The increased interest in laminate flooring is due to obvious reasons. Consumers are attracted by practicality, decorative qualities, the ability to eliminate defects during operation, and economical installation options (if you do it yourself). Laminate flooring creates a cozy atmosphere thanks to various color schemes and increases the functionality of the room. Sound insulation creates acoustic comfort. Thanks to thermal insulation, a laminate floor remains warm and pleasant to the touch even in the cold season.

Laying laminate on linoleum

Speaking about the economic component, it is worth paying attention to the wide range of prices. The market provides a wide selection for various characteristics.

An important factor is the ability to lay laminate flooring without dismantling the old material. This avoids additional costs. If you take into account all of the above and choose the right laminate for the original coating, the service life of the material can be significantly increased.

A popular finishing floor covering is linoleum.

What are the opinions of experts on installing laminate over it? Is this option suitable for all rooms? How to choose the optimal combination of laminate and linoleum? How is installation done?

Sometimes laminate can be laid directly on top of linoleum

You will find answers to these and other questions in this article.

Different points of view on the problem

Often people decide to do repairs themselves using the most economical options. Therefore, the opportunity to lay laminate on top of linoleum is very attractive. This issue is discussed on many forums and websites.

Let's turn to the basics, that is, the requirements when laying laminate flooring. The base floor must meet the following characteristics: be level, clean and dry.

If the floor covered with linoleum meets the above indicators, installation is possible.

Some comments put forward a number of positive aspects of this use of linoleum:

- performs a substrate layer: evens out small defects in height, increases the elasticity of the coating;

- increases sound insulation;

- saves money.

Interesting! Linoleum, which is laid on a laminate, can serve as a substrate.

However, it is worth studying the problem comprehensively.

Large manufacturers operating in the laminate flooring market do not consider linoleum as a potential base layer.

Savings on dismantling the coating can result in further costs during operation:

- You cannot leave linoleum that has defects: cuts, unevenness;

- the original canvas must be properly connected to the base;

- the base floor (as a surface) must be level.

If the linoleum has some defects, you should not lay laminate on it

Linoleum and any underlay, even the highest quality, will not be able to compensate for differences in the floor. According to building codes, the height differences on linoleum should not exceed 2-3 mm. Over time, the coating will deform, creaking will appear, and possibly defects in individual plates where the joint between them is broken.

If you take linoleum as a basis, you need to prepare it well. To do this, it is not enough to “estimate by eye.” It's worth taking advice from professionals to ensure you have the right starting point for your renovation.

What you need to pay attention to:

- the height of the linoleum should not exceed 3 mm;

- minimum lamella thickness - 8 mm;

- an important characteristic is the density of the material (affects the durability of use);

- It is worth carefully comparing the manufacturer’s recommendations and the initial data of the room being repaired.

The linoleum under the laminate should not be too thick, maximum 3 mm

Particular attention must be paid to the rigidity of linoleum. Soft types of coverings are not suitable for installing laminate flooring.

Don't forget that the floor is part of the overall space of the room. Incorrect thickness (increase) of the floor covering can lead to blocking of doors. A special case is when removing the base floor can significantly lower its level.

To achieve durability, sound and heat insulation, and evenness of the floor covering, installation conditions must be observed. One of them is multi-layer styling.

The floor should not be too thick - in this case, problems with opening/closing doors may arise

Traditionally, these are two layers - an underlay on top of the base floor, then the laminate itself. If you leave a layer of linoleum, the composition becomes more complicated. The service life will now depend on the quality of the linoleum. It can increase the duration of use or negate all the efforts invested.

In fact, linoleum must meet the requirements for laminate substrates.

Thus, to the question “Is it possible to leave linoleum under laminate?” cannot be answered unambiguously.

Whether it is possible to put laminate on linoleum depends on the condition of the underlying floor covering, its thickness, quality

The quality of linoleum will affect the service life of the laminate. Worn material cannot be used as a base.

And even an outwardly well-preserved coating is not the main sign of subsequent long-term use. The construction products industry is developing dynamically. Therefore, linoleum produced 15-20 years ago is considered not only physically, but also “morally” obsolete.

Interesting! During this period, the manufacturing technology of products, the quality of the materials included in its composition, and the characteristics of accompanying elements (glue, for example) have changed.

