Crushed stone is a bulk material in the form of stones, which is a product of crushing raw materials and then sifting through sieves. This is one of the basic materials used in construction, road, and landscape work.

Crushed stone comes in different types depending on several factors.

The material can be classified:

- By origin

- By faction

- By post-processing method

The possibility of using crushed stone in certain works directly depends on this classification. Therefore, below we will describe each in detail.

Advantages of dolomite crushed stone

Due to its distinctive qualities, dolomite crushed stone is a universal building material that is actively used in modern construction and production.

The main advantages of dolomite crushed stone are

- low level of natural radiation

- high frost resistance and strength

- low water absorption

- high adhesion

- fire resistance

- low bulk density coefficient

- excellent decorative properties

Main characteristics of limestone.

Most often, rock processing occurs near the quarry in which it is mined. Limestone is crushed and passed through sieves, three main fractions are obtained:

- 5-20 mm – small;

- 20-40 mm – average;

- 40-70 mm – large.

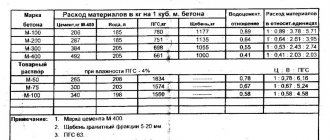

Grains larger than 70 mm are considered non-standard and are used as rubble stone or recycled. The most popular fraction is medium crushed stone with a grain size from 20 mm to 40 mm. In terms of strength, crushed limestone is divided into four grades, in which the numbers indicate the compression test value of the material in kg/cm2:

- M200;

- M300-M600;

- M600-M800;

- M800-M1200;

- M1200-M1400.

Since this material is mainly used in road and construction, a very important indicator for it is the compaction coefficient of crushed limestone 20-40. Its value should be in the region from 1.01 to 1.52 tons/m3. Using this value, you can calculate the need for material to perform a particular type of work.

The next, no less significant indicator is the specific gravity of crushed stone 20 40 limestone. In accordance with the requirements of state standards, this value should be in the range from 1260 kg/m3 to 1320 kg/m3, with water absorption of 1 - 2.2 percent. Flakiness is considered normal when its size varies between 11-12%. The smaller this value, the higher quality the crushed stone is considered. It is reduced by using rotary crushers instead of cone crushers for crushing.

Many people confuse concepts such as specific gravity and volumetric weight of crushed limestone 20 40. The specific gravity of a material is determined in its compacted state, while the volumetric weight is determined in its free state. Many materials with high density have the same specific and volumetric gravity, while for bulk materials it is always different.

Due to its natural qualities, crushed stone from limestone rocks, the basis of which is calcium carbonate, is limited in use. It cannot be used in the production of serious prefabricated and monolithic reinforced concrete structures that absorb and transmit significant loads. However, the use of crushed limestone in road construction is quite widespread, due to its high compactability and workability.

We invite you to familiarize yourself with Crafts for kindergarten on the theme of Autumn: as many as 14 ideas on how to make simple crafts for kindergarten on the theme of Autumn.

In addition, crushed limestone is used as the main raw material in the production of quicklime and Portland cement, as well as for the following:

- Facing works.

- Irrelevant foundation, concrete and reinforced concrete structures. To build foundations, even under minor loads, you need to know the composition of the soil. The nature of limestone is alkaline, so it quickly deteriorates in an acidic environment.

- Drainage systems.

- Landscape design.

The color possibilities of crushed stone have made it in demand when arranging home and summer cottage areas. It is used to create small architectural forms, garden decor items, and concrete sculptural compositions. Fine crushed limestone is often used in the design of flower beds, as well as for the formation of textured plaster solutions.

Compared to granite, dolomite and other types of high-strength bulk materials, crushed limestone is more cost effective and more widely distributed. That's why its use is so popular.

1) Factions.

• up to 2cm (small);

• from 2 to 4 cm (average);

• from 4 to 7cm (large).

2) Durability.

Limestone crushed stone does not have very high strength - M200-M-800. The most popular crushed stone is M-400, M-600. So, if you decide to buy limestone crushed stone, you should turn your attention to these options for this material.

3) Flakiness.

It must be said that crushed limestone has very good flakiness characteristics. The % content of substandard needle-shaped and plastic fractions in the material fluctuates in the following range: 10-15%. Those. this suggests that, according to the GOST classification, limestone belongs to the group of materials of class I-II - high quality crushed stone.

3) Chemical composition, presence of impurities.

Limestone crushed stone, like other types, has a small amount of foreign inclusions. It must be said that high-quality crushed stone contains approximately 5-10% impurities, soft inclusions and about 2% clay and dust.

• environmental Safety;

We invite you to familiarize yourself with Lime plaster: pros and cons

• low cost;

• low radioactivity;

• high frost resistance;

• impact resistance;

• resistance to temperature changes;

• dense compaction during installation.

The fact is that crushed limestone has flakiness, which is characterized by the second class. In other words, this is very high quality crushed stone. However, this material is used not only for construction purposes:

- production of soda, calcium carbide;

- production of mineral fertilizers;

- production of quicklime.

Extraction can be carried out using a quarry method. In this case, using specialized equipment, the rock is first removed from above to provide direct access to the limestone.

