Correctly laid tiles on a foam block or aerated block can increase the strength and moisture resistance of the structure. And such work is most often performed on the walls of bathrooms and kitchens, also providing decoration for their interior.

Foam blocks are a building material characterized by high heat and sound insulating properties, lightness and a relatively affordable price. That is why they are increasingly used for housing construction. However, in addition to its advantages, the material also has a small drawback - the need for finishing that can preserve its characteristics and increase its service life. The internal surfaces of blocks in living rooms require plastering and painting. And sometimes it becomes necessary to lay tiles on a foam block - both in order to protect the enclosing structures from high humidity, and to decorate the interior.

Possibility of installation

Homeowners who are renovating a foam block house often have a question about whether it is possible to lay tiles on a foam block. The answer to this is positive - however, due to the increased fragility of such a base, pieces of material may begin to fall off along with the tile over time. This situation is prevented by first using a primer and then plaster or special tile adhesive.

Most often, the need to lay tiles on foam blocks arises when finishing the enclosing structures of a bathroom and kitchen. Indeed, in addition to the fact that the humidity here is noticeably higher than in other rooms, there is a possibility of water getting on the foam concrete and, as a result, destruction of the blocks and the appearance of mold. It is worth noting that ceramics can also be laid on the floor in such rooms, however, work with foam blocks is carried out only when finishing the walls.

Can I put it on glue?

It is very important in the summer to carry out the arrangement of the foundation, which must completely harden before the onset of the first stable frosts. Only in this case can winter masonry technologies be successfully applied.

You can carry out masonry in the frosty season, following certain rules.

Low-temperature conditions can complicate construction work that involves the hardening of cement mortars, so in the cold winter period it is necessary to warm up the aerated concrete and also use special anti-frost additives . Experienced specialists in the construction industry recommend combining the use of chemical and physical methods of protection with work on heating the stacked blocks and mortar.

Tile selection

An important nuance when laying tiles on foam blocks in the bathroom or kitchen is the correct choice of finishing materials and finishing area. Thus, by giving preference to the option with ceramic cladding up to the ceiling, you can visually make the room smaller, creating the illusion of a lower ceiling. Therefore, in small bathrooms or kitchens, it is advisable to lay tiles, leaving at least 30–40 cm to the ceiling. And choose smooth materials in cool colors. For a large bathroom and kitchen area, an excellent option for tiling a foam block would be tiles in warm colors.

The dimensions of the tiles should depend on the filling of the premises with furniture and other items (household appliances and plumbing fixtures), their area and height:

- if there are a lot of interior elements, you should choose large tiles or a plain light mosaic;

- for a small bath in a minimalist style (with installation of only the essentials, without a washing machine and wall cabinets), the ideal option is a small square tile measuring 100 x 100 mm;

- For low rooms, vertically placed rectangular tiles are suitable, for low rooms - square-shaped products.

Conclusion

The technology for laying aerated concrete blocks is quite simple, however, it requires strict adherence. Therefore, the most important thing when building with aerated blocks is accuracy and adherence to the above sequence.

You can get more information on this topic from the video in this article.

After erecting the walls of a house made of cellular concrete, care should be taken to ensure that the tiles are laid correctly on the foam blocks. For all its attractiveness, lightweight concrete has a number of features that determine the specifics of internal and external finishing work. Therefore, before answering the question of whether it is possible to veneer foam and aerated concrete, you should learn more about the physicochemical properties of these materials.

Cellular concrete is a lightweight building material, porous in structure, made on the basis of traditional cement and sand, but with the addition of a specialized foam and gas former.

The most popular types of lightweight concrete for monolithic and classic house construction are:

- Foam concrete is a cement or cement-sand mortar into which a foaming agent (SDO, adhesive rosin foaming agent) is introduced at the mixing stage. After hardening and shrinkage, foam concrete has a porous structure of concrete mass and many closed bubbles. Modern technologies make it possible to significantly improve the quality of foam blocks by supplying foam to a still dry mixture using a foam generator or producing the material under conditions of excess pressure.

- Aerated concrete is a concrete mixture into which a gas-forming agent is added at the stage of mixing the dry ingredients. The formation of spherical pores communicating with each other occurs during a chemical reaction with the release of hydrogen when lime water is introduced into the mixture.

