Home |Reinforcement |Reinforcement of aerated concrete with reinforcement

Date: February 18, 2017

Comments: 0

Construction technologies do not stand still. New materials are appearing that ensure high quality of constructed objects, and old ones are being improved. Aerated concrete, widely used in private construction, was not particularly popular at the time of its appearance. Possessing a number of positive qualities, it faded into the background due to increased fragility. The walls gradually became covered with cracks, requiring a quick response and additional investment of money. This problem was solved by using reinforcement of aerated concrete blocks.

Reliable reinforcement has brought tangible results. Gas-filled materials have gained well-deserved respect among developers. Aerated concrete made it possible to reduce construction time and achieve improved thermal insulation of premises. When constructing buildings, special attention is paid to the reinforcement of high-risk areas: door and window openings, entrance thresholds, walls exposed to increased wind loads. Houses made of aerated concrete, after carrying out measures to increase strength, can withstand significant forces aimed at tension, compression, and bending.

Recently, a building material such as aerated concrete block has become very popular.

Properly reinforced material allows it to be used in the construction of external walls and internal partitions of various configurations. Let's look at the existing methods of strengthening structural elements and decide what kind of reinforcement will be needed for the work.

General concepts

When deciding whether it is necessary to reinforce aerated concrete with reinforcement, you should know the properties and characteristics of the gas-filled composite in order to make the right decision. The production method, which involves the formation of air cavities in the concrete composition, determines increased thermal insulation properties, allowing the construction of buildings that do not require additional insulation. Aerated concrete blocks reduce heating costs by up to 25 percent. The main characteristics that distinguish aerated concrete from the general list of building materials include:

- High degree of thermal insulation.

- Increased frost and heat resistance.

- Excellent sound insulation properties.

- Impossibility of rotting.

- Environmental Safety.

- Ease of processing.

- Light weight.

Aerated concrete blocks significantly increase the speed of construction and reduce the cost of wall construction due to the fact that they do not require additional thermal insulation

Cracking of gas-filled elements associated with reduced strength is compensated by reinforcement. Let's determine which areas of buildings require reinforcement.

Metal fittings

The blank for this type of reinforcement is rods with a corrugated texture (BP1), corresponding to GOST standards. The diameter of this wire varies from three to five millimeters. What is unique is that the thickness of the reinforcement is identical to the thickness of the masonry joint, which is recommended by professionals. Thanks to this feature, the reinforcement does not create cold “bridges” in the seams, since the interblock gap is not enlarged.

A number of advantages that characterize metal masonry mesh for foam blocks:

- The technology for creating this product is complex (using resistance welding with low-carbon steel elements), which gives the frame high strength.

- This product is produced exclusively at specialized enterprises using high-tech equipment.

- Working with this material is quite harmless, since the surface of the mesh does not have sharp “burrs” or smell, but you should not neglect safety rules and it is better to work with gloves

- Ease of transportation due to the fact that the metal mesh goes on sale in the form of a neatly rolled roll

- Adequate pricing policy

- Available in two formats: cut squares and rolls

- It is easy to choose the width of the mesh for the foam block, as it is produced in different widths

- Reduces the amount of solution consumption, as it prevents the composition from penetrating deep into the pores, and also helps to increase the level of thermal conductivity of the masonry

The cell sizes of metal masonry mesh are different, the most common are:

- 10 x 10 mm.

- 16 x 16 mm.

- 25 x 12.5 mm.

- 25 x 25 mm.

- 50 x 50 mm.

- 75 x 25 mm.

- 75 x 75 mm.

NEED TO KNOW! A significant disadvantage of masonry mesh made of metal is its susceptibility to corrosive changes, in other words, it can simply rust and lose its properties. There is an exit! It is necessary to treat the material on all sides with moisture-protective agents to avoid or slow down the corrosion process.

Note! The only significant drawback of metal fittings is susceptibility to corrosion. You can protect the metal from such a process by treating it on all sides with a moisture-proof solution.

