Walls made of small blocks

Small blocks are made from lightweight concrete with fillers in the form of slag, expanded clay, pumice, etc., from ceramics and natural stones.

Small blocks can be solid or hollow. The dimensions of the blocks are set in accordance with the dimensions of the brick, so that they can be combined in combined masonry. The dimensions of whole stones are 39.0X19.0X18.8 and those of halves are 39.0X9X18.8.

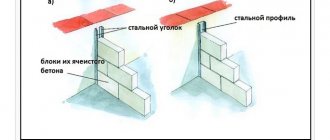

The laying of slag concrete walls is carried out using light or heavy (mixed) mortars, with the obligatory sequential bandaging of the seams. The thickness of such walls is established by thermal engineering calculations, and the smallest is used in accordance with the dimensional length of 39 cm, which in terms of thermal properties is identical to the thickness of the brickwork of 51 cm. The increased dimensions of the blocks complicate the possibility of constructing cornices from them, framing window and door openings. In this case, the latter are made without quarters and lintels, or special shaped stones or ordinary bricks are used for these purposes.

Cornices, plinths and other architectural details can be made of brick, concrete or special shaped stones.

Rice. 1. Three-row masonry of small blocks: a - bandaging of seams in the corners of the walls; b - ligation of seams at the intersection of walls

Smoke and ventilation ducts in cinder concrete walls are installed in special brick inserts. The most common type of hollow blocks are stones with slot-like blind voids. Walls made from them are usually laid with a thickness of 39 or 49 cm. Light mortar is used. The masonry is laid spoon-wise with the voids facing down. Walls made from these blocks have high heat-insulating properties and are close in strength to effective brick. They are used in the construction of low-rise buildings and for filling in frame walls of multi-story buildings. The outer surfaces of the walls are plastered or tiled. The arrangement of cornices, window and door openings is similar to their arrangement in walls made of solid slag blocks.

Rice. 2. Smoke channels in walls made of lightweight concrete blocks

Rice. 3. Walls made of slag concrete stones: a - from stones with horizontal voids; b - stones with vertical voids; c - a wall made of these stones; 1 — seven-slit blocks; 2—six-slit blocks; 3 - blocks with horizontal voids; 4 - bricks; 5,6,1 - facing slabs

In addition to hollow and light bricks, hollow ceramic stones measuring 25X12X13.8 cm are also used. In Fig. 3, and shows an example of laying a wall made of ceramic stones with horizontal voids. In terms of thermal engineering, stones with vertical voids are the most effective (Fig. 3, b). An example of laying a wall made of such stones and facing it with slabs is shown in Fig. 3, c.

Read more: Floors in a building Frames of multi-storey buildings Natural and artificial foundations Classification of buildings Staircase structures General information about stairs and elevators Gates of industrial and warehouse buildings Doors of civil and industrial buildings Windows of civil and industrial buildings Filling of window, door and gate openings

Walls made of ceramic and lightweight concrete stones

Previous15Next

The modernized well masonry (Fig. 3.12) fully meets the requirements for thermal protection. Here, monolithic (poured) polystyrene concrete is recommended as a structural and thermal insulation inner layer.

Rice. 3.12. Brick walls with insulation made of monolithic polystyrene concrete:

a - low-rise buildings; b - mid-rise buildings;

1 - external plaster; 2 - outer skin; 3 - air gap; 4 - outer layer of masonry; 5 - monolithic polystyrene concrete;

6 - fiberglass rod connections or metal mesh; 7 - inner layer of masonry; 8 — internal lining; 9 - internal plaster

A layered brick wall (Fig. 3.13) with thermal insulation located between the load-bearing layers of masonry allows you to take advantage of both internal and external insulation. Mineral or glass wool, foam boards, etc. are used as insulation. The load-bearing layers of the wall are connected at the floor level with reinforced concrete brace frames, and at the level of three rows of masonry above and below the window openings - with metal braces made of stainless steel or fiberglass rods. Expanded polystyrene boards and other flammable insulation materials can be used only if fire protection measures are observed. In the layered masonry at the floor level, fire-resistant cuts are made from fiberglass slabs 150 mm high. The installation of fiberglass slabs is also provided along the perimeter of window and door openings.

| Rice. 3.14. A wall with a self-supporting facing layer of brick: 1 - load-bearing layer of masonry; 2 - slab insulation; 3 - facing layer of masonry: 4 - flexible connection: 5 - floor slab |

| Rice. 3.13. Brick layered wall: 1 - brickwork; 2 — polystyrene foam insulation; 3 - fire-resistant insulation made of non-flammable insulation; 4 - flexible connection made of steel or fiberglass; 5 - reinforced concrete bracing frame; 6 - reinforced concrete lintel; 7 - reinforced concrete floor slab; 8 - window block |

The wall, where the brick serves as a facing material and is a self-supporting layer of the fence, is shown in Fig. 3.14. The load-bearing layer of brickwork is provided with a thickness of 250 mm (for low-rise buildings) or 380 mm. Thermal insulation boards are laid along the wall, and then a facing layer of masonry is installed, connected to the load-bearing layer with a variety of flexible steel or fiberglass connections.

