What is stamped concrete

Many countries in the world with developed infrastructure prefer to equip sidewalks with decorative or printed concrete. Using this type of concrete laying, you can give absolutely any look to the product:

- Paving stone shape.

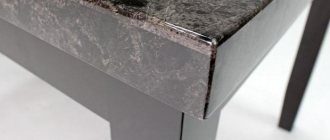

- Polished wood look.

- Granite stone

On top of that, this type of road surface fits perfectly with any architectural design and will appeal to every connoisseur of beauty.

This method of concrete processing is very popular among builders because of its resistance to changes in temperature conditions. And the strength is much higher in comparison with traditional coatings - asphalt and tiles. Also, the recipe for the production of printed concrete implies complete environmental safety.

The raw materials used to create decorative printed concrete are:

- cement mortar (M350, M400);

- cold water (for dilution);

- equal amount of sand;

- plasticizer;

- fiber divided into fibers;

- sealed varnish for protection;

- separation components and natural dyes.

How to make a path in the yard from art concrete with your own hands: production technology

Decorative concrete in private construction is often used to design garden paths.

It is not difficult to prepare the mixture yourself, but in order to achieve the necessary strength and beautiful appearance, it is important to follow the working technology.

Site preparation

First you need to clear the required area - remove stones, branches and other elements. After this, mark the filling area, marking the perimeter with pegs. Dig the soil to a depth of 20 cm, install formwork and reinforcement cage. Then start preparing the cement mortar. Find out about finishing one-component putty for cars in this article.

Decorative concrete hardens quickly, so stamping should not be delayed.

Hardeners

Upon completion of pouring hydroconcrete or ordinary concrete, wait for the water to evaporate from the surface, apply the hardener in powder form in an even layer. It allows you to make the path more even and smooth; it is recommended to use a special ironing device for processing corners.

Coloring pigments

The distributive coloring component gives the necessary shade and enhances strength. It can be purchased in powder or solution form. Apply it with a flat brush over the entire surface, and upon completion of the work, treat the corners with textured skins.

Stamping cement surface

Before proceeding to this stage, you should make sure that the concrete has become plastic - you can check the consistency of the material with your hands. To apply an imprint, place a metal stamp on the surface using physical force (for example, by stepping on it).

The texture is added within 24 hours.

Elimination of defects

Residues of the cement mixture may remain in the corners and at the joints of the dies. Rub the frozen solution with medium sandpaper, and then roll it with a thick roller.

Flushing and spreading sealant

After a day, rinse the frozen surface with a stream of water - this allows you to remove excess dirt. At the final stage of work, apply a sealant that protects the path from wear and penetration of aggressive substances into the pores. To distribute the product evenly, use a roller and go through the corners with a brush.

Additionally, it is recommended to treat the surface with weak hydrochloric acid, which helps to open up the voids in the material.

Laying stamped concrete

In a simplified version, the technology of printed concrete includes the following steps:

- First, you need to prepare the base for future laying (the process cannot be distinguished from preparing the base for laying ordinary concrete).

- Then you need to prepare a mixture of sand and cement, at the rate of 1/3. It must be mixed in a concrete mixer; reinforcing fiber is added at the end.

- Plasticizers are added at the rate of 1 kg. per 1 m3 of the resulting concrete solution.

- The plasticizer significantly reduces the water level when mixing concrete, which subsequently eliminates the possibility of pores appearing in the poured product.

- The technology for preparing concrete is completed by laying the mixture on a previously prepared site, after which it is leveled (you can watch a detailed video of the process on the Internet).

- Immediately after leveling is completed, you need to add dye at the rate of 2 kg. per 1m2.

- After 4-5 hours of drying, the surface is ready to be given the desired shape. Anti-caking agents must first be applied to the workspace after the stamped concrete molds have been installed.

- The very final touch after installing and carefully removing the printing forms will be to wash in the release components after the printed concrete has dried.

Ordering from “Philosophy of Stone” is reliable

“Philosophy of Stone” is the author’s designer finishing of architectural surfaces at a reasonable cost and in a reasonable time. You have good reasons to cooperate with us:

- turnkey work from the stages of measuring and delivery of material to delivery of the finished designer finishing;

- working with proven manufacturers of quality materials;

- more than 500 satisfied clients in Russia, the CIS and Europe;

- working with objects of any complexity;

- 9 years on the market.

Our other services

- Paving stone renovation

You will need to repair facades or paths made of printed concrete no earlier than after 20 years. And when this time passes, just call us again: after the update, everything will shine like new and will last for at least another 20 years.

- Finishing fences

- Cladding of columns

- Cladding retaining walls

- Production of an individual logo, pattern or coat of arms

We can also imprint your logo on the concrete. You can choose a print design from those already available in the catalog or order a unique one that only you will have. This could be your family coat of arms, your initials, or any symbols. Such an image will remain for centuries.

If you have any questions or would like to order printed concrete, please contact us by phone or leave a request in the form at the top of this page.

