This building material belongs to the group of heavy concrete mortars and is used in the construction of critical structures. The mixture contains a large amount of Portland cement, which is a determining factor in strength indicators. Concrete 400 is designed for use in difficult conditions. An important feature in its application is strict adherence to established design standards and work performance requirements. Today, m400 concrete is used much more often than five years ago. The popularity is explained by increased government control over the construction of facilities.

Areas of use

M400 concrete, which meets the requirements of GOST, is used for the construction of objects whose operation involves the impact of significant mechanical loads, which creates significant stress in the concrete body.

Such objects include:

- bridges with railway tracks, overpasses for road transport, viaducts, overpass lines, etc.;

- bank vaults - concrete m400 f150 is used for their arrangement;

- load-bearing structures in the form of columns, beams, lintels, etc.;

- concrete class B30 m400 is indispensable for hydraulic structures;

- monolithic high-rise buildings, critical reinforced concrete products - in these cases, M400 concrete is used, made on the basis of granite aggregate.

Application area

Concrete grade M400 is used where high strength and frost resistance are extremely important:

- In the manufacture of beams, piles, lintels and other elements of load-bearing structures of buildings.

- For filling areas for heavy equipment.

- When constructing swimming pools, dams, sewers, etc.

- For the construction of bank vaults, tunnels and other objects where high strength and water resistance are required.

- Construction of monolithic walls for high-rise buildings.

- During the construction of bridges, viaducts, interchanges.

Heavy concrete is not used in low-rise construction

That is, M400 concrete has mainly industrial applications. In private construction, even when building swimming pools or foundations for cottages, it is excessive in strength and therefore is used very rarely by private owners.

In addition to too high strength, a high hardening speed also interferes. On the one hand, this is a plus: concrete quickly gains strength. So fast that you can walk 8-10 hours after pouring. But it is possible to lay it without cold seams only with continuous supply and the presence of a qualified team. In all other cases, there is a high probability of getting delamination and cracks. The introduction of additives to increase the time before setting begins increases the already considerable price. And the price is high, because to ensure the required strength, high-quality cement is needed, and even in large quantities. So private owners use M400 concrete extremely rarely.

Characteristics of concrete m400

The state standard regulates the following technical characteristics for concrete grade 400:

- strength corresponds to class B30. The average compressive strength is 390 kg per square centimeter;

- frost resistance corresponds to three hundred freeze-thaw cycles;

- moisture resistance - this indicator allows the use of this material in the construction and repair of objects that are constantly in contact with the aquatic environment. Its interpretation is concrete m400 b30 w4, in which the last value indicates the level of water resistance;

- the specific density value is 2,400 kg per cubic centimeter;

- mobility coefficient – P4. The material is characterized by workability, on the basis of which it is used in constructing structures with a dense reinforcing base without the need for additional compaction.

Concrete strength classes m400

The class of a concrete mortar is determined by the value of its compressive strength; the letter “B” and numbers 0.5 – 120 are used to designate it, indicating the maximum level of pressure withstanding in MPa.

The axial tensile strength class is designated “Bt”.

In addition to the class, the strength of the mortar can be specified by the “M” grade. The adjacent numbers indicate the maximum compressive strength and are expressed in kilograms per square centimeter.

The data on the class and brand of concrete are similar, the difference is that the brand indicates the average strength, and the class indicates the same indicator, but with guaranteed security.

Note that stamps have long been abolished, but most builders prefer to use this indicator.

So, what class is M400 concrete? As follows from special tables, the strength class of such material is B30.

Compound

M400 concrete mortar is made according to a specific recipe. The composition of concrete includes the following ingredients, taken in certain proportions:

- Portland cement;

- river or quarry sand;

- pure water;

- granite or crushed gravel.

In order to impart special properties to the concrete solution, special plasticizer additives, colors and other components are used.

Manufacturing technology

Making high-quality M400 concrete at home is quite difficult. To do this, it will not be enough to select the desired proportion of ingredients and mix them. It is necessary to strictly follow the technology and carefully select the material. Each component of a building material has certain requirements, the list of which looks like this:

- The sand must be clean, without inclusions of clay, earth, silt or limestone - they increase the viscosity of the mixture, which negatively affects the adhesion and strength of the building material. It is best to purchase this element for concrete production in special construction stores, where a high-quality product without impurities is delivered. Ordinary river or quarry sand will also work, but it must be thoroughly washed. If there is still moisture in the material by the time the concrete is prepared, it must be dried. You can also reduce the amount of water in the mixture, but then it will be difficult to calculate the appropriate proportion.

- The water for the mixture must also be free of foreign impurities that can negatively affect the hardening process and the final properties of concrete. It is best to take a warm, but not hot liquid.

