What is cellular concrete

To make such a material, ordinary cement is used as a base. But during the production process, raw materials are subjected to special influences.

For example, it is additionally thoroughly mixed until foam forms or a chemical foaming agent is added to it. In any case, a mixture is formed in which there are many air bubbles.

After the raw material hardens, the resulting material contains a huge number of pores. It is this feature that determines what practical qualities cellular concrete has.

Continuous development of production technology

By adjusting the composition of concrete, you can make it impervious to water, increase frost resistance, plasticity, change the speed of setting and strength gain, and ensure the possibility of laying the mixture in winter at low temperatures. Today there are formworks that control the process of water absorption and remove excess moisture from the hardening mixture, leveling out unevenness. This allows you to achieve an ideal result when concrete gains strength, increasing the reliability and durability of the structure.

Active development is underway and there are already samples of concrete, the cracks of which tend to grow together. The restoration of the structure occurs as a result of the work of special bacteria introduced into the mixture and producing limestone. Activation of concrete restoration processes occurs under the influence of atmospheric waters.

Disadvantages of concrete with a cellular structure

And yet it should be understood that the cellular structure is also associated with certain disadvantages. Due to its porosity, cellular concrete cannot withstand too much load.

Therefore, the material is suitable for the construction of houses of 2-3 floors, but not higher.

In addition, the cellular structure easily absorbs moisture. It is desirable that a house made of such material be additionally protected with waterproofing.

If you use cellular concrete correctly, you can get a reliable and inexpensive house.

It is only necessary to take into account these features. Share:

Advantages and disadvantages of concrete

There is no doubt that progress does not stand still. Almost every day in our lives new objects, technical means, devices and devices appear that greatly simplify human life. Using all this, people get a wonderful opportunity to save not only their own energy, but also time, which is very important in the twenty-first century.

Modern cities are growing at tremendous speed. And this is also very easy to verify. It will be enough to walk along one of the city streets. Today, almost everyone can see with their own eyes how fast modern cities are growing. If just a few decades ago it took several years to build a house, today building a house can take only a couple of months. And there are reasons for this. The most important reason is, of course, the use of new technologies and new, more efficient building materials, as well as new and improved construction equipment, thanks to which the construction process has become a real pleasure for those who do it.

According to many experts, a special role in this case is assigned to building materials. In this article I would like to draw your attention to one material, without which any construction process is unlikely to be carried out. This material appeared on the construction market relatively recently. But, despite this, he managed to gain wild popularity. Probably, many have already guessed that we are talking about concrete. Nowadays, concrete is a universal material. Today, diamond cutting of concrete can be carried out even by those who do not have the appropriate qualifications.

But we should not forget that while having many advantages, such a building material as concrete is not without its disadvantages.

Let’s try to list at least the main advantages and disadvantages of concrete.

Perhaps we should start with the positives. Concrete is a relatively inexpensive building material compared to expensive steel, which has become less and less preferred lately. In addition, the indisputable advantage of reinforced concrete is its reliability, strength and durability, high fire resistance, as well as ease of use. It is worth paying attention to the fact that the preparation of the mixture can be carried out even by a person who does not have special education. When working with this building material, you do not have to worry about your own health. Concrete does not pose any danger.

As for the disadvantages, it is worth mentioning the low level of heat and sound insulation. In this case, even wood and brick have significantly higher thermal and sound insulation rates than concrete.

Plus, concrete structures do not have great tensile strength. As a result, cracks may appear prematurely in concrete structures.

Basic properties

The characteristics of cellular concrete vary greatly due to differences in composition, manufacturing method and density.

