Concrete drainage trays: pros and cons, types, technical characteristics, installation features

Concrete drainage trays are a structure of concrete gutters and channels that direct the flow of water into the city sewer system. If you properly build a drainage system, then when precipitation falls, there will be no puddles, dirt or dampness in the area. Concrete trays serve to extend the life of the surface next to them, so they are often placed along heating mains, streets, railways and highways.

A concrete drainage tray installed at the dacha promotes normal drainage of rain and melt water, which in turn improves the quality of the soil. Typically, concrete trays are installed during the construction of a residential building, highway or country house. In the future, they protect the foundations of buildings, basements or ground floors from soil erosion, thereby increasing the service life of the facility.

Advantages and disadvantages of concrete drainage trays

Modern concrete wells are made by vibration pressing. The essence of this method is as follows: concrete is poured under a press, and, thanks to the pressure of the press, excess moisture and bubbles are removed from the concrete. Vibrated concrete consists of cement and fine aggregate, which is reinforced with polymer fiber, steel rope or fiberglass. All reinforcement and embedded products are treated to prevent rust before installation. Thanks to this production method, concrete drainage trays have a number of positive qualities:

- resistance to dynamic loads;

- resistance to temperature changes and moisture;

- additional equipment of the trays with steel reinforcement makes them corresponding to load class F 900;

- The smooth surface of the tray does not trap debris.

Disadvantages of concrete drainage trays:

- the heavy weight of the trays makes their delivery and installation difficult;

- Despite the cheaper price than other options, concrete trays are expensive to transport.

There is also a second method for producing concrete trays, vibratory casting, but this method has a number of disadvantages, and the products are unable to withstand chemically aggressive substances and high humidity.

Technical characteristics of concrete for the manufacture of concrete drainage trays (according to GOST 26633–91, GOST 17608–91, GOST 13015.0−83).

Edge concrete drainage trays

They are used along roads and highways. The functioning and operation of roads depends on their performance. If the trays do not cope with their function, water will accumulate on the roads, which, when penetrating through the roadsides into the ground, will lead to cracks and swelling of the road surface.

Elimination of such defects is only possible with major repairs of the route, so the heterogeneity of the road surface increases the risk of accidents. Rainwater accumulated on the roadway causes the effect of aquaplaning, when a water wedge forms in the contact zone of car tires and the road surface, and the wheels of the car completely lose traction.

Characteristics of bait drainage trays

The most popular is tray B1−18−50. Tray B1−20−50 is an analogue of the first tray, only it has a greater height. They are installed at the junction of the roadway and the curb. Trays cannot be installed above or below the surface of the roadway. Water formed by precipitation rolls off the surface of the highway on both sides of the roadside, and if the trays are installed higher or lower, water will accumulate near them, which is unacceptable. Water flowing from the road into trays contains road dust, soil particles and chemicals from automobile fuel. In this regard, roadside trays should be cleaned weekly, or even more often.

To collect large amounts of water, trays B1−20−75 and B1−22−75 are used. They are installed on a cement concrete base using a leveling rod and a level template. The seams between the trays are filled with cement mortar, and the nodes between the trays and the road surface are coated with a special bitumen-rubber mastic. This must be done to prevent water from entering the layers of the road surface.

Concrete tray B2-22-40 is a quarter of a solid block B1-22-75. It is usually used at turns, where long trays are inconvenient to use.

Installation of bait water concrete blocks is carried out manually. First, the inner surface of the tray is cleaned and treated with a protective material, the same bitumen-rubber mastic. In this case, the bitumen emulsion must be in a cold state. After collecting all the trays, the surface is also treated with bitumen. Once the bitumen has dried and becomes black and smooth, the installation can be considered complete.

Telescopic trays

Telescopic trays are made of heavy concrete of class M-200 and M-300, so they are resistant to moisture and temperature changes. This is achievable through the use of polymer concrete, which prevents the destruction of the product under the influence of storm water (if there is no storm sewer) mixed with sand and chemically aggressive substances. Telescopic trays are reinforced with steel rod reinforcement treated against corrosion. They are mounted together with the stop blocks. For example, the B-6 telescopic tray is compatible with the B-9 stop block, and the B-7 tray is compatible with the B-9A stop block.

