenient to use reinforced concrete lintels.

How to choose the right lintels for brick walls, for what purposes should they be used? All partitions perform the following functions:

- are the main part of the opening;

- strengthen the structure of the floors: if the upper part of the openings is not strengthened, then the wall will collapse, as it will not be able to support the load;

- create the basis for further laying of rows.

For lintels, materials with high strength properties are used; they are often made from similar raw materials as the street wall, but sometimes the raw materials of the blanks differ in all available indicators.

Regardless of the type of material, the partition should maximize the strength of the opening and also redistribute the force of gravity above it. Before choosing the necessary lintels for brick walls, you should consider the types.

They are made from 4 main materials:

- brick;

- reinforced concrete;

- metal;

- wooden beams.

If you need to expand the size of the opening, then you should take care of the correct location of the partition above it. It will not be possible to expand the height upward only if you remove the rows from below. When changing the opening width, it is necessary to lengthen the strengthening beams, taking into account the minimum support of the lintels on the brick wall.

How to calculate the load

Technically, the lintel at the top of the opening is a regular beam and the calculation for it is carried out in a similar way. There are two main requirements that this part must satisfy:

- The sections of the walls on which the lintel rests must adequately bear the load.

- The residual deformation (deflection) of the lintel under load should not exceed the permissible values for windows or doors installed in the opening.

Related article: What is needed for the production of plastic windows

It is always necessary to take into account the self-supporting properties of the wall. Very often, when constructing masonry, opening lintels perform their function only for the first 2–3 weeks after their installation, and then they simply remain in the walls without any need. This applies to those openings over which a masonry pillar is preserved, equal in height to the length of the span. Here, a lintel is not needed at all - the wall will support itself, and the larger the blocks used for masonry, the smaller the height of the pillar should remain.

In other cases, the jumper is calculated based on the applied load, including:

- own weight of the jumper;

- the weight of the wall taking into account its self-supporting capacity (the height of the masonry above the opening);

- distribution of the weight of the wall (for summer masonry, only 1/3 of the width above the opening is taken into account, for winter masonry - the entire wall);

- the load caused by the support of beams or floor slabs on a given section of the wall.

The linear dimensions of the jumper are also important. Its width is determined by the thickness of the wall, its height by the required load-bearing capacity. The length of the lintel corresponds to the width of the opening plus twice the depth: from 10 cm for brick walls and up to 30 cm for loose porous blocks.

In most cases, to determine a suitable lintel, it is enough to make a selection from tables with standard prefabricated concrete products (series 1.038 for standard and 1.225 for very wide openings). The required product is determined by the width of the opening, taking into account the depth of the filling. If the required lintel is thinner than the wall, you need to install several of these, or at least two of them.

Of course, no one insists on purchasing finished products. You are free to cast reinforced concrete lintels yourself, as well as replace them with wooden or steel ones at your discretion, having first performed a calculation of the lintel for deflection.

Brick partition

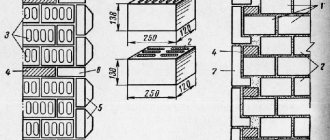

When assembling a brick lintel, supports from pipes are used.

The formwork will be held directly on the masonry; when dismantling it, the protruding stones are cut off. If the width of the opening is more than 1.5 m, then the box rests on wooden circles mounted on the edge. In addition to the wooden formwork structure, pipe supports are also used; this structure is quite easy to assemble.

To do this, take a couple of pieces of pipe with a diameter of 5 cm and fix them into a larger one with a diameter of 6 cm; during the installation of a brick partition, the structure is moved apart in different directions so that the ends of the smaller pipes fit into the masonry itself. For each opening, at least two circles should be installed, then red brick is used to lay beam or wedge partitions with seams in the form of wedges.

First lay out the support heel

Laying brick partitions: a - front view, b - section of the partition, c - lintel on wooden formwork, d - structure on circles made of pipes; 1 - reinforcement, 2 - board, 3 - circles from the board, 4 - Ogarkov circles.

The thickness of the seams should be up to 25 mm at the top and approximately 5-7 mm at the bottom. Before laying lintels in the opening, it is important to build the walls around the entire perimeter to their level. Initially, it is worth laying out the supporting brick heel, and only after that install the partition itself.

Before installing the supporting plane, you should prepare the necessary template, then lay the masonry in transverse rows on the manufactured formwork. It is important to produce it so that their number horizontally is odd. The central row of bricks is considered a castle row; it is located strictly in a vertical position.

The laying of wedge or beam partitions is carried out in such a way that on each side from the heel to the central lock the row ends with a central brick, then the correct location of the seams is checked using a rope, which is secured in the places of the supporting parts on the brick wall.

If the opening width is more than 2 m, then it is prohibited to lay a wedge lintel, as they may collapse.

Arched lintels

The rows of partitions are laid perpendicular to the direction of the acting force.

Installation of arched partitions is carried out in the same sequence as wedge partitions. The seams of the bricks should be placed perpendicular to the masonry frame with a thickness of 25 mm at the top and 5 mm at the bottom.

The load during the construction of arches acts tangentially, so the rows should be laid perpendicular to the direction of the acting force, and the masonry seams should be tightly filled with cement. To increase the reliability of the arches, its surface must be plastered, the thickness of the layer should be at least a quarter of the thickness of the brick.

The correct placement of the seams is checked using a rope, and the placement of the rows is checked using a template. The wooden box for the arches should be assembled in such a way that after laying all the bricks it can be easily loosened, lowered and disassembled. Wedges are installed under the circles, with the help of which the formwork is raised or lowered.

