Recently, an increasing number of new products have appeared on the building materials market, which a non-professional cannot understand. One of these new technologies is the use of fiberglass reinforcement. Manufacturers position their product as reinforcement that has many advantages over conventional steel rods, but is this true?

What is composite reinforcement and its types

Composite materials are a whole group of reinforcing bars that differ in the type of raw material. The composite got its name due to the fact that it contains several elements. The first is fibers from various types of raw materials, the second is a thermosetting or thermoplastic polymer (resin). After the binder hardens, strong rods are obtained.

Depending on the origin of the fibers, several types of reinforcement are distinguished:

- fiberglass;

- basalt-composite;

- carbon composite;

- aramidocomposite;

- combined, consisting mainly of one type of fiber, but having inclusions along the entire length of another type.

The most common use of fiberglass reinforcement, which will be discussed further. The structure of fiberglass reinforcement is similar to the structure of wood. In the same way, fibers are located along the rod, which, due to the binder, form a single whole.

Is fiberglass (composite) reinforcement suitable for a strip foundation – Piles Mania

Fiberglass reinforcement, which is used to strengthen the foundation, belongs to the category of new building materials that are superior to previous ones in many characteristics. Most consumers do not yet know whether it can be used to reinforce aerated concrete walls or to strengthen the foundation. This article will provide answers to these and many other questions.

The use of fiberglass reinforcement in slab foundations

What is fiberglass reinforcement

Reinforcement, for the production of which fiberglass materials are used, was developed quite a long time ago, back in the 1960s.

However, due to its high cost, it was used only in harsh climates, where conventional steel reinforcement structures, susceptible to corrosion, could not last long.

The reinforcement, which was made from fiberglass materials, was used mainly to strengthen bridge supports and other equally important structures operated in fairly harsh climatic conditions.

Over time, the development of the chemical industry has contributed to a significant reduction in the cost of fiberglass reinforcement. This made it an affordable material that performs well in building structures for various purposes.

The active use of this type of reinforcement led to the fact that in 2012, experts developed and approved GOST 31938-2012, the provisions of which stipulate not only the requirements for the production of this material, but also its testing methods.

You can familiarize yourself with the GOST requirements for polymer reinforcement by downloading the document in pdf format from the link below. GOST 31938-2012 Composite polymer reinforcement for reinforcing concrete structures. General technical conditions Download

The surface of fiberglass reinforcement can be corrugated, smooth or sprinkled

In accordance with the state standard, fiberglass reinforcement is produced in the diameter range of 4–32 mm. However, the most common diameters for products of this type are 6.8 and 10 mm. Such fiberglass reinforcement products are supplied to the customer in coils.

This standard, in addition to the requirements for the diameter and other geometric parameters of fiberglass reinforcement, specifies what the condition of its outer surface should be. So, on the surface of the reinforcement there should be no chips, delaminations, as well as dents and other defects.

Main characteristics and main disadvantage

Based on the type of continuous reinforcing filler used, composite products are divided into the following categories:

- ASK – glass composite;

- AUK – carbon composite;

- ACC – combined;

- other.

If it is necessary to use fiberglass reinforcement to strengthen the foundation of a house, the following characteristics should be taken into account. Upper temperature limit during operation

The lower limit of this parameter for glass-composite reinforcement products starts at 60 degrees Celsius.

Tensile strength

This parameter is characterized by the ratio of the applied force to the cross-sectional area of the product. For ASK it should be 800 MPa or more, for AUK - at least 1400 MPa.

Tensile modulus

According to this indicator, fittings of the AUK category are more than 2.5 times superior to ASK.

Compressive strength

This indicator for fiberglass reinforcement of all categories must exceed 300 MPa.

Shear strength

For ASK this parameter should be more than 150 MPa, for AUK - 350 MPa or more.