Telescopic trays are used in road and bridge construction, as well as in the arrangement of local areas. They are installed on slopes, slopes and embankments, and they serve to collect and drain rainfall. Thanks to telescopic trays, it is possible to dump accumulated water into a lower, specially designated place, thereby protecting the foundation of the building from possible destruction. In road construction, telescopic trays are used to create transverse drainage. Thanks to their easy and quick installation, they are very popular in the field of water drainage.

Characteristics of telescopic drainage trays series 3.503.1−66

Telescopic trays are installed only on reinforced road embankments. They are installed at a certain distance, as intended in the project. First, trenches are dug and leveled with an excavator. Then 10 cm of crushed stone is poured onto the bottom of the trench, which is also leveled and compacted. Stop blocks are placed using a crane, and all joints are filled with concrete. Using a crane, the first telescopic tray is placed on the rafter loops. All subsequent ones will be placed with the narrow end in the previous tray. The seams between the stop block and the tray are cemented.

For successful operation, in addition to the tray itself, you need to purchase special drainage grates. They protect trays from debris, and also ensure safety for vehicular traffic and pedestrians. Due to the fact that the grate can withstand a load of 1.5–90 tons, it is made of durable material, such as cast iron or galvanized steel. For a strong and reliable connection of the grille to the tray, anti-vandal fastenings are used.

Prices for bitumen-rubber masks

septik.guru

VII. MATERIAL AND TECHNICAL RESOURCES

A. Requirement of basic materials

| Name of materials | Unit | Quantity |

| Crushed stone | m3 | 1,1 |

| Blocks for inlet socket | PC. | 5 |

| Blocks for outlet socket | PC. | 6 |

| Telescopic tray blocks | PC. | 78 |

B. Machinery, equipment, inventory

| Name | Brand, GOST | Quantity |

| Excavator | E-4010 | 1 |

| Truck crane | K-61 | 1 |

| Four-line grip with hooks | — | 1 |

| Steel tape measure | — | 1 |

| Scrap | GOST 1405-65 | 1 |

| Hammer | — | 1 |

| Sledgehammer | GOST 11401-65 | 1 |

| Shovels | GOST 3620-63 | 3 |

| Bayonet shovels | — | 3 |

| Manual rammers | — | 2 |

| Compressor | ZIF 55 | 1 |

Concrete trays - installation, assembly options, monolithic structures

The most popular components of a linear drainage system are concrete gutters and trays. They are intended for blocking and draining rainwater during construction work in parking lots and highways. Concrete trays are also used for heating mains and other similar structures.

Drainage concrete products

What are they made of?

When starting to work on concrete trays, it is recommended to find out how this product was made. There are two main options:

| Vibration pressing | With this method of work, all elements are secured with steel cables, which are mounted in concrete. Such concrete trays can: · resist the effects of acidic and alkali metals; · are not subject to the harmful effects of road reagents. |

| Vibrocasting | This method is slightly different from the previous one. It has peculiar disadvantages, for example: · concrete trays are highly susceptible to moisture; · they are unstable to temperature changes and the influence of chemicals. When pouring, the material is pressed, due to which the raw material releases excess moisture and minimizes the occurrence of air bubbles. Working with concrete trays becomes possible only when fully equipped. |

A very important factor is the presence of special drainage grids, which provide:

- protection against the penetration of debris into the system;

- safety of pedestrians and vehicles.

Concrete cable trays with grating

They vary in:

- form;

- sizes;

- depth.

Advice: design calculations should be based on the estimated water pressure on the product.

According to the classification, products can be divided into:

- edge - used on roads, when servicing prefabricated water structures;

- telescopic - used for water outflow from roads under construction, tunnel bridges and in housing construction.

Concrete drainage trays with spherical internal shape

Installation

The asphalt concrete block is installed after the bulk layer has been erected over the pipe to the required parameters. This work must be carried out within temperature limits exceeding 0˚C. If the pipe diameter is less than 1.5 m, concrete trays must be assembled directly at the installation site or at the construction site before installing the pipes.

In the photo - installation of a reinforced concrete tray

If installation work is carried out at an air temperature below 0˚C, the instructions in this case recommend that work be carried out according to a special project. The total length of the product should not be greater than the length of a section of a similar indicator, which will make it possible to connect them with standard corrugated parts.