Problem areas that require strengthening

When starting construction, identify areas of reduced strength and strengthen the following areas:

- the zone of contact between the foundation and the initial row of masonry, which absorbs the forces created by the mass of the walls and roof. To give strength to the base and uniform distribution of forces, aerated concrete is reinforced with a mesh;

- Reinforcement of aerated concrete masonry is carried out evenly, maintaining a constant interval of 4 rows. Reinforcement is performed with steel rods, less often with metal mesh;

- walls made of aerated concrete of increased length and surfaces that absorb lateral forces. Reinforcement of aerated concrete masonry creates an additional level of reinforcement to compensate for the effects of strong winds and provides additional thermal insulation of the object. Strengthening is recommended to be done with masonry mesh;

- area that receives loads from the roof. The supporting surface is reinforced with metal reinforcement with a diameter of 10-14 mm, with the help of which a single reinforcing system is created that evenly distributes the loads of the truss structure along the perimeter of the structure. The loads are equalized, eliminating the occurrence of deformation of the aerated concrete wall;

Many builders are wondering whether it is worthwhile to additionally strengthen the masonry from aerated concrete blocks

- areas of window and door openings. Reinforcement is carried out by concreting reinforcing bars with a diameter of 8-12 mm in pre-prepared longitudinal grooves in the upper level of the floor blocks. There is no doubt whether it is advisable to reinforce door and window openings - after all, they take the load from the total weight of the masonry elements located above.

Houses made of aerated concrete, reinforced in compliance with the rules, are much stronger. Alternating forces do not have a detrimental effect on the structure, which increases the service life.

Masonry mesh for aerated concrete

Home page » Mesh - information » Mesh by application » Masonry mesh for aerated concrete

Some block manufacturers do not require the use of masonry mesh for aerated concrete when laying walls for reinforcement. They say that modern aerated concrete has sufficient mechanical strength and enough reinforcement, and then only in places where door and window openings are supported.

On the other hand, designers in any project of a house with aerated concrete walls, in order to avoid the appearance of cracks during shrinkage of the house and temperature changes, indicate the requirement to use masonry mesh. They argue that the tensile loads that arise in this case can be quite large and only a masonry mesh can cope with them.

Maybe the builders are just reinsurers?

Application of masonry mesh: is it necessary or not?

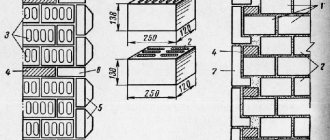

In fact, it all depends on the size of the aerated concrete block and the type of masonry.

If an external wall is built from 1st category blocks of large format D500 625 x 400 x 250, having a strength of B3.5, then reinforcement is not required. But, if the same wall is built from two 200 mm blocks, then mesh reinforcement is mandatory. It must be done every 3-4 rows, even if you place the blocks not on the solution, but on glue. The same requirement will be mandatory in the first case, if, at the same time, facing bricks are being laid outside.

If blocks of the 3rd category D500 60 x 20 x 30, having a strength of B2.0, are used, and are also placed on mortar, then it is imperative to use a masonry mesh every 3 rows.

When constructing multi-storey buildings, the first floor must be reinforced.

Reinforcing aerated concrete blocks will avoid this.

Find out more: Reinforcement of aerated concrete blocks

Types of masonry mesh for aerated concrete

Two types of masonry mesh are used:

- welded steel mesh.

The most commonly used standard sizes, mm: 50x50x4 and 50x50x3; Mesh reinforcement - composite and fiberglass. It is made of basalt-plastic and fiberglass reinforcing bars located in two mutually perpendicular directions. The rods are fixed in the contact assembly to create the correct and specified cell geometry using clamps, wire or special glue.

A short video about basalt-plastic mesh

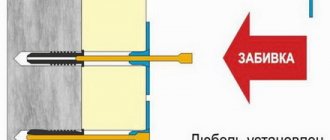

Alternative types of reinforcement for laying aerated concrete blocks

The most common alternative type of reinforcement is steel rod. To lay the rod (Ø8 mm is most often used), it is necessary to mark (in compliance with a number of requirements) and make a groove measuring 12 x 12 mm. A rod is formed according to the location of the groove. The groove is filled with glue (glue composition: calibrated sand, high-strength cement and special additives) and a rod is placed there. Excess glue is removed. Next, the next row of blocks is laid on the glue or mortar, etc.