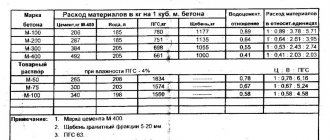

The following is a comparative table of porous blocks according to their main properties:

| Type | Volumetric weight (density), kg/m3 | Strength, kg/cm2 (N) | Coef. thermal conductivity | Interaction with moisture |

| Foam concrete | 200…800 | 25 | 0,12 | Open pores, requires protection |

| Aerated concrete on ash | 600 | 35 | 0,14…0,17 | Requires protection from moisture and water |

| Aerated concrete | 400…1600 | 7…60 | 0,1…0,33 | Moisture resistant |

Cellular concrete includes another group of porous materials with a polymer filler - polystyrene concrete. These are blocks whose cells are filled with polystyrene foam balls. The products have excellent thermal insulation, but are more afraid of heat than others (the polymer compound, when melted, releases gases that are hazardous to health and life) and do not allow moisture to pass through.

Of the large group of concrete blocks, gas and foam blocks are in greatest demand.

Their more detailed technical characteristics, which experts rely on when choosing wall materials:

| Parameter | Units | Aerated concrete | Foam concrete |

| Product characteristics | |||

| Density | kg/m3 | 400…800 | 400…1200 |

| Density grade | D | D350, 400…700 | D400…800, 1000…1200 |

| Coef. Thermal conductivity | W/m∙°С | 0,1…0,14 | 0,09…0,38 |

| Compressive strength class | B | B2.5 at D500 | B2.5 at D750 |

| Vapor permeability | mg/m∙h∙Pa | 0,2 | |

| Water absorption | % by weight | 20…25 | 10…16 |

| Frost resistance | Cycles, minimum | 50 | 25 |

| Masonry | |||

| Seam material | Glue | Glue, cement mortar | |

| Seam thickness | mm | 2…3 | 10 |

| Average shrinkage | Mmm | 0,3 | 2…3 |

| The need for masonry reinforcement | Eat | No | |

| Single-layer masonry wall thickness | m | 0,4 | 0,63 |

| Pore type | Closed | Open | |

The production and key parameters for porous concrete blocks are regulated by GOST 21520-89 “Small cellular concrete wall blocks”.

Prospects for use in road construction

Almost 90 thousand kilometers of highways in the United States are made of concrete. Compared to traditional asphalt pavement in our countries, concrete roads have a longer service life (up to 30 years) and offer less resistance to moving vehicles, which reduces fuel consumption by more than 10%. Concrete roads are easier to maintain in good condition, they do not float and allow cars to reach higher speeds while maintaining a safe driving mode.

Another cutting-edge development of British scientists, highly porous concrete for highways, is distinguished by its ability to absorb water in incredible quantities - about 400 liters per minute over an area of several square meters. At the same time, thanks to the porous structure, such a composition can significantly reduce the noise load on busy routes. The material reflects light well, making the road more visible in low light conditions at night, and, accordingly, increasing the level of road safety.

Dimensions

Cellular concrete blocks are produced in a wide range of sizes depending on their purpose:

| Block type | Length, mm | Width, mm | Height, mm |

| Wall | 400…600 | 200…500 | 150…400 |

| Septal | 300…600 | 100…150 | 400 |

A wide range of products allows you to select the most suitable products for laying out structures of any complexity, thereby saving construction time and labor costs.

Decorative concrete: advantages and disadvantages

The area near any house needs qualitative changes, since standard materials (usually the simplest and most affordable) have long ceased to cope with their purpose. And if the same asphalt or concrete does not raise any questions as a hard surface underfoot, then because of the standard it is better to forget about aesthetic pleasure. Especially when the surface begins to become covered with unsightly cracks.

Is there an effective way out of this situation? Decorative concrete. It's just gaining popularity, but it's a truly impressive option for any backyard as it can create a masterpiece that will take your breath away. What is noteworthy is that there are really many options for implementing existing ideas - there are no barriers, even if the flight of fancy goes beyond the usual boundaries.

There are three technologies for creating decorative concrete:

- stamped;

- sprayed;

- stencil

Stamped decorative concrete – it is also called printed concrete, which is a reflection of the creation process. Monolithic concrete layers that have already been laid are treated with a special mixture that strengthens the solution and gives it a certain color. After this, the surface is covered with a material that prevents the matrix from sticking to the mixture itself, and stamping is performed. After removing the matrices (you must wait more than 12 hours for drying), the surface is additionally coated with a protective composition, which ensures the durability of the work done.

Sprayed decorative concrete - a colored polymer-cement coating is applied to the surface, which not only gives the desired appearance, but also makes the material more reliable. Additionally, it is coated with a protective composition to preserve color and protect the decorative layer from the influence of nature and damage during use.

Stencil decorative concrete - a color fixative is applied to the surface, which is rubbed in using special equipment, also performing smoothing. After a short period of time (from 10 minutes), using stamps placed on the concrete, impressions of the drawings are made. Every other day, the surface is processed - all unnecessary material (material for stamps) is removed, after which the entire area is covered with protective varnish.

Decorative concrete is most often used to create:

- pedestrian paths;

- car entrances and parking lots;

- patios and areas for various purposes.

There are so many advantages of decorative concrete that you have to dwell on only some of them to get a rough idea of how successful the choice will be. A special place is occupied by a durable surface, which is not afraid of fading, moisture, or abrasion, although over time some of this will still make itself felt. The real trump card is high-quality imitation for tiles, wood, slate and much more that the customer may desire. The words that there are no restrictions are true, which is not so difficult to verify in practice.

There are no serious shortcomings, but there are certain difficulties that require a special approach. Firstly, the customer will have to come to terms with the fact that the process will take quite a lot of time - there is no point in talking about high-quality execution in a short time. Secondly, the means at hand will simply not be enough, so it is necessary to have special equipment and appropriate knowledge so that problems do not arise at the most crucial moment. Thirdly, the cost is several times more expensive than ordinary paving slabs.

Waterproof concrete: pros and cons

A special type of very dense concrete is called waterproof. There are no pores or capillaries through which water penetrates into the material, leading to corrosion of the reinforcement and, when frozen, to cracking of the concrete object. will prepare for you all types of concrete mixtures, including those with special properties. Our concrete plants in St. Petersburg are at your service, as well as an impressive fleet of mixers that carry out prompt delivery of ready-mixed concrete throughout the city and Leningrad Region.

It is important to understand that the use of waterproof concrete does not eliminate the need to take care of waterproofing buildings. The impermeability of the material itself is important, but concrete always contains structural and expansion joints, and openings are provided in foundations and walls for the entry of communications.

Therefore, often builders by the term “waterproof concrete” mean not only the artificial stone itself, produced according to a special recipe, but its complex use with special joint fillers that ensure sealing of the joints. In this case, we can only talk about monolithic buildings: it is impossible to achieve waterproofness of prefabricated structures due to the large number of moving seams.

Do you want to order waterproof concrete? It has both obvious advantages and some disadvantages - it is important to consider the features of this building material from all sides.

Excellent waterproofing properties are the most important advantage of such concrete. Products made from it can remain in the open air or in the ground for a long time without suffering from atmospheric and ground moisture. Therefore, such compositions are chosen for objects that will be operated in places with variable water levels or even completely in water.

Another important advantage of waterproof concrete is its high resistance to sudden temperature changes. After all, concrete is destroyed mainly due to the freezing (and expansion) of water that gets into it. And in the composition of such special concrete there is not enough moisture so that if there is a temperature difference, it can cause serious harm to the structure of the material.

As for the disadvantages, the price of waterproof concrete is one of them. To ensure proper waterproofing characteristics, a precisely calculated amount of special additives (quite expensive, and their amount must be equal to 3-6% of the volume of the concrete batch in order to obtain the required parameters) is added to the mixture at the concrete plant.

Another negative point is the rapid setting of such concrete mixtures. They must be laid with maximum speed; problems with transportation naturally arise. Since our company’s concrete plants are located in three different areas of St. Petersburg, delivery of your order will be carried out from the nearest production facility - and therefore will take the least amount of time.