Assembly options

If the gutter or tray is constructed in conjunction with prefabricated units, the final production parts are installed directly on the job site. To do this, it is necessary to treat the surface inside the pipe until clean and fill it with a protective layer (rubber-bitumen mastic) in advance.

Laying any concrete block on a bitumen base is done by hand. The bitumen emulsion must be cold.

Tip: Use low blocks at the bolt connection points.

Stages of construction of monolithic concrete structures:

- Cleaning the pipe surface.

- Laying the tray.

- Compact concrete to the width of the tray.

The product is compacted using a metal vibrating screed for concrete. It is possible to use a vibrating platform with a cylindrical working surface, but the cost of the work will be higher.

Scheme of the device of a reinforced concrete tray

Working with concrete blocks involves laying them on a pre-treated base manually in the direction opposite to the supply of this product. If asphalt concrete trays are laid in pipes on a construction site, then they are installed simultaneously in two directions, from the middle to the sectional ends or pipes. A number of prefabricated parts of small height are mounted at the connecting points.

If you plan to install a prefabricated tray, then it is delivered to the construction site using specialized containers with shelves that are made of flat corrugated sheets. Upon completion of the installation work, it is treated with a specially prepared bitumen emulsion.

After its complete collapse, the installation of the prefabricated tray is considered finally completed. The surface of such material becomes black and completely smooth.

Monolithic structures

If installation of a monolithic concrete tray is being considered, work is carried out exclusively during its repair. The mixture is delivered to the pipes in an all-metal special container. Further transportation is carried out using the constructed deck.

Edge drainage trays

The last element of the tray should be prefabricated, which will make it possible to remove its individual parts from the pipe when laying the mixture. With this approach, work is performed in the direction opposite to the supply of the mixture.

Depending on the type of concrete trays used, the following equipment is required:

- concrete mixer;

- metal vibration screed;

- vibration platforms (with a working surface in the shape of a cylinder);

- nozzle;

- mobile bitumen plant;

- metal engines;

- brush;

- wooden rollers.

This design system also involves securing the riverbed and embankment slopes, taking into account the provided standards and requirements for the production process, when installing reinforced concrete culverts.

Conclusion

In this article, we learned that concrete rain gutters and other products of this type can be prefabricated and monolithic, and can also be made using vibrocompression (preferred) or vibrocasting. We talked about how to properly install and repair them. The video in this article will help you find additional information on this topic.

masterabetona.ru

VI. MAIN TECHNICAL AND ECONOMIC INDICATORS

| The name of indicators | Unit | According to schedule B | According to calculation A | By what percentage is the indicator according to the graph greater (+) or less (-) than according to the calculation? |

| Labor intensity for the entire scope of work | person-day | 7,9 | 10,15 | -22 |

| Average level of workers | 3,73 | 3,86 | -3,4 | |

| Average salary per worker | rub.-kop. | 6,33 | 4,92 | +28 |

Concrete drainage trays - what are they good for?

Currently, concrete drainage trays are used everywhere. Any construction, from a country house to the development of entire microdistricts, industrial enterprises and airfields, cannot be considered complete without a water drainage system.

Each reinforced concrete plant has a production line for such products. Reinforced concrete drainage trays are produced in different sizes and with different characteristics. Their price is reasonable, but this is not the only reason for their popularity.

Photo of a concrete tray.

Tray with grid.

Concrete has always been associated with capital construction. In this article we will look at the main types of these products, their classification and installation principles.

What is a tray

This part is perhaps the main component of a linear system designed for drainage and removal of groundwater, rain or melt water. The product is made in the form of a gutter, and trays connected in series form a system of channels directed to the sewer or sump. (See also the article Cover for a concrete ring: features.)

Let's consider the most popular materials used for the manufacture of linear drainage structures.

Polymer concrete gutter.

- The most common and popular is concrete. The drainage reinforced concrete tray has one of the highest characteristics. They are strong, reliable and durable.

- Polymer concrete drainage trays are already a product of high technology; they are much lighter than their reinforced concrete counterparts. These products have absorbed most of the positive qualities of concrete and plastic. But they have the highest price, plus they are less resistant to high temperatures.

- As for plastic products, their main advantages can be safely called low cost, ease and speed of assembly. Other technical characteristics are much lower than those of concrete products. In winter, they can be squeezed out of the ground; they cannot withstand harsh mechanical stress and temperature changes.

Plastic product.

Types and some technical characteristics of products

Drainage reinforced concrete trays are classified according to GOST 21509-85. This technical document regulates the requirements for both products installed in the ground and for gutters placed on piles. Plus, the dimensions and technical requirements for the trays are determined.

Load classification

The design of a linear drainage system closed with gratings in itself provides increased resistance to mechanical loads.

In order not to make a mistake with the model, the existing classification is given below.

Drainage at gas stations.

- A-15 - a concrete drainage tray of this brand is considered the weakest, the maximum load does not exceed 1.5 tons. It is used for pedestrian paths, parks and sports grounds.

- B-125 - has a maximum limit of 12.5 tons. Suitable for parking lots, garage cooperatives, and widely used in private construction.

- S-250 – can withstand a load of up to 25 tons. It is mounted on auxiliary roads, gas stations and car service centers.

- D-400 – have a tensile strength of 40 tons. They are widely used as drainage concrete road trays on intercity highways with high traffic intensity.

- E-600 - such a product can withstand a load of 60 tons. A concrete drainage tray 1000x500x500 mm is the most common in this class. It is used for arranging drainage systems in ports and industrial enterprises.

- F-900 - considered the most powerful and stable, can withstand a load of 90 tons. They are mounted at airfields or military bases with heavy equipment.

Important: in special conditions and under increased load, the instructions provide for the installation of concrete drainage trays using fasteners and covering meshes made of high-strength steel.

Types of products

Edge tide.

The configuration of the product can be U-shaped, trapezoidal and parabolic.

Depending on the purpose, products can be of several types.

- Edge drainage structures - this type of drainage structures is used to drain wastewater along the edge of the road in places bordering the sidewalk or blind area. They are designed to protect the road tightly from washing out.

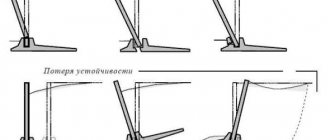

- Telescopic – designed for installation on slopes. They have the shape of a truncated cone, which makes it easy to assemble the gutter.

- Linear - the range of these gutters can easily be called the widest. Most often they are U-shaped and are intended for installation of a linear drainage or drainage system.

Gutters designed for heavy weight.

In addition, reinforced concrete drainage trays are divided according to the production method.

- The cheapest and most outdated method is vibration casting. Its essence lies in the fact that a solution is poured into a certain form and installed on a vibrating table. Thus, the concrete composition is compacted unevenly, mostly from the outside. The price is low, but the quality leaves much to be desired.

- Nowadays vibration pressing is more common. The concrete used here is of a higher quality; in addition to vibration, the composition is pressed under high pressure, as a result the quality of the product increases significantly.

Some installation rules

Warehouse of reinforced concrete trays.

- Installing concrete drainage trays is a responsible matter; if you do not have sufficient construction skills, we do not recommend installing them yourself.

- The throughput capacity of the tray is selected depending on the average precipitation in the area, plus 25%.

- The linear slope, per 1 linear meter, must be at least 10 mm.

- In most of our homeland, the soil freezes quite deeply. The concrete drainage channel itself has a fairly large mass, but to install it you still need to make a good blind area, since as a result of seasonal heaving of the soil, the gutter can be squeezed out to the surface.

- As in the case of the foundation, it is better to make the blind area complex. The depth of the bookmark should be at least 20 - 30 cm under the tray. The lower ball is filled with crushed stone, followed by sand; for gutters designed for heavy loads, a layer of liquid concrete can also be poured.

- A sand catcher must be installed at the outlet of the system; this is a trench of a similar configuration, but located below the installation line.

Product range.

Important: vibration-pressed gutters are quite strong and reinforced concrete is cut with diamond wheels to adjust the dimensions. To drain nearby soil, diamond drilling of holes in the concrete is used, from the sides and along the bottom of the tray.

The video in this article shows the principle of installing the system.

Conclusion

Concrete drainage trays have been used for a long time, and there is practically no cheaper replacement for them without compromising quality. The service life of such gutters reaches 50 – 70 years. They can withstand temperatures from +350º C to -50º C.

And most importantly, this material is considered completely environmentally friendly. The video in this article shows one method of cleaning gutters.

Installation on the sidewalk.

masterabetona.ru

Transportation Features

When ordering delivery of concrete trays, please note that the weight of one product can reach 50 kg. On average, concrete trays weigh about 23-30 kg.

Concrete drainage trays are sensitive to improper transportation. They may simply break or “crack”.

At our factory, we group the trays and bundle them in a special way. Delivery is carried out by our own trucks.

Installation of concrete trays

Concrete trays or concrete gutters are the most well-known component of a linear drainage system.

Concrete trays serve to drain melt and rain runoff. They come in several types, depending on the purpose and load.

They are used to drain and intercept rainwater from sites, highways, during the construction of parking lots, winter terraces and other structures of this type.

Components

The grid reliably protects the tray from blockages.

Before you begin constructing concrete trays, experts recommend finding out how to manufacture these products. During vibrocompression, each such element is strengthened using a steel rope, which is mounted inside a concrete tray.

Another method - vibration casting, unlike the first method, has some negative features. For example, concrete trays obtained in this way are easily exposed to moisture and do not withstand temperature fluctuations and chemically active substances.

concrete is poured under a press, then excess moisture is removed from the raw material, and the appearance of air bubbles is minimized. As for vibro-pressed concrete trays, such products are resistant to acids and alkali metals, and are also not subject to the negative influence of road reagents.

The construction of a concrete tray is carried out only when this product is fully equipped. The presence of special drainage gratings is no exception in this matter. Their task is to protect against debris from entering the system, while ensuring the safe movement of pedestrians and vehicles. Since the drainage grate bears the main load (within 1.5-90 tons), it is made of durable materials, for example, copper, cast iron, galvanized steel. The selection of this element is carried out taking into account the permissible load class. To ensure reliable fastening of the gratings to concrete gutters, experts recommend using appropriate anti-vandal fasteners.

Telescopic concrete trays are mainly installed on slopes and slopes.

The construction of concrete trays is carried out taking into account their different shapes, depths, sizes, including the expected water load in a given area. There is the following classification of concrete trays:

- edge - used for arranging prefabricated water structures on roads;

- telescopic – used for drainage of water during the construction of roads, bridges, roadside areas and in housing construction.

Installation highlights

The installation of an asphalt concrete tray should be carried out after the embankment has been erected above the pipe to the required level. When carrying out this work, the air temperature must be positive. If the diameter of the pipe used does not exceed 1.5 m, then the installation of concrete trays can be carried out at the site where the sections are collected or directly at the construction site before installing the pipe.

Diagram of the drainage tray.

If laying a concrete tray is carried out at sub-zero air temperatures, then experts recommend carrying out the work taking into account a special project. This document provides measures that ensure the performance of the tray material in accordance with established requirements.

VI. MAIN TECHNICAL AND ECONOMIC INDICATORS

| The name of indicators | Unit | According to calculation A | According to schedule B | By what percentage is the indicator according to the graph greater (+) or less (-) than according to the calculation? |

| Labor intensity for the entire scope of work | person-day | 10,55 | 8 | -24 |

| Average level of workers | — | 3,8 | 4 | +5 |

| Average salary per worker | rub.-kop. | 4-87 | 6-43 | +32 |

How much water has flowed, or the capacity of the drainage tray!

The determining factor when choosing trays, in addition to the material, are installation parameters and throughput. Plastic drainage trays, which are often installed on private estates, fully cope with the task and remove excess water from a large area, the main thing is to choose the right size. Remember that surface drainage is one of the important factors in landscaping.

Plastic and reinforced concrete drainage trays, the installation of which directly depends on the design parameters, contain such basic elements as gutters and covers in the form of grids of different shapes to give an aesthetic appearance. So, the throughput of the tray depends on the size of this very gutter, through which water flows rush to wells or other collection points.

In civil engineering, concrete and plastic products are most often used. When ordering the installation of a drainage tray, remember that the price of such a service is considerable, but it is carried out taking into account the long service life of the system, that is, for decades. Therefore, serious requirements are placed on the trays.