Polystyrene concrete lintels (PSBP) are highly durable and easy to install. This product has found application as insulation and material for the manufacture of door and window openings. However, this is not the entire area of use of polystyrene concrete lintels. Before working with this building material, you need to familiarize yourself with its overall dimensions, installation features, properties and find options for leveling out weaknesses.

General presentation and characteristics

A popular working material among developers, polystyrene concrete is a type of lightweight concrete that contains cement, polystyrene, clean water and special fibers. The latter minimize microdefects caused by temperature fluctuations and shrinkage of the mixture during hardening. The combination of such components gives it excellent technical characteristics, including good thermal insulation, low weight and high strength.

Builders choose polystyrene concrete directly for lintels, since it can be prepared independently at home without much difficulty or skill.

Walls made of polystyrene concrete are thinner and warmer than internal partitions made of other similar cellular concrete. But in order to get a positive result when using polystyrene cement crossbars, you need to strictly adhere to the production stages and take into account the installation features. Types of jumpers made from polystyrene-based solution:

Products of this type are provided with a reinforced frame that enhances their properties.

- Non-load-bearing. It has low load-bearing capacities and is considered the most budget-friendly on the building materials market.

- Self-supporting. Equipped with a reinforcing welded frame, which provides high strength and the ability to withstand increased loads.

- Brand D800. Such products can withstand up to 2 tons and are resistant to sub-zero temperatures.

Features of the construction of monolithic polystyrene concrete floors

Polystyrene concrete floors serve to strengthen window and door openings, as well as the basis for the next levels of masonry. In order to increase strength and rigidity, such products are reinforced with steel frames.

At the same time, the density of polystyrene concrete floors ranges from 300-500 kg/m3 , and in terms of strength parameters they must correspond to certain classes. Their load-bearing capacity must be within the range established by the basic nomenclature for such floors. The approximate figure will be 50-150 kg/m, while technologies make it possible to produce products with a load-bearing capacity of up to 300 kg/m. Jumpers made of such polystyrene concrete will weigh about 15 kg.

The main parameters by which polystyrene concrete floors are: height - 29.5 cm or 23.5 cm, length - from 120 to 300 cm, thickness - from 11.5 to 18 cm. In addition, it should be noted very high frost resistance characteristics of these products. They vary between 35-100. When choosing dimensional characteristics, you should be guided by the structural features of the building and the climatic characteristics of the region, on which the operating conditions depend.

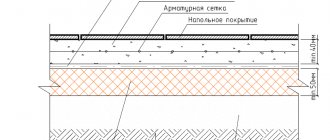

based on polystyrene concrete : an assembly system (load-bearing beams and filling elements - floor slabs) and a monolithic system (on corrugated sheets) .

Floor installation system

The use of monolithic polystyrene concrete together with I-beams allows us to make floors that meet all the above requirements!

Compound

Dimensions:

- Thickness: 0.241 to 0.457 m

- Length: up to 9 m

- OSB - Oriented Strand Board (OSB, English oriented strand board, OSB) - is a multi-layer (3-4 layers) sheet consisting of wood chips glued with phenol-formaldehyde resins with the addition of synthetic wax and boric acid.

Properties:

- high strength - the physical and mechanical properties of OSB are 2.5 times higher than those of chipboard (chipboard) and are approximately the same as those of coniferous plywood;

- moisture resistance - the material does not collapse and retains its strength characteristics when placed in water for 1 day (swelling coefficient - about 10%);

- ease of processing - slabs can be easily cut and drilled, can be glued and painted with any adhesives and paints intended for wood;

- the retention rate of fasteners is 25% higher than that of coniferous plywood and chipboard;

- low level of defects (delaminations, knots and voids);

- OSB board is not susceptible to damage by insects

- Polystyrene concrete grade D350

- I-beam - made of OSB-3 boards and ordinary wood in accordance with technical specifications, they have a high load capacity and can be installed over large areas without defects such as bending, are not subject to shrinkage, deformation, cracking. Holes for sewage, electrical, gas, water and ventilation can be easily cut in the walls of the beams.

Characteristics of monolithic polystyrene concrete for flooring

| Name | D350 |

| Load-bearing capacity, kg/m² | up to 300 |

| Deflection, mm | L/480 |

| Coefficient of thermal conductivity, W/m°C | 0,075 |

| Vapor permeability coefficient, mg/(m*h*Pa) | 0,09 |

| Weight, kg/m² | from 85 to 110 kg |

To improve the load-bearing capacity, fiberglass reinforcement can be used.

