What is backfill brick

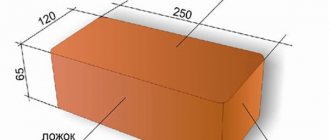

Like most ceramic materials, the base for backfill bricks is clay. It is processed using semi-dry pressing. Backfill brick is also called ordinary brick, as it is often used in construction. Which is not surprising, since it is a durable and cheap material. The standard size of backing brick according to GOST is 25-12-6.5 cm. It weighs about 3.5 kg. One-and-a-half ordinary bricks are also on sale. Its parameters are 25-12-8.8 cm. Double blocks are considered the largest. They can weigh up to 4 kg with parameters of 25-12-14 cm.

Backfill brick

Backfill ceramic products have many advantages:

- strength;

- high-quality adhesion in brickwork;

- fire resistance;

- frost resistance;

- durability.

Ordinary brick is not suitable for cladding buildings. The material may contain chips, roughness and unevenness. Backfill brick is red, but heterogeneous impurities are possible. Also, some blocks may not be ideally shaped. Backfill bricks with corrugated edges are in great demand, as this provides improved adhesion to the mortar during laying of the material.

Types of bricks offered

Type/characteristics (use)

| Model | Description |

| It is divided into: solid, used for laying walls of buildings, pillars, columns, laying chimneys and stoves; hollow, which is used for constructing partitions, filling frames, and additional external walls; facing (“front”, “facade”), which is used for cladding buildings. | |

| The speed of laying is ensured by protrusions on one side and rounded recesses and recesses on the reverse. Used for the construction of partitions, load-bearing walls, cladding, masonry of decorative columns and support pillars. | |

| It is divided into types: porous, thermally efficient, cement-sand, ceramic, diatomite foam. Hollow is used for load-bearing walls and internal partitions. There are different block sizes. One-and-a-half slotted ones are suitable for main walls, single slotted ones are suitable for lightweight construction, and double slotted ones are indispensable for large-scale construction. | |

| Brick loaf | Produced by a brick factory in Makhachkala. Characteristics: red, double, full-bodied, backfill, weight up to 7 kg. Used in the construction of frames, load-bearing walls, supports, dimensions - 250x120x65 mm. |

| Attention is paid to the following parameters: bricks must be of the same shape and size; surface – smooth, without chips or cracks; the color is rich and uniform. Typically, full-bodied red is used for the base, which may be burnt. Used: clinker, acid-resistant ceramic, red clay, silicate. | |

| For external decoration of buildings, narrow facing is used. The application is purely decorative. Often used for finishing small objects, for example, interior wall cladding and fireplaces. | |

| English is presented in yellow, red-brown, black and blue, and can be variegated or uniform. The old method of producing handmade bricks (available at IBSTOCK factories) is based on hammering a lump of clay directly into a wooden mold. Usually used for finishing work. | |

| Italian can be whole or half (there is also a spil). Stylish and refined in appearance, it allows for masonry with displacement of elements to different depths. | |

| Rough (worker, ordinary) is used for the construction of partitions and walls that require subsequent plastering, putty, painting or cladding. Used for the construction of basements and foundations. | |

| Used to build walls. | |

| Used to create an original interior. Ideal for laying window and door openings, circular and bay windows, for all structures with arched elements, including arches. | |

| Clay, chopped straw, water and additives that regulate mechanical properties are used for production. Area of application: southern regions with a hot and dry climate. Often used in rural areas when constructing outbuildings. | |

| For the construction of partitions in buildings, hollow or porous ones are used. | |

| Refers to a finishing building material, used for decorating architectural elements of building facades, internal cladding works, and street barriers. Features - the presence of a cut on one of the corners. | |

| The tile is elongated in shape, reminiscent of a brick, the chamfers (facets) are beveled, which gives a convex appearance. It is used as a finishing material for loggias, bathrooms, public spaces - beauty salons, restaurants, cafes. | |

| In the form of backfill (rubble) brick there is a red ceramic stone, the appearance of which has disadvantages, namely: chips, roughness, oblique edges, heterogeneity of texture and color. Used as a simple working material. | |

| Scope of application of torn stone: cladding of fireplaces, facades, plinths, pillars and other surfaces. It is made by decorative pecking (one of the sides), which protrudes the front side and gives it a torn texture. | |

| The method for producing ceramic red brick is firing clay at high temperatures with the addition of plasticizers and fixatives of natural origin. This is the most environmentally friendly and warm material. Used in the construction of residential buildings. | |

| Able to withstand the effects of acids. Used in industrial enterprises to protect equipment in contact with aggressive substances. They are used in the construction of gas ducts, chimneys, gutters, towers, and tanks. | |

