Published: March 3, 2012 Category: Construction Views: 4388

Waterproofing the foundation with coating liquid bitumen-polymer mastic

Surface and groundwater cause invaluable damage to the foundation. In order for it to serve and hold the house for a long time, it must be reliably protected at the construction stage. Waterproofing is reliable protection of the foundation from moisture, which often becomes the main cause of destruction of building materials over time. The foundation of the house needs high-quality waterproofing. Moreover, reconstruction of the base of the building will cost much more than the money spent on waterproofing materials, and the work is much more complicated. It is necessary to isolate the foundation from moisture efficiently and for a long time.

Insulating the foundation of your home

Insulating the foundation of your home is a necessary construction process. By insulating the foundation, you can reduce heat loss at home by up to 20%.

Why do you need to insulate the foundation? At first glance, it would seem that the matter is completely useless, the foundation has been waterproofed, why else insulate it? Waterproofing protects the foundation of the house from moisture penetration. When the waterproofing is done, now we need to protect the foundation of the house from freezing temperatures. Such foundation protection or its absence negatively affects the aging of the foundation, that is, again, its durability.

By insulating the foundation, you will create a favorable microclimate in the basement of your home. If you have some premises planned for the basement floor, and heating will be installed, insulating the foundation will save you from such an unpleasant phenomenon as condensation on the walls. Everyone knows from a school physics course that when a cold surface is combined with warm air, moisture is released from the warm air and deposited on the cold surface, which is called condensation.

How to properly install a vapor barrier on a wooden floor

The vapor barrier is laid with an overlap on the walls.

A vapor barrier for the floor in a wooden house protects the insulation from steam entering it, if, of course, it (the insulation) needs it. Special protection should be in the bathroom, for example, when insulating the bathroom. Naturally, the floor in this place is filled with screed, which is quite possible with a finished wooden surface. Both polystyrene foam and high-density mineral wool can be placed under the screed. The density of stone wool can exceed 200 kg/m. cube, which is more than enough.

Let's figure out how to properly lay a vapor barrier on the floor in a wooden house under a screed:

- a diffusion membrane is laid on the subfloor with the advertising side facing down;

- then the insulation is laid;

- a vapor barrier material for the floor is placed on top of the insulation;

- damper tape is glued to the walls around the perimeter;

- reinforcement mesh is laid;

- the solution is poured.

In this case, laying a vapor barrier on the floor allows you to immediately solve two problems. The first one prevents the absorption of moisture from the solution until it hardens completely, and the second one protects against the ingress of steam during operation. Concrete has a porous structure, it has the ability to absorb moisture and conduct steam, of which there is more than enough in the bathroom. At the same time, everything that has leaked into the insulation can easily leave it through the diffusion membrane.

For insulation of ventilation air ducts, foil thermal insulation penofol is mainly used.

Here we describe the correct installation of jute on timber with your own hands.

Now let's look at how to lay a vapor barrier on the floor in residential premises. It is impractical to pour screed throughout the entire wooden house, if it is not a frame, so the finished floor is placed on beams (joists). Regardless of whether the house has a basement or not, insulation will be required in any case. The first step is to fill the subfloor. The bottom thermal insulation layer must be protected from moisture getting into it, and the insulation cannot be enclosed in an airtight cocoon. Therefore, you need to lay a diffusion membrane on top of the subfloor, smooth side down.

Insulation is laid on top of the membrane without any gaps. The thickness is calculated in each individual case separately. This depends on the region and the thermal conductivity of the insulating material you choose. If you take mineral wool, then in the middle climate zone the layer is at least 10 cm, then a vapor barrier is placed.

Further opinions on how to properly install a vapor barrier on the floor are divided:

- with an indentation between the film and the finished floor;

- without any space between the film and the finished floor.

Arguments against the gap are based on the fact that there will be no air circulation there anyway. Those who advocate a gap argue that even without ventilation, moisture will evaporate. At the same time, the finished wooden floor will always be dry, which will significantly extend its life.

Woolen felt for insulating doors should be covered with some moisture-resistant material, for example, a leather substitute.

The correct installation of inter-crown insulation on a log is detailed here.

Condensation on the walls

It would seem that waterproofing has been done on the foundation, everything should be in order with moisture, and again there it is, moisture. The consequences of condensation on the walls of the basement, that is, the foundation, are just as unfavorable as in the absence of waterproofing.

Condensation causes the plaster and finishing materials to peel off from the surface of the foundation walls; accordingly, tiles may fall off along with the plaster.