Advantages of using polystyrene concrete floors

- Floors do not need to be insulated

- High thermal insulation properties

- High noise insulation

- No need for waterproofing

- Ease

- Durability

- High specific strength allows the use of beams on long spans;

- No bends and consistent dimensions;

- Application in wall and floor structures;

- Not subject to shrinkage and deformation;

- Provide savings in labor costs and materials;

- The beams can be easily laid using ordinary carpentry tools (no trucks required);

- In building structures it is possible to use 40-60% less materials;

- With proper installation, storage and operation, they are guaranteed for the entire service life

Watch the video: “Filling the floor with polystyrene concrete.”

Application

Typically, beginners and experienced builders use polystyrene reinforced concrete lintels when constructing external walls over windows, doors and other structural openings in the wall. In addition, due to their lightweight weight, such products are perfectly combined with all kinds of wall materials, including:

These products can be used in brick construction.

- brick;

- foam block;

- gas block;

- wood concrete

But the field of activity is not limited to this and polystyrene concrete crossbars are actively used in the construction of frame multi-apartment buildings from porous blocks. Accordingly, such structures require lightweight window lintels, so polystyrene concrete in this case will come in handy.

Polystyrene concrete lintels

Finally, low-rise construction is beginning to change more towards rational rather than more economical ones.

Reinforced polystyrene concrete lintel 1PB-20-4, 2 m long. for a window opening 1.7 m wide. weighs only 36 kg and can withstand a load of 400 kg/l.m. It is clear that, unlike a conventional concrete lintel, it will be much easier for two masons to install polystyrene concrete lintels. As a result, the wall will be a single whole, since the height of the polystyrene concrete building block and the lintel are the same. Low thermal conductivity, reliability and ease of installation, delivery integrated with the blocks, high adhesion to plaster mixtures greatly simplify construction, saving not only time, but also money.

As soon as they don’t arrange window and door openings in private housing construction! Some install blocks on a metal corner, others lay wooden beams. As a rule, in such cases they are guided mainly by the need to reduce the cost of construction. We forget that metal corners must be reliably protected from corrosion, that in blocks it is necessary to make a sample for the corner, that in the future we need to think about reliable fixation of the plaster. And still, no matter how much the metal is protected, after a few years, red rust spots begin to appear on the wallpaper. In addition, metal corners as jumpers play a wonderful role as a cold bridge.

With wooden lintels, things are also not so simple. They don't rust, but wood has a completely different coefficient of linear expansion than building blocks. Wood dries out over time, can develop large cracks, and is driven by a screw. As a result, all the savings turn into a serious problem for homeowners. Through gaps in the wall, repair of the facade and interior decoration, etc.

As a rule, we stubbornly save money now, hope for “maybe”, and with doom we get involved in repairs in the future.

But if you think about it, the choice in favor of polystyrene concrete lintels is not so difficult. Firstly, everyone is accustomed to the fact that the lintel is usually heavy and concrete, which is not so easy to install on a 3-meter wall. Secondly, we know that a metal corner capable of holding the same load as a jumper is also not cheap. Thirdly, the angles (or wooden beams) are not sold in the same place where the building blocks are made, and therefore a separate delivery organization will be required. Of course, you can optimize the process and bring the corners along with the reinforcement for the foundation, but during construction, they will lie on the site and most likely in the open air and rust. Fifthly, you will have to spend time on rust protection, adjusting the blocks to the corners, etc. Sixthly, ... You yourself will now list all the reasons why polystyrene concrete lintels are easier to use in construction. But, perhaps, the most important thing in choosing a polystyrene concrete lintel will be its reliable operation in the future, when you start living in your home.

Strengths

PSB products are perfectly combined with concrete blocks, which allows the construction of buildings that can reliably retain heat. As a result, there is no need to insulate the building, and this significantly saves budget and time for installation work. Polystyrene concrete lintels are gaining popularity for a number of other advantages:

The product parameters allow it to be quickly and easily installed without any complex equipment.

- Good sound insulation. The building material perfectly absorbs noise from the outside and does not let it into the room.

- Strength. Products based on polystyrene are characterized by high durable characteristics and reliability.

- Convenient sizes and light weight. Installation does not require excessive effort or the use of auxiliary loading and unloading equipment, and the low weight of the jumpers greatly facilitates the transportation of building materials.

- Precision of geometric shapes. The elements have smooth edges, which allows you to make identical seams and save on the amount of adhesive. And thanks to this criterion, the heat-insulating properties of the walls are improved.

- Safety. The structure of the porous material used for the installation of jumpers does not contain dangerous ingredients that poison the human body. All components of polystyrene concrete do not cause damage to the environment and do not act as a habitat for mold fungi.

Advantages

The advantages of using such products in construction work are obvious. Thanks to their combination with concrete blocks, it is possible to erect buildings that reliably conserve heat without additional insulating materials. Today there is growing interest in door and window polystyrene concrete lintels. They are considered the most reliable energy-saving materials on the construction market.

An example of laying a beam above a window.

Modern technologies have greatly facilitated the work of builders. After all, when building cottages or constructing multi-storey buildings, they do not have to purchase additional heat-insulating building materials, since reinforced products have all the necessary indicators. In addition, there are other advantages, including:

- material strength;

- soundproofing;

- low weight facilitates transportation and installation work;

- reduction of labor costs during the work process.

The accuracy of the geometric shapes of products has a positive effect on the seams located inside the building materials. This allows you to reduce the amount of special glue during installation work and improve the heat-insulating properties of the walls.

It should also be noted that products made from this material do not harm the environment and have antiseptic qualities (mold does not form on them). Reliable and lightweight materials can be easily transported to the construction site.

Disadvantages of polystyrene cement

Additional ventilation is a necessary measure that people resort to to compensate for the inability of the material to “breathe”.

Despite the many advantages of PSBP, they also have weaknesses, which, if not taken into account at the construction stage, will cause problems in operation. Thus, a significant disadvantage is the lack of ability of the walls to “breathe” due to the fact that partition structures made of polystyrene cement do not allow steam to pass through or retain it. Therefore, additional ventilation is always installed in rooms with polystyrene concrete lintels. In addition, such products have increased shrinkage, which also needs to be taken into account when installing jumpers.

Disadvantages of polystyrene concrete - is it worth using polystyrene concrete?

So, in order, the information is confirmed by test reports from leading manufacturers of polystyrene concrete, I drew a conclusion for myself and wrote it at the end of the commentary.

MOISTURE RESISTANCE and HYGROSCOPICITY This is the most important property of any building material, especially in areas with high humidity. The higher the moisture resistance of the material, the more durable, stable and warmer it is. Polystyrene concrete absorbs no more than 6% moisture from the atmosphere; it can be exposed to the open air for an almost unlimited time.

STRENGTH Due to the super-strong cement-polystyrene matrix, polystyrene concrete has unique strength characteristics. This material is so durable that a fall from a five-story building will not cause significant damage to the block.

FIRE RESISTANCE Polystyrene concrete does not burn; it is able to withstand enormous temperatures caused by fire, due to its unique thermal conductivity coefficient, and does not allow heat to penetrate deep into the wall. Flammability class NG. Fire resistance class EI180.

DURABILITY The service life of a house made of polystyrene concrete is at least 100 years. Over the years, the strength of polystyrene concrete only increases.

FROST RESISTANCE Tests for frost resistance and the amplitude of temperature fluctuations from + 75°C to - 30°C were carried out on 150 freeze-thaw cycles without loss of integrity and heat-insulating ability. THERMAL INSULATION It has long been recognized that polystyrene (foam) is the best thermal insulator in the world; it is warmer even than wood! A house made of polystyrene concrete does not require insulation: it is cool in summer and warm in winter.

SOUND INSULATION Polystyrene concrete provides the best indicator for noise absorption, 18-20 cm dampens sound from 70 decibels. Consequently, a house made of polystyrene concrete has special comfort: noise from the street and inside from neighboring rooms and bathrooms is not disturbing. ECONOMICAL

The cost per square meter of a finished wall is cheaper than other materials. Due to the high level of heat retention, walls made of polystyrene concrete can be built 25% thinner than those made of alternative materials (aerated concrete and foam concrete) and 4 times thinner than those made of brick. Saving on wall thickness leads to overall savings on the construction of the box (foundation, roof and walls) of up to 50%. At the same time, the quality of the house will be even higher, and the house itself will be warmer.

EARTHQUAKE RESISTANCE Seismic resistance 9-12 points. Polystyrene concrete has not only compressive strength, but also the highest tensile and bending strength. Therefore, polystyrene concrete is considered the most reliable and earthquake-resistant material.

LIGHTWEIGHT A large-sized block of 200x300x600 mm does not exceed a weight of 17 kg, which facilitates the work of a mason and reduces the time for laying walls: it replaces 20 bricks in volume, and is almost three times lighter in weight.

ANTISEPTIC The additive used in the production of polystyrene concrete does not allow insects and rodents to enter the walls, and prevents the formation of mold and mildew, which have a negative impact on health.

VAPTOR PERMEABILITY Walls made of polystyrene concrete “breathe” similarly to walls made of wood, and there is no danger for them from condensation and waterlogging. This ensures a comfortable environment in houses made of polystyrene concrete.

PLASTICITY Plasticity is the only material made from cellular concrete that allows the production of window and door lintels; its flexural strength is 50-60% of the compressive strength, for concrete this parameter is 9-11%.

CRACK RESISTANCE Polystyrene concrete, due to its elasticity, is incredibly resistant to cracks. And this guarantees a long period of preservation of the interior decoration and durability of the entire house.

TECHNOLOGY High speed of construction of wall structures due to the lightness and convenient geometry of the blocks. They are easy to saw and groove, making it possible to give the building material any geometric shape.

ENVIRONMENTAL FRIENDLY The International Building Code (IRC) classifies polystyrene as one of the most energy efficient and environmentally friendly insulation materials.

Thus, polystyrene concrete has a lot of undeniable advantages over materials such as expanded clay concrete, autoclaved and non-autoclaved aerated concrete, foam concrete, wood concrete, etc. The disadvantages of polystyrene concrete only appear if the brand is chosen incorrectly and the technology of masonry and preparation for interior finishing is violated. We can say with absolute certainty that there is not a single significant advantage for materials such as aerated concrete and foam concrete over polystyrene concrete. At the same time, polystyrene concrete significantly surpasses them in key characteristics.

Important facts

When choosing polystyrene concrete lintels for building buildings, you need to know the intricacies of working with them. Since this architectural element, used to cover door openings in the wall, takes the load from its own mass and the weight of the blocks, the building material for installation in accordance with GOST should not be lower than grades D300-D600. When laying polystyrene concrete elements, tolerances are left within 1.5-3 mm. The thinness of the interblock seams improves the wall's ability to retain heat and allows you to save on mortar. And the light weight of the jumpers makes installation work quick and eliminates the need to use lifting equipment. The service life of properly installed PSB connecting devices reaches one century.

Peculiarities

The main requirement for lintels is strength, since they need to withstand their own weight, as well as the weight of the blocks that lie above the opening. Therefore, for their manufacture, these beams in accordance with GOST R 51263-99 use concrete with a density of at least D300-D600.

Among their features the following points can be highlighted:

- High precision of shapes - tolerances are ±1.5-3.0 mm. Thanks to this, installation can be done using glue with a joint thickness of 3-5 mm. The small thickness of the seams improves the heat-insulating properties of the wall.

- Light weight - which allows two or three workers to install the beams with their own hands, without the use of lifting equipment.

- The service life is up to 100 years.

- The sizes of polystyrene concrete lintels can be very different, which allows you to select the most suitable product depending on the parameters of the structure being built.

Note! The instructions for installing jumpers assume an area of their support on the wall of at least 200 mm on each side.

These are, perhaps, all the main features of polystyrene concrete lintels.

Polystyrene concrete lintel: application features, advantages of use

Expanded polystyrene concrete is a relatively new building material, which, nevertheless, has proven itself in private residential construction in the harsh weather conditions of Russia. Taking into account the technical and operational characteristics of the material, reinforced polystyrene concrete lintels are successfully used in the construction of door and window openings. Their main task is to hold the weight of subsequent rows of masonry above the opening.

Each lintel has a welded metal frame made of reinforcement inside with a cross-sectional diameter of 10-12 mm. The rods undergo additional anti-corrosion treatment.

Standard sizes, production technology, technical and operational indicators of polystyrene concrete lintels are regulated by GOST R 51263-99 “Foamed polystyrene concrete”. A sand-concrete mixture with a density of D300-600 is used as a binder. The lintel must extend into the wall to a depth of at least 20 cm on each side.

Advantages of using polystyrene foam lintels

Laying speed and material compatibility. Most often, polystyrene foam lintels are used in buildings constructed from:

- Brick;

- Foam blocks;

- Gas blocks;

- Arbolita

and other lightweight building materials.