Cellular concrete is strong, but at the same time easy to process, cheap, heat-resistant, low in weight, and has good thermal insulation properties. These advantages make it possible to create a favorable, environmentally friendly microclimate for living in a house built from foam blocks.

However, porous concrete also has a drawback: high moisture permeability. At the same time, aerated concrete, due to its structure, has higher hygroscopicity rates than foam concrete. Moistening of cellular concrete and subsequent exposure to negative temperatures leads to rupture of the structure of the material and loss of its structural properties. At positive temperatures, water entering the pores reacts with carbon dioxide released by residents, which leads to carbonization shrinkage and destruction of walls. For these reasons, before laying tiles, the surface of porous concrete should be protected from moisture penetration.

Glue selection

Before purchasing tile adhesive, you should pay attention to its increased elasticity. And when choosing a method for laying tiles on foam blocks in the bathroom, pay attention to such a characteristic as resistance to high moisture. For the working wall in front of the kitchen stove, you should give preference to tiles, the operation of which is possible at elevated temperatures.

Suitable materials for finishing dry rooms (corridors, living rooms or offices) are compositions based on a conventional cement-sand mixture of type CM9. And among the special options for tile adhesive, mosaic adhesive stands out separately, intended for sticking mosaics on walls. Due to the presence of white cement in the composition, this material does not have its own shade and provides increased strength of the cladding.

Protection of foam concrete from moisture

The bathroom is considered the dampest room in the house, so the foam block masonry must be reliably protected from moisture penetration into the concrete body.

This is done in several ways:

- Plastering walls followed by coating with waterproof compounds (paint, varnish, etc.).

Since foam concrete is a rather soft material, it is recommended to attach a fiberglass reinforcing mesh to the walls before applying the plaster mortar. This is necessary for better adhesion of the solution to the surface of the foam blocks and obtain a better coating.

- Covering with moisture-resistant decorative panels or slabs (siding, PVC panels, etc.).

It is produced using a frame or frameless method. In the first case, a frame is mounted under the panels, on which the panels are hung; in the second version, the slabs are glued directly to the wall.

With this finishing, the masonry of foam blocks in the bathroom will be especially susceptible to dampness, so it is necessary to attach a vapor barrier membrane to the walls under the frame or facing material, which will not allow moisture to penetrate inside the masonry, but will lead it out.

In a separate toilet, it is not necessary to take such measures, but experts still recommend laying a vapor barrier at least spot-on, in problem areas - around pipes, ventilation holes, doorways, where condensation is possible.

- Cladding with decorative ceramic tiles.

In this case, the tiles will perfectly protect the foam concrete from dampness; only it is advisable to make the seams between the tiles as thin as possible and caulk them with a special grout containing moisture-resistant components. When using a simple mixture, mold or mildew may develop. But for ideal installation of tiles, it is advisable to level the walls and impregnate them with special deep penetration compounds.

In conclusion, it must be said that the use of foam blocks for laying bathroom and toilet partitions is the fastest and most profitable option, which even a non-professional can handle. And with proper protection from moisture, a bathroom made of foam concrete will last for many years without repair.

If something remains unclear, we suggest looking at the photos and videos in this article, which will give a more complete picture of this topic.

One of the options for cladding buildings made of foam concrete, which combines practicality and accessibility for any category of citizens, is clinker or ceramic tiles. Such tiles are laid on a foam block quickly and do not require additional reinforcement of the entire structure or foundation.

Foam concrete is considered one of the most popular materials for the construction of residential buildings; it has high thermal insulation and strength, but, unfortunately, does not tolerate moisture well, so walls made of foam concrete require mandatory protection.

When choosing the type of cladding for a foam concrete surface, the following aspects must be taken into account:

- Resistance to moisture and temperature changes;

- High frost resistance;

- Durability and resistance to mechanical stress;

- Aesthetic appearance.

Tiles meet all these qualities; they are made from various materials that are suitable for both interior and exterior use.

Ceramic tiles or mosaics are most often used for interior decoration. Manufacturers offer a wide selection of shapes and colors of products that will suit any interior.

The following types of tiles are used for façade cladding:

- Facade ceramic tiles;

- Porcelain tiles;

- Clinker tiles.

With the correct choice of material and compliance with all the subtleties of laying tiles on foam concrete, it will be possible to note an increase in the strength and durability of the structure.

