Lumobeton production technology is a new profitable idea for business

Investments: from 90 thousand rubles.

Income per month: from 600 thousand rubles.

Lumobeton is an original decorative stone for cladding building facades. The material is perfect for cladding not only outside, but also indoors: fireplaces, bar counters, wall decor.

Lumobeton stone differs from conventional finishing materials in its original property - to glow in the dark. In the light it is an ordinary stone, but as soon as you turn off the light, the magic begins. The stone glows in the dark for several hours, delighting and surprising the owner of the house and his guests.

Everyone would like to have such a finishing stone in their home.

Lumobeton advantage:

Durable, suitable for both indoor and outdoor use. Resistant to weather conditions.

Facade stone is lighter than natural stone.

Harmless - the main components are of natural origin - sand and cement.

Lumobeton belongs to the “NG” category - non-combustible materials and has high fire-resistant properties.

Artificial stone Lumobeton is easy to process. With it you can implement various modern design solutions.

The production of artificial stone glowing in the dark is a new type of business.

This direction does not depend on the season. The production of Lumobeton is relevant in summer and winter.

Until recently, a similar product did not appear on the construction market. The technology was developed and proposed by the Oscar company. In addition, it offered its partners basic consumables at a discounted price.

The production of Lumobeton is very similar to the production of conventional artificial stone. Production technology can be accessible even to a novice entrepreneur. The technology developer shares all the nuances of production and provides a detailed recipe that eliminates unnecessary costs.

So, why is the original Lumobeton technology suitable and why is it important? The video uses the original recipe and the recipe with violation. Let's see what comes out and how it is reflected in the glow:

For the production of products, the main raw materials can be several components:

quartz sand (0.63 mm is suitable)

gypsum G16

dye – iron oxide pigments are ideal

cement

Since Lumobeton is perfect for cladding outdoor houses, plasticizers are used in the technology. They give plasticity to the solution and strength to the luminous stone for the facade.

The developer also shares his experience on what additives are best to add to reduce moisture absorption in the finished product.

Liquid composition Lumobeton is the main element that gives a glow to the material. Liquid Lumobeton is a very important component; without it it is unthinkable to produce a luminous facade stone at a low cost.

Then everything is even simpler. The mixture must be poured into prepared forms and kept on a vibration table for 2 minutes. This step helps prevent voids from forming in the tile due to air bubbles in the mortar.

Artificial stone can be dried at room temperature or in a dryer, but not above +30 degrees. After hardening and finishing, the finished façade stone Lumobeton can be kept for about 12 hours.

After this you can send it for sale. It is important to follow the original production technology. Used components can only be replaced upon the recommendation of the technology developer.

Then the quality and cost of the finished luminous artificial stone will be quite decent.

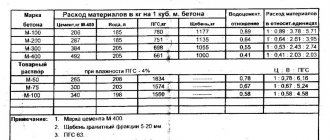

Cost price

The cost of the finished product per 1 m2 will be about 450* rubles. It's very profitable. 80% of this amount is spent on the main substance gypsum or cement and the liquid composition Lumobeton. The rest are inexpensive supplements that we listed above.

The recommended price for selling luminous facade tiles is 1000-2000 rubles. per m2.

With a productivity of 100 sq. m. per week, you can earn from 100 thousand rubles.

The production of Lumobeton does not require large investments in equipment. It is enough to have:

• Lumobeton production technology – from 90 thousand.

• mortar mixer – included in the business package

• vibrating table – from 10 t.r.

• press molds for stone – included in the business package.

Result: from 100 tr.

The production of Lumobeton is quite suitable for a home business.

How much space is needed to open a production workshop? It is enough to have a room of 20 square meters. m. If you have a larger room, that’s good; you have somewhere to store ready-made inventory.

Promoting the product to customers

The finishing material Lumobeton will be in demand among buyers in construction stores. Markets with finishing materials are also always full of visitors. You can advertise in newspapers and magazines on this topic. Streamers along the roadway advertise the product very well.

