Amplification methods

After an examination of the object, a suitable method of strengthening its reinforced concrete structures is selected. There are several such methods, and there is a conditional classification of them. They are traditional, innovative and combined.

Innovative methods

These are the most modern techniques and the most effective. Such methods of strengthening reinforced concrete structures include reinforcement with composite materials (usually carbon fiber), injection and reinforcement with prestressed ropes.

Let's talk about each method in more detail.

- Reinforcement with composites

is a technology that pays off when it significantly increases the load-bearing capacity of building structures. The method is quickly implemented by a team of professionals. It consists of gluing thin layers of carbon fiber to those structures that require reinforcement. The internal dimensions of the room remain unchanged, since carbon fiber is only a few millimeters thick. - Injection

means filling. The method is effective only when there are cracks or other cavities in the load-bearing elements of buildings. The resulting cracks cause fragmentation in the reinforced concrete structure. Injection can glue and unite these disparate areas together. If you need to strengthen the foundation, you can also make the soil monolithic. - Reinforcement with prestressed ropes

increases the strength characteristics of the structure, its rigidity and resistance to cracking. The meaning of the approach is that it uses stressed elements or ropes, but the stress in them has a sign opposite to the sign of the stress under the actual load. This technology is usually used to strengthen monolithic structures.

Traditional methods

This is a construction “classic”, the methods are old and proven. These include

- Concreting. This method consists of applying an additional layer of concrete. This increases the cross-sectional area, and therefore the strength of the entire structure.

- Reinforcement with rolled steel means, say, enclosing walls with steel ties, and surrounding holes with channels or corners and similar manipulations.

- Installation of additional load-bearing elements. An example is the spacers added when strengthening columns.

Combination of methods

The combination of traditional and advanced techniques is called a combined method. In some situations this approach should be taken.

How are structures reinforced with carbon fiber?

Strengthening building structures with carbon fiber is a method of strengthening structures that involves “sticking” carbon fiber sheets onto almost finished elements, allowing them to take part of the “pressure” to increase the overall endurance of structures.

In Russia, this method has been used not so long ago - about 20 years, but has already managed to win a huge number of fans among builders. How are structures reinforced using carbon fiber?

- First, all surfaces are prepared for strengthening. To do this, firstly, a primary marking is made on the strengthening zones, and secondly, it is completely cleared of any unnecessary objects, products or decor, in particular from other finishing materials to the main concrete wall. For this purpose, specialized machines and installations are most often used.

- After getting rid of unnecessary attributes, it is necessary to polish the concrete as much as possible, since the quality of the work done in the future and the maximum possibility of strengthening the load-bearing properties directly depend on this.

- At the third stage, all components necessary for repair work are prepared. First you need to remove the maximum amount of concrete dust from the previous step. Typically, carbon fibers are wound and packaged sheets that are spread out and cut to the required shape.

It is also necessary to prepare the “glue” with which the canvas will be glued to the concrete. As a rule, for such actions a two-component adhesive is used, which must be mixed only according to the manufacturer’s instructions.

- Direct installation of carbon fiber.

Installation work can be carried out in two types depending on the type of carbon fiber, so carefully read which fabric you use during construction.

Installation is carried out:

- dry method, in which adhesive is applied to the structure, then carbon fiber is applied, and at the end a layer of adhesive is applied again;

- the wet method, which involves applying a solution directly to the wall, as well as soaking the canvas in the solution, which is subsequently applied to the structure and glued with a roller.

It is important to remember that these operations require serious skills and dexterity, so it is better to turn to specialists!

We are experts in strengthening buildings

Strengthening reinforced concrete structures through combined and innovative methods is the specialty of REINFORCE. More than 40 projects related to strengthening using various methods were implemented by our specialists. They all have specialized education, they periodically undergo internships and improve their professional skills.

We approach each customer individually, carefully design the reinforcement in order to offer the most cost-effective and reliable implementation.