The higher the “age” of linoleum, the greater the danger of its contamination by pathogenic bacteria and fungi.

The “older” the linoleum, the higher the risk of developing fungus and mold, so it is better not to leave the old material

The material has a service life, after which it can release toxic substances, violating the environmental standards of the living space.

Thus, dismantling linoleum should be done if there is severe deformation of the main covering. Experts recommend thoroughly sanding the concrete base. The ideal option is to produce a polymer screed.

If the shelf life of linoleum has not expired and the coating meets all requirements and standards, it can be used as a base for laminate flooring.

If the linoleum is in satisfactory condition, you can lay laminate on top

Is it safe to put linoleum on old laminate flooring?

Experts generally advise dismantling the old flooring to install a new one. In the case of laminate, it’s worth thinking about it. The old material is an excellent sound, noise and heat insulating base. An important plus: do not forget that the original newly made substrate will be able to perform the function of shock absorption and leveling the base of the floor for laying linoleum.

How to disassemble laminated planks?

What kind of premises are suitable?

The functional purpose of the room is the first thing that needs to be taken into account when decorating the walls and floors. Parameters that influence the choice of material for repair:

- air humidity;

- temperature changes;

- load on the floor, resistance to abrasion (number of people, frequent or rare movements of furniture).

So, in which rooms is it advisable to simplify the installation of laminate flooring by skipping the dismantling of linoleum? This is a living room, bedroom, children's room, perhaps a hallway.

You should not experiment in the bathroom, toilet, or kitchen. Unfavorable factors will negatively affect the flooring. The floor may deform and creak. If necessary, experts advise strengthening the waterproofing by laying a double layer of polyethylene under the substrate.

You should not lay laminate over linoleum in the bathroom or kitchen, as there is a high risk of deformation of the floor covering

You need to know that the moisture resistance of linoleum is much lower than that of laminate. And if you lay new material on top of linoleum damaged by moisture, the longevity of the repair may be in question.

Experts suggest conducting a simple test to determine the suitability of the previously used coating. Seal the oilcloth onto the floor area. Check the result after a few days. Even a few drops of condensation in the area being tested will indicate the unsuitability of linoleum. Work will have to begin with dismantling. Otherwise, the accumulation of moisture will lead to deformation of the coating, unevenness and swelling will appear.

Main stages of work and instructions

New material can only be laid in compliance with technology. All actions are performed step by step and in stages. Among the main stages are:

- foundation preparation and measurements;

- purchasing the required amount of material;

- laying the substrate.

The underlay and laminate are used simultaneously. First, a substrate is placed along the entire row, after which the laminate is placed on it. The installation itself is performed as follows:

- Individual lamellas are connected into a whole row, after which this row is pressed against the wall. You should retreat 5-10 mm from the wall (this distance is required so that the boards can expand when humidity changes).

- After this, the second row is assembled and connected to the first.

- Then all actions are repeated. The technological gap is ensured by special wedges. After installation they are removed.

During the work, it will be necessary to carry out various types of cuts and adjust individual lamellas. The boards must be laid in a checkerboard pattern. After connecting the first 3 rows, the process becomes much easier.

Which laminate class is suitable?

There are several different classifications of laminate flooring. The lamella (a plate of building material) consists of several layers. The degree of abrasion resistance of a product depends on the thickness and strength of the top layer.

There are two options for producing the top layer. For direct pressing laminate, it consists of a decorative layer with a protective coating and is pressed immediately with the base and bottom layer.

It is very important to choose the right laminate

For high pressure laminate, the top layer includes kraft cardboard, a decorative layer and protection. It is pressed separately and is more stable. However, this does not mean that direct pressing laminate is not suitable for use. Traditionally, it is used for domestic premises.

In Europe, a classification of laminate flooring is used based on:

- abrasion;

- impact resistance;

- moisture resistance;

- soundproofing.

Based on the above parameters, two types are distinguished.

| View | Description |

| For domestic use | Digital code - 2. Includes classes 21-22-23. |

| For commercial use | Digital code - 3. Includes classes 31-32-33-34. |

There are two types of laminate - household and commercial

There is also laminate of classes 41, 42, 43. They are characterized by maximum strength.

Wear resistance is coded separately. Letter code AC in the range from 3 to 6.

The laminate class must be selected in accordance with the functional load of the room.