However, in this case, the cost of such raw materials increases several times. The cheapest crushed limestone comes from large deposits.

They are developed for a minimum period of 10 years. Naturally, small mining operations can also be organized near the construction site. But due to the need to develop the deposit from the very beginning, the price of such crushed stone is also not very affordable.

When carrying out construction work, the developer often chooses between these two materials. In some characteristics, dolomite crushed stone wins (price), in others - granite (water absorption).

Taking into account the fact of climatic conditions (Russia has a harsh climate), the reaction of the material to frost should also be taken into account.

Speaking about dolomite crushed stone, we can say with confidence that it can withstand negative temperatures without much difficulty. But in construction it is recommended to use limestone crushed stone, the grade of which is not lower than F300.

Application of marble crushed stone

Due to its environmental friendliness, dolomite crushed stone can be used both as a filler for concrete and for finishing premises, including in schools and kindergartens.

High durability, due to high frost resistance and strength and low water absorption, allows the use of dolomite crushed stone when performing external and internal facing work, landscaping, producing dry building mixtures and concrete, and producing products from natural and cast stone.

Possessing excellent binding properties compared to other types of crushed stone, thanks to the rough surface of dolomite, it increases the binding of components in construction, which allows significant savings on binding additives during road construction. This also makes it possible to produce tiles with anti-slip properties.

Dolomite crushed stone has a lower bulk density coefficient than, for example, granite crushed stone. Therefore, the consumption of dolomite crushed stone during road construction will be less, which means the use of dolomite crushed stone is more profitable.

Due to its natural shine, dolomite crushed stone is widely used in interior design, for interior decoration and in landscape design.

The refractoriness of dolomite crushed stone allows it to be used for lining as a refractory in metallurgical furnaces. Dolomite is also often used as a flux in metallurgy.

And, of course, dolomite is a raw material for the extraction of metallic magnesium and magnesium salts.

Delivery-SM also offers to buy

Quarry sand

For carrying out work at the zero construction cycle, for backfilling foundations, in road construction, for landscaping areas and constructing embankments. After sifting - for preparing building mixtures for concrete, masonry and plastering work.

Read more…

Sand screening

It is, in fact, gravel that has not been divided into fractions. Good for filling a road, parking lot or area for installing a garage or shell. It is not recommended to use it for the production of concrete solutions.

Read more…

Gabbro-diabase

Characteristic

Crushed stone is obtained from diabase, a volcanic rock with properties similar to basalt. It is characterized by high strength, frost resistance and low water absorption.

Another advantage of crushed gabbro – diabase – is low flakiness. Thanks to this property of the rock, it is possible to produce high-quality cube-shaped crushed stone, suitable for the construction of especially durable roads and the construction of foundations.

Unlike crushed granite stone, which is similar in strength, gabbro-diabase is not radioactive.

Fractions and properties

Crushed stone of this type is produced in the form of the most popular fractions: 5-20 mm, 20-40 mm, 40-70 mm. It is also possible to produce crushed stone with fractions of 25-60 mm.

The strength of crushed stone made from gabbro is diabase M1400, frost resistance is F300. Flakiness of crushed stone – 12% (group II). Bulk density from 1.55 to 1.67 t/m3 depending on the size of the fractions.

crushed gravel

Characteristic

Crushed gravel is obtained either from sedimentary rocks or by crushing river or sea gravel.

In terms of its properties, crushed gravel is very similar to granite, with one exception: it does not emit or absorb radiation. As a result, crushed gravel is used very widely, and is especially recommended for use in the construction of nuclear power plants and other objects exposed to radiation.

Fractions and properties

The most popular fraction is 10-20 mm. Less common, but also in great demand are fractions of 20-40 mm, 40-70 mm and screenings.

Crushed gravel with fractions of 90-150 mm stands out especially. It is called rubble and is used for finishing and strengthening the coasts of rivers and artificial reservoirs.

Crushed gravel strength grade is M800 – M1200, frost resistance grade is F200 – F300. Flakiness group - II (10-15%). Bulk density averages 1.3 – 1.4 t/m3.

Application

Crushed gravel is in demand in construction, production of reinforced concrete products, and for laying and strengthening roads. Approximate in strength to granite, but not radioactive, crushed stone can be used without restrictions.

Granite crushed stone

Characteristic

Granite crushed stone is obtained from sedimentary rocks of igneous origin. Due to its strength and bulk density, granite crushed stone is a very popular material.

The disadvantages of granite crushed stone include high radioactivity, which limits the scope of its application: this crushed stone is not applicable in housing construction and when laying roads within the city.

Fractions and properties

The most widely used crushed stone is 5-20 mm. They also produce fractions of 20-40 mm, 40-70 mm and screenings (0-5 mm).

Granite crushed stone is high-strength (M1200 - M1400), frost-resistant (F300 - F400) and belongs to the II or III flakiness group (10-15% or 15-25% of lamellar and needle-like grains, respectively). Bulk density is 1.32 – 1.39 t/m3.

Application

Granite crushed stone is used in the production of high-quality concrete for especially durable structures, as well as in laying railway tracks.