Assistive technology

This business idea involves investing in the purchase of equipment and initial raw materials. But you need to buy raw materials only after using special equipment:

- concrete mixer. It can be absolutely anything, the average cost is 22,000 – 25,000 rubles;

- press forms to give a decorative look to concrete. 1 form on average costs about 10,000 rubles. And for organic work you will need at least 15 of them;

- additional tools. To purchase the necessary tools you will need 50 thousand rubles. The price will include the purchase of tampers, beating cords, die cutters, extension handles, edgers, etc.

In total, the initial start will cost about 220-25 thousand rubles.

Preparatory work before pouring the floor screed with poured concrete

Of course, pouring a repair screed over a defective one is permissible only if the defective screed is filled with a cement-based mortar. If you suspect that the screed was made with gypsum mortar, you need to conduct a test pour on a small area of the floor or submit a sample of the old screed for examination.

If the old screed meets the required conditions, then you need to carefully seal the cracks, cut out the swinging fragments or, if they are too large, fix them with anchors to the real floor. Place a dividing tape around the perimeter of the premises, and prime the surface of the old screed with deep penetration soil, after vacuuming it with a professional vacuum cleaner.

Before setting the beacon guides, you need to measure all the rooms with a laser level, determining the highest point. In relation to it, you also need to set the guides under the laser (or optical in the case of a large open room) level. The beacons need to be grabbed with piles of solution. Guides can be removable or non-removable. As removable beacons, you can use ordinary smooth pipes with a diameter of at least 20 mm. The distance between them should correspond to the length of the rule minus 30 cm.

Environmentally friendly product

When creating decorative concrete, only inert materials made from mineral substances are used. The price of printed concrete is not so high, which allows this product to be used everywhere. The advantage is that this type of road surface can be recycled in the future.

Photos on the Internet are not always able to convey the durability and aesthetic beauty that printed concrete is endowed with. But reviews about it say that this product is durable, pleasing to the eye and is widely used in all areas - from covering car parks to paths in the courtyard of a house.

Advantages of the method

The technology for creating a decorative surface on concrete has many positive aspects, the main ones being:

If the technology and recipe are followed when performing all activities, then negative aspects when using the printing method are excluded.

Let us consider in more detail the features of the technology of decorative stamping of concrete.

Stamping is carried out directly on the cement mortar applied to the surface, due to which the lifespan of the decor is significantly increased.

Profit calculation

It all depends on the complexity of the work and the client’s wishes, but on average prices range from 1,200 rubles per 1 m2. As statistics from some companies show, the average price for one order is from 50 thousand rubles. The main clients are owners of country cottages, governmental and non-governmental organizations who express wishes to decorate city roads and sidewalks. Also, many modern restaurants and amusement parks resort to the use of decorative printed concrete.

By promoting the services of his company, the owner can create a portfolio of completed work and make photographic reports. You can also add reviews from satisfied customers and receive guaranteed profits.

The company can provide services not limited to the territory of one city. Covering roads with printed concrete is gaining popularity in all CIS countries. When a large order appears, you can offer your services abroad.

The cost of laying the coating

| Name\Area | Up to 50 m2 | Up to 100 m2 | Up to 200 m2 | Up to 1000 m2 | From 1000 m2 |

| Approximate cost of work, rub. | 990 | 950 | 790 | 700 | 600 |

| Approximate cost of materials, rub. | 2 100 | 1 900 | 1 790 | 1 700 | 1 600 |

| Total cost in rubles. | 3 000 | 2 850 | 2 580 | 2 400 | 2 200 |

At the same time, the cost of a concrete pad does not depend on the selected texture. The price of work and materials is indicated approximately; for a detailed calculation, please contact us at one of the above contacts.

The cost of work includes:

- acceptance of concrete;

- reinforcement (reinforced mesh);

- laying concrete;

- stamping (all consumables: hardener, separator and sealer);

- cutting seams.

Required Documentation

When creating a business, you need to remember that everything must be done legally. You can open either a small individual entrepreneur or an LLC, and the second option is a little more profitable. The tax system should be in the simplified tax system format. You don’t need permission documents, but it is advisable to acquire certificates to trust potential clients.

When opening a business producing printed concrete, you need to be prepared for some difficulties, including the problem of finding and training personnel, as well as advertising the company. But after all the difficulties are over, the profit will quickly cover the investment.

Types of stamps

Creation of printed impressions on concrete is made using a variety of stamps made from the following materials:

- light aluminum alloy cast in a special shape. The stamp allows you to imitate patterns on stone and brickwork;

- flexible polyurethane, a stamp from which is cast on natural materials in order to accurately replicate the original texture.

The degree of relief depends on the rigidity of the shape. The higher the density of the matrix, the easier it is to reproduce a high-quality print using it. When using elastic forms, difficulties arise in the work due to the need to apply significant effort during the stamping process.

Today, molds are cast from polyurethane directly onto the surfaces of materials whose texture needs to be conveyed.