Types and necessity of using locks for formwork

The difficulties that were encountered during the installation and dismantling of formwork structures were left far behind when special locks for formwork were invented, giving a certain comfort to working with its components. In certain situations, for example, when constructing large monolithic structures, such locking mechanisms are indispensable devices that make work easier and reduce labor costs.

Reasons for popularity

Spring clamp and installation key

This method of fastening is popular in construction for a reason. After using the formwork reinforcement clamps , no traces remain. This is far from the only advantage. The entire work process will take much less time, physical effort and, most importantly, funds that can be used for other purposes.

Another advantage of using a spring lock for formwork is saving you money. You save not only your money, but also time and physical effort. To use a spring lock for formwork, you will not need any additional equipment other than a key. To use the castle, no additional buildings are required either. The process of using it is very simple.

Clamp Installation

Clamp Installation

You won't need any pinch screws at all for this process. To use clips, you will need a special key, which is used to tighten the clip after putting it on a special wire, maximum diameter is 10 mm. Formwork clips are widely used. They are used in the construction of premises of any type. Convenient packaging has been thought out for customers, which is packed in boxes and then into pallets.

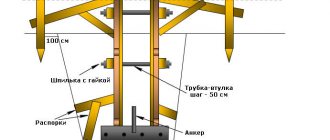

To install the clamps, which are a kind of lock, it is necessary to extend the reinforcement behind the formwork to a length of about 15 cm.

A spring lock for formwork is the best option, thanks to its design you can:

- save your money during construction;

- formwork clamp is a universal tool that is suitable even for use with non-standard sizes;

- using formwork clamps, you will use much less physical effort;

- in addition, you will do the job faster and better than using clamping screws and nuts.

Need for use

Locks for fastening formwork give connections reliability and strength.

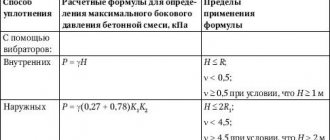

Their main purpose is to hold the necessary shapes of the structure into which the concrete solution is poured.

In addition, with the help of locks, the panels of formwork systems are tightly connected to each other and can withstand significant loads created by the concrete mass. The concreting process is simplified, working time and even financial resources are saved.

Wedge castle

Most often, in order to give the assembled system the necessary strength, wedge locks for formwork are used - elements with which panel sets are assembled and leveled. When installed properly, the lock gives the joint areas density and the ability to withstand load forces, which allows you to pour smooth and even reinforced concrete structures.

The standard version of a wedge lock for formwork consists of steel jaws and a cast iron wedge. This combination makes it possible to create a reliable fastening point that can withstand loads and can be used many times in the future.

To fix the universal wedge lock on the joining sections of the formwork panels, a wedge is driven into the hole made in the jaws. As soon as the clamp is fully seated, the jaws are compressed in the profile channel and the formwork system is given additional rigidity. Using a settling wedge, panel elements are trimmed and tied together.

If the wedge mechanism is manufactured using technology, it is used for a long period, using it more than a dozen times.

Technically, the wedge lock is a non-separable device.

- the cost of one lock is from 400 rubles;

- the device is used on formwork made of iron or aluminum;

- element weight – 2.5 – 3.6 kg, sometimes its weight reaches 1 kg;

- galvanized locks or coated with powder paints perfectly withstand the effects of precipitation;

- The locks are easy to install, quickly dismantled, and conveniently stored.

Wedge locks are also distinguished by type of protection, focusing on their color shade:

- galvanized locks – silver-metallic color;

- a yellow tint indicates that this is an anodized element.

If the impact (wedge) lock intended for panel formwork is covered with paint, then its color can be blue, red or black.

Universal lock

This fastening device is popularly called a “crocodile”. It is considered a subspecies of the previous connecting element. A universal formwork lock tightens steel and aluminum panels at the joints in a similar way, but is mainly used on a large panel system. As in the first design, the universal device consists of a wedge inserted into the hole of the upper lip. The difference lies in the type of second jaw and the method of placing the wedge itself. After entering the upper lip, the wedge is fixed on the ribs of the lower lip using a special groove.

Using a rack (universal) lock for assembling formwork, the thickness of the insert is easily and quickly adjusted; the connection is suitable for panels and panels of different sizes.