The resistance of the material to abrasion and mechanical stress increases in classes from 31 to 34.

For example, if laminate is required to finish the floor in a bedroom, you can choose products of class 31. Materials with codes 33 and 34 are designed for maximum load in public places with a large flow of people. Accordingly, the cost of production increases along with the class.

The stronger the laminate, the higher its class

Among building materials experts, a correlation is accepted between the resistance class and the moisture resistance of the material.

However, large manufacturers provide their products with detailed descriptions of characteristics and recommendations for use.

When choosing the right material, you need to understand exactly what parameters are most important to the buyer. The high price of laminate may be due to some exclusive quality.

Interesting! A large selection of products allows you to make a purchase that is justified in terms of price and required characteristics.

You should not purchase the cheapest possible laminate, because... it can wear out quickly - literally in a couple of years

The basis for high-quality installation and long-term operation of the floor covering is a flat base floor. The permissible difference is 2-3 mm. Thanks to the different thickness of the lamella and the properties of the substrate, it is possible to “even out” the base for the laminate.

How to determine the evenness of a floor? Builders resort to a proven and accurate tool - a laser level. However, this tool is expensive and is available in the arsenal of professionals.

For one-time use, you can use more affordable options: building level, strip, ruler.

An even simpler way is to stretch a cord from one wall to another. The resulting line shows the places of irregularities, bulges, and differences. It is quite easy to get readings using a hydraulic level.

Laminate flooring should only be laid on a flat floor, and this can be checked using a building level

Preparatory stage

Before proceeding with the installation of the coating, it is necessary to prepare for the work.

The purchased laminate must “acclimatize” to the room in which it will be installed. Permissible changes that will occur in the material must occur before installation. Otherwise, the entire coating will deform. Typically, a period of 3-4 days is considered sufficient.

When choosing a product, you must carefully check the uniformity of the pattern and shades of the lamella. Related products, tools, and protective clothing are purchased in advance.

Installation of such flooring requires a thoughtful approach. At first glance, the technique is accessible even to those who are not involved in professional finishing work. But in the process, problems arise related to unevenness of the floor, inconsistency of purchased materials, and calculations. In most cases, the optimal solution is to entrust the preparation and installation to a professional.

Even if you have no experience, you can lay laminate flooring yourself, but you need to take into account the peculiarities of the technology

Installation rules

Laying laminate flooring is not difficult if you have the skills. It is recommended to follow the following rules to obtain a strong and durable coating:

- The thickness of the laminate should be such that the laid covering does not interfere with the opening of doors leading from one room to another, to the kitchen, bathroom and other rooms of the cottage or apartment.

- Installation should begin after the laminated board has been in the room for several days. During this time it will reach room temperature and humidity.

- After laying the first layer of material, special wedges are used to secure the panels. This will prevent them from moving and make it possible to quickly lay the remaining material.

- Each new row can be started from a cut piece, which makes it possible to create a unique pattern and save material. To cut laminate, use a fine-toothed saw or jigsaw, or you can use a power tool.

Selecting a substrate

The backing layer or base is intended for better installation of the laminate. It is laid between the base floor and the lamella.

Performs the following functions:

- moisture insulation;

- ensuring static coverage;

- the role of the damper;

- thermal insulation;

- soundproofing.

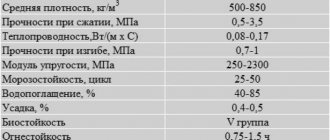

When choosing products, you need to pay attention to the following parameters:

- material of manufacture;

- plate or roll thickness;

- density;

- environmental friendliness;

- resistance to fungus and mold;

- fire resistance, release of toxic products during combustion.

It is worth laying a substrate under the laminate. If there is linoleum underneath, you don’t have to do this

Modern production offers a substrate made of natural and synthetic materials. Each product has its pros and cons.

Among natural materials, cork is the most popular. The range includes products made from cork tree bark, as well as combined compositions with the addition of bitumen and rubber. The latter increase the moisture resistance of the product.

One of the latest positions on the flooring market is coniferous underlayment. It is made of pressed pine needles, wood fiber and wood, bonded with thermoactive synthetic resin.

Natural materials are environmentally friendly, have the ability to level the floor, maintain shock absorption, acoustic comfort, wear resistance, and the ability to retain heat.