What is carbon concrete

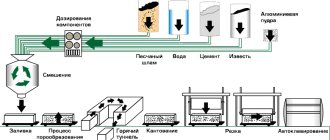

Initially, the idea of reinforcing concrete with carbon fiber came to the minds of scientists from the Institute of Monolithic Construction (Dresden). Previously, the production of carbon fiber-based composites had already been practiced: various parts of aircraft, gliders, cars, boats and even bicycles have long been made from such materials. However, replacing metal reinforcement with carbon fiber in concrete, creating a completely new material, has become an innovation in the construction market.

Strengthening reinforced concrete structures with carbon fiber

Coal concrete is a more “advanced” type of reinforced concrete. It contains built-in carbon threads woven into carbon fabric - a thin fabric that is produced on knitting and stitching machines. Each thread of carbon fiber is individually thinner than a human hair (its thickness is 5-10 microns). About 50 thousand of these threads form a kind of “rope”, and it becomes the basis of “textiles”.

Our guarantees

Only a company that is confident in the level of services gives serious guarantees. REINFORCE has such confidence, which is why we provide a guarantee of up to 5 years for all work performed.

3 carbon fiber reinforcement technologies practiced by REINFORCE

There are quite a lot of reinforcement options when using a composite material, namely carbon fiber. Which of the three types of amplification to choose is determined by the specifics of the task.

- Carbon fiber tapes with epoxy adhesive

are used in the case of extended objects, such as bridges and long spans. It’s not surprising, because the roll length reaches 250 linear meters. This is a material of high rigidity and excellent load-bearing capacity. - Carbon scrims with epoxy adhesive

are used to strengthen columns, beams, beams, slabs, openings, and other civil engineering elements. They can be given almost any shape due to the good flexibility of the material. - Carbon fiber mesh with cement binder.

Their areas of application are strengthening masonry, brick and stone, and reinforced concrete. Such meshes have fire-resistant qualities, high vapor permeability and, of course, excellent strength.

Carbon fiber reinforcement: advantages

Let us list the properties of carbon fiber plastic that make it the preferred material for reinforcement:

- High level of corrosion resistance;

- 6-10 times higher tensile strength than steel;

- Extremely high fatigue resistance;

- Carbon fiber plastic does not create additional load on the element to be reinforced, since it weighs only 230 g/m2. m.;

- This material does not change the internal geometry of the room, since the plate is only millimeter thick;

- Work with carbon fiber is carried out very quickly, since there is no need to build scaffolding, welding or any additional work, say, injection or caulking of gaps;

- The cost of performing the work is low;

- Versatility: this is a method suitable for the vast majority of building materials;

- Durability: This is a material with a design life of at least 50 years.

REINFORCING FLOORS

Floors are horizontal building structures that, as a rule, divide a building into floors and bear operational loads. In addition, floors often provide spatial rigidity to the building. During design and construction, mistakes are often made, as a result of which the load-bearing capacity is reduced. In some cases, unacceptable floor conditions arise, for example, with excess deflections or through cracks.

Reinforcement of floors is required in the following cases:

- During a major renovation of a building;

- When reconstructing a building;

- When the load-bearing load on the floors increases;

- In the presence of obvious defects in the floors (cracks, excessive deflections or stresses);

- In case of mechanical damage to the ceiling;

- Due to the natural aging of concrete and corrosion of reinforced concrete reinforcement.

Task

If you:

- Carry out major repairs to the building or its reconstruction

- Noticed cracks, deflections or other defects in the ceilings

- It so happened that during construction an error was made in reinforcement, anchoring, reinforcement spacing, etc.

It is necessary to conduct a survey of the floors to understand how these important elements are able to cope with their functions. If the result of the inspection is the identification of critical defects in the floors, they will need to be strengthened.

Solution

There are many technologies that can strengthen reinforced concrete floors and eliminate the risk of building destruction. Similar methods include:

- Increasing the section of the floor - that is, installing an additional reinforcing frame on the floor and applying a new layer of concrete;

- Installation of additional rigid supports under the ceiling.