Advantages of fiberglass reinforcement

Reinforcement made of polymer materials has a significant drawback: it has very low fracture strength. Due to this drawback, the scope of use of this fittings is limited. Manufacturers of such products must indicate the scope of their application, and if the consumer goes beyond the specified scope, he does so at his own peril and risk.

The use of reinforcement of this type is justified only in cases where increased demands are placed on the thermal conductivity, corrosion resistance and dielectric characteristics of reinforcing structures.

Comparison with metal fittings

Fiberglass fittings, when compared with metal ones, have the following advantages.

- Reinforcement products of this type are characterized by high corrosion resistance: they are not afraid of both acidic and alkaline environments.

- Fiberglass reinforcement is made from polymer materials, so it is distinguished from metal products by very low thermal conductivity. Thanks to this, when used to reinforce foundations and other building structures, there are no cold bridges, which is especially important for our climatic conditions.

- This fittings, made of dielectric, do not conduct electric current and also do not generate radio interference.

- The specific gravity of fiberglass reinforcement is 8–10 times less when compared with its metal counterparts.

- The cost of metal and fiberglass products for reinforcing building structures is almost the same, but using fiberglass reinforcement is much more convenient.

- In terms of tensile strength, which for similar steel products is 400 MPa, fiberglass reinforcement is two to three times superior to metal rods.

- Fiberglass reinforcement is produced in rods 100–150 meters long, which makes it possible to install reinforcing structures practically without seams. Experts know that the joints of metal reinforcement are the weakest points of reinforcing frames. When strengthening foundations and other building structures using fiberglass products, there are no such weak points in the reinforcing frame.

- The advantage of using fiberglass reinforcement is that the consumer can purchase exactly as much product as he needs without paying for unexpected waste.

- To install and lay the reinforcement frame, which is made of fiberglass elements, there is no need to use a welding machine or other specialized equipment.

- Fiberglass reinforcement is much more convenient to transport, since it can be supplied to the customer both in rods and in coils, which can easily fit even into the trunk of a car.

- When foundations and other concrete structures are reinforced with fiberglass, cracks do not occur in the latter, which is explained by the fact that fiberglass and concrete have similar thermal expansion coefficients.

Areas of application

Reinforcement made from fiberglass is used in both residential and industrial construction. The popularity of this material, used for reinforcing foundations and other concrete structures, has recently been gaining momentum.

Considering the above advantages of fiberglass reinforcement, we can draw conclusions about where it is better to use this innovative material, and where you can resort to the most traditional and time-tested options.

For example, very common areas of use of reinforcement made from fiberglass are bank protection, as well as reinforcement of road surfaces in areas where it is exposed to aggressive environmental factors.

Fiberglass reinforcement is often used in the construction of bridges and overpasses

In cottage construction, reinforcement made of fiberglass is also widely used. In particular, such products are used for reinforcement:

- concrete structures acting as fencing (it should be borne in mind that fiberglass products cannot be used to reinforce load-bearing structures and floors);

- strip and other types of foundations;

- masonry made from aerated concrete and foam concrete blocks.

Composite reinforcement is also used in the construction of walls using permanent formwork technology.

Many experts agree that when using fiberglass reinforcement for laying gas and foam concrete blocks, it is better to reinforce the corners using steel products. With such combined reinforcement, building structures will have higher strength, stability and reliability.

Strengthening foundation structures

When used to reinforce strip and other types of fiberglass foundations, rods with a diameter of 8 mm are used, which is equivalent to the use of 12 mm steel reinforcement.

Calculations for replacing steel reinforcement with fiberglass

It is not difficult to carry out the procedure for such reinforcement with your own hands, if you adhere to the following algorithm.

- When installing the formwork, it is recommended to wrap its elements with parchment, which will allow them to be reused.

- On the inside of the formwork elements, using a horizontal level, mark the line up to which the concrete solution will be poured. This procedure will allow the concrete solution to be more evenly distributed throughout the entire internal volume of the future strip or any other foundation.