The facing tiles will protect the surface from water, precipitation, mechanical damage and other adverse influences. Let's take a closer look at the features of laying tiles on foam concrete, find out what to look for when choosing a material, and how to install the tiles yourself.

Preparation for installation

Before preparing foam blocks for tiles, you should evaluate the evenness of the wall surface. If the foam concrete laying was done correctly, practically no additional finishing is required. If there are significant irregularities, the contractor will have to do serious work preparing the base and plastering the foam block.

Since the foam block strongly absorbs moisture, it is ideal for wet rooms to waterproof the walls and ceiling.

Applying primer under plaster.

The next stage is priming the blocks. For this purpose, specialized materials are used, and a wide range of primers is available. When decorating bathrooms, it is worth additionally waterproofing the walls; in the kitchen such work is not required. Having finished with the preparation, they move directly to the question of whether it is necessary to plaster the foam block under the tiles - as a rule, they choose the option with plaster, which is more expensive, but also provides increased strength to the walls. Tile adhesive is quite suitable for these purposes. Having plastered the surface on which the tiles will be laid, proceed to the main part of the work.

Main stages of work

The first stage of laying tiles on a foam block or aerated block (the principle of gluing ceramics to both materials is the same) is preparing the solution. To do this, add a dry adhesive mixture and water to a pre-prepared container, mixing them using a hammer drill with a special attachment. Mixing proportions are usually indicated on the glue packaging.

Despite the instructions for preparing the adhesive mixture, it is advisable to independently control the mixing process. The finished substance should not be too liquid and without lumps, but also not very hard, so as not to impair the adhesion of the tiles and the wall.

Continuing work, you should:

- Apply the prepared adhesive mixture using a notched trowel;

- Place the first tile against the wall and press firmly;

- Check the horizontality of the material with a level and, if necessary, level the tiles. It takes no more than 10–15 minutes to level the tiles after applying the adhesive. If this time is over, the glue should be removed and reapplied;

- Repeat the same steps for the next tiles. In order to leave tile seams of equal thickness, plastic crosses are used;

- If it is necessary to cut tiles, use a tile cutter, running the cutting part of the tool along the marked surface of the tile;

- Plastic corners are placed in the corners of the room to ensure even seams. And to bypass the water, gas and heat supply pipelines, holes are cut in the tiles.

Features of laying tiles on aerated block

Home owners often ask whether it is possible to glue tiles onto gas silicate blocks. When facing walls outside or inside a building, it is necessary to take into account the following features:

- High vapor permeability. When there is a difference in outside temperature and a warm room, accumulated moisture is absorbed into the walls. This occurs due to the structure of aerated blocks. Covering the surface with ceramic tiles contributes to the accumulation of moisture due to poor ventilation. Accumulation of factory humidity and wet construction work must be taken into account.

- Relatively low flexural and compressive strength. Depending on the brand of gas silicate block, it is B3.5-B5. During construction, the basic rule is followed: all subsequent finishing layers on a stone structure are durable if the strength is less than or equal to the base.

- Preliminary surface preparation. To level the surface, use only special compounds. A mixture that meets the following requirements is suitable:

- The deformation parameters of cellular concrete and plaster must be the same.

- The plaster mortar contains additives that form a porous surface.

- High moisture retention rates. For this purpose, plasticizers are added to the composition.

Is it possible to lay tiles with aerated concrete adhesive?

Structures built using aerated concrete are very popular. This method of construction is accessible and relatively simple, which allows you to complete all the work yourself, even in the absence of special skills. However, you need to know some of the intricacies of working with this type of building material, as well as follow the construction technology. One of these subtleties is laying aerated concrete in winter.

It is when independently erecting walls from aerated concrete blocks that there is a risk of not calculating one’s strength, not meeting deadlines during the warm summer months, and thereby completing the planned work in the autumn cold, or even in winter frosts.

Laying tiles indoors

The purpose of interior decoration of a house made of aerated blocks is to reduce the permeability of walls from the room side. To ensure that the product adheres well to the surface, it is recommended to use a primer and then plaster or tile adhesive.

Tile selection

To maintain a good indoor microclimate and decorative finishing, tiles, bricks, artificial or natural stone are used. Facing material has a number of advantages:

- Large selection of products in texture, color, shape. You can create a unique interior.