Universal and wedge formwork locks

The most widely used locks on domestic construction sites are universal locks and wedge locks. The following features can be distinguished in the operation of these locks:

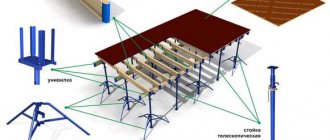

- The universal lock aligns and tightens the panels, ensures the angular mating of the panels (external corner) and allows you to assemble and clamp additional inserts. Thanks to the lock rack and helical grooves of the wedge, the effect of a worm gear is created, which perfectly resists vibration. The lock also serves as a leveling bolt, since the lock body is the plane to which the ribs and profile of the formwork panels are pressed. The operation of the lock is structurally presented in Figure 3.

- A wedge lock only aligns and tightens panels and does not offer the same design benefits as a universal lock.

| Starting position. The shields are not in the same plane and are not pulled together. The lock wedge is in the upper position. | Intermediate position. When driving the wedge, the shields are aligned into a plane, but are not yet connected to each other | Final position. The wedge is clogged. The shields are aligned and pulled together. |

Rice. 3. Scheme of operation of a universal lock.

Extended lock

This fastening option is a subtype of a screw connection. The elongated lock used for assembling the formwork is represented by an element equipped with a locking device with a thread, moving and stationary parts. The dimensions of the inserts reach twenty-five to thirty-five centimeters.

The lock is used for various formwork structures, but its main purpose is to fix a pair of panels at an angle of ninety degrees. And if a monolithic foundation is to be poured, experienced builders advise using this particular connection option.

The lock is made of steel and coated with a protective paint. There are also galvanized and anodized options, but their prices are significantly higher.

The advantages of an elongated lock are:

- giving the formwork system evenness, the ability to adjust the panels;

- ease and speed of assembly, not requiring special skills or special tools;

- used when joining hinge-type corner sections, as well as for external and internal corners.

Extended lock 250 for formwork - suitable for wall formwork , aluminum formwork .

This lock is designed for strong alignment and connection of formwork panels to each other.

The main difference between an elongated lock and a conventional wedge lock is that it allows the use of an insert up to 250 millimeters wide between panels. It is used in cases where it is impossible to use a conventional cast lock.

Monolithic construction is used everywhere, and formwork , as the main component of this construction process, is in great demand today. To save time and simplify installation, various elements and components for formwork . If a wooden insert is used when connecting and aligning the panels, then use an elongated formwork lock . Like other fasteners, this product aligns the panels in one plane and creates a tight fit. As a result, such a structure can withstand the pressure of the concrete mixture and dynamic load.

The design of the 250mm long formwork includes a body and a movable support. The latter moves around the body using a screw pair. The clamping force is achieved through the shaped bosses while tightening the screw handle. The fasteners are designed to be installed by one person. No additional equipment is required for operation. The element can fix large elements with an area of up to 3 square meters. The product compresses two movable plates using a screw connection. For fixation, a screw and a nut , which is welded to the body. The main feature of the elongated formwork lock is the ability to install an additional block or board between the panels. The width of the additional element should not exceed 250mm. A block may be required if the formwork structure being erected must have non-standard dimensions. To ensure the most reliable connection between the formwork panels and the insert, it is necessary to clean the connecting surfaces before assembly.

The product is used when forming corners. The element allows you to connect panels at an angle of 90 degrees, which is required for pouring the foundation. The convenient design of the lock eliminates the possibility of losing any elements during work. The total length of the fastener structure is about 500mm, the length of the functional part of the product is in the range from 35 to 400mm. To connect two panels, you need to place two fasteners. Thanks to the simple operating mechanism, installation and dismantling requires a minimum of time. Removing one fastener does not affect the stability of the formwork structure as a whole. The use of this product simplifies the connection of formwork systems. In our company you can buy an extended lock for formwork 250 and other components that are required for monolithic construction . Our specialists will answer all your questions regarding manufactured products and performance characteristics.

Screw fastening

Using a formwork screw lock, insert elements measuring twenty to twenty-five centimeters are connected. This type of fastener is completed as follows - moving and stationary parts, a threaded section represented by a tightening screw and a nut securing it.

According to its purpose, the locking device performs the same functions as the universal fastening - it connects and aligns.

Made of steel, most often powder coated, it is easy to use and has a long service life. The main disadvantage is its significant weight, reaching up to five kilograms.

Spring clamp for formwork - design features

The body of the spring clamp is made of steel using stamping and spot welding.