Brick walls with external thermal insulation in two versions are shown in Fig. 3.16 (with protective and decorative plaster) and fig. 3.15 (with suspended facade cladding).

| Rice. 3.15. Brick ventilated wall with curtain facade cladding: a - vertical section; b - horizontal section at the window opening; 1 - masonry; 2 - insulation; 3 - hydro-wind protection; 4 - crossbar of sub-cladding structure; 5 - vertical element of the sub-cladding structure; 6 - air gap; 7 - facing stone |

Rice. 3.16. Brick wall with external plastered thermal insulation:

a - fragment of a wall in the ceiling area; b - connection to the base;

c - connection to the balcony slab; 1 - brickwork; 2 - Insulation;

3 - vapor-permeable plaster; 4 - dowel; 5 - floor slab;

6 - balcony slab; 7 - foundation; 8 - waterproofing; 9 - ceramic tiles

Previous15Next

Date added: 2016-09-26; views: 2287; ORDER A WORK WRITING

Similar articles:

Walls made of lightweight concrete stones

Lightweight concrete wall stones are widely used in our construction. The raw material base for the manufacture of lightweight concrete parts is available almost everywhere in Russia. Particularly large reserves of necessary materials are found in industrial areas in the form of blast furnace, locomotive, boiler and other slags.

It should be emphasized that when using accelerated methods of hardening the concrete mass (steaming, steaming, etc.), various binders of local origin (lime, gypsum, slag, lime-pudzolanol and other cements) can be and are successfully used in practice, which allows saving significant amounts of Portland cement. Therefore, lightweight concrete stones are currently one of the main materials for laying walls of residential, public and other buildings.

Despite a number of advantages of hollow stones (lightening weight, saving concrete, increasing the heat-shielding properties of external fences, etc.), at present, along with them, it is necessary to recommend the use of solid stones. The latter can be made from concrete of lower strength, which makes it possible to more widely use local low-active binding materials. When manufacturing, transporting and laying solid stones, there is less waste. Masonry made from them is stronger and more durable than that made from hollow ones using low-active binders.

Lightweight concrete stones can be used for load-bearing walls. The thickness of horizontal seams is 10 mm, vertical seams are 6 mm. The advantage of this type of masonry is that it does not require the manufacture of a special type of stones for the joint rows (type 2 stones). 1

The width of the partitions must be at least 61 cm - 1.5 stones - and is made, if possible, a multiple of half the stone, taking into account the thickness of the seams.

Chimneys are made of brick or prefabricated elements.

Jumpers with a span of up to 1.5 l are constructed reinforced with round steel with hangers, and those with a larger span are made of precast reinforced concrete.

Very convenient are lintels made from the same X-stones, reinforced at the bottom and top with round steel rods and filling the recesses with concrete.

Such jumpers are manufactured on site. Their length is assigned by the project.

At the level of the bottom of the floors, continuous strapping-belts are installed with the laying of 8-10 mm round reinforcement in a cement layer or with a lining under the beams of the support slabs.

Windows and doors Windows are elements of a building intended for lighting and ventilation of premises. Doors serve as a connection between isolated rooms and for entering the building. The windows in the building are designed with double glazing. The thickness of the window blocks is 80mm, which gives the right to judge that they have sufficient heat and sound insulation. ...

Floors on prefabricated slabs. Their dimensions are detailed in the specification. Floor slabs and tie slabs are laid on a longitudinal frame. Rigidity in the longitudinal direction is provided by bonded plates. The floor structure is laid on the floor slabs. In the attic floor, a layer is placed on the flooring slabs...

Calculation of storage facilities and areas The stock of building materials to be stored in a warehouse is determined by the formula: where Q is the amount of materials required for construction; — coefficient of unevenness of receipt of materials to the warehouse, ; n1 — material supply rate in days (tabular value); K - coefficient...