That is, it is clear that plaster is the basis of finishing. And its violation entails disruption of all finishing works. Plus, condensation leads to the development of fungal microorganisms and the appearance of mold on the walls. As you can see, the picture is not pleasant.

Types of waterproofing

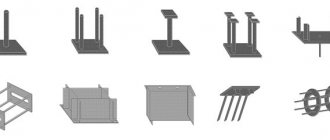

Waterproofing is needed for any type of foundation - pile, columnar, strip or slab, it does not matter, since any foundation material (metal, rubble stone, concrete) is exposed to melt and groundwater, which, in addition, can be aggressive.

To protect the foundation of a private house, choose one of the types of waterproofing that corresponds to the composition of groundwater and the foundation material:

- Coating.

- Pasting.

Coating waterproofing

The simplest material for waterproofing is coating with bitumen mastic, which is applied to a surface previously primed with a primer. This is an inexpensive and fairly effective composition, the reliability of which has been proven by a century-long history of use.

More modern and expensive materials - waterproofing mastics, plasters and deep penetration compounds are used in especially critical structures (dams, swimming pools) and for protection against aggressive groundwater. These materials include liquid rubber, compositions of the Penetrat and Vetonit brands.

Pasted waterproofing

Pasted waterproofing is carried out using rolled materials based on fiberglass or polyester fabric.

There are many brands of rolled waterproofing materials - hydroisol, isoplast, mostoplast bipolycrin, ecoplast, with which you can provide reliable protection of the foundation. These materials can be fused using a construction hair dryer or glued to surfaces using bitumen-containing mastics or special adhesives.

The latest materials for adhesive waterproofing are membranes reinforced with fiberglass.

There are several other types of waterproofing, for example, penetrating or injection, which are usually used in industry and for repairs.

Heat loss

Heat loss from a house through an uninsulated foundation accounts for about 20% of all building losses. If the basement floor does not provide heating, for example, if you have a garage there, then insulating the foundation will allow you to maintain a constant microclimate and a temperature of +5 - 10 ° C, even without heating.

Also, insulating the foundation allows you to reduce the impact of frost heaving of the soil on it in winter. For statistics, I will say that about 80% of the foundations of buildings and structures are affected by frost heaving of the soil, taking into account the characteristics of the climate of the middle zone.

Waterproofing device

Whatever type of waterproofing is chosen, 50% of successful work is the correct preparation of the foundation. Before treatment, the surface must be leveled, cleaned of traces of solution, dirt, oils, and washed. Leveling the surface is especially necessary when protecting the foundation with rolled materials, so as not to accidentally damage them.

Before applying coating bitumen, or pasting with bitumen-containing roll materials, the surface is dried and primed with a primer - a solution of bitumen in kerosene, to increase adhesion. The composition is applied with a brush or roller, carefully covering all the seams between foundation blocks or rubble stones.

Before applying the plaster compositions, the cleaned surface is primed with a special adhesive mastic. You can work with the compositions as with a regular plaster mortar for thin-layer plaster - using a trowel and a float.

If roll waterproofing is chosen, and the monolithic strip foundation turns out to be uneven, the surface will have to be leveled with cement-sand plaster over a chain-link mesh. The mesh is rolled out over the surface of the foundation, fixed with dowels, then the plaster composition is applied. Before gluing the waterproofing, the plaster must dry for 3-4 weeks, then it is primed with a primer and proceed to gluing or fusing the roll material.

The work is carried out from the bottom up, with an overlap of panels of 150 mm, carefully gluing the seams and smoothing the fabric over the surface, avoiding air bubbles. Upon completion of the work, the foundation is covered with soil, drainage and blind area are performed.

Drainage

To prevent the accumulation of rain and melt water near the foundation, it is important to perform drainage that removes moisture into the storm sewer system. For this purpose, below the blind area along the perimeter of the building, a layer of sand and gravel mixture 200 mm thick is poured over a layer of geotextile or rolled waterproofing material, then drainage pipes pre-wrapped with geotextile are laid with a slope of 2–3% towards the drain, and a drainage to the storm sewer is carried out. The drainage system is filled with sand and gravel mixture, a blind area is made, which is also included in the foundation waterproofing system.

What to make foundation insulation from

Considering the extreme environment in which the insulation will be located, this is the influence of groundwater, storm water, melt water in the soil, as well as the influence of soil heaving, the material must be resistant to the perception of moisture and physical impact. Today, extruded polystyrene, which looks like polystyrene foam, is used for such work.