- Installation of additional fittings.

All of the above methods of strengthening floor slabs share a number of significant disadvantages, the main of which are:

- Significant increase in load-bearing load on other building elements;

- A clear change in the internal geometry of the building;

- The need to stop the operation of the facility while the work is being carried out.

Fortunately, the modern construction market is able to offer a more progressive way of reinforcing floors with composite materials. The essence of the method is that carbon fiber is glued to the damaged floors in thin strips, the strength of which is several times greater than the strength of the same reinforced concrete: in particular, the tensile strength of carbon fiber is 3000 MPa, while the same indicator for class A500 reinforcement does not exceed 500 MPa . Carbon fiber reinforcement is possible for all types of floor slabs - monolithic, hollow-core and ribbed.

—>

Benefits of reinforcing floors with carbon fiber: comparison with traditional methods

| Advantages | Carbon fiber | Traditional methods |

| — Carbon fiber has high corrosion resistance; — The low weight of carbon fiber completely eliminates the occurrence of additional load on building elements — Carbon fiber plates are only 1 millimeter thick, so the internal geometry of the building remains unchanged; — The service life of carbon fiber is at least 50 years — The tensile strength of carbon fiber is at least 6 times higher compared to reinforced concrete — The work is carried out without additional equipment - you do not need to pay for the delivery and lifting of heavy structures — Carbon fiber reinforcement does not require expensive repairs of floors (for example, injection of cracks) — Reinforcement of floors with carbon fiber is carried out by a small team of workers; — Preservation of the object is not required. | — Relatively low cost of materials; — High strength, including fatigue. | |

| Flaws | — High cost of materials. | — Low corrosion resistance compared to carbon fiber; — Large weight, adding load to supporting structures; — High material costs for labor, delivery and installation of additional equipment; — The need for conservation of the object, since reinforcement with reinforced concrete requires the construction of scaffolding and complex installation of reinforcing structures. |

To verify the reliability of the technology for reinforcing floors with composites, watch the video of a beam test:

—>

– expert in the field of reinforcement of floors with carbon fiber

specializes in strengthening floors with composite materials. At the moment, we have successfully completed more than 30 similar projects and have impeccable experience in this field. By contacting SDT LLC, you can be sure that your problem will be solved by real professionals who are fluent in the technology of reinforcing floor slabs with carbon fiber.

Procedure for strengthening floors with carbon fiber

- Inspection of the ceiling, identification of places requiring reinforcement and calculation of the required loads;

- Creation of a floor reinforcement project;

- Approval of the final estimate;

- Cleaning the ceiling from all particles and dust (for better adhesion);

- If necessary: repair of the ceiling (sealing cracks and other defects);

- Gluing carbon fiber;

- Applying a sealing layer;

- If necessary: sprinkle the surface with quartz sand for better adhesion to finishing materials.

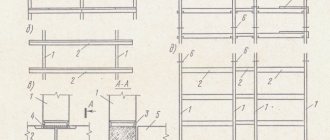

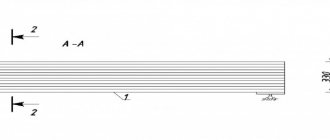

Possible schemes for reinforcing floors with carbon fiber

The scheme for reinforcing floors with carbon fiber depends on the type of damage and is determined by specialists of SDT LLC on an individual basis. Below, as an example, are the most typical floor reinforcement schemes developed by SDT LLC:

1. Increasing the stretched overlap area

2. Increasing the compressed and stretched overlap area

3. Changing the design scheme of the floor

4. Combination of increasing the cross-section with changing the design scheme

Prices, terms and guarantee

The cost of reinforcing floor slabs with carbon blank starts from 3,000 rubles per 1 square meter. The time frame for carrying out the work is short: to strengthen the floors with a total area of 500 square meters, SDT specialists will need only 14 days! After completion of the work, you will be provided with a 5-year guarantee - we are confident in the quality of our work!

To invite our specialist to the site and get more detailed advice, please contact us by phone:

+7.