Glue packaging

More information on the topic:

- Reinforcement of aerated concrete blocks with mesh or reinforcement;

- Reinforcement of aerated concrete blocks with fiberglass reinforcement

Advantages and disadvantages of different types of reinforcement

Reinforcement with welded steel mesh is the cheapest type of reinforcement. As a rule, mortar is used (the seam is thick and the use of more expensive material - glue is not justified). “Cold bridges” form through the metal. The mesh metal is exposed to the aggressive environment of the solution and becomes unusable. Therefore, it is possible to use it on interior walls made of large-format blocks.

Reinforcement with composite or fiberglass mesh . High cost of fittings. The harmful effect of the mortar on the metal and the formation of “cold bridges” are excluded. Can be used in the construction of external walls.

Learn more about fiberglass mesh for reinforcing aerated concrete.

Reinforcement with steel rod . Possible for all types of walls. When reinforcing blocks up to 200 mm wide, one row of rods is used; over 200 mm, two rows are used. There is only one drawback: high labor intensity.

Reinforcement of aerated concrete with steel reinforcement (learn more here).

Video about testing masonry mesh, useful to watch

Where can I buy

WHERE TO BUY MASONRY NETWORK

Manufacturers of masonry mesh

And here is where to buy basalt masonry mesh.

Tags: Masonry mesh Sections: Mesh by application

Materials and tools

To reinforce aerated concrete walls, you need to prepare the following materials:

- Metal mesh. Depending on the tasks, the diameter of the wire and the size of the cell change. To reinforce aerated concrete masonry, a 50x50 mm cell made of wire with a diameter of 3-5 mm is sufficient. The masonry is strengthened by fixing a reinforcing mesh to the surface, followed by covering it with cement mortar. The composition is applied with a margin of 2-3 mm, in order to avoid corrosion processes that occur when moisture enters. Strengthening the contour of the openings is done with a mesh made of wire with a diameter of 4 mm with a cell size increased to 70 mm.

Those rows that are the most loaded should be reinforced: blocks under lintels, window openings and the first rows of blocks

- Steel rods, diameter 8-14 mm. The higher the expected loads, the larger the diameter of the reinforcement used when performing the work. The installation process is not complicated, but requires certain skills and accuracy. In the elements to be strengthened, longitudinal grooves are made corresponding to the size of the steel rods, cleaned of dust, and moistened. Then the reinforcement is laid and filled with cement mortar. Reinforcement of an aerated block located in the corner zone is carried out similarly, with one difference - the groove is formed rounded, according to the configuration of the reinforcing rod.

- Knitting wire to create a reinforcement frame.

It is not difficult to lay and strengthen aerated concrete blocks if you have:

- sharpened saw. With its help, blocks are adjusted to the required size. Products made from gas-filled concrete are easy to process without loss of strength;

- manual or electric tool (wall cutter) – necessary for forming grooves;

- building level, square, tape measure;

- grinder with a working body diameter of 250 mm. Its purpose is to cut steel bars;

- a device for bending reinforcement when forming the corners of a building;

- crochet hook or welding machine for attaching reinforcing elements.

Reinforcement itself does not increase the load-bearing capacity of the walls of a building, but it remains an important condition that must be met during construction

Materials for reinforcing aerated concrete masonry

Reinforcement of aerated concrete masonry is carried out in several ways. The main method is to strengthen load-bearing walls using hot-rolled steel reinforcement of periodic profile AII, AIII. Available in skeins or measuring rods of 6–12 m.

It is a corrugated profile with two longitudinal ribs. The weight of one meter is 6.3–7.9 kg.

To knit the jumper frames and install the upper reinforced belt, low-carbon reinforcement is additionally used, or rather VR-1 wire and soft knitting wire 0.8–1.2 mm.

The low price and low weight of fiberglass (composite) reinforcement determine its widespread use when performing masonry work from aerated concrete blocks.

As you already understood, the main disadvantages of composite reinforcement are: low heat resistance, the impossibility of connecting rods by welding, and cannot be bent at home.

Therefore, when using fiberglass reinforcement to reinforce aerated concrete masonry, reinforcement in the corners of load-bearing walls must be carried out either with special corner elements or steel reinforcement.

, galvanized masonry mesh Ø 3 mm , with a cell size of 50x50 mm, is usually used

The use of mesh is possible if the masonry is carried out using cement-sand mortar, since the thickness of the adhesive layer is 2–3 mm, and reinforcement with such material will increase the masonry seam by another 3 mm.

An alternative to mesh and fiberglass reinforcement can be perforated mounting tape . It is a strip of galvanized steel 4–8 mm thick and 25–100 mm wide. Available in rolls.

The reinforcement technology is the same as when using reinforcement, with the exception of masonry scraping. The strips are laid with glue or fastened with screws to aerated concrete masonry.

Reinforcing tape is mainly used when it is necessary to reinforce a pediment made of aerated concrete or to lay interior partitions.

Masonry strengthening technology

The main load of the building is taken by the bottom row of blocks. In order to protect the foundation as much as possible from damage, it is customary to strengthen them, adhering to recommendations based on many years of experience of practicing builders:

- Make parallel grooves along the edges of the product. Use a wall chaser or other convenient tool.

- Use a grinder to cut the rods to the required length.

- Clear debris from grooves.

- Place the reinforcement in the grooves, fasten it by welding or crocheting into a single structure. Remember that the use of welding weakens the metal and impairs its strength characteristics. Use the manual fastening method whenever possible.

- Fill the grooves with cement mortar and carefully level the surface with a spatula.

Developers often have a question about how to reinforce the base more easily - without the use of welding or bonding? This option is possible if reinforced with a masonry mesh, which will eliminate the need to connect the reinforcement elements of each block to each other. You can make the work easier by laying the mesh directly into the cement layer and fixing the edge. By ensuring that the mesh is fully covered with a binder solution, you will create a reliable reinforced layer without much physical effort.

The construction of a reinforcing belt is influenced by many factors: house design, soil quality and others

Polymer reinforcement

To make the base of the mesh rod, the material is heated, stretched and then impregnated with polymers and other compounds.

Let us outline the advantages of this material:

- High resistance to various types of hazards (fungi, pests, rotting)

- Sufficient elasticity, which makes the material plastic and more pliable

- Safety during operation, absence, as a rule, of sharp, protruding elements

- Practical in work and transportation due to its lightness, and also convenient in cutting to the required size

- Resistant to aggressive environments, including alkali

- Acceptable cost

Polymer masonry mesh is produced in various sizes, which in turn vary from 5 x 5 mm to 50 x 50 mm, in joints with a width from 400 mm to 1000 mm.

NEED TO KNOW! The mesh made of polymer compounds, despite its lightness and flexibility, has sufficient strength, almost identical to metal alternatives.

For buildings with small volumes, fiberglass mesh is ideal, as it has relatively low strength and resistance to mechanical loads. Ideal for the construction of garages, country houses, fencing and the like.

Objects of large volumes allow the use of masonry mesh made of basalt. It is quite durable and strong, in most cases it is not inferior to metal, and in addition it is resistant to changes associated with corrosion. Suitable for reinforcing large-scale objects and load-bearing walls.

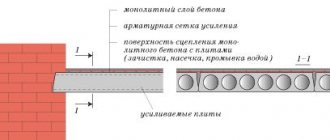

High Level Gain

Particular attention is paid to strengthening the upper perimeter of the walls, which serves as the base of the roof. The weight of the roofing structure, especially those equipped with natural materials (tiles, slate), creates loads on the aerated concrete wall, which can lead to deformation and damage. Therefore, thinking about whether it is worth reinforcing the upper chord of the building is not appropriate. The gain circuit will help:

- reduce individual, point-applied loads;

- distribute the efforts evenly along the entire upper perimeter of the wall;

- level the masonry horizontally without using expensive compounds.