The base thickness is 4 mm, the wall thickness is 3 mm. Painting the surface of the housing provides additional protection against corrosion. Unlike the standard clamp, the reinforced model is equipped with a special support, which allows for increased reliability of fixation due to the additional rigidity of the clamp design. Particular attention is paid to the clamp tongue: it is made of durable steel and undergoes special hardening in a nitrogen environment, which increases the strength and reliability of the element. The reinforced spring clamp is designed for repeated use - this is facilitated by the high quality of the teeth of the tongue that fix the reinforcement - they do not lose their sharpness for a long time. The device is equipped with an elastic tight spring. Galvanization of device parts protects the metal from corrosion.

Installation

Metal formwork panels are fixed with locks in increments sufficient to give the entire structure the required strength, taking into account the pressure generated by the concrete solution being poured per square meter. To give the fastenings reliability, holes are drilled in the sheets for installing locking legs. In addition, the strength of the formwork system is increased by wooden beams installed at the points of interlocking joints along the entire length and width of the assembled structure.

With the help of such beams, the pressure from the lock is distributed, local deformation of metal sheets is eliminated.

As you know, fasteners are necessary for assembling any formwork structure, the features of which determine the installation process. The algorithm of actions is as follows:

- formwork panels are installed according to the design solution;

- their preliminary alignment is performed;

- locks are installed;

- After this, the system is finally leveled and firmly tightened.

Devices for connecting panels

Wedge castle

To connect and align the formwork panels, different types of locks are used:

- wedge locks made of cast steel, cast iron and steel screw locks with a working range of up to 140 mm;

- universal elongated locks, connect planes at right angles, working range up to 390 mm.

The joints between the formwork panels are reinforced with leveling beams from 800 to 4500 mm long. The corners of large panels assembled from individual panels are fixed with corner beams. Corner elements made of aluminum or steel are used to form the corners of column formwork. As additional components, if it is necessary to increase the length of the formwork, additional compensator panels with a length of 60-200 mm and a height of 300 mm are used.

Dismantling formwork locks

When using formwork systems in the construction of monolithic reinforced concrete structures, you should not only know the rules for their installation, but also carefully dismantle the structure in order to use it in further activities.

Dismantling work begins when the concrete mass has completely hardened and gained the required strength. First of all, the fastening locks are removed, for which the following steps are performed:

- in the wedge joint, knock out the wedge with a hammer and remove the lock jaws;

- if the connection was made with a spring lock, it is necessary to dismantle the clamping elements, leaving the reinforcement in the concrete and cutting off its protruding sections;

- in a screw connection, simply unscrew the nuts.

Having removed the fastening elements, they begin to carefully disassemble the panels in order to move them to a new area of work.

Price for spring lock for formwork

provides you with all the necessary auxiliary construction equipment. We sell, rent, and lease not only complete systems, but also their individual elements. Here you can buy panels, locks, etc. at affordable prices. The price of a spring lock for formwork is the most comfortable. We cooperate with direct manufacturers of building structures, thanks to which we can reduce prices within reasonable limits. We provide a factory quality guarantee. Contact experienced managers. We will answer all your questions, introduce you to the technical characteristics of the product, select the best system and provide favorable discounts.

Formwork fasteners

- In stock

- Wholesale / Retail

- 05.02.20

Platform size – 70*105 Platform thickness – 2.2 Tongue thickness – 4.5 Maximum load – 2500 kg Country of origin – Turkey Weight – 0.31 kg Installed on reinforcement (rod rod, wire) with a diameter of 6 to 10 mm and tightened with a special wrench

- In stock

- Wholesale

- 06.02.20

Huge selection of equipment If a product is not in the price list, ask the manager about its availability

- To order

- Wholesale / Retail

- 05.02.20

Art. 157503. The roof is made of galvanized steel, with a polyester coating; the door is 1000 mm wide, has hinges for opening to the right and is locked.

- To order

- Retail

- 31.01.20

The Stroyland company is a successfully developing organization in the field of supply of construction equipment and building materials. Over the past time, since its formation, it has established itself as a serious partner with reliable connections among suppliers.

- To order

- Wholesale / Retail

- 06.02.20

bolt_. Manufacturing_bolts. All types and sizes of bolts. Steel 40x, 12x18n10t, 30xma, 20x13, 09G2S and other steel grades. bolt_according to drawings. Additionally – galvanizing, heat treatment.

Universal lock for formwork: purpose, features, selection tips

The universal (leveling) lock for formwork in the catalog of the 1st FORMWORK COMPANY is presented in several varieties. This ensures that a person with any preferences will find a suitable option.

We offer only products in which we are 100% confident. The quality is confirmed by domestic tests and repeated use on construction sites located even in places with an unfavorable climate. If you need this fastening element or any other parts for formwork, we will certainly find common ground.