This material can be found in different colors, but usually orange or yellow, and can have different names, since each manufacturer gives its own name, and there are a lot of manufacturers of this material, both well-known manufacturers of construction brands and little-known ones. Of course, this material is designed specifically for these purposes. And foundation insulation made of extruded polystyrene is an ideal option for thermal insulation.

But I want to say that as an alternative to extruded polystyrene, ordinary polystyrene foam, which is popularly called fine-grained, is also used for foundation insulation work. It has a high compression ratio and is very well suited for such purposes in terms of technical characteristics.

Types of vapor barrier materials

The construction market is overflowing with types of vapor barriers. It can be either liquid or in rolls. Each material has its own purpose and composition. Some are used for walls outside the house, others only indoors.

We suggest you familiarize yourself with: Foil insulation for walls, how to attach foil insulation to a wall, characteristics of the material

Mastic

The mastic has a bitumen-polymer base. It is applied to the surface, creating a layer that protects from moisture and allows the rough base to “breathe.” The mastic is applied to clean, dry walls made of various components (wood, brick, concrete) with a brush in 2 layers. The second time bitumen is applied to the dried first layer.

Membranes

There is a large selection of membrane materials on the construction market. They have the following properties:

- laying on the outside of the insulation. The membrane protects the outer wall from precipitation and winds. Siding and lining are installed on top;

- For vapor barrier for walls inside the house, Megaizol V is used - a polypropylene film in 2 layers with an anti-condensation surface. The film protects the walls from the appearance of dew points, which leads to the development of fungus and dampness;

- Izospan FD, FS, FX – reflective surfaces used in bathrooms, baths, saunas.

When choosing a wide range of membranes, you need to pay attention to what purposes they are intended for - for the street, a bathhouse or vapor barrier inside the house.

For vapor barrier, a film with a thickness of less than 0.1 mm is used. It is the most used of all listed. It has no perforation and does not allow air to pass through. However, recently breathable films have been produced.

Vapor barrier film is applicable due to solutions to such problems:

- Micro-ventilation of walls and insulation occurs.

- The condensate collected when the outside temperature changes is partially removed.

- In saunas and baths, where there is high humidity and high temperature, which other vapor barriers cannot withstand.

The vapor barrier film does not allow small drops of water to pass through, but at the same time “breathes”, which allows you to solve problems.

Liquid rubber

This material is sold in the form of a bitumen-polymer liquid product. After application, a “rubber” covering appears on the surface, which follows all the recesses on the wall. The rubber surface prevents moisture from penetrating and provides hydro-thermal insulation protection.

Types of liquid rubber:

- Emulsion – applied by machine. Applicable on floors for vapor barrier.

- Emulsion applied to the floor manually.

Liquid rubber is also applicable to protect the foundation from the street side.

In some places it can be difficult to put down a protective cover. Where the roof and ventilation pipe are connected, a pipeline wrap is created and secured with tape; drywall seam tape can be used.

In the gaps near the hatch or attic window, you need to use a special apron.

The product should also be secured using tape. The window openings near the ceiling are closed so that a deformation fold of 20 mm remains. This is done in order to prevent precipitation.

Equipping a vapor barrier system in your home requires a responsible approach.

Steam has the highest permeability. To prevent it from leaking into particularly important places, the room must be provided with excellent protection against vapor permeability.

By properly insulating all surfaces inside the structure, it will be possible to live quietly in the house for a long time, without worrying about its previous destruction.

You can find many different materials on the market designed for this purpose. To understand which one is better to choose, it is worth studying the main types on sale.

You can find many different materials on the market designed for this purpose.

Membranes

The vapor barrier membrane for walls includes polypropylene as the main material, with fiberglass mesh, which increases reliability. It also has a coating of cellulose-viscose fabric, it can be covered on both sides, or only on one; this fabric provides vapor and moisture insulation. Rough matter creates a barrier that prevents moisture from penetrating the wall and insulating element. This moisture then simply evaporates during natural ventilation.

Due to its multi-layer nature, the membrane “breathes”. By stopping moisture, the material allows a small amount of air to pass inside, which prevents the formation of greenhouses, the surface will “breathe” and can last for many years.

Rough matter creates a barrier that prevents moisture from penetrating the wall and insulating element.

Film

There are several types of film protection. The first polyethylene films are distinguished by the fact that they are reinforced with fabric or reinforcing mesh. What makes the product more reliable. They also have their own subspecies:

- Perforated, in which there are mini-holes that make them vapor permeable. But they do not perform this function well enough to obtain the necessary effect in the frame pie; they make a gap;

- Non-perforated, they are mounted using tapes created to fasten the canvases.