The diameter of the reinforcement is selected based on the calculated weight of the roof structure.

Types of meshes

Suitable for aerated concrete, as well as foam blocks and cinder blocks:

- metal;

- basalt;

- monolithic fiberglass mesh.

Metal mesh is the most durable. Galvanized metal mesh is used to reinforce not only aerated concrete (as well as foam block and cinder block) walls, but also for brickwork. Despite its strength, this is not the best option for aerated concrete, since even with a zinc coating, such a mesh is subject to corrosion. The gas blocks are connected with a special glue; under its action, the mesh rusts and loses its original strength.

Basalt masonry mesh for aerated blocks is practically not inferior in strength to metal mesh. At the same time, it is much more resistant to alkaline environments and corrosion. Another advantage of basalt mesh is its low weight, which makes it easy to work with.

Monolithic fiberglass mesh also resists corrosion processes well, but it is much less durable compared to previous options. It is used to reinforce walls that are not subject to heavy loads. It cannot be used for load-bearing structures.

Types of strengthening load-bearing walls

The question of whether it is necessary to reinforce the outer surface of the walls does not have a clear answer. It is possible to reinforce walls from gas-filled blocks, but the load-bearing capacity will not increase. The only plus is the reduction in the likelihood of cracks forming due to temperature fluctuations and shrinkage of the building during operation.

Reinforcement of walls makes the geometry of the building unchanged and prevents the structure of the building from further deformation

Feasibility is determined individually. There are three known types of reinforcement of external surfaces aimed at preventing formation:

- Cracks around design openings. It is carried out by the method of horizontal reinforcement of aerated concrete blocks.

- Temperature-shrinkage cracks, characteristic of buildings erected in regions with increased temperature fluctuations. It is relevant for the accelerated construction of walls using freshly made blocks that are subject to changes in size during the shrinkage period.

- Deformations in the process of negative impacts of natural phenomena (hurricanes, earthquakes). The type of reinforcement is vertical, combining the foundation and the upper level reinforcement belt into a single system.

Features of reinforcement of masonry made of aerated concrete blocks

First, let's look at areas of aerated concrete masonry that must necessarily be strengthened, that is, reinforced, when constructing the walls of a building made of aerated concrete.

It is necessary to reinforce:

- The first row of masonry for the outer walls of the structure (masonry roll mesh or reinforcing tape for aerated concrete).

- Every fourth row of masonry (reinforcement bars).

- Lintels for window and door openings (rebar frame).

- The upper belt of masonry reinforcement at the floor level (reinforcement frame).

- Reinforcement of aerated concrete partitions (masonry mesh or perforated tape).

- Strengthening the masonry of gables.

Strengthening openings

Strengthening the openings is necessary due to the increased loads occurring in the overlap areas. The mass of elements located above the opening creates stresses that contribute to the occurrence of cracks. The occurrence of defects can be avoided by reinforcing the openings with steel reinforcement having the required configuration. Rods laid in prepared grooves and filled with cement mortar will add additional strength and ensure reliability. Strengthening work can be made easier by using special U-shaped concrete elements. A reinforcing frame is formed in the cavity, which is poured until completely covered, compacted, getting rid of air cavities, and smoothed with a spatula. Pouring is carried out directly at the site of the ceiling, with the preliminary installation of a supporting structure or at the construction site, followed by lifting to the installation site.

The need for a grid for laying blocks

Block construction technology involves reinforcing walls and other structures. For this purpose, metal construction masonry mesh is used. It is recommended to buy it for use as a structural material. It performs several functions:

- reduces the intensity of tensile loads;

- increases the resistance of low-rise construction projects to deformation;

- protects against cracks in surfaces.

The material is used in the construction of buildings made of brick, standard or hollow, aerated concrete, foam concrete. Made in various formats, it becomes an element of reinforcement and other structures, in particular, self-leveling floors, blind areas, and small architectural forms.