- Crushed stone for the production of concrete mixture should be selected that is not too large, but not small either. Its optimal fraction is from 5 to 20, that is, the maximum size of an individual pebble should not exceed 0.5-2 cm. The strength of the material is also important - only high-quality varieties with this characteristic from M1100 or higher, obtained by crushing and processing hard rocks, are suitable breeds

- The main requirement for cement in the production of concrete is that it must be of the same grade as the planned final product. Otherwise, when mixed with water, crushed stone and sand, the specific gravity is too low, resulting in the ingredients being redistributed. It is best to choose fine-grained varieties of cement. In addition, it is important that it is stored in the right conditions, dry and fresh, preferably no more than 3 months from the date of manufacture.

READ Composition and main characteristics of M500 concrete

Having selected high-quality components and measured their proportions, you can begin making concrete. This is done in the following steps:

- First, cement and sand are mixed. This is done very carefully until the resulting mass becomes completely homogeneous.

- Then add water. Many qualities of concrete depend on its quantity, from strength to porosity and frost resistance, so in this process you need to be careful and carefully measure the quantity.

- The crushed stone is placed last, after which the mixture is thoroughly mixed again until smooth. The consistency should resemble very thick sour cream.

- After this, you can begin transporting and pouring concrete. It is important to maintain positive temperatures during this process to prevent premature hardening.

Heavy concrete is difficult to mix manually - most of it is produced in concrete mixers according to a predetermined program. But if for some reason it is needed in private construction, and it is not possible to buy or order building materials, with due diligence it is quite possible to achieve satisfactory results in independent production. The main task will be to continuously knead it without being distracted by any external factors. An assistant will also be useful for adding components conveniently and in a timely manner.

Proportions

Let's consider the ratio of the components used in the preparation of M400 concrete.

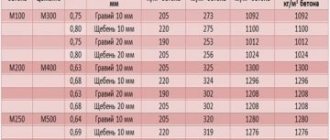

The composition of raw materials per 1m3 of concrete material is given in the table:

| Grade of cement material | Ratio C:P:SH:W | Cement, kg | Sand, kg | Crushed stone, kg | Water, l | weight of 1 m3 of concrete m400, kg |

| M400 | 1:1.5:2.5:0.5 | 420 | 625 | 1 085 | 190 | 2315 |

From the data in the table it immediately becomes clear how much cement is in 1 m3 of m400 concrete. From here you will understand how many other components you will have to purchase to make M400 concrete with your own hands.

If a large amount of concrete material is required at the same time, you should order finished products, which will be transported by special transport directly to the construction site.

This type of service can be provided by an enterprise located in Dmitrov.

Concrete brand 400 what class and composition

Concrete M-400 class B 30 is a heavy building material and was developed for use in high-strength structures. These are objects such as subways, tunnels, hydraulic structures, storage facilities, reinforced concrete columns, crossbars, beams, swimming pools and building structures with special strength requirements. In large-scale industrial production and in the private sector, M400 concrete is rarely used, since it must meet special requirements for the operation of such structures.

Strength and compressive class are the main characteristics of concrete of any grade. The class is indicated by the symbol “B” and numbers from 3 to 40 (for example, 30), strength - by the symbol “M” and numbers from 50 to 1000. The numbers in the strength designation reflect the maximum load for a particular class of concrete. Thus, grade M 400 corresponds to a maximum load of no more than 400 kg per 1 cm2.

In the private sector, grade 400 concrete is rarely used. It is unpopular for the following reasons:

- The strength of the material is much higher than required according to SNiP requirements for low-rise buildings. As a result, construction costs are higher;

- The fast setting time of the working mixture is harmful when transporting over long distances, even when using special equipment: automixers, concrete trucks or concrete mixers - workers may not have time to accept and place the liquid solution into the formwork;

- The high cost of grade 400 is due to the high percentage of cement. This brand is produced on crushed granite with plasticizer additives.

Properties and characteristics

Durable concrete of class B30 is used in construction areas that have special requirements for external factors. The technical characteristics of this building material are very high: frost resistance up to F300, water resistance up to W12. A structure made of such material can only be destroyed with a force of at least 395 kg/cm2. The table shows how the grade density of other materials differs in comparison with grade 400:

Brand Specific gravity, kg/m3

| 250 | 2348 |

| 350 | 2502 |

| 400 | 2376 |

| 500 | 2298 |

Concrete grade M-400 class B 30 corresponds to moisture resistance classes W6-W12, frost resistance F100-F300 and mobility P3-P5. When W6 is waterproof, its density is 2430 kg/m3.