| They are used in the construction of cottage and multi-storey houses, gazebos, arches, fences, for interior decoration, and in the reconstruction of small architectural forms and buildings. There are 23 colors. | |

| Fireproof (heat resistant) | Used for the construction of objects that are maximally exposed to elevated temperatures or open fire (fireplaces, chimneys). There are: fireclay, carbon, quartz, basic. The weight of fireclay is heavier than that of construction, with the same dimensions. The most famous manufacturer is Vitebsk. |

| Used for the construction of furnaces. Types: oven red and oven face. | |

| Refers to fireproof. It is used in the construction of melting pots and furnaces in civil, residential and industrial construction. Withstands ultra-high temperatures over 1000°C. | |

| An excellent decorative facing stone, developed using vibration pressing technology. Available in a wide range of colors. For its production, elite grades of cement, plasticizers, and fine sifted sand are used. | |

| For façade cladding, a facing cladding is used, subdivided into: clinker, ceramic, silicate; hyperpressed (concrete). | |

| Brick-ceramic building blocks. Suitable for different types of wall laying in one row or more: main and non-main, external and internal, filling spaces between walls, laying partitions. |

- Advantages of block bricks over conventional ones:

- ease of operation due to the large dimensions of the blocks;

- strength;

- fire resistance;

- environmental friendliness;

- coefficient of thermal conductivity;

- flexibility in finishing and decoration.

- Aerated concrete:

- durability;

- low thermal conductivity coefficient;

- environmental friendliness;

- high fire resistance;

- efficiency.

- Cinder block:

- inexpensive to purchase;

- speed of laying;

- strength.

- Foam concrete:

- efficiency;

- comfort at home;

- high heat and sound insulation properties.

- Gas silicate:

- construction is possible without further insulation;

- high environmental friendliness;

- strength;

- good sound insulation;

- low cost.

- Available in blocks:

- thermal insulation;

- thermal insulation and structural;

- structural.

- Brick is also offered:

- size 250x120x60 mm made of soapstone;

- size 250x120x38 mm - Kashira construction slotted brick;

- 190x90x70 mm - decorative modular, gives the facade of the house a “techno-style”.

IMPORTANT! Soapstone is a rock formed from soft minerals. This is a polished stone that resembles marble.

Red (ceramic) brick size

Sand-lime brick size

Dimensions of facing bricks

Characteristics according to GOST

| Dimensions | Type | View |

| 250x120x65 mm | Standard | Yellow |

| 250x120x60 mm | Single | Yellow |

| 250x120x103 mm | One and a half | Yellow |

| 250x120x65 mm | Single | White |

| 250x120x90 mm | One and a half | White |

| 250x120x65 mm | Single | For facade |

| 250x120x88 mm | One and a half | For facade |

| 250x120x138 mm | Double | For facade |

| 210x100x50 mm | Single | |

| 240x115x52 mm | Single | Custom size brick |

| 210x100x65 mm | Single | Custom size brick |

| 240x115x71 mm | One and a half, clinker | |

| 250x60x65 mm | American standard, ceramic | |

| 250x85x65 mm | Euro | |

| 250x88x85 mm | Euro |

Ceramic brick size

Fireclay brick size

Solid brick size

Hollow brick dimensions

Specifications

| Dimensions | View | Manufacturers |

| 250x120x88 mm | One and a half | Brick |

| 250x120x140 mm | Double | |

| 250x85x65 mm | Euro | Brick |

| 288x138x65 mm | Modular single | Brick factories - Stary Oskol, Khabarovsk |

| 250x200x70 mm | Ceramic | Brick factories - Stary Oskol, Khabarovsk |

| 250x120x88 mm | White silicate hollow | Brick |

| from 250x120x140 mm to 260x510x219 mm | Large large format ceramic blocks | Brick factories - Stary Oskol, Khabarovsk |

Brick is a building material that is characterized by its strength and durability. It is considered the oldest known building material and is made by firing clay briquettes, previously well pressed.

Red brick allows you to build a building in the required architectural concept, as well as save on the construction process. especially popular in private housing construction.

, during the construction of fences, garages and other auxiliary buildings. Anyone who is engaged in construction, knowing the dimensions of the red brick, only needs to correctly calculate the required quantity that will be required for the construction of the facility. It can be called the most versatile material.

Types of backfill bricks

Depending on the shape, a distinction is made between solid and hollow backfill bricks.

The difference between hollow and solid bricks

Solid ordinary brick has voids of no more than 13%. This is a material with high thermal conductivity, so it definitely requires an additional heat-insulating layer when building housing. Solid backfill brick is suitable for building load-bearing walls, brick foundations, and basements. Compared to hollow bricks, solid bricks are the most durable, due to which they also have more weight. This type of brick is not suitable for buildings in places with high levels of humidity.

A brick with holes inside is called hollow. The number of voids in high-quality bricks does not exceed 46% of the total structure of the block. It is the presence of voids that creates additional thermal insulation and also allows construction in areas with high humidity. Hollow backfill brick is suitable for the construction of private houses and other low-rise premises. It is also ideal for the construction of interior partitions, as it carries minimal load on the foundation of the building. But for the construction of load-bearing walls it is better to choose a denser material.

How much does a red brick weigh?

For the use of this building material, the indispensable properties are heat retention, moisture resistance, strength and, of course, its weight. There are several types of red brick, but its most optimal shape and size is 250 * 120 * 65 millimeters.

With these parameters, the mass of one brick varies within 4.3 kilograms. But with all this, more bulky bricks, which have the appearance of a block, can reach a mass of 25 kilograms. After all, the weight of a brick depends directly on the composition of the mixture and the dimensions of the building material.

It should also not be argued that if a brick has a bulkier and heavier weight, then its strength is the highest. This is absolutely not true, because each type of brick is made using a special production technology and has a specific composition.

In addition, most bricks have different firing temperatures, which also significantly affects the weight of the brick. Undoubtedly, the mass of a brick is not its main characteristic, but it is not the most important one either.

How much does a solid red brick weigh?

This type of brick is used mainly in facing works. For example, in the construction of basement construction, masonry of fireplace equipment and other objects.

Very rarely, red solid brick is used in the construction of load-bearing walls due to the fact that it has poor functional hardness and strength.

In addition, solid red brick has a low level of heat retention.

For this reason, when building walls, it is necessary to thicken their layer into several bricks, which places significant pressure and load on the foundation of the house - the foundation.

The weight of such a brick varies depending on its dimensions and purpose. In its average value it has a result of 3.3 - 4.2 kilograms.

The building materials market is often replete with hollow red bricks. Such bricks are absolutely not suitable for load-bearing structures. It is used only for decorative and facing work on the facade of a building. The weight of such building material can be from 1.5 to 2.5 kilograms.

How much does a red stove brick weigh?

The stove type of brick is quite common in the construction of premises. It can be used in more common areas, since the physical characteristics of the brick allow such use.

Kiln bricks can be used to construct load-bearing walls and decorative work on the façade of a house. The mass of such a brick can be from 3.6 to 4 kilograms.

Brands of backfill ceramics

Before choosing backfill bricks for construction, you need to decide on the markings. Brick blocks are marked depending on their strength.

The bricks indicate the pressure that the brickwork can withstand per 1 square meter. Backfill bricks are available in three main markings: M-100, M-125 and M-150.

M-100 is the cheapest backfill brick, which is suitable for small buildings. Most often it is used for the construction of one-story or two-story private houses. Since the brick has good frost resistance, even with the M-100 marking, the house can stand for decades without cracking.

M-125 is used as an intermediate type of material between two other types of backfill bricks. It is suitable for the construction of low buildings and is slightly stronger than M-100.

Backfill brick labeled M-150 is used for the construction of high-rise buildings. The blocks are suitable for both foundation construction and load-bearing walls.

Brickwork from backfill blocks

The technology for constructing brick walls depends on exactly how the blocks will be positioned in relation to each other. Bricks have standard edge names that are used during construction. The longest edges are called the upper and lower beds. The long side rib is called a spoon, and the short one is called a poke.

Backing brick edges

There are several basic methods for laying bricks:

- Near Lozhkov. In this case, all blocks of one row are joined at the butt. Several rows are connected by seams between the upper bed of one block and the lower bed of another. In this case, the front part is a spoon.

- Tychkov is nearby. As in the spoon, the rows are connected using bed interlocking. The difference is that the blocks are joined on the spoon, and the poke is placed on the outside of the masonry.

- Verst. This is a row that is located on the edge of the building and forms the outer part of the masonry.

- Zabutka. This is the gap that is located between the outer and inner parts of the wall.

The importance of standardization

The normal dimensions of the brick are in the ratio 1:½:1/4, which makes it possible to give the building structure additional strength using masonry ligation. This happens due to the fact that longitudinal and transverse alternation of building material is carried out

in relation to the axis of the masonry and, as a result, the load is more evenly distributed.

In addition to the above, the proportionality that is present in the standard brick size allows masonry work to be carried out with low labor costs. The briquette lifts easily and can be held with one hand.

Also, the size of a standard window when building a brick house is much more convenient to determine based on the standardization of the dimensions of the material.