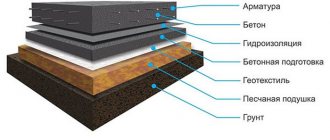

- The reinforcement elements with which you will strengthen your foundation must be covered with a layer of mortar at least 5 cm thick. In order to maintain this distance, you can use ordinary bricks that are laid on the bottom of the future foundation.

- Two rows of reinforcement are placed on the bricks laid at the bottom of the future foundation. In this case, it is desirable that solid rods be used, without joints. By measuring the length of the sides of the foundation being poured, you can easily determine how long the rod you will need to unwind and cut from the overall coil.

- After laying the longitudinal reinforcement bars, it is necessary to attach transverse jumpers to them, which are fixed with plastic clamps.

- Then you need to make the upper level of the reinforcement cage, which should be identical to the lower one. Both levels of such a frame, the cell dimensions of which should be approximately 150 mm, are connected using vertical jumpers.

- After making the reinforcement frame, they begin pouring the concrete solution. It is up to you to decide what concrete mixture will be used for this, but preference is most often given to the M400 brand solution.

Reinforcement of the foundation belt with fiberglass reinforcement

To quickly and continuously pour the foundation, it is better to use the services of a mixer

It is not difficult to calculate how much mortar you will need to fill the foundation: to do this, you need to calculate the perimeter of the future foundation, and then multiply the result by its width and depth. When pouring concrete mortar with your own hands, it is important not to forget that it must be compacted periodically so that air bubbles do not form in the foundation mass.

It will take 2-3 weeks for the poured concrete solution to completely harden. During this period, the poured foundation must be covered with a film from rain, and if the weather is hot outside, its surface must be periodically moistened with water.

Reinforcement made from fiberglass is a relatively new material on the domestic construction market that has not yet stood the test of time. Therefore, when using such material to reinforce concrete structures, you must understand the extent of responsibility for your choice.

Source:

Which is better reinforcement for the foundation: composite fiberglass or iron?

To improve the strength characteristics of concrete, iron reinforcement is traditionally used.

With the development of construction technologies, metal is being replaced by composite materials, including fiberglass. It is non-corrosive, lightweight and durable.

Reinforcement of this type is successfully used in monolithic construction. In this article we will try to answer the natural question: which reinforcement is better for the foundation?

Composite reinforcement varies both in composition and appearance

Composition and structure of composite reinforcement

Fiberglass reinforcement rods are a bundle of fiberglass, each 15 microns thick, impregnated with epoxy or other resins and having a corrugated surface for better adhesion to concrete. A properly constructed rod should have a central core of fibers that is spirally braided with a second layer of fiberglass.

The type of fiber material determines the properties and name of the reinforcement. In addition to fiberglass, there are carbon fiber and basalt products.

The diameter of the reinforcement bar is in the range of 4-18 mm, and the maximum length is limited only by the settings of the production equipment. The density of fiberglass is only 1.9 t/m3, and 1 cubic meter of steel reinforcement weighs at least 7 tons. Due to this property, composites have been used in the production of lightweight concrete since the 60s of the last century. The average service life is at least 80 years.

Source: https://svaimania.ru/kak-sdelat/podojdet-li-stekloplastikovaya-kompozitnaya-armatura-dlya-lentochnogo-fundamenta.html

Advantages of use

Reinforcement with such material has the following advantages:

- The ability to wind material into coils greatly facilitates its transportation and reduces the cost of independent construction - the reinforcement can be delivered using your own vehicles.

- The low weight of the products makes it easier to work with your own hands. There is no need to use a large amount of labor and lifting equipment. For comparison, the density of steel is 7850 kg per cubic meter, while a cubic meter of composite material has a mass of 1900 kg. From this we can calculate that the mass of fiberglass reinforcement is 4.13 times less than steel.

- Corrosion resistance. The main problem with steel rods is that they are susceptible to rust. Fiberglass is not afraid of water and various aggressive environments. Reinforcement with composite material is well suited for concrete with the addition of various modifiers (anti-frost, etc.).

- Another advantage is that fiberglass is a poor conductor of heat and does not conduct electricity. Concrete structures do not provide the necessary thermal insulation of a building, so they are always provided with a layer of insulation that prevents heat loss. In this regard, the low thermal conductivity of the composite does not play a significant role. The non-conductivity of electricity offers some advantages. But sometimes reinforced concrete structures provide for the release of rods for grounding or lightning protection. When using fiberglass reinforcement, such measures are impossible.

Advantages

10 times lighter than metal . Compared to steel rods, fiberglass rods have a lower density - about 4 times. It is important to note that fiberglass reinforcement for foundations, reviews of which are positive in this aspect, does not lose in elastic-strength properties when reducing weight.

If you use two structures made of fiberglass and metal, which have equal strength, then the first one will be almost 10 times lighter. But this does not negatively affect the durability and reliability of the structure.

In addition to convenience during the installation process, the cost of transporting material is reduced . So, if a small truck is sometimes required to transport metal reinforcement, then an average passenger station wagon can handle composites of the same size. If we are talking about building a foundation for one private house, then the savings may not be so significant (although for the budget of one family this cost reduction can be significant), then for enterprises serving dozens of construction sites, this is a weighty argument.

Durability . This is a fundamental selection criterion that experts pay attention to first. If the reinforcement used is not capable of providing sufficient tensile strength, then there is no point in including it in the foundation.

The opinion of experts on this matter is clear: with the same diameters, fiberglass reinforcement is almost 3 times stronger than metal reinforcement. For example, fiberglass reinforcement for foundations, reviews of the use of which confirm its strength, even with an 8-mm diameter can act as a replacement for 1.2-centimeter metal rods.

Does not corrode . Although modern metal fittings are produced with protective anti-corrosion coatings, controversy surrounding their resistance to rust processes still does not subside. This is partly due to the risks of damage to such coatings during installation. In the case of composite rods, the likelihood of corrosion is completely eliminated . However, it may be negatively affected by other characteristics of the concrete environment.

Low thermal conductivity threshold . A high percentage of metal content in concrete foundations often becomes a “cold bridge”, due to which the foundation and, accordingly, the lower part of the house freezes.

Expert opinion notes that fiberglass reinforcement, whose thermal conductivity characteristics are minimal in relation to similar properties of metal, has virtually no negative impact on the thermal insulation of the foundation .

The thermal conductivity of composite rods is 100 times less than that of steel. This helps retain heat and generally reduces heat loss in the structure.

Radiotransparency and dielectricity . If you are near a concrete building or steel-reinforced structure, you may notice the following phenomenon: the phone has poor network reception or there is interference in the emission of other radio signals. This is how a metal “skeleton” works, forming a barrier around itself for the propagation of electromagnetic waves.

Fiberglass rods are absolutely devoid of such qualities - they

do not interfere with radio waves, and also do not accumulate static energy .

This determines the possibility of using composites in the construction of critical structures - for example, airports and hospitals, for which it is very important to maintain the stable operation of radio equipment. Return to content

Disadvantages and myths

The material is quite new, so it has not been fully studied. The use of this type of rods in mass construction makes it impossible to have a regulatory framework for calculations. For fiberglass, there is only GOST 31938-2012. This is a recently appeared and only regulatory document. GOST provides technical requirements for the material, but does not provide recommendations for calculation; manufacturers provide only approximate values for the corresponding steel rods.

Composite reinforcement has the following disadvantages:

- Inability to bend: the material can only be bent at the factory according to pre-provided diagrams;

- Inability to use welding. Typically, welding is used on large frames; in private housing construction, reinforcement is often knitted.

- Instability to high temperatures. Steel begins to lose its properties when heated to 600 degrees Celsius. In the case of a composite, the loss of load-bearing capacity occurs much earlier. This means that in the event of a fire, concrete floors and beams will collapse faster.

In addition to the shortcomings, there are dubious points that are worth knowing about.