Despite the size of the reinforced lintel, its weight still remains small - up to a maximum of 60 kg. This allows installation without the use of specialized lifting construction equipment.

The material is resistant to microorganisms: mold, fungi, rotting. Products made from it are non-toxic and odorless. They have high resistance to alkalis, soda and acids, oils, fuels, solvents, etc.

Extremely low hygroscopicity. Unlike classic reinforced concrete concrete, polystyrene concrete has a small number of capillary channels. Moisture that gets on the surface cannot seep inside. Accordingly, the frost resistance of the material also increases, and in combination with its high thermal insulation parameters, the use of jumpers of this type will neutralize one of the main sources of heat leakage (the cold bridge above the window) in an energy-saving house.

Fire safety class G-1. High level of adhesion to other materials. Provided that special adhesives are used and installation technology is followed.

Manufacturers and developers who actively use foam concrete building elements position buildings made of foam concrete as durable with a guarantee of the integrity of load-bearing structures for up to 60 years.

Expanded polystyrene is well processed, this not only facilitates the installation process, but also allows you to quickly knock out grooves in the material for installing cables for various purposes.

Flaws

The low vapor permeability of the material leads to the need to install an extensive system of natural or forced ventilation in the house. In addition, the material shrinks significantly compared to denser bricks and concrete.

Installation features

Foamed polystyrene concrete lintels have minimal tolerances (1.5-3mm) and precise dimensions of the elements. Special glue is used to install them. The working thickness of the binder solution is 3-5 mm. This significantly reduces heat loss from cold bridges, which are cement joints.

According to research, heat loss due to installation and cement joints averages up to 15% of all heat loss in a building.

A variety of standard sizes allows you to choose an element that is ideal for each specific opening. Each product has an arrow indicating the top and bottom of the lintel. This is due to the use of prestressed rods in the reinforced lattice, which must be located at the bottom.

Reinforced polystyrene foam concrete has significant strength characteristics, but to a greater extent it is a heat-insulating material. The thermal conductivity coefficient is 0.08-0.15 W/m°C. Typically, such houses are not additionally insulated, however, according to SNiP 2.01.01-82 “Building climatology and geophysics”, polystyrene foam lintels cannot be used in areas where the estimated air temperature is -46ºС.

stroitel5.ru

Technological features of the work

This modern building material is used in the construction of various structures. As a rule, D400 brand blocks are used. One stone weighs about thirteen kilograms, which facilitates the installation process and eliminates the need to use special equipment.

First you need to decide what the blocks will be laid on and prepare the base. For this:

- mix cement material and sand in a ratio of 1 to 3;

- spread the prepared solution evenly on the surface of the foundation base;

- We lay the first row of blocks, checking the evenness with a level.

The remaining rows of polystyrene concrete are laid out using glue. When working, you should use a trowel or comb. Dust is removed with a brush. During the laying process, you should use a level or beacons along which the cord is pulled.

Once the glue has hardened, it will be impossible to change the position of the block.

Reinforced lintels

Order

A unique offer for Tyumen! offers reinforced lintels of its own production from polystyrene concrete. We have been producing load-bearing lintels on the market since 2007 and have been pioneers in promoting this product. We have the widest range of polystyrene concrete lintels!

Lintels can be used in both low-rise and high-rise construction to cover door and window openings.

How do polystyrene concrete lintels differ from other lintels?

- They are warm. Due to their composition, the lintels do not require additional insulation.

- They are reliable . To ensure the necessary load-bearing capacity (up to 3000 kg per linear meter), a factory-made spatial triangular frame is used inside the lintel.

- They are light. Polystyrene concrete is 6 times lighter than ordinary concrete! Only two workers can install the lintel in the opening - the weight of the average lintel is about 50 kg.

Jumper dimensions (L – length, H – height, B – width)

The lintels are made of polystyrene concrete grades D500-D600; such lintels can be used in regions with a design air temperature of up to minus 46°C. Since the lintels are highly frost-resistant, their service life is more than 100 years. They are not afraid of moisture and atmospheric influences, which means they do not require any special finishing. The low weight of the jumpers allows you to significantly save on their delivery to your site. When purchasing blocks, you can immediately order the required number of lintels, and we will bring them to you in one car along with the blocks for building a house.

Reinforced lintels produced by TPK Block-Beton LLC can completely replace cellular concrete lintels at construction sites. Compared to mesh lintels, our lintels do not break during delivery because... polystyrene concrete is a very durable and elastic material. The production capacity of our company allows us to produce lintels of almost any cross-section and length.