You can put a backing made of cork, pressed pine needles

There are also disadvantages. The coniferous substrate absorbs odors, and the cork coating can form swelling when installing too heavy stationary furniture.

Popular synthetic materials: foamed polypropylene, extruded polystyrene foam.

The manufacturing technique is based on “filling” the base with gas.

The substrate is distinguished by its ability to level out differences of up to 4 mm, excellent waterproofing, and resistance to fungi and mold. This material does not biodegrade.

However, the service life is often limited to 6-7 years. Over time, the gas bubbles burst. The thickness of the substrate loses its uniformity, density, and is pressed through, which affects the floor covering.

Extruded polystyrene foam supports combustion and releases substances that are toxic to humans.

You can also choose an extruded polystyrene foam backing

One of the advantages of synthetic substrates is the cost-effectiveness of the investment.

Interesting! Most experts are inclined to believe that the substrate is a mandatory composite layer when installing laminate flooring. There is no clear answer to the question whether linoleum can replace the substrate. Its solution must be approached individually.

Significant nuances

There are a number of subtleties of laying laminate on linoleum:

- only relatively new material is suitable for this; if it has already been used for more than 10 years, it is recommended to replace it with a new substrate so that the laminate can perform its functions for a long time without deformation;

- it is permissible to install a laminated board only on linoleum glued to the floor, otherwise, after some time, changes may appear on the floor, which will lead to problems;

- the floor material on which the panels will be laid must be intact, without significant damage, abrasion, cuts, or cracks.

If necessary, you can restore the linoleum. To do this, the damaged part of the material is cut out, and a new piece of the same shape is glued in its place using the cold welding method. It is also possible to use hot welding, during which the linoleum is melted using heating elements. The resulting seams are rubbed down to form a smooth surface on which the laminate will be mounted.

Required Tools

Installation of laminate consists of several stages. Each of them requires certain tools and protective clothing. For example, when preparing the floor you will need not only overalls, but also safety glasses, gloves, and a respirator.

A general set for working with flooring includes:

- tools for marking: ruler, square, tape measure, marker, pencil;

- for cutting material: sharp knife (shoe knife, stationery knife);

- for fixation: engineering tape or masking adhesive tape;

- hammer with a regular or rubber striker;

- hacksaw;

- electric tools (electric saw, electric jigsaw, electric drill), extension cord.

To install the laminate you need to prepare tools

To install laminate you will additionally need:

- tamping block having a special profile;

- factory-made installation wedges, which differ in the required thickness, expansion angle and special notches;

- to prevent the formation of cracks and gaps - brackets and clamps for laminate flooring;

- for perfect formation of panels - a laminate knife.

In specialized stores you can purchase a kit for laying laminate flooring. It contains the necessary tools and consumables.

Features of laying laminate

The laminate lamella is a multilayer structure. Each layer has its own purpose. The basis is wood board. Its characteristics determine the quality of the product. The top layers are responsible for the decorative component and resistance to wear and mechanical deformation. The lower layers are responsible for repelling moisture and sound insulation. The purpose of the substrate and base floor was discussed earlier.

Usually laminate is fixed using locking joints

The structure of the laminate tiles determines the stages of installation of the floor covering.

Basic principles of laying laminate:

- the subfloor must be level (the maximum permissible difference is no more than 2 mm for every 2 m);

- the base layer should not allow moisture to pass through and should be dry initially;

- under conditions of low temperatures, the possibility of freezing of the floor requires additional thermal insulation;

- for installation on the “old” coating, you can use a flexible adhesive-based laminate;

- traditionally the plates are fixed using locking connections;

- the use of glue for the “floating” installation method increases the waterproofing effect;

- the “warm floor” system requires selection of the type of laminate;

- When working with a foil substrate, you should remember to insulate the wires passing nearby.

Answers to many questions can be found in the manufacturer's recommendations.

How to prepare the base for laying laminate flooring

Is it possible to lay laminate on top of the old flooring?

Basically, old linings must be dismantled.

But if they comply with building regulations and follow the manufacturer’s rules, such a base will serve as an excellent substrate with the ability to dampen sound resonance, as well as as a shock-absorbing and leveling layer. Having thermal insulating qualities, linoleum allows you to reduce heat loss. For the first floors of apartments located on the floors of foundations and basements, this quality is an important advantage.

