Where is bitumen used in construction?

There are three main stages where bitumen can be used:

- Foundation waterproofing;

- Roof covering;

- Asphalting roads.

For all its ordinariness, bitumen is not an ordinary material. It consists of resin, coal, oil and peat, and therefore has a specific black color. At high temperatures it softens greatly, which makes it universal for many applications. But more often, modern construction sites try not to use bitumen in construction. Perhaps this is due to ignorance of some of its features, or due to the fact that other materials were found. But it is worth noting that a material cheaper than bitumen has not yet been created.

Classification, types of bitumen

Liquid bitumen

Bitumen is an asphalt-like material, which is a mixture of various heteroorganic compounds with high molecular weight hydrocarbons.

The composition of bitumen mixtures determines their colloidal structure, technical and quality parameters, and operational properties.

Chemical additives are aimed at improving the performance of the material.

The characteristics of bitumen are determined by the ratio of its components: asphaltenes, resins, oils, mineral components.

The predominance of certain components in the biochemical composition increases strength and increases the softening temperature of mixtures.

Resins, oils, and organic substances increase the ease of melting, softness, and increase the plasticity of bitumen compositions. Different versions of liquid bitumen differ in terms of strength, degree of elasticity, and hardness.

Based on composition and scope of application, bitumen is classified into:

- natural (natural)

- construction (waterproofing, roofing)

- road, which is divided by density into viscous and liquid

- special purpose bitumen compounds

Depending on the raw materials used, bitumens are:

- peat

- coal

- petroleum (residual, oxidized, cracked, extract)

Based on the nature of origin, bitumen is classified into artificial and natural (natural). The composition of natural bitumen mixtures includes natural components, derivatives of oil, which are formed as a result of violation of the technology of conservation of its deposits under the influence of complex biochemical-oxidative processes.

Technical, artificial bitumen mixtures refer to products obtained during the purification of oils, during the processing of coal, oil, peat, coal, and organic resins.

Based on consistency, bitumen mixtures are classified into: highly plastic, plastic, viscous, liquid, brittle.

Liquid bitumen is a ready-to-use homogeneous mixture of black color, viscous consistency, which is obtained by mixing viscous BND bitumen with distillate fractions and solvents that evaporate after a certain period of time after installation. Liquid bitumen contains peat, petroleum products, organic compounds, resins, and mineral residues.

Why using bitumen may be useless

At a certain degree of heating, bitumen becomes a viscous and soft material. However, then, after it is applied to the desired surface, the oils from the bitumen composition evaporate, and the canvas hardens tightly. It will be impossible to peel off this layer, so when pouring and applying, jeweler's precision is required. The main reasons for refusing to use bitumen in construction can presumably be listed as follows:

- Requirement for high-quality and even laying of the canvas, without the possibility of subsequent correction of errors;

- Inattentive study of the specifics of this or that bitumen, which can melt at certain temperatures.

Therefore, before looking for shortcomings of the material, it is better to familiarize yourself with the features of its use.

Bitumen (from Latin bitumen - mountain tar, oil)

Bitumen is an amorphous substance, that is, in a solid state it exhibits the properties of a liquid. To prove this, in 1927, an employee of the University of Queensland, T. Parnell, placed bitumen in a funnel and waited for it to flow out. The experiment was a success: the first drop fell after 8 years, for which T. Parnell was awarded the Ig Nobel Prize.

Bitumen is the oldest construction and finishing material.

Ancient people knew about the properties of natural bitumen - “earth resin”, used to fasten the tips of ancient spears and make dishes waterproof, back in the Neolithic era. Bituminous utensils preceded earthenware.

Bitumen was used in construction to insulate wood, which was quite rare in Mesopotamia.

Natural bitumen was often used as a binder when creating mosaics from semi-precious stones and shells (Ur Standard, mosaic panel from al-Ubaid).

In the ancient world, the monopoly on natural bitumen originally belonged to Mesopotamia and constituted a significant part of its exports.

In Ancient Egypt, bitumen was used for embalming and mummification.

In Ancient Sumer this substance was called “esir”, the Akkadians called it “iddu”, the Arabs who lived in Iraq gave it many names: “sayali”, “zift” and “kar”.

Natural bitumen:

- viscous substance or solid material consisting of carbohydrate compounds and their derivatives,

- formed during natural oxidative processes of oil polymerization,

- common in oil fields.

Types of bitumen:

- pure natural bitumen is a rather rare substance,

- asphalt bitumen - found more often than natural bitumen, located in porous rocks,

- petroleum bitumen - obtained during oil refining.

Petroleum bitumen:

- these are solid or liquid water-insoluble organic materials, which are a mixture of hydrocarbons and their sulfur, oxygen and nitrogen derivatives;

- it contains asphaltenes, resins and oils;

- obtained from residues from tar petroleum distillation, cracking and oil refining.

Bitumen composition: carbon - up to 80%; hydrogen - up to 15%; sulfur - up to 9%; oxygen - no more than 5%; nitrogen - up to 2%.

The components of bitumen can be classified into 3 groups.

- The solid component is high molecular weight hydrocarbons - asphaltenes and paraffins,

- Resins are amorphous materials that are dark brown in color,

- Oil fractions are various hydrocarbons that have a density of less than 1.

An increase in asphaltenes in its mass will lead to an increase in hardness, brittleness and softening temperature.