Polypropylene film materials have been used for a long time. The main positive properties are strength and resistance to UV rays. There is an anti-condensation layer that does a really good job of absorbing moisture.

The main positive properties are strength and resistance to UV rays.

Mastic

The coating vapor barrier for walls is mastic, it is easy to work with. They are a solution; before use, it is stirred and applied to the surface to be treated; it is suitable for working with smooth surfaces; it can be used to process joints and seams. After drying, the coating becomes vapor permeable.

Suitable for working with smooth surfaces, you can process joints and seams.

Liquid rubber

Liquid rubber is becoming popular today; it is a bitumen-polymer mixture based on water. It is very easy to work with and spreads easily on the surface. The coating appears after complete drying and takes on the appearance of rubber, which monolithically covers the surface.

We invite you to familiarize yourself with: Expanded clay as wall insulation

The types of this product can be distinguished:

- A composition that can only be applied using an automated method.

- Composition for manual application.

It is very easy to work with and spreads easily on the surface.

It is also necessary to mention this type of product, such as films laminated with aluminum foil, which also do an excellent job of vapor and waterproofing, but they can only be used in bathhouses and swimming pools.

Foil can only be used in baths and swimming pools.

When choosing a material, you should pay attention to several important criteria, including the following:

- Vapor permeability, the ability to absorb moisture and let air pass through is one of the most important factors; it is measured in g/m2 per day;

- Life time. Cheap materials can tear very quickly; membranes made of non-woven artificial fibers show the best indicator of this criterion;

- Difficult to install. When choosing, you should find out how the material is attached (what kind of overlap is made, and what tapes are needed); it must be attached tightly to the insulation, or leave a gap;

- Price. Products for this purpose are sold in rolls. In a store, they usually pay attention only to the price, but do not take into account that rolls come in different sizes; in order to sensibly assess the cost, you need to compare these two factors and calculate the real price.

The ability to absorb moisture and allow air to pass through is one of the most important factors.

Insulation of the foundation, installation of thermal insulation

Foundation insulation slabs are installed using bitumen-polymer mastics. Let's say that it simply sticks to the surface of the waterproofing. If the waterproofing is done by coating or pasting, then there is no need to carry out preliminary preparatory work; the surface is almost ready for thermal insulation work.

Insulation boards can be secured to the adhesive waterproofing by melting the outer layer of insulation and gluing the board. You need to melt 5 - 8 points per plate.

If the waterproofing is penetrating, then the insulation boards can be mounted using a special glue designed for gluing insulation during thermal insulation work on building facades. This glue is not expensive.

Thermal insulation boards can also be glued to mastic, but for this you will need to first prime the surface of the foundation with bitumen-based soil.

Thermal insulation slabs are attached to the above-ground (basement) part of the foundation using quick-installation dowels, 5-8 pieces per slab.

Have a successful and error-free construction.

Waterproofing

The best basis for waterproofing has always been considered liquid bitumen, which is applied with a roller to the entire surface of the foundation. Its disadvantages: it takes a long time to melt, hardens quickly without constant heating, it emits harmful fumes when applied (therefore it is advisable to use a mask or respirator), and you also have to come to terms with the fact that it will take a very long time to wash off after such work (by the way, it does an excellent job with this acetone). Therefore, many people categorically do not accept this method of waterproofing and recommend using TechnoNIKOL sheets, gluing it with a gas torch. But such waterproofing cannot be achieved with bitumen with TechnoNIKOL. Its only advantage is ease of installation. But in the end, it will still have to be applied over bitumen. So, by limiting yourself to only gluing Technonikol, you will miss the most important step - filling all the pores and small cracks on the surface, which is what is actually achieved when performing waterproofing.

You can buy bitumen in bars, then you need to melt it. An excellent option for this is a 200-litre metal barrel, pre-installed on several bricks. It is necessary to add any used oil to the barrel in advance at the rate of 50 liters of waste oil per 130-150 kg. bitumen The oil is suitable for both diesel and gasoline engines. The essence of adding mining is to give the bitumen plastic properties after application to the surface. In ordinary language, so that the bitumen does not crack from frost and other weather conditions. It should be applied with a roller to all underground sides of the foundation. And from the outside - also above the surface of the earth.

When the bitumen has been applied, proceed to gluing the Technonikol. As already mentioned, using a torch. We glue the sheets from top to bottom, constantly smoothing them and releasing the formed air under them. Important note: do not hold the burner close to the sheets! The best distance is 20-25 cm, otherwise they will melt. After completing work with TechnoNIKOL, coat the joints of the sheets with mastic.

When waterproofing is completed, you can begin thermal insulation.