Design characteristics

The calculation of reinforced concrete elements is carried out according to the joint venture “Concrete and reinforced concrete structures” according to 2 groups of limit states (LLS).

- 1 GPS - calculation based on bearing capacity. They check whether the element can withstand the load applied to it. The calculation is carried out taking into account the strength of the material.

- 2 GPS - calculation based on rigidity. Here, deformations and the magnitude of crack opening in reinforced concrete structures are taken into account. The calculation is carried out taking into account the elastic modulus of the material.

In a reinforced concrete element, the compressive load is assumed by the concrete, and the function of the reinforcement is to prevent destruction under the influence of deformations. Composite manufacturers claim high strength characteristics (Rs), but are silent about the elastic modulus (Es). It is this value that determines the deformability of the structure.

Deformability can be calculated by dividing the strength by the elastic modulus. For steel reinforcement A400 Rs = 360 MPa, Es = 200000 MPa, hence we obtain a deformability equal to 0.0018 or 0.18%. For fiberglass reinforcement Rs = 1000 MPa, Es = 50000 MPa. Deformability is 0.02 or 2%. Those. per 1 meter of structure, stretching of composite reinforcement is possible up to 2 cm versus 0.18 cm for steel reinforcement, imagine what cracks will form in the structure. The reinforcement is designed to prevent cracking and stretching. Composite copes with this function 10 times worse than steel.

This quality is especially important when reinforcing floor slabs and various beams. Here the deformations are very large, so reinforcing such elements with a composite is impossible.

When used in structures with prestressing, its loss over time for steel is 20-30% (the extent to which the rigidity of the structure is lost). For fiberglass reinforcement, this value can reach 80-90% in 5-10 years, because it is an organic material. That is, the whole point of pre-stress disappears.

Please note that not a single manufacturer of prestressed reinforced concrete (slabs, beams) uses composite reinforcement. There are no regulatory documents for it (SP, SNiP), so it is impossible to calculate how it will behave.

Based on this, the manufacturers’ assurances about the high strength of the material are true, but the normal operation of the structure is affected not only by strength. In terms of deformability, fiberglass is significantly inferior to steel.

Reducing the weight of the structure

The small mass of the material significantly reduces labor intensity, but the rods cannot provide a significant reduction in the weight of the entire structure, which is used to reduce the load on the foundation.

For justification, numerical values are given:

- The load on the foundation from a slab 6 m by 1.5 m and 0.2 m thick made of reinforced concrete is equal to the sum of the mass of concrete and reinforcement. We accept the percentage of reinforcement as 3%. Volume of concrete = 6 * 1.5 * 0.3 = 2.7 m³. Multiplying this volume by the percentage of reinforcement, we obtain the volume of steel = 2.7 * 0.03 = 0.081 m³. Concrete mass = 2.7m³ * 2000 kg/m³ = 5400 kg. Weight of steel = 0.081 m³ * 7850 kg/m3 = 636 kg. Total mass of the slab = 6036 kg.

- For the same slab, reinforcement is provided with fiberglass. The volume of concrete and reinforcement does not change, nor does the mass of concrete. Weight of reinforcement = 0.081 m³ * 1900 kg/m³ = 154 kg. The mass of the slab is 5400 kg + 154 kg = 5554 kg.

From the above calculations it is clear that the total mass of the element differs by less than 500 kg. With a plate weight of more than 5000 kg, this is not a very large value. Therefore, the use of fiberglass reinforcement to reduce the load on the foundation is economically unjustified, since the composite is more expensive.

Durability

You can take the manufacturers of composite reinforcement at their word that the service life of composite reinforcement is 80 years. But two facts make their words dubious:

- Steel has been used by humans for many years, there is a lot of information about it, and its service life can be quite accurately determined in certain conditions. Composite rods are a new material. There is no information about its operation over a long period, namely certified 80 years.