- No finishing plaster required.

- Good vapor barrier is easy to achieve.

- Due to the additional finishing layer, thermal insulation is improved and the penetration of extraneous noise is prevented.

- The shortcomings of walls made of gas silicate blocks are hidden.

Block decorative masonry also has negative aspects:

- Wrong choice and poor-quality masonry leads to the material lagging behind the surface.

- The room must have good ventilation.

- The use of thick decorative blocks reduces the usable area.

When choosing tiles for a bathroom or kitchen, you need to take into account the volume and height of the ceiling. Laying tiles on a gas block in a small room from floor to ceiling visually reduces the area. Therefore, it is recommended to leave at least 40 centimeters from the upper ceilings and use a square shape measuring 100x100 millimeters.

The selection of decorative blocks depends on the size, furniture and style of the interior.

Glue selection

It is difficult to unambiguously determine the best adhesive composition. The choice is influenced by many factors. Any glue is suitable for work inside the house. The exception is the bathroom. Due to the high humidity in the room, you should choose an adhesive composition with high elasticity and resistance to water.

In the bathroom, the seams between the tiles must be sealed with waterproof grout. This will help prevent the formation of mold and mildew.

Preparatory work

Before installing finishing tiles on interior walls, you should evaluate the evenness of the base. Properly executed laying of gas silicate blocks requires minimal preparatory work. Only the surface is primed. The solution deeply impregnates the gas blocks and a more durable base is obtained. The use of primer mixtures helps:

- increase the adhesion of the subsequent layer;

- prevent the formation of fungus and mold;

- increase the durability of the repair.

In case of significant defects (deviation is 0.5-1.0 centimeters), the walls will have to be plastered. The surface is covered with waterproofing paste. Each layer must dry well. Then, using plaster: gypsum, cement-sand, lime, the base is leveled. To strengthen the base, use fiberglass or metal mesh.

Direct laying of aerated concrete

Due to its high technological and operational characteristics, aerated concrete has long occupied a leading position in the construction market.

Scheme of aerated concrete masonry: 1 – Masonry, 2 – Ceiling, 3 – Strapping belt, 4 – Mauerlat, 5 – Rafter roof.

The use of this material allows the construction of residential buildings and industrial facilities in a very short time with minimal costs.

However, aerated concrete blocks, like any building material, require certain knowledge and skill in working with them. Having studied in detail the technology of laying aerated concrete and wall finishing options, you can correctly erect a structure without hiring professional workers.

Material characteristics

Aerated concrete is an artificial stone, in the production of which only natural ingredients are used: sand, lime, cement and aluminum powder. During the operation of objects built from aerated concrete blocks, there is no release of toxic substances into the environment, and in terms of its environmental properties, aerated concrete is practically not inferior even to wood.

In its structure, aerated concrete has evenly distributed spherical pores (d1-3 mm) and comes from the group of cellular concretes. Depending on the type of production, there are autoclave (steaming) and non-autoclave (air hardening) types. Aerated concrete block is a lightweight building material. Its weight at a stone density of 500 kg/m? and size 600X250X300 mm is about 20 kg. This feature of gas silicate blocks allows you to replace 30 bricks when laying a wall with a thickness of 640 mm, which in the total mass ranges between 120 kg.

Scheme of laying an aerated concrete wall.

Aerated concrete, produced from a mixture of water, a blowing agent, a finely dispersed silica component and a hydraulic binder, has a light porous structure and is therefore easy to process. Blocks can be cut, sawed, grooved and nailed.

Properly laid aerated concrete walls have the following properties:

- Relatively light weight, which contributes to less load on the foundation.

- Fire resistance. Being a non-combustible material, aerated concrete blocks can withstand fire for 7 hours and do not contribute to the further spread of fire.

- Environmentally friendly. Blocks made only from mineral raw materials have the same properties as wood or brick, which allows the walls to breathe.

- Frost resistance. Being a porous material, when ice and water freeze, they are forced into reserve pores without compromising the integrity of the block.

- Low thermal conductivity - there is the possibility of significant savings on heating the house.

Aerated concrete blocks are used in modern construction in the construction of internal and load-bearing walls, partitions, and also as wall filler for frame high-rise buildings. Since aerated concrete has high penetrating properties, the cladding of the outer surface, made of tiles, plaster and other facade cladding materials, requires special technologies for their installation.