In what cases is paving updated:

- the desire of the owner of the new apartment to change the floor finish;

- high-quality laid linoleum has become outdated over time, a change in interior style is needed;

- savings in installation work when laying laminate flooring.

The advantages of this double coating:

- economical consumption of building materials and working time;

- change of style in the interior of the room;

- Strengthening;

- increase in service life;

- improvement of thermal insulation.

Only floorboards laid according to the rules recommended by the manufacturer, without violations of the technological process, can ensure a long service life of the coating. Illiterate installation will lead to deformation of the locking systems, the formation of cracks, penetration of moisture and dirt. The quality of these works depends on the condition of the foundation.

Features of installing laminate flooring on old flooring

Laying laminate flooring on linoleum has its own characteristics. Exact adherence to technology is a guarantee of long-term operation of laminate flooring.

During installation, it is necessary to carefully align the butt seams. Experts believe that it is necessary to start laying the lamella from the window in a perpendicular direction. This optical effect has long been used in finishing work - light from the window makes the seams “invisible”.

The joints between rooms can be masked with special thresholds. Installing the door frame before installing the laminate can make the job difficult. In this case, a small cut is made at the bottom of the box for the panel. The gap will allow you to give the connection more flexibility and avoid further deformation of the entire coating.

It is better to install the door frame after laying the laminate on the linoleum

The same point should be provided for walls. The flooring begins with two boards of the first row. It is impossible to imagine a room in which the temperature, humidity and lighting do not change. The deformation gap in relation to the wall should be up to 10 mm. Then the connection of the slabs will be able to “walk” without deformation of the entire coating.

Special spacer wedges will help you set the ideal gap. Their thickness, expansion angle and the presence of special notches are important. You can purchase ready-made wedges at a hardware store.

The end joints of laminated panels in adjacent rows must be laid with a gap of up to 300 mm. The pressure on individual plates or their moistening will be evenly distributed over the entire flooring.

There should be a gap of 10 mm between the wall and the floor covering, which will be covered with a plinth

The first row ends with a trim of the panel, which is called “short”. You can use it to start the next row. But first, you need to measure it - the cut panel should be more than 5 cm long.

Interesting! It is more convenient to install laminate flooring using the “lock on itself” method.

In the second row, the angle of application of the boards to the adjacent panel should be 45°.

A clamp is used to tamp the outer laminated boards located near the walls. Its thickness must be at least 5 mm. The wide end is applied to the end part of the lamella to provide the necessary clearance. To work, you will need a hammer, which is used to hit the narrow end of the tool.

During installation, it may be necessary to cut out the laminate around the pipe. The tool required for this is an electric jigsaw (can be replaced with an electric drill with a special attachment). Do not forget about the deformation gap, which is decorated with a plastic overlay.

For pipes in the laminate you need to cut a hole

An important part of laying laminate flooring is the installation of a plinth, which serves a decorative purpose and prevents the penetration of moisture and debris into the deformation gap. An additional bonus is baseboards with channels for wires (telephone, electrical) and cables.

Stages of laying laminate on linoleum

The answer to the question of whether it is possible to put laminate flooring on linoleum is quite simple. Of course you can. However, for this you need to know the main features of this process and follow all stages of implementation. Laying laminate over linoleum is done in 4 steps:

- purchase of material and the period of its “acclimatization”;

- preparing the base for installation;

- installation of the substrate;

- laying the material.

Even at the stage of purchasing the material, you should carefully inspect the laminate for matching colors, textures and patterns. After delivering the panels from the store, you should store them for some time in the room where the laminate will be installed. This must be done so that the laminate gets used to temperature conditions and humidity. Next, you need to prepare the grounds. Old linoleum must be thoroughly inspected for defects. It must be securely attached to the floor, without swelling or cracks. If there are any holes, they can be sealed with linoleum of the same type. In order to find out the moisture level of old linoleum, you can use plastic film by spreading it on the floor. The humidity level will be normal if no condensation droplets appear on it after a few days. After the surface has been prepared, a substrate needs to be made on top of the old material, which will help preserve the material from damage.

Deservedly the best substrate is cork substrate. This is due to a number of properties that this material has. The cork backing is very elastic, thanks to which it does not lose its shape even under heavy loads. The substrate must be made with a thickness of at least 2 - 3 millimeters. If you skip the stage of laying the substrate, this can lead to the formation of cracks on the new laminate, or more precisely, on its seams.