- Composite rods are an organic material. Over time, polymer bonds break in any organic substance, the so-called process of “aging” of organics, this leads to a loss of properties of the material, sometimes to destruction (for example, rubber becomes hard and begins to crack after a certain time).

Disadvantages of fiberglass

Builders call one of the disadvantages the insufficient thermal stability of the material, the strength of which is lost when the temperature rises above 200 C°.

This does not allow the use of fiberglass reinforcement in objects where heating to high temperatures is expected.

Also, experienced builders often refuse to use this reinforcement due to low elasticity, which is why the building material easily bends and requires more accurate calculations.

In particular, such reinforcement cannot bend and form angles when the design requires it.

Reinforcement rods are not subject to welding, therefore, if a welding connection is necessary, metal tubes are put on the ends of the rods.

Possible applications

The previous paragraph paints everything in black and white. But when reading it, you should not forget about the merits of the material. Due to its physical properties, this type of reinforcement will be a good solution for:

- Masonry reinforcement. Antifreeze and other aggressive additives are often used in masonry mortars, which have a bad effect on steel products. Fiberglass is not affected by such modifiers.

- Reinforcement of strip foundation. Laying reinforcement in a strip foundation is often of a constructive nature (without calculation), so fiberglass reinforcement, lightweight and resistant to chemical influences, may be suitable, but it should be used with caution, especially for massive buildings and foundations on problematic soils (high groundwater levels, heaving, subsidence soil, etc.).

- Reinforcement of the roadway. The reinforcement is not destroyed upon contact with the ground.

Remember that there is no regulatory documentation for composite reinforcement (SP, SNiP), so no designer will be able to correctly calculate a structure with such reinforcement. There can be no talk of using this reinforcement in slab foundations and grillages, because tensile loads can be high.

Advantages of fiberglass

Fiberglass weighs little, is very durable, does not corrode, has low thermal conductivity and is inert to magnetism and non-conductive of electric current.

Compared with metal reinforcement, fiberglass reinforcement has many advantages. Fiberglass is three times lighter, four times stronger, less susceptible to wear and does not allow cracks to form. The main advantage is the low price.

If prices for steel reinforcement increase by 10 percent per year, then the price increase here does not exceed three percent. Transportation savings are about 40 percent due to the low weight of the material. At the same time, when installing the structure, the use of a welding machine is not required.

In terms of the coefficient of thermal expansion, composite reinforcement has similar indicators as concrete, which cannot be said about metal reinforcement. Therefore, fiberglass does not break the structure when exposed to high temperatures.

Builders highlight ease of installation as a special advantage. For example, you can cut fiberglass with ordinary cutters, and even one person can lay it, without the involvement of specialists.

Calculation of fiberglass reinforcement for different types of foundations

Correct calculation of fiberglass reinforcement for the foundation will allow you to buy the right amount of material, pre-determine the costs of its purchase, and avoid unnecessary expenses or additional problems caused by a lack of reinforcing bars.

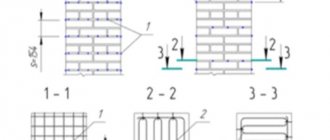

To calculate the reinforcement for a slab foundation, it is necessary to determine the length and number of rods based on the area of the base and taking into account the pitch of the frame mesh. You should also know that the slab has two armored belts (upper and lower) and they are connected to each other by vertical rods over the entire area of the slab in the corners of each cell.

The calculation for a strip foundation is performed in a similar way.

To reinforce a columnar foundation, the reinforcement in the columns is installed in reverse, that is, ribbed - vertically, smooth - horizontally. For the frame, 2-4 vertical rods with a length equal to the height of the pillar are usually used. For wide (more than 20 cm) pillars, more rods are taken, which are evenly distributed inside the pillar. In addition, each post requires at least 4 horizontal rods.

The use of fiberglass reinforcement for the foundation: how to knit, can it be used

When constructing a new building, it is important to equip a high-quality and durable foundation. For this task, different materials can be used, the main thing is that they are reliable and can withstand heavy loads. In modern construction, the use of fiberglass reinforcement for foundations is widespread.