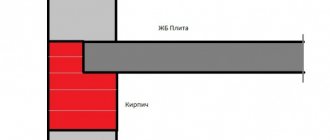

Base structure

Foundation diagram for a house made of aerated concrete.

The construction of a house from aerated concrete, first of all, begins with the construction of the foundation. A correctly selected foundation will allow you to proportionally distribute the weight of the entire building onto the ground, avoiding uneven shrinkage of the structure and the appearance of cracks in its walls.

The foundation for laying aerated concrete must be approached with special care. Since the material is relatively light in weight, it is not recommended to install a lightweight base. One of the disadvantages of gas silicate blocks is their low bending strength - the maximum permissible value for deformation is about 0.5...2 mm/m. Therefore, taking into account all the features of the material, preference should be given to several types of base:

- Monolithic slab.

- Monolithic strip foundation.

- A structure made of foundation blocks, where the upper and lower parts of the foundation will necessarily be reinforced with stiffening belts.

The most optimal option for foundation for a house is a strip foundation, since all others have some nuances during installation. A monolithic slab is considered one of the most financially expensive projects, and the construction of a base from foundation blocks requires the use of special equipment, which is not always acceptable when building a house on your own.

Laying aerated concrete walls

Preparatory stage

Aerated concrete laying diagram.

Since aerated concrete blocks are lightweight and easy to process, developers are increasingly giving preference to this material. To work with it you need to have the following tools:

- a mixer for mixing the solution or a similar device;

- blades with different widths for applying the solution;

- rubber hammer for laying blocks;

- level;

- electric or hand saw for cutting additional blocks;

- special graters for leveling the surface of the masonry at the seams;

- a square that determines the correct angle for cutting blocks.

Next you need to prepare the adhesive solution. In this case, it is recommended to use not a sand-cement mortar, but an adhesive mixture. Since using the latter allows you to reduce the solution consumption by 1 unit. working area 6 times. In addition, laying blocks connected to each other with mortar does not provide high-quality thermal insulation due to the large thickness of the seams and the occurrence of “cold bridges”.

Scheme of laying gas blocks.

A correctly selected adhesive mixture allows you to avoid unevenness of the masonry, and also increases the compressive and bending strength of the structure. And the use of other solutions not intended for working with aerated concrete is considered a gross violation of the entire technological construction process.

Aerated concrete blocks, regardless of their type, will be correctly laid with filled load-bearing and vertical joints to capacity. The seams between blocks connected in a tongue-and-groove manner may be partially unfilled. The average thickness of the adhesive mixture is 1…3 mm.

Masonry technology

It is better to lay aerated concrete at a temperature from 5 to 25? C. If this parameter is exceeded, the blocks are wetted with water during installation, and at low temperatures an anti-frost additive is added to the adhesive composition. The same condition must be met when finishing the outer surface of the building using plaster or tiles.

To properly lay walls, you must follow the following steps:

Diagram of a gas block wall.

- Lay a layer of waterproofing on the prepared foundation to prevent the blocks from getting wet. Level the surface well and check with a level.

- Next, lay the first row of gas blocks on the waterproofing. The first row begins to be laid from the corners. It is very important to align it vertically and horizontally, since this determines how correctly the building will be built. The aerated concrete blocks of the initial row are laid out on a sand-cement mortar, after which the work is left for an hour for the seams to harden.

- Subsequent rows must be laid with ligation of blocks.

- The construction of load-bearing walls and interior partitions is practically no different from the masonry of external walls. The only difference when installing a vibration-isolating partition will be the laying of a material that can dampen vibrations and at the same time prevent it from coming into contact with the main wall. Metal anchors are used as fastenings of any kind between partitions and walls.

- To strengthen the walls and prevent the occurrence of cracks in the masonry, reinforcement is carried out. To perform the operation correctly, grooves are made in aerated concrete for the reinforcement. When laying, reinforcing metal is installed in them, and the groove is filled with glue. Reinforcement is carried out in the first and every fourth row of masonry.

Aerated concrete blocks are laid on a uniformly applied adhesive solution after the block has been cleaned of dust. A thin layer of glue can be applied with a notched ladle. Next, the aerated concrete is adjusted with a special rubber hammer. The glue that comes out of the seams should not be rubbed over the surface, as it can create additional unevenness when installing tiles or plastering walls. Residues must be carefully cleaned off.