After installing the brick arch, it must be supported in the formwork. The exact hardening time of the solution depends on the brand of cement.

Reinforced concrete lintels

Ready-made lintels will save time.

Installation of reinforced concrete partitions is designed to strengthen the opening in a load-bearing wall. You should first make a calculation, and then use it to select lintels in brick walls. Often builders do not purchase finished products, but prepare them on site, since the cost of assembled goods is much higher than those made at home.

They install formwork from boards, lay reinforcement in it and fill it with ready-made concrete mortar. The design of a lintel in brick walls most often depends on the product itself, the geometry of the opening and the pressure on the walls. If there is neither the time nor the opportunity to make the part yourself, then ready-made partitions are installed. For more information about the types of jumpers, see this video:

To securely hold them, it is necessary to additionally lay a reinforcing belt only at the border of contact between the reinforced concrete and the load-bearing wall.

When installing reinforced concrete structures, it is important to follow the recommended rules for their installation. How to choose suitable lintels for brick walls? They should completely cover the entire opening, and also rest at least 25 cm on each edge.

Most often, standard straight blanks are used in construction, but if you wish, you can make a lintel of any shape, you just need to first make a template. It will be much more reliable to use a reinforced concrete semicircular type instead of a wedge-shaped brick one; it can also be used on openings more than 2 m wide.

Factory solutions

The technology for using lintels in private housing construction has several fundamental differences from the installation adopted in modern and mass construction using cellular aerated concrete. Currently, several types of jumpers are used, which differ in design features and rules of application .

Ready-made version of reinforced gas silicate lintel according to GOST

Ready-made factory aerated silicate (aerated concrete) lintels are ordinary aerated concrete beams with a rectangular cross-section and an internal frame in the form of reinforcement coated with a special anti-corrosion compound.

Arrows on the element indicate the correct direction of installation.

The main advantages are:

- properly reinforced aerated concrete does not crack , does not “float” and does not collapse during long-term use;

- aerated concrete lintels are high-strength, lightweight structures that do not place additional load on the constructed walls and foundation;

- the cellular structure of the aerated concrete lintel is identical to the structure of the building blocks, therefore it does not cause a decrease in thermal efficiency , and as a result there is no need for additional insulation.

Main dimensions of gas silicate jumpers:

- Height - 124 mm;

- Width - 115 mm, 150 mm, 175 mm;

- Length - 1300-3000 mm.

Check on the manufacturers website.

U-block construction

The most popular option is to install precast lintels over windows in walls made of cellular aerated concrete with permanent formwork based on U-shaped elements.

Related article: Sun protection screen for windows

The article provided by the link provides information about the manufactured sizes of these elements and the method of self-production. U-shaped lintels are prefabricated elements . They are easily sawed to the required length using a hacksaw for aerated concrete. A welded reinforcement frame structure is laid in the furrows of the products, after which installation is carried out over a window or doorway using wooden formwork. Reinforced concrete elements are made using heavy mixtures based on concrete and reinforcing rods.

Reinforced concrete lintels

These factory products are concrete beams with reinforcement inside.

In terms of thermal conductivity, concrete is noticeably inferior to gas silicate.

If you plan to insulate the walls of the house with mineral wool, then these beams can be used.

But for walls without insulation, reinforced concrete will act as a cold bridge.

In this case, the aerated concrete lintels proposed in the first option look better.

Metal

Before choosing a beam, make calculations for deflection.

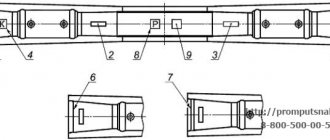

To strengthen the holes in the load-bearing wall, metal elements are used. The partitions are made of angle iron, the material of which has high strength and is able to cope with high pressure on the surface.

How to choose the right lintels for brick walls? Before selecting metal corners, a calculation should be performed to prevent the partition from deflecting above established standards, then the strength of the selected iron elements must be determined.

To install an iron profile into an opening, the part is adjusted to fit the seams between the masonry bricks; there is no need to additionally strengthen the edges with connecting fittings. For more information on how to make a jumper, watch this video:

In order for the corner to be firmly held and cope with the load, it is important to place it at least 15 cm on each side.

Prefabricated iron partitions are used for all types of structures. Gain calculations are not required before installation.

Support depth and maximum opening length

The depth of support refers to the distance to which the beam extends onto the wall of the window or doorway. When constructing buildings, builders take into account such concepts as the maximum length of the overlapped clearance and the minimum support distance. The degree of resistance and safety of silicate walls depends on the area over which the weight of the beam is transferred.

The peculiarity of the calculation is that with a small contact area, destruction of blocks under load may occur. A large support depth leads to an increase in construction time and cost.

There are such calculation standards when designing buildings made of foam blocks:

- Reinforced concrete columns. The products are designed for installation in an opening whose distance does not exceed 300 cm with an overlay on each side of at least 30 cm. After installation, additional insulation is required. If this is not provided for by the project, protective finishing is not required.

- Monolithic foam concrete window lintels. They can be used for gaps up to 200 cm in length with an overlap of 25 cm on the sides. After construction, insulation is not applied; a waterproof external finish is required.

- Demountable silicate beams with reinforcement. Depending on the type of frame, the maximum opening width varies. With internal reinforcement, it is 200 cm. When using external reinforcement (corner, rods), the maximum distance is 120 cm with a support depth of 20 cm. Insulation is not carried out after installation. Facade plaster is applied.

When choosing a construction method, you should remember that for aerated concrete you need to use light and strong fastening materials that do not exert critical pressure on the blocks.