Benefits and where to use it

The popularity of using fiberglass reinforcement for strip foundations is associated with a lot of advantages, including:

- No vulnerability to corrosive processes. Due to this property, fiberglass can be used in environments with high humidity or other aggressive influences.

- Small dimensions and weight. This facilitates comfortable transportation and use of the material. The reinforcement process does not require much human power. The material is easily wound into coils and easily delivered to the construction site.

- Affordable price. Composite products are much cheaper than their steel counterparts.

- Increased strength properties. Fiberglass reinforcement is characterized by high strength, which is 2-2.5 times higher than the strength of metal rods with the same cross-section.

- Low thermal conductivity, resistance to electric current. Concrete structures are not able to protect the building from heat loss, and they are additionally insulated with insulating material, so the low thermal conductivity properties of the composite do not play a big role. The non-conductivity of electricity is an important point that protects the building from discharges.

However, in addition to the positive features, reinforcing a strip foundation with fiberglass reinforcement also has disadvantages:

- The structure is not resistant to bending, so it is not able to absorb tensile loads. Since the reinforcement is laid on a concrete surface, it is already subjected to extreme tension.

- The areas of use of the material are limited, since it can only be installed in tension.

- Fiberglass is not suitable for the construction of large-sized and multi-story buildings. Therefore, it is most often in demand when solving simple problems by beginners.

- Inability to use welding equipment to connect elements. In most cases, welding is used in the construction of large frames. The method of step-by-step knitting of rods is suitable for arranging the foundation of a private house.

The material appeared relatively recently and is considered not fully studied.

Application areas include both residential and industrial construction. The use of fiberglass reinforcement in the foundation is in great demand, which is associated with a number of advantages over concrete structures.

In private construction, products are needed to strengthen:

- Concrete structures that perform enclosing functions. In this case, it is prohibited to use material for reinforcing load-bearing structures.

- Foundations of strip or other type.

- Foam concrete or aerated concrete masonry.

Calculation of fiberglass reinforcement

To calculate the amount of reinforcement for a strip foundation, you need to take into account a number of important nuances and be guided by the joint venture “Concrete and reinforced concrete structures”.

The calculation is performed in two stages:

- GPS. Determination of the load-bearing capacity of the structure and assessment of the ability of the foundation to cope with loads.

- GPS. Determination of rigidity indicators. This stage involves taking into account deformations and the size of cracks in products with a reinforced concrete base.

Most of the compressive loads are absorbed by concrete, and fiberglass reinforcement is used to combat destructive processes.

Leading manufacturers of reinforcement report such advantages as strength, but do not talk about the elastic modulus, which affects the deformability of the structure.

Foundation reinforcement

To determine whether it is possible to use fiberglass reinforcement for a strip foundation and how to knit fiberglass rods with such a base, you need to consider that there are two types of base with tape:

- Rectangular.

- T-shaped.

In the second type, the installation of reinforcement is carried out without preliminary calculations, and the sole is designed to absorb bending loads. The material can be sewn into the wall, but when installing it into the sole you need to be especially careful.

Tools and materials

Before you start knitting a strip foundation, you need to prepare the following tools and materials:

- The measuring device is a tape measure.

- A device for adjusting and processing rods is a grinder.

- Personal protective equipment.

- Water type level.

- Plastic clamps for fastening rods.

Excavation

Before starting reinforcement, you need to prepare a recess, guided by the layout of the future building. The bottom surface needs to be leveled and compacted, then pour a layer of sand (10-15 cm), pour liquid over it and compact it. The next layer will be crushed stone with a similar thickness. After compacting the top covering, a reliable cushion with a flat plane is formed at the bottom.

Construction of formwork

The surface of the walls is covered with parchment, which is fixed with a stapler. The purpose of this material is to maintain the cleanliness of the boards and combat the leakage of liquid from the concrete screed.

Next, marks are placed on the walls that will determine the level of concrete pouring. You should follow this line when installing reinforced elements. To perform the work more accurately, you should use a water level.

Knitting technology

To understand the knitting technology, you should take into account the simple advice of experienced specialists and adhere to the following algorithm of actions:

- Before starting knitting, you need to prepare drawings of the frame and cut all the elements, following the calculations.

- To position the cross bars in the lower layers, clamps are used. They are secured both before the installation of the fittings and after completion of the assembly.

- The diameter of the cells is determined by the parameters of the tape that is being strengthened. In most cases it varies from 15 to 30 cm.

- Before connecting the longitudinal rods, they need to be laid out on the ground and marked on them at the places where the transverse parts are attached. During the knitting process, you must maintain a right angle.

- The transverse elements are fixed with the longitudinal ones on the bottom side. To ensure reliable reinforcement, plastic clamps or wire are knitted as tightly as possible.

- First of all, it is necessary to prepare the horizontal layers of reinforcement, and then begin securing the vertical ones. Fixation is carried out from the inside of the cells to increase the reliability of the structure.

- Corners need to be given special attention. Experts recommend not bending them by exposure to temperature, as this may worsen the strength properties.

- After completing the knitting of the reinforcement structure, it must be placed inside the formwork.

If fiberglass reinforcement is knitted using wire, then to make the work easier, it is better to use a crochet hook. An old screwdriver can play its role.

Construction of reinforcement cage

When arranging the frame, you must adhere to the key requirement - the product must be completely filled with concrete, maintaining a distance between the walls of the formwork of at least 5 cm. To prevent reinforced elements from being placed at the bottom of the recess, bricks should be secured, and longitudinal rods and horizontal cross members should be placed on top of them. These elements are connected using plastic clamps.

What is reinforcement made of composite materials?

Composite reinforcement is an excellent alternative to traditional products for similar purposes made from metal. Today, the following options for reinforcing products are presented on the construction market:

- from staple fiberglass, produced from inorganic glass by melting it (fiberglass of this type has good thermal insulation and reinforcing characteristics, which predetermined the main areas of its application: thermal insulation boards, glass wallpaper for wall decoration, canvases for reinforcement, individual fibers are produced from staple fiberglass, with the help of which concrete screeds and plastered surfaces are strengthened);

- with materials used as binding elements (thermosetting resins of the non-curing type, the most famous of which are epoxy and epoxy-diane);

- with additives, the use of which makes it possible to increase the ductility and strength characteristics of reinforcement made from composite materials.

One of the stages of creating non-metallic reinforcement: feeding and unwinding of roving

The fittings, made of composite materials, are available in two versions.

The technology for obtaining such a surface is as follows. A fiberglass thread is wound onto a smooth rod of composite material, which forms the corrugation elements. Then the surface of the rod with the thread wound on it is covered with a thin layer of resin made of a polymer material. A reinforcing bar with such corrugation, due to the increase in the contact area, is much better bonded to the concrete mortar, strengthening it well. These rods are used to reinforce foundations and other massive concrete structures.

An improved type of fiberglass reinforcement

In order to ensure good adhesion of such a rod to the concrete solution, a powder is applied to its surface, which is fine sand. Due to the complex technological process of manufacturing such reinforcement, its cost is slightly higher than the price of other types of composite reinforcing products.

Composite reinforcement coated with quartz sand

Comparative parameters of products made of fiberglass, basalt and carbon fiber will help you better navigate the characteristics of reinforcing elements made of composite materials.

- The modulus of elasticity for products made from fiberglass is 55,000 MPa, and for products made from basalt fibers – 78,000 MPa.

- The tensile strength of reinforcing products made from fiberglass is 1250 MPa, and that of reinforcement made of basalt fibers is 1450 MPa.

- The advantage of fiberglass reinforcement is its cost, which is approximately 15% lower than the price of products made from basalt fiber.