Considering that façade stone has long been loved by customers, its additional glowing property will become an additional reason for word of mouth, like free advertising in the city.

Source: https://www.oscar-sib.ru/lumbeton-ideya-bussinesa.html

General information

You may have come across such names as Kevlar concrete or granite, but they are produced using the same technology, the essence of which is the same - a concrete pellet is created that looks like a ball.

This is facilitated by the use of a modified concrete mixer. In fact, ultraconcrete technology, although it has different names, uses the same material preparation method, recipe and raw materials.

Paving slabs with photoluminescent additives

The process boils down to the fact that they begin to remove air from the concrete mixture, which was prepared according to a special recipe. For this, a gravity concrete mixer is used, which produces pellets with a reduced ratio of water to cement, which increases their density.

You can produce various small architectural forms

This method makes it possible to obtain an imitation of natural materials, such as:

- granite;

- malachite;

- amber;

- marble,

as well as color tints.

This is a very durable, modern and new type of concrete, which is used for the manufacture of:

- paving slabs;

- borders;

- fences;

- facade stone;

- fireplaces and other MAFs.

Beauty and unusualness of the material

Use of material

Ultraconcrete is based on fundamentally different solutions adopted in the field of manufacturing decorative architectural colored concrete using the method of gravitational pellet formation. In this case, it is possible to obtain a product with high physical and mechanical parameters.

The casting surface has perfect density and high gloss. In this case, it is possible to obtain a color range of varying complexity, regardless of the area of the cast element and its overall dimensions. This creates the effect of a natural or artificial material ranging from plastic to malachite.

In the production of building materials for architectural and landscape work, effective schemes are used, with the help of which it is possible to obtain new types of concrete.

To reveal the range of their applications, various are used:

- raw materials;

- astringents;

- fillers;

- plasticizers;

- experiments with methods and stages of adding chemical modifiers, as well as mineral active additives;

- optimization work with the composition of multicomponent concrete;

- ways to manage technology.

To create products, almost any form-building equipment and molds are used. At the same time, the products have high physical and mechanical properties, which combine high compressive strength values - B 40-90. This is similar to concrete grades M600-1200 and higher.

Manufacturing process

Below are instructions that will help you understand this issue:

- At the first stage, it is necessary to introduce a pre-calculated mass of aggregate into a modified concrete mixer.

Advice: it is imperative to monitor the moisture content of mineral aggregates.

- The mixing process until a homogeneous mass lasts no more than 1 minute . At the same time, prepare an aqueous solution of plasticizer.

Tip: you need to control the temperature of the water that is used to mix the plasticizer.

- Add the required amount of Portland cement to the modified concrete mixer and mix everything for one minute . At the same time, prepare the required amount of pigments according to the tinting recipe. Typically a color chart is used.

Manufacturing process

- Add a dose of plasticizer solution with water to the dead zone of the installation . In this case, the order of water supply will affect the size and number of pellets.

- After 15-20 seconds, carry out the initial control of the pellets, after 1 minute - the final one . It is necessary to inspect the appearance and check the density of the pellets, as well as the dryness and density of their internal structure, for which the pellets should be broken.

Ultraconcrete – pellet in section

- Carry out tinting, and after 10 seconds (no later), unload the pellets into the molds . At the same time, turn on the vibration table.

- In the processing field, turn off the vibrating table, remove the tray with forms from it and move it to the curing area.

Tip: cover the molds or the entire pallet with polyethylene film.

- Carry out unmolding after 18-20 hours, if you used hardening accelerators - 4-8 hours and store the finished product.

