Natural and artificial factors affecting concrete

The impact on the exposed parts of concrete is somewhat different from the factors affecting the durability of the underground part of concrete structures - hence the very conditional division into two main groups of impact.

Aboveground part

Types of impact on open elements of reinforced concrete products:

- Atmospheric phenomena and natural processes in the form of precipitation, changes in air temperature, the number of freezing and thawing cycles, the phenomena of tides, floods, flooding;

- Deformation phenomena of a temperature nature - swelling of soils from frost, natural or technological deformation of soils from loads; action of aggressive liquids and gases, petroleum products, acids.

Underground part

Parts of concrete structures buried in the ground are subject to numerous one-time and systematic destructive effects:

- frost heaving of soils;

- seismic natural phenomena;

- pressure and unevenness of groundwater levels;

- unstable and unregulated chemical composition of groundwater.

Special cement and modifying additives

The content of various chemical components in water is quite unpredictable for a particular place and even time, depending on a large number of external factors.

The presence of salts and sulfates in water, which can lead to the destruction of concrete, forced cement manufacturers to look for ways to protect the material.

To increase the moisture resistance of reinforced concrete products and structures, it is possible to use higher grades of concrete or special additives.

Special types of concrete and products made from them have been developed against the effects of aggressive chemical components of water. One of the most common types is sulfate-resistant concrete - it can be prepared from ordinary grades of cement using modifying additives.

But a more reliable and practical option is to use special-purpose Portland cement, sulfate-resistant cement, as a binder for concrete that is resistant to aggressive environments.

Hydraulic concrete

Standard concrete is used in many areas of modern construction, as well as some other related areas. This material is known for its versatility. However, this factor does not imply effective use in specialized areas. To ensure this, special types of compounds are used that have the characteristics necessary for each specific case. It is worth considering in more detail hydraulic concrete and the features of its preparation.

The main problem of structures located in water is destruction under the influence of absorbed moisture. At the same time, it is not those parts that are located below the surface that are in greatest danger. A significant problem is the variable water level, which has an extremely negative impact. Thus, hydraulic concretes must have certain distinctive features. The main criterion is resistance to aggressive external environments. Additionally, a minimum rate of heat generation during the curing process should be ensured. If we consider the classification of hydraulic concrete, the most popular is the division into eight grades, in accordance with the ultimate compressive strength: 100, 150, 200, 250, 300, 350, 400, and 500. The peculiarity of this composition is that its samples should be taken only six months after installation, which significantly exceeds the same period for other types of mixtures. It should be noted that various methods are used to establish a mark at any time. One of the most important indicators is water resistance. It is determined by the maximum pressure hydraulic concrete can withstand so that it does not leak moisture into its internal structure within 180 days. Frost resistance is another characteristic of hydraulic concrete that deserves special attention. It involves division into several grades: 50, 100, 150, 200, 300, 400, 500. The main evaluation criterion is how many cycles of temperature changes around the freezing point of water can hydraulic concrete experience before its strength decreases by 15 percent of nominal level.

This building material uses Portland slag cement and pozzolanic cement, as they provide resistance to aggressive environments. If there is a variable water level, substances with specialized characteristics are used. This includes sulfate-resistant Portland cement, which has moderate exotherm, as well as hydrophobic Portland cements.

Since for hydraulic concrete

, located in different parts of the structure, different factors act, then the requirements for its characteristics may differ. There are 3 zones:

- surface;

- underwater;

- borderline.

The last is the most difficult area, because despite the fact that the substance is in the open air most of the time, its humidity reaches the maximum value for this material. Hydraulic concrete

It is constantly washed with water, which negatively affects the strength of its structure.

Significant temperature changes also do not add strength to the material. It is for this reason that many structures require materials with high frost resistance. The risk zone includes spillway elements of dams, port berths, cooling towers of thermal power plants and metallurgical enterprises. Hydraulic concrete

is made from special aggregates that are characterized by high frost resistance and purity: the alkaline content should not exceed 0.6 percent.

Sand for preparing the mixture must be of the highest category and have a minimum amount of any third-party inclusions. In the process of preparing the solution, it is necessary to take into account the requirements of GOST 8736 of 1993, which regulates a set of requirements for such a component of the solution as fine aggregate. According to this document, hydraulic concrete is produced from sand with a density of 2-2.8 t/m3. The grain size of the component should not exceed 2 mm, otherwise a number of problems may arise related to the mobility of the solution. Any hydraulic structure, such as a bridge or dam, requires a material that not only has high waterproofing characteristics, but also sufficient strength. In order for hydraulic concrete to obtain the necessary reliability, coarse aggregate must be selected with special care. Of course, in most cases it is granite, which is not only distinguished by its ability to withstand enormous loads, but also practically does not allow moisture to pass through.

In addition, experts try to take into account such characteristics as flakiness. The higher it is, the closer the shape of the individual element is to flat. It is obvious that hydraulic concrete, which is made from needle-like aggregate, will have less strength than a composition that contains cube-shaped crushed stone. Such grains make it possible to obtain maximum density when laying in formwork, which means they can distribute higher loads throughout the entire volume. Fewer voids will not only increase strength, but will also reduce the consumption of sand and cement. Hydraulic concrete

for creating bridges, which is also called pavement, is characterized by fairly high strength. Such compositions are used for the construction of sewage treatment plants, bridge overpasses and other objects built in similar conditions.

Only this type of mixture can ensure the creation of long-distance structures operating in direct contact with water.

Hydraulic concrete

during the installation process, it requires operations aimed at compacting it. Most often, deep vibrators are used for this purpose, allowing to achieve maximum characteristics for a given type of solution.

Clinker minerals and concrete degradation

All types of cements differ significantly in mineralogical and chemical composition, since the sources of raw materials and the ratio of raw materials are different.

Four types of minerals

Scientists from different countries have made attempts to control the properties of cements for accurate classification by type of purpose and to eliminate the procedure of constant physical tests. But an attempt to establish the maximum ratios and quantities taken as a basis for four clinker materials was unsuccessful. The reason for the failure is that the mineralogical composition of the raw materials cannot be sufficiently accurate and does not take into account the required properties of cement, which means control physical tests of cement are necessary.

Main clinker minerals

- C2S - dicalcium and C3S - tricalcium silicates;

- C4AF tetracalcium aluminoferite;

- C3A - tricalcium aluminate.

Mechanism of concrete destruction

Interacting with water containing sulfates, C3A aluminate. calcium hydrosulfoaluminate is formed with further crystallization in the concrete structure. This leads to expansion of the volume with subsequent destruction of concrete.

Such crystallization is most often observed with a large number of cycles of concrete flooding followed by drying. First of all, this applies to hydraulic structures - bridge supports, buried piles, submerged foundations.

Even efflorescence crystals on a brick wall can lead to its destruction. Reinforced concrete reinforcement is also subject to similar processes; anti-corrosion additives are used to protect against them.

Sulfate-resistant cement: composition and standards

Technological solution for the production of sulfate-resistant cement: limiting the amount of clinker mineral C3A in the total volume of cement to 5%.

In sulfate-resistant cement with mineral additives, more than 8% C3A is not allowed. GOST 22266-94 provides the same limitation for sulfate-resistant pozzolanic and Portland slag cement.

Tricalcium silicate C3S in sulfate-resistant cement without mineral additives should be no more than 50%; this standard does not apply to other types of sulfate-resistant cements.

Types of cement

The main difference between cements that increase the resistance of concrete to the effects of sulfuric acid salts is the special chemical composition of the clinker used for their production. The content of tricalcium aluminate, magnesium and aluminum oxides in it is reduced.

Classification by composition

Sulfate-resistant cements are classified into 4 types according to their composition:

- CEM I - Portland cement;

- CEM II/A - a mixture of Portland cement with additives (content up to 20%);

- CEM II/B - a mixture of Portland cement with additives (content from 21 to 35%);

- CEM III/A - Portland slag cement (slag content from 36 to 65%).

Granulated blast furnace slag, pozzolana, and their mixtures with microsilica are used as additional components.

Strength classification

Based on compressive strength, cements are divided into classes and 2 subclasses; sulfate-resistant cements are produced in only 4 types.

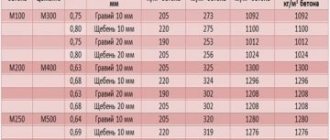

Table 1. Minimum compressive strength of cements that increase the resistance of concrete to sulfate corrosion (MPa)

| Class | Subclass | 2 days | 7 days | 28 days |

| 32,5 | N | – | 16 | 32,5 |

| B | 10 | – | 32,5 | |

| 42,5 | N | 10 | – | 42,5 |

| B | 20 | – | 42,5 |

Subclasses: N - normal hardening; B - fast-hardening.

Profitable proposition

The BESTO Group is an experienced professional supplier of almost all types of cement, including bagged sulfate-resistant cement.

The properties of this special cement are no worse than other brands in conventional construction, but if unforeseen circumstances arise, the developer has additional confidence in the quality and durability of the structure being built using sulfate-resistant cement.

Our price for cement with protective properties is similar to the price of other brands, which means you are purchasing a material with free additional improved properties.

Applications and advantages of hydraulic concrete

Various objects are built from hydroconcrete above and below water:

- dams;

- dams;

- gateways, etc.

In addition, material with high waterproofing characteristics is used for the construction of runways, highways, and radiation shelters. It is also used to build structures in the Far North, where buildings are exposed to harsh climatic influences.

Due to the physical and chemical characteristics, the main advantages of hydroconcrete have been formed:

- waterproof regardless of operating conditions;

- immunity to temperature changes;

- high strength compared to building mixtures of standard brands.

At the same time, hydraulic concrete is more expensive than other types of mortars, and its installation requires special knowledge and skills.