Components of B-30 mixture

| Weight of cement, kg/m3 | 400 |

| Water mass, l/m3 | 160 |

| Filler weight, kg/m3 | 660 |

| Total mass of gravel, kg/m3 | 1166 |

| Mass of gravel size 20 mm, kg/m3 | 700 |

| Mass of gravel size 10 mm, kg/m3 | 466 |

| Mass of plasticizer in l/m3 | 2,4 |

| Water/cement ratio | 0,4 |

To obtain grade 400 concrete, it is necessary to add cement of the same strength or higher to the solution. When adding smaller grades of cement, their low density will result in a low specific gravity, resulting in an overconsumption of the constituent materials. The table shows the correct proportions of materials for preparing M400 concrete:

Cement Proportions cement/sand/crushed stone Volume of components sand/crushed stone Volume of concrete in liters from 10 liters of cement

| M 400 | 1 : 1,2 : 2,7 | 11 : 24 | 31 |

| M 500 | 1 : 1,6 : 3,2 | 14 : 28 | 36 |

What necessary components are needed to prepare concrete M 400 per 1 m3 using cement grade M 500:

Class Density Ease of installation Cement, kg Sand, kg Crushed stone, kg Water, liters

| B 30 | 2430 | P 2 | 420 | 770 | 1080 | 155 |

| B 30 | 2430 | P 3 | 445 | 765 | 1040 | 165 |

How to prepare the solution

To prepare concrete M 400 (B-30), specially prepared components are used. High-quality cement with a small particle size, purified sand, granite crushed stone and water, which regulates the mobility of the solution. Concrete M 400 and its components must be added in strict proportions.

For 1m3 of solution you need:

- 395 kilograms of cement per 1m3 of finished mortar. It is recommended to add PC 500 cement, which meets the requirements of GOST 10178-85.

- 870 kilograms of first class sand according to the requirements of GOST 8736-93. Sand in the solution is intended to create a dense concrete structure and fill voids.

- 1075 kilograms of dense granite crushed stone per 1 m3 of concrete M 400, corresponding to GOST 8267-93 and GOST 26633-91. The strength of crushed stone should be 1200 units. Crushed stone fractions – 5-20 mm.

- The volume of water is at least half the mass of all components, but in such quantity as to fully react with cement. For 1m3 of the finished mixture you will need about 170 liters of water with a neutral pH (acidity level).

- 7.6 kilograms of plasticizers. The density of standard plasticizers is 1.172 kg/l, produced in liquid form with a 30% concentration of additives.

If moisture resistance is not lower than W10 for grade M-400, additional waterproofing additives will not be needed.

In individual construction, mortar for a house or foundation is often prepared using ordinary buckets as a measurement. To reduce the error in the proportions measured in this way, crushed stone and sand in buckets should be lightly pressed down and leveled along the edges of the bucket. Dry building materials are mixed in a suitable container or concrete mixer. If the tank is homemade, then shallow grooves for cement are formed in the mixture, where it should be poured. All components are thoroughly mixed until a uniform, monochromatic mass is obtained.

Example: you need to calculate how much sand, crushed stone, M 500 cement and water are needed to prepare M 400 concrete. If you take 20 buckets of M 500 cement, then you will need 32 buckets of sand, 64 buckets of crushed stone, 10 buckets of water. Knowing the density of all materials, you can convert the number of components in the buckets into the required units of measurement. For example, a ten-liter bucket of cement weighs 12 kg, where 1200 kg/m³, the same bucket of sand will weigh 14 kg, and a bucket of gravel will weigh 15 kg.

Current cost of concrete grade M400

This brand is much more expensive than materials lower in the table of properties and characteristics of concrete. Price range - 4100-4400 rub/m3. This building material belongs to the middle class of efficiency; ready-made mixtures with mobility classes P3-P5 are available for sale.

This solution can be ordered from manufacturing plants operating in every region of the Russian Federation, or purchased at a construction supermarket. It is very difficult to visually determine the brand of the mixture, therefore it is necessary to require accompanying documents and product quality certificates - in order to prepare high-quality construction concrete of the M400 brand, it is recommended to strictly adhere to the technology of its preparation, the ratio of the proportions of materials and batch recipes.

Useful tips

The correct mixture of grade 400 mortar for pouring the foundation is: cement - 10 parts, sand - 30 parts, gravel/crushed stone - 50 parts. Water should be added half as much as the total weight of all components. If the sand is wet, it needs to be dried or less water added to the solution. Sand must be added only purified or river sand, without admixtures of clay, limestone and other binders, so that the adhesion and strength of concrete does not decrease.

The consistency of the finished solution should resemble thick sour cream. It is better to pour formwork for any concrete structure at positive temperatures, otherwise you will have to bear the costs of heating the formwork, arranging drainage, and resisting premature hardening of the concrete.

Based on data on the properties of concrete and the characteristics of the components, it can be argued that grade 400 is used only in the construction of critical construction projects that are subject to heavy loads during operation. Even based on the weight of 1 m3 of M400 concrete, you can see that this building material has a high density and can withstand any load perfectly.

Where M400 concrete is used updated: November 23, 2020 by: Artyom

okbeton.ru

Examples of calculations

For convenience in work, we give an example of the proportions of raw materials in buckets. The unit of measurement will be a ten-liter bucket, with 1 liter equal to 1 cubic decimeter. It turns out that the bucket is equal to 0.01 cubic meters.

We determine the need for cement material. Its specific density is 1,300 kg per cubic meter, so one liter equals 1.3 kg. The need for cement for a cube of concrete will be 323 liters, which is 32.3 buckets.

Now let’s calculate the amount of sand in the M400 concrete recipe. With a material density of 1,500 kg per cubic meter, 1.5 kg of sand will fit in one liter. Therefore, kneading will require 416.6 liters - 41.7 buckets.

It remains to find out the amount of crushed stone for concrete grade M400. If the material is granite, then its specific density will be 1,350 per cubic meter. m. For 1 liter there will be 1.35 kg of stone. In total, you will need 804 liters or 80.4 buckets.

For water everything is simple - 19 buckets.

Knowing the number of initial components, it is possible to determine the specific gravity of one cubic meter of material and calculate the volumetric weight of concrete m400.

Preparation

It should be noted that the production of M400 concrete mortar is practically no different from mixing any type of similar material. However, in order for a concrete mixture to receive a certificate of conformity, it will have to strictly adhere to certain technologies.

The slightest deviations can cause a decrease in the characteristics of concrete 30 m400.

Proper selection of starting components will allow you to prepare high-quality concrete of the M400 grade, which will correspond to class B30.

When purchasing cement material, it is recommended to make sure that it has not absorbed moisture during storage and was made no more than three months ago. Another important feature in preparing concrete is the choice of good raw materials. Having prepared everything you need, you can start preparing the batch. The work is performed in the following sequence:

- cement and sand are mixed until the mass becomes homogeneous. By the way, you can purchase ready-made dry concrete M400 in bags, which will greatly facilitate and speed up the work process;

- water is added, the volume of which will determine the strength of the entire structure. It is recommended to infuse the liquid in certain doses;

- Lastly, crushed stone or other filler is added, everything is thoroughly mixed and put to work.

The setting time of concrete depends on the amount of cement material used in the batch.

Advantages and disadvantages

From the main characteristics of this brand of concrete you can understand what its strengths are. These include the following properties:

- excellent strength and density of M400 concrete, allowing it to be used in the construction of almost any part of the structure;

- good performance in everything related to protecting a home or other structure from weather conditions and other negative environmental influences;

- high resistance to mechanical damage;

- faster setting than other brands, which speeds up the process of construction work using this material.

READ Composition of expanded clay concrete, its proportions, properties and application

But B30 concrete also has significant disadvantages that greatly limit its use in private construction. These include the following factors:

- Relatively high cost. Although M400 belongs to the mid-price concrete category, it is significantly more expensive than M200 or M300. This is partly compensated by its excellent technical characteristics, but in private construction they are most often simply not required, so people find the use of other brands more appropriate.

- Setting period too short. From a certain point of view, this is a plus, since the speed of work increases, but if it is necessary to transport the mixture to distant locations, this property creates many problems. Concrete can harden prematurely and become unsuitable for pouring, processing, cosmetic cement, making holes in blocks for fastening, and so on.

- Difficulty in producing at home. Although the qualitative composition of this brand of building material is no different from that of others, a very small amount of water is used when mixing its components. This makes it very difficult to get the mixture to the desired consistency without using a concrete mixer.

- Low aesthetic qualities. They are also aggravated by the fact that M400 concrete is very difficult to process to correct this deficiency. That is why it is used in residential buildings.

The pros and cons of this brand of concrete are due to the same compositional feature - a large amount of expensive cement. Whether the advantages of a building material outweigh its disadvantages depends on the area of application.

Some useful tips

To fill the foundation base, materials should be used in the following proportions:

- cement material – 10 kg;

- river sand – 30 kg;

- crushed stone or gravel – up to 50 kg.

The amount of water is taken to be half the total weight of all ingredients. It is recommended to take into account the degree of sand moisture. It is either dried or the amount of added liquid is reduced.

Ideally, the consistency of the finished mortar should be such that the concrete flows freely and quickly from the shovel.

Before arranging the foundation, determine the need for concrete, for which you will have to find out the number of tapes to be filled with mortar. Then all that remains is to multiply their parameters, for convenience, converting the values of length, width and height into meters and add up the results.

The foundation is poured in layers, no more than twenty-five centimeters high, leveling the poured mass and compacting thoroughly. At the end of the work, air is released from the poured base, for which reinforcing bars are stuck into the concrete. But it is quite difficult to carry out such an event, since M400 concrete is characterized by rapid setting.