In brick buildings it solves another pressing problem - it prevents the mortar from falling inside the hollow building material, thereby preserving its high heat-insulating qualities.

Reinforcement of aerated concrete blocks - technology

When a material is selected, it is recommended to study the technology of its use. If you ignore this stage, you may, through your own fault, become disappointed in aerated concrete and the manufacturers who sell it so effectively. One of the important stages is the reinforcement of the gas block.

The essence of the work is as follows:

- Two strips of steel reinforcement (8.0) mm are glued into the external blocks. When increasing the thickness of the wall, you will need either more frequent reinforcement or an increase in the diameter of the rod;

- one tape is introduced into the partition blocks;

- I and every IV row are reinforced (every 100 cm). If the block height is 30-35 cm - every third row;

- the reinforcement is laid in oblique wall structures under mansard and sloping roofs and a row at the level of the mauerlat underneath them;

- The modules above which the lintels are mounted and those located under the window reinforcing belt are also reinforced.

Such manipulations help reduce potential cracking and neutralize low resistance to bending loads and fragility.

According to the technology, the reinforcement bars must be enveloped in an adhesive solution on all sides . For this purpose, grooves - grooves - 25x25 mm (width and depth) are made in the masonry of walls made of aerated concrete blocks. The distance from the outer and inner edges of the block should not be less than 60 mm . Wall chasers are used for work. Before filling, dust is removed from the recesses and they are moistened until they change color.

Excess glue during reinforcement is removed with a trowel or spatula - this is important, otherwise when laying the next row the master will not be able to get a thin seam, thereby worsening the thermal engineering of the structure

Implementation of work

Reinforcement of aerated concrete blocks is carried out after the grooves are ready, but before the glue is prepared. At this stage, the ends are joined, all corners are bent, while the laying is done overlapping, without getting into the joints of the modules. External walls are connected with partitions.

When all the work is completed, the fitted fittings are removed and you can begin preparing the adhesive solution. All grooves are filled with it (2/3 of the height), then the rods are recessed so as to be completely covered with the solution.

On walls with a thickness of 25 cm or more, a second row is installed , maintaining a 60 mm distance from the outer edge. If the thickness is below 20 cm, one rod (8.0 mm) is used, placed in the center. Anchoring is mandatory , otherwise there can be no question of structural integrity.

Reinforcement of door and window lintels

At this stage, U-shaped modules are used. The blocks on which the lintel will rest are reinforced by at least 90 cm in each direction (the figure may vary depending on the width of the opening). A supporting wooden structure is installed in the window opening on which the block will rest.

Sequencing:

- modules are laid with the thick side facing out;

- the groove is insulated, for which you can use 30-50 mm polystyrene foam boards;

- the side walls of the external blocks are closed;

- the frame is laid;

- the lintel is filled with concrete;

- when the material is mature, the wooden structure can be dismantled.

In an identical way, only around the entire perimeter, you can build an armored belt. As an alternative, you can use partition blocks, insulating them and exposing the formwork from the inside. The reinforced belt cannot be poured over the entire thickness of the wall - concrete is many times colder than blocks and this section will reduce all efforts to obtain an energy-efficient house to a minimum.

Rows of reinforcement are placed above and below the row of masonry in the plane of the floor, if the wall structure does not provide monolithic strapping belts, for example, as in prefabricated wooden floors.

The ends of the rods, which are not combined into a complete strapping circuit, are bent at an angle of 90 degrees and deepened into recesses for reliable anchoring in the wall.

In the presented technology, reinforcement mesh is never used when reinforcing external walls.

Recommendations for reinforcing sloping walls under attics

The master, working in this area, must take into account the following:

- when a light roof is being erected, it is optimal to implement row reinforcement of gas silicate blocks in two rods;

- for better load distribution, the pitch between the rafters should be reduced;

- for heavy roofing, it is recommended to provide an additional row of u-shaped blocks;

- this row is laid on already reinforced, oblique modules sawn at a given angle;

- Grooves are filled using thicker concrete than when working on horizontal surfaces.