Finishing walls made of aerated concrete

Aerated concrete has many good reviews as a building material, but it requires mandatory exterior wall finishing. Since during operation the blocks are constantly exposed to precipitation, this causes the loss of not only an attractive appearance, but also the gradual destruction of the house.

For exterior wall decoration, bricks, various types of tiles, plaster or textured, vapor-permeable paints can be used. However, each type of work has its own technological feature. The main condition for installing tiles, bricks or applying plaster mixtures is that there are no obstacles to the passage of moisture, which can accumulate between the masonry and the finishing material.

Installation of various types of tiles and wall panels requires the installation of a ventilated facade. This design is a metal frame system mounted on aerated concrete. The elements of the façade system are universal, which allows for the installation of various types of tiles and wall panels. The air gap created between the wall and the finish helps reduce the heat transfer of the building. And to enhance this property, it can be laid with thermal insulation material.

Clinker and fiber cement tiles, natural stone, ceramic granite, galvanized steel cassettes and composite aluminum panels are used as wall finishing for the ventilated facade.

https://www.youtube.com/watch?v=YBuR-1–LOg

As a decorative element on aerated concrete, you can use not only tiles, but also bricks. To do this, it is necessary to provide for this option at the design stage. The brickwork is secured to the wall using flexible ties.

Another easiest way to finish walls, as well as insulate them, is plaster. It is carried out using the same technology as for brick walls. Mixtures based on a cement binder are used as plaster mortar. To prevent the plaster from peeling off from the surface, cement grades with high resistance to water are selected for the mixture.

o-cemente.info

Laying tiles outside

Exterior decoration gives the building an aesthetic appearance. Decorative blocks provide additional thermal insulation of the object and slow down the process of resolving external walls made of aerated concrete.

Selection of facing tiles

Durable types of ceramic products are used to decorate the external walls of the building. The material must have high performance characteristics:

- Strength. Achieved using a technological process: strong pressing and firing at a temperature of 1200 degrees.

- Frost resistance. High frost resistance value. Relevant for harsh climatic conditions.

- Durability. Long service life and preservation of the original appearance.

- Easy to maintain decorative finishing of the object.

- Environmental safety of the material.

When choosing, you should pay attention to the characteristics of the product, glue, and climate of the area. For example, ceramic tiles absorb moisture well due to their structure. The porosity value affects the service life. The average is 3 percent.

Large size tiles are distinguished by their weight, low adhesion and installation features. A special frame structure is installed around the perimeter of the entire building. This allows for additional insulation of the facility and ventilation.

The construction market offers a large selection of facade tiles:

- from natural stone;

- shell rock;

- sandstone;

- clinker;

- porcelain stoneware;

- concrete tiles;

- dolomite;

- bituminous

Selection of adhesive composition

To cover the façade wall, she uses glue for exterior use. It is necessary to take into account climatic conditions: sudden changes in temperature, precipitation, humidity, exposure to ultraviolet radiation and gusts of wind. Therefore, the glue must have:

- good adhesion to the base of gas silicate blocks;

- resistance to various climatic conditions.

Features of the work

It is recommended to finish the façade of a building in late spring, in summer, and early autumn, when the likelihood of precipitation is minimal. To avoid excess moisture getting into gas silicate blocks. Decorative tiles will help provide:

- reliable protection from precipitation;

- design solution for the appearance of the object and its attractiveness;

- protection against temperature fluctuations;

- effective ventilation of walls.

The lined external base of the object, made of gas silicate blocks, should displace moisture and steam outward. Therefore, several methods are used for facade work:

"Wet" technology

The surface of the load-bearing walls is plastered with a cement-sand mixture with the addition of glue. The applied layer will cover any defects in the masonry and prevent moisture from entering.

To strengthen the wall, it is recommended to use fiberglass or metal mesh. Then the finishing layer of plaster is applied. After complete drying, the finishing material is laid.

To ensure reliable fastening, intermediate reinforcement is made using dowels. Hats are hidden in the seams between the tiles. On average 4-5 connections per square meter.

Ventilated facade technology

The process consists of separate stages:

- External walls are treated with a good waterproofing agent.

- Installation of an aluminum frame around the perimeter of the entire building.

- Insulation of gas silicate blocks with fiberglass or basalt wool. Be sure to cover the entire surface with a vapor barrier layer.

- Mounting plasterboard sheets onto the frame, which is suitable for finishing from the street.

- Laying facing blocks on the resulting base.

Thermal insulation material should not touch the gas blocks. It is recommended to use a vapor barrier layer.

Decorative tiles are ideal for finishing the facade and interior walls of a building.

Aerated concrete has features that need to be taken into account when tiling the outside and inside of a heated room with ceramic tiles:

A. The gas block has high vapor permeability. In winter, moisture from a warm room escapes through the structure of the stone. Cladding on the facade made of ceramic tiles slows down movement and leads to the accumulation of moisture underneath. Periodic freezing causes, over time, rejection of the lining. The situation is complicated by the initial (factory) humidity + moisture accumulation during wet construction processes.

B. _ The aerated block has relatively low compressive strength (B 5 - B 3.5) and bending strength. For any stone structure, the rule is true: all subsequent finishing layers on it will become durable, provided that the strength is less than or equal to the base. The strength of any tile adhesive and cement-based waterproofing is always higher than the strength of gas silicate. A durable (high modulus of elasticity) outer layer, when deformed, causes stress in the underlying layer, which has a different temperature and humidity. Deformation of the finishing layers (tiles) occurs more strongly in winter: heating of the ceramics in the sun during the day and sudden cooling at night.

Q. Despite the smooth edges, it is difficult to lay aerated concrete walls without subsequent leveling with plaster for cladding. Conventional CPS is not suitable for plastering - it is necessary to use ready-made cement mixtures specially designed for plastering such a surface:

- the deformation characteristics of the plaster should approach those of cellular concrete.

- plaster solutions must be porous (by introducing additives into them that form pores).

- the plaster must have a high water-holding capacity so that it does not dry out on aerated concrete. It is necessary to introduce plasticizers.

- gypsum plaster is quite suitable for all requirements, but for a bathroom, cement plaster is preferable.

How to glue tiles to aerated concrete walls

For walls made of aerated concrete, it is necessary to take into account some features of the material when planning this or that type of cladding. It is very convenient and popular to use tiles for walls in the bathroom and kitchen. A huge selection allows you to choose and buy to suit your taste at the best possible price. And a house made of aerated concrete will in no way interfere with the desire to cover the walls with decorative tiles. Gas silicate blocks absorb water. This deteriorates their technical characteristics and increases their weight. To protect aerated concrete, the walls must be primed very carefully. For this purpose, special suitable solutions or a regular cement-based mixture are used. This will not change the quality. After applying the primer, you need to wait time for it to dry thoroughly. For more information, follow the link https://keramikfest.com.ua/wallblocks/aerated_concrete/gazoblok-gazobeton-poltava-kupit. This may take a week. Next, a mesh is applied to the wall using good tile adhesive and the tile itself is attached to it. There is nothing complicated in this algorithm. It is very important to buy quality materials. The service life of the tile will depend on this.

You also need to do the job well. If you do something wrong, the tiles will start to fall off. If part of the tile falls off, it is very easy to understand what the error is. If the tiles have adhesive, then the primer was done poorly. If the slab is clean, then the reason is the quality of the glue. To prevent this from happening, everything needs to be done efficiently. You can also use facing tiles to give an aesthetic appearance to the facade. As with other materials, you need to pause first. This is due to the fact that excess moisture must be removed from the aerated concrete. After erecting the box, the building needs to stand for some time. Sometimes this may take several months. The process of performing the work is the same as inside. First, the aerated concrete wall is primed. Then a reinforcing mesh is attached. And the tiles are attached to the glue on top. When tiling aerated concrete, it is important to adhere to proportions. The thickness of the joints must be at least 25 percent of the size of the tile itself. This is necessary for high-quality steam exchange. It is through the seam that excess moisture will be removed from the room. This will protect the walls from dampness and all the problems that come with it. A large selection of tiles, as well as their variety not only in colors, but also in patterns, will allow you to give the facade individuality. The result will be not just a building, but a full-fledged artistic creation. And price will not be the key factor here. You can buy not the most expensive model, but use your imagination and do all the work efficiently. And enjoy the result.

www.istragorod.ru