Paraffins reduce the plasticity of bitumen, so during production attention is paid to reducing their content to 5% or less.

Scope of bitumen:

— road construction; roof installation; waterproofing; — production of electrical cables; rubber - technical products, - production of batteries; paint and varnish products; — metallurgy; production of coal briquettes; — oil refining.

BND-petroleum road bitumens are used in road construction (GOST 22245-90):

— For regions with temperatures below -20 ˚С, use BND 200/300, BND 130/200, BND 90/130, — for regions with temperatures in the range from -10 to -20 ˚С, use the above BND ІІ and ІІІ climatic road zones , as well as BND 60/90, - for regions with temperatures in the range from -5 to -10 ˚С - to the above are added BND 40/60, BN 90/130, BN 130/200, BN 200/300, - for regions with a temperature not lower than +5 ˚С - BND 40/60, BND 60/90, BND 90/130, BN 60/90, BN 90/130.

Housing construction. use petroleum bitumen GOST 6671-76:

- BN 70/30, BN 90/130, BN 50/50 - universal grades used in road and housing construction.

— Petroleum roofing materials GOST 9548-74 — BNK 90/30, BNK 40/180, BNK 45/190.

Important properties of bitumen are plasticity, softening point, fragility, flashing, viscosity, adhesive qualities.

Adding oils to the material helps increase plasticity.

Flash point according to GOST +200 ˚С and above.

Features of using bitumen

Depending on the place of use, different attitudes towards bitumen are required. The main directions of use and tips are:

- When applied to the roof, some modifiers must be added to the bitumen. Due to its natural composition, bitumen can be damaged by high temperatures or heavy hail, and added mastics will give the material strength and durability;

- When waterproofing a foundation, on the contrary, you do not need to add any other means to the bitumen. It is only important to ensure that every millimeter of the foundation is in contact with the bitumen layer;

- When laying asphalt, there is a lot of dissatisfaction with the use of bitumen. In its pure form it will not provide the required strength and durability, so it will also require the addition of plasticizers.

Many old building materials are becoming a thing of the past if they are replaced by better, more durable and cheaper analogues. But bitumen still has a strong position.

Bitumen for asphalt and roads

Bitumen and products created on its basis are one of the main materials used in modern road construction (up to 80% of the total mass of bitumen used is used for construction and road repair work). The product acts as a binder in asphalt concrete mixtures intended for laying and repairing road surfaces. The material acts as a binding component, reliably holding all components of asphalt concrete mixtures together, ensuring the strength and safety of asphalt. Moreover, it is much cheaper than concrete.

Improving the properties of road products is one of the main ways to improve the quality of asphalt concrete mixtures. Basically, by improving properties we mean introducing various additives in order to improve the adhesive properties of the material, resistance to temperature changes and overcoming the tendency to aging (drying out).

Description of material

Bitumen can be not so much natural substances of natural origin, but also artificial ones, which are extracted during the processing of petroleum products. As for natural ones, they are mostly distributed as separate formations or are mined by processing rock. In addition, these include tar resources, extracted by transforming fuel in solid rock using complex and high-tech equipment.

A small part of bitumen is extracted in almost finished form, although the main production method is based on the processing of heavy oil residues. When extracting fossil material, a complex physical impact is applied to the bituminous rock.

As a rule, a number of mastics or substances made from bituminous materials can be identified:

- Bitumen. These materials are from petroleum products or mixtures of petroleum or natural bitumen;

- Tar. Mostly consist of oils, mastics or pitches;

- Mixed bitumens. Products that are produced by exposing petroleum rocks to oxygen;

- Tar, bitumen-polymer. Alloys containing tar substances, polymers and petroleum bitumen.

Photo of construction bitumen

Areas of application and operating features

Bituminous substances and petroleum elements are widely used in construction and the production of building materials. As for tar products, their use is somewhat limited, since they are used for the manufacture of various chemical products.

Moreover, the tar substances themselves and the elements made with their use quickly lose their performance characteristics under the influence of various external natural factors, such as exposure to oxygen, sunlight or humidity.

Types of cold asphalt

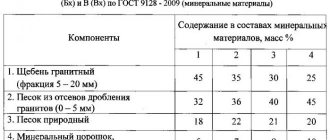

Like hot asphalt, cold asphalt is classified according to the mass fraction of crushed stone. If it is half or more, the coverage belongs to A-class. There are no cold mixtures category. Therefore, there is no abbreviation “Ah”. The last letter in it indicates the cold type of coating.

If the crushed stone content in the asphalt is from 40 to 50 percent, the coating belongs to class B. “B” is the designation for a mixture with 30-40 percent gravel. Next comes the marking “Gx”. This mixture contains up to 30 percent crushed stone. It's minimum.

However, there is also a D-class of the hero of the article. This is a mixture without gravel at all, but with a 70 percent content of sand and crushing screenings, that is, stone chips. Its abundance is the reason for the fragility of the hero of the article. Sandy asphalt is acceptable only in garden and park areas.

Also, asphalt grades are expressed in numbers. They reflect the full composition of the coating and its density. Class “3” includes only hot asphalt. It contains bitumen, crushing screenings, sand and mineral components.

Cold concrete is marked with the numbers “1” or “2”. The first indicates a mixture of sand, bitumen, crushed stone and mineral powder. The second class is placed on packages with a mixture of crushed screenings, crushed stone, sand, bitumen and mineral powder. Both options are porous.