The process of installing laminate flooring on linoleum is not very different from the process of standard installation of this material. Work should be carried out from the first row with two boards. When laying between the material and the wall, a small indentation should be made, at a distance of approximately 10 millimeters. Thanks to this, the coating will have free movement, which is necessary when the material swells. If such a gap is not left, there is a possibility that the laminate will swell. Installation of this material is carried out using the “lock on itself” system. Thanks to this technology, its installation is quite simple and does not take much time.

An important point: it is necessary to “bandage” the laminate. To evenly distribute the load on the floor surface, it is necessary to leave a gap of more than thirty centimeters between the joints of adjacent rows. To install the final row of laminate flooring, you will need clamps.

In order to make the seams between the laminate panels invisible, it should be positioned so that the light from a lamp or daylight falls along the panel.

Rules for the use and care of laminate flooring

Any material comes with care rules that increase its service life.

Basic requirements for caring for laminate flooring:

- For household products, dry cleaning is preferable;

- wet cleaning is carried out no more than once a week;

- To treat the coating, use specialized cleaning products, soft brushes and rags to remove stains;

- the products differ depending on the type of laminate (matte, glossy);

- in the absence of severe dirt or stains, you can use warm water (40-50°C), which must be changed frequently;

When cleaning laminate flooring, use a barely damp cloth. - furniture legs should be equipped with protective protectors made of felt, Teflon or cork;

- Teflon self-adhesive overlays will not only protect the laminate, but will also allow you to move furniture without effort;

- laminate is “afraid” of sharp objects (falling cutlery, scissors, heels);

- The main enemy of laminate flooring when cleaning is strong moisture;

- For wet cleaning, a soft mop is suitable;

- The ideal option is to use a water-wash vacuum cleaner with a special soft non-scratch nozzle or a steam cleaner.

You can use a steam cleaner to clean laminate flooring

To prevent life in your home from turning into a nightmare, consider where the risk of damage to the coating is highest. Additional protection for the hallway, for example, can be provided by laying a special rug.

How to properly care for laminate flooring

Reviews

Many interesting details can be gleaned from reading user reviews.

Nikita, Moscow:

“The renovation was designed for a small budget. I consulted and decided to save money on removing linoleum. I installed it myself 2 years ago. The floor is fairly level, but not perfect. Therefore, I purchased polyethylene foam for the laminate as a backing. A year and a half has passed, there are no defects or deformations, no rattles when moving.”

Victor, Kaliningrad:

“Much depends on the initial condition of the floor. We laid the laminate according to all the rules, with a backing, on linoleum. After a few months, we noticed deformation in the joint area. I started checking the floor level and found there was a big difference. I shouldn’t have hoped that the substrate and linoleum would level it.”

Many people lay laminate directly on linoleum, and they are satisfied with the result

Evgenia, Kazan:

“They decided to revive the condition of the floor with laminate. Before this, a thorough renovation was done, with a screed. Therefore, they did not remove the linoleum. No problems have arisen in 2 years. I take care of the coating according to all the rules, I don’t moisturize it too much. I clean with a soft mop.”

Rustem, Orel:

“I didn’t bother removing the linoleum. I invested minimally and did everything myself. The laminate was laid on isolon. We've been using it for a year now, no complaints. I advise you not to look for unnecessary problems.”

Svetlana, Krasnodar:

“They left old linoleum on the floor. The floor was previously leveled to almost perfect condition. Therefore, we decided not to take the substrate. After 5-6 months the coating began to creak. They called a repairman and said that the waterproofing was insufficient. Linoleum cannot completely replace the substrate.”

Remember that linoleum cannot replace the substrate in all cases

Laying linoleum on laminated flooring

Laminate flooring is popular, but can be boring or disappointing. For example, the coating in the kitchen with constant exposure to moisture warps and loses its original appearance. It is necessary to lay other material that meets the necessary requirements. Experts advise paying attention to linoleum. Moreover, lay it without dismantling the old laminated covering.

Laying linoleum on laminate

Important! A distinctive feature of linoleum is its ease of installation; the owner does without the help of specialists. In order not to damage the purchased flooring, it is recommended to apply the requirements for the work.