Jumper installation diagram. The lintel is supported at each end by at least 200 mm. At the end of the jumper the installation position is marked with an upward arrow.

Reinforced polystyrene concrete lintels are economical!

- Lintels made of polystyrene concrete do not require insulation, which means there is no cost for additional work and materials.

- The weight of our lintel is 6 times less than that of a reinforced concrete lintel - lower delivery costs (can be delivered in a gazelle and unloaded manually), lower installation costs (two people can easily install the lintel in the opening).

- Lintels made of polystyrene concrete are much cheaper than cellular concrete and are always in stock. Plus, you can order jumpers before the start of the season, and we will offer you free storage in our warehouse.

Price list for lintels produced by LLC TPK “Blok-beton”

| Width (mm) | Height (mm) | Length (mm) | Price per piece (rub.) | Load t/m. | Application |

| Reinforced load-bearing lintels 300 mm wide | Openings in walls made of polystyrene concrete blocks, foam concrete blocks, aerated concrete blocks 300 mm thick | ||||

| 300 | 188 | 1290 | 1400 | 3 | |

| 1550 | 1600 | 3 | |||

| 1710 | 1900 | 3 | |||

| 1810 | 2350 | 3 | |||

| 2210 | 2550 | 3 | |||

| 2550 | 3050 | 2 | |||

| 2880 | 3400 | 2 | |||

| 3500 | 5500 | 2 | |||

All lintels are made of polystyrene concrete in accordance with GOST R 51263-99 and TU 5741-002-85446944-2009. Products are certified.

We also produce non-standard sizes of jumpers according to the requests of our clients. Mostly lintels of non-standard sizes are used in the construction of multi-storey residential buildings. Such lintels can have a cross-section of 20x20 cm, 30x30 cm, 12x20 cm and even 8x20 cm. The cost of such lintels is calculated individually for each order, taking into account the required load-bearing capacity. You can order lintels longer than 3 meters; such lintels are used to cover large openings, for example in a garage. Long lintels are made with a cross-section of at least 300x300 mm using reinforced reinforcement frames. You can receive a quality certificate for all jumpers.

Below is a correspondence table for reinforced concrete and cellular lintels

| Dimensions | Design load kN/m (kgf/m) | Analogs | |||

| Length | Width | Height | Concrete products | Cellular concrete | |

| 1200 | 300 | 200 | 29,41 (3000) | 1PP12-3 | 3PP12-3Ya |

| 1400 | 300 | 200 | 29,41 (3000) | 2PP14-4 | 3PP14-3Ya |

| 1700 | 300 | 200 | 29,41 (3000) | 2PP17-5 | 3PP17-3Ya |

| 1900 | 300 | 200 | 19,61 (2000) | 2PP18-5 | 3PP19-2YA |

| 2200 | 300 | 200 | 19,61 (2000) | 2PP21-6 | 3PP22-2Ya |

| 2700 | 300 | 200 | 9,8 (1000) | 2PP25-7 | 3PP25-1Ya |

| 2900 | 300 | 200 | 9,8 (1000) | 2PP25-8 | 3PP28-1Ya |

| 1200 | 200 | 300 | 29,41 (3000) | 3PB13-37 | 2PP12-3Ya |

| 1400 | 200 | 300 | 29,41 (3000) | 2PP14-3Ya | |

| 1700 | 200 | 300 | 29,41 (3000) | 3PB16-37 | 2PP17-3Ya |

| 1900 | 200 | 300 | 19,61 (2000) | 2PB19-3 | 2PP19-2YA |

| 2100 | 200 | 300 | 19,61 (2000) | 2PB22-3 | 2PP19-2YA |

| 2400 | 200 | 300 | 9,8 (1000) | 2PB25-3 | 2PP22-2YA |

| 2700 | 200 | 300 | 9,8 (1000) | 3PB25-8 | 2PP25-1Ya |

| 2900 | 200 | 300 | 9,8 (1000) | 3PB27-8 | 2PP28-1Ya |

| 1200 | 332 | 300 | 29,41 (3000) | ||

| 1400 | 332 | 300 | 29,41 (3000) | ||

| 1700 | 332 | 300 | 29,41 (3000) | ||

| 1900 | 332 | 300 | 29,41 (3000) | ||

| 2100 | 332 | 300 | 29,41 (3000) | ||