Use cement without additives

Raw materials

The composition of ultraconcrete looks like this:

| Portland cement | Brand M400 and M500 D0, i.e. without additives. Otherwise, it has an increased reactivity to CO2, which is in the air. Because of this, primary efflorescence is formed and the decorative qualities of the product are reduced, and the composition hardens more slowly. |

| Sand | Use quarry or river, fraction 1.8-2.5. The price is quite affordable. |

| Granite screening | A material fraction of 0-5 mm is used. Sifting is not used in this technology. |

| Plasticizer | Superplasticizer S-3 or SP-1 is suitable, but without air-entraining additives. Its use will allow the monolith to form faster and increase productivity. The compositions should only be in powder form. |

Various shapes can be used for the material

Tip: If you want to paint ultra concrete a specific color, use dyes and pigments to color concrete.

Production of luminescent concrete: a profitable business for beginners

Beginning entrepreneurs interested in new technologies should pay attention to the so-called luminous concrete, which is rapidly gaining popularity among consumers in Russia today.

And you can organize your own business in this direction at a minimum cost, since the technology for producing luminescent concrete is simple, you can do without special equipment and renting a spacious workshop.

It's time to start!

Lumobeton is a building material for exterior and interior decoration, which is a decorative stone that glows in the dark. This effect is achieved due to the fact that the products absorb sunlight throughout the day, releasing it at night.

The production of luminescent concrete at home, in addition to the simplicity of the technology, is characterized by some other advantages:

- Low competition in the consumer market.

- High profitability.

- Availability and relatively low cost of raw materials.

Many entrepreneurs started their own business without spending even 100,000 rubles. And these costs pay off in less than 1 season.

Do-it-yourself luminous concrete, if in the future you competently approach the advertising of manufactured products, will be in high demand, which is not at all surprising - the material has many positive qualities:

- strength,

- reliability,

- attractive appearance,

- resistance to negative environmental factors.

Did you like this idea? Then you should start drawing up a business plan, since even a small family business does not cancel the strict elaboration of the project.

Lumobeton manufacturing process

Learning how to make luminous stones with your own hands will not be difficult even for those who have never mixed cement mortar before. The technology itself differs little from that used to produce many other decorative stones.

Before releasing the first batch of products, the entrepreneur will have to work out the composition of the luminescent concrete. Not a single functioning workshop will discover its own “working” recipe, and therefore, without having certain skills and knowledge, you will have to act by trial and error.

The recipe includes the following components:

- quartz sand;

- dyes containing iron oxide;

- luminescent pigments;

- titanium white;

- latex polymers;

- water repellents;

- chemical fibers.

Many dealers today offer ready-made technologies with proven recipes for sale. If you don’t have time to work out the exact mixture ratio, you can use this option. The cost of such a “business package” ranges from 60,000-150,000 rubles.

So, all the components have been purchased. All that remains is to find out how to produce high quality material. The production of glow-in-the-dark stones includes the following steps:

- Accurate dosage and mixing of all components with water.

- Pouring the resulting mixture into special molds.

- Processing molds on a vibrating table.

- Drying products.

- Packaging of finished tiles.

What equipment will be required in the process?

Many craftsmen start their activities without having any equipment at all. But the technical equipment of the workshop will allow not only to produce products of much better quality, but also to significantly reduce the process of their production. Therefore, it still won’t hurt to purchase some special equipment.

The production of luminescent concrete will require the following equipment:

- scales;

- mixer;

- forms;

- vibrating table;

- drying cabinet.

If we take the minimum, then the purchase of equipment will cost ≈120,000 rubles. And you can save a lot if you purchase used devices - for a small home business, its power will be enough to produce small batches of goods.

The dimensions and configuration of the forms have a direct impact on how wide the range of products offered to customers will be.

High-quality molds are quite expensive on the market, and if you want to save money, you can make them yourself. First, a wooden mold of a certain size is prepared.

A purchased polyurethane mixture is poured here, which, after hardening, turns into a full-fledged form.

Over time, having developed a customer base, it is possible to replace semi-automatic equipment for the production of luminous concrete with fully automatic machines that allow the production of larger batches of products. This will take your home business to a completely different level.

Sales of finished products and business profits

At first, production based on our own garