The modern market for drainage structures presents to the consumer various products for the reinforcement of which not metal material is used, but special fiberglass or fiber. This group of products is distinguished not only by the characteristics inherent in reinforced concrete elements, but also has a significantly lower weight, reasonable cost, and improved anti-corrosion properties. It should be added that a concrete road drainage tray is installed even in areas with weak soil compositions or high groundwater levels.

Varieties

The design of concrete drainage trays is intended only for moving groundwater flows and precipitation. The products are easy to operate, they have quick access, simple installation, and significant load-bearing capacity.

Taking into account their purpose, drainage channels are divided into several groups.

It is customary to distinguish:

- culverts - through such sections water is drained by gravity;

- stormwater – collects and discharges natural precipitation;

- drainage – used in foundation structures, basements and basement levels of objects;

- edge - along them excess water flows from road surfaces into ditches;

- telescopic - drain water from sloping areas and bridges;

- sewer - direct water flows to sewerage collectors.

Drainage sections are manufactured in two modifications - solid or prefabricated.

By structural characteristics, both varieties are divided into certain forms:

- concrete tray for water drainage - a bracket in the shape of the letter “P”, having rectangular or rounded gutters;

- Floor slabs are made in the shape of trapezoids or parabolas.

In addition, in order to solve various problems, gutters are made that have solid sides or openings for removing water, installed vertically.

In total, there are about one and a half hundred standard sizes of reinforced concrete channels for draining water. They are marked with the letter “L” (tray) and a pair of numbers separated by a hyphen. The initial one (from 1 to 38) means the serial number, the second one means the maximum permitted load on the tray.

Sometimes manufacturers indicate additional symbols behind the main letter, the meanings of which are explained in the accompanying documents accompanying the products. For example, “Ldr” points out that the product is intended for arranging a drainage collector element. Another option is “Ld”. This means that the tray is an additional one, its length is shortened to make it more convenient to complete the construction of the road.

Sections made of concrete, reinforced with fiberglass material or fiber, are presented on construction markets in load classes from A 15 to F 900. In most cases, concrete drainage trays with gratings made of cast iron material are supplied and have two- or three-level sand collection systems.

This feature is important when the cost of construction is included in the estimate documentation.

Products from the Basic A-15 and B-125 series have proven excellent in local areas, pedestrian and bicycle paths.

The standard selection of Standard C-250 is used in the arrangement of pedestrian areas, roads with a minimum number of vehicles, and parking lots.

Trays from the Super D-400 categories (E-600 and F-900) can carry loads in accordance with the markings. They are used in areas of active vehicle movement. In order to confirm the declared characteristics, edges made of steel material are installed along the edge sections of the trays, which are corners, the thickness of which is three to four millimeters.

Note that road drainage trays are produced with an additional drainage element of a vertical type and can be equipped with their own internal slopes of five to fifty millimeters.

In order to improve the sealing of the entire system, the tray elements are connected with a one-component MS polymer - sealant.

Slope of drainage trays

During the installation of the drainage system, it is necessary to ensure that the trays run at a certain angle for the natural flow of water under the force of gravity. The angle of inclination is usually small - around 0.5-1%. If you take a section 1 m long, then the height difference between one end and the other will be approximately 7-10 mm. If there are problems with the amount of free space or it is not technically possible to withstand the slope of the drainage trays for other reasons, then you can take trays with the gutter already tilted. That is, the sections are laid on a flat area, and the water still flows freely down the gutter.

| IMPORTANT! If there is no slope or insufficient angle, water will stagnate and dirt will accumulate. Over time, such a system will become clogged and stop functioning. |

DIY drainage trays

Concrete and composite sections weigh a lot and, according to professional construction regulations, require the use of special equipment:

- mini-excavator - for digging a trench;

- front loader - for backfilling the gravel-sand cushion;

- manipulator truck - for careful unloading and laying of reinforced concrete trays.

Therefore, you can install drainage trays with your own hands only if you choose a plastic option. The sections can be delivered even by car, and their laying and leveling can be done alone and without special tools. At the same time, experts strongly recommend making a concrete base for the tray, or at least backfilling it with crushed stone and sand.

Typical sizes

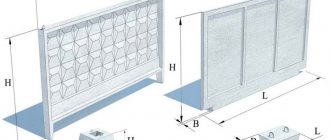

In order to clearly navigate the huge assortment of concrete drainage trays with gratings, it is recommended to correctly understand the generally accepted designations:

- D.N. This marking option was borrowed from the Germans. It shows the width of the internal gutter part in millimeters. 100 are considered European standards; 150; 200; 300; 500. Since the times of the Soviet Union, the standard values of 100 have been used in its former territory; 110; 150; 160; 200; 300; 500. Occasionally there is a marking “with a fraction”. In this case, the subsequent number marks the depth of the gutter channel in millimeters.

- L. The size of the section length, reaching from 50 cm to 3 m. There are manufacturers who produce longer structures, reaching six meters in length, or additional (shortened) elements of 50 - 70 centimeters.

- B. This letter indicates the outer width of the product. Taking into account the known DN and wall thickness, dimensions of 40 – 190 cm can be found.

- H. The depth of the product or its height. Domestic manufacturers in most cases work in parameters from 38 to 150 cm.

The manufacturer prescribes the weight of the tray with or without the grid in a metric compiled at its own discretion.

What to focus on when choosing?

There are three main factors that you should consider when choosing sewer trays.

It's about:

- about operational characteristics;

- about the features of installation work;

- about economic feasibility.

The choice of storm drainage trays is varied

When purchasing, do not forget to pay attention to the product’s throughput, configuration, service life, and, importantly, the requirements for the installation site.

Because these qualities determine how smoothly the entire system will function. H

As for the installation of storm drainage trays, it is better to first read the step-by-step instructions and strictly follow them.

Basic terminology

Drainage trays with gratings have incorporated certain formulations into their concept:

- Stormwater wells - the depth characteristics of such containers vary depending on the expected operating conditions. Such wells are mounted to storm drains;

- well for collecting sand - this container is designed to collect grains of sand, soil elements, and other solid objects. The element is made of several parts mounted into one sealed structure. Sand catchers that have one part are often used;

- waste bins are removable parts. They are classified as drainage trays and wells for collecting sand. This is where solids and debris accumulate. To remove them, the basket is removed from the well and cleaned;

- nominal value of the tray width – a design parameter, corresponds to the largest integer parameter of the tray in millimeters, taken horizontally;

- supporting tray surface - a reinforcement attachment, additional elements, and sometimes gratings are installed on it;

- reinforcing attachments - a construct necessary to protect other open-type elements from various damage likely from interaction with motor vehicles;

- contact surfaces – top of pads for reinforcement.

Concept

The storm drain tray is an oblong shape with a recess.

It collects moisture formed during rains or during snow melting.

In addition to the collection function, this design ensures the transportation of wastewater to the place of its further removal from the site.

Storm drain tray

Trays for storm drainage are needed by those who pursue the goal of creating optimal conditions that allow the use of open spaces.

In addition, stormwater is characterized by such advantages as:

Option for storm drainage tray

- preventing the accumulation of excess moisture and waterlogging;

- increasing the service life of the building’s foundation, sidewalks, blind areas and driveways;

- eliminating unpleasant situations associated with flooding of premises located below ground level;

- protection against erosion.

This is what a flooded building looks like

Product pricing

Concrete drainage products are made from raw materials that have an acceptable cost, which influences the final pricing policy. For example, a concrete tray without a lid, small in size and light in weight, costs from 200 rubles. for a unit.

The cost is formed from the cost of raw materials, parameters, completeness, shaped differences, performance indicators for throughput capabilities and transferred load forces.

The total cost includes the quality of the product, which depends on the production equipment. A significant role in pricing is given to the cost of the grate, which can be made of cast iron, steel material or polymer composites, and have a built-in vertical drain.

Direct wholesale purchases directly from the manufacturer guarantee the lowest prices and possible discount systems. The retail price depends on the number of intermediaries participating in the “supplier-buyer” chain.

It should be remembered that when purchasing such products, it is imperative to check the documents confirming the quality of the trays.

Video

The range of reinforced concrete sewer trays is represented by various models capable of withstanding loads from 1,500 to 90,000 kg. These reinforced concrete products are used for water drainage:

- Sports grounds, parking for cars, pedestrian areas (up to 1500 kg).

- Garages, private streets (up to 12,500 kg).

- Gas stations, car washes (up to 25,000 kg).

- Transport terminals, automobile enterprises (up to 40,000 kg).

- Warehouses, large enterprises (up to 60,000 kg).

- Military training grounds, airfields (up to 90,000 kg).

Do you want to know how much reinforced concrete storm drainage trays cost? The price of all products sold by the company can be clarified with consultants. And to buy concrete sewer trays wholesale and retail, just call an employee of the supply department.

Recommendations for the operation of storm drains

Surface drainage systems must be periodically cleaned of debris that has entered them. For this purpose, the following cleaning methods are most often used:

- mechanical cleaning of trays using improvised means. It involves removing and reinstalling the grilles;

- hydrodynamic cleaning with water pressure under pressure. In this case, only one grid is removed to insert the hose into the channel. The water rushes through the canal, washing away all the garbage. It is carried out using fire fighting equipment or special devices that create high water pressure.

There are also other methods of cleaning storm drains, which are used less frequently, mainly to clear ice from channels. Thermal cleaning involves pumping hot water into the ducts, while chemical cleaning uses chemicals to remove layers of ice. However, the last two methods are not so popular.

Advice: In order not to spend a lot of effort cleaning already clogged drainage systems, take timely care of storm drains by performing regular preventive cleanings throughout the year.

A drainage system assembled in accordance with all the rules will ensure high-quality surface drainage of the area for many years.

Approximate price level

The table shows the approximate price level for storm drainage trays of various types, among those most used when arranging storm drains in private households:

| Model | Short description | Strength class | Dimensions | Weight | Price per one. |

| SUPER DN 100 | ABCD | 1000×145×205 | 15,1 | 2400 | |

| SUPER DN 150 | Reinforced concrete tray with cast iron grate | ABCD | 1000×250×130 | 59 | 3900 |

| DN 100 | Lightweight concrete channel | ABC | 1000×160×157 | 32,5 | 450 |

| H-60 | Shallow plastic DN 100 without grille included | ABC | 1000×145×60 | 1 | 295 |

| H-185 | Reinforced plastic DN 100 without grille included | ABC | 1000×160×185 | 4,3 | 780 |

| "Light" - DN 70 | Lightweight plastic channel with galvanized grid | A | 1000×115×95 | 1,75 | 580 |

| H-125 | Polymer concrete gutter DN 100 without grating included | ABC | 1000×140×125 | 14 | 780 |

| H-130 | Polymer sand tray DN 100 without grid included | ABC | 1000×140×130 | 10,2 | 400 |

As you can see, the choice of gutters is quite large. There is always the possibility of the most optimal selection of the required models, both in terms of operational characteristics and installation work, as well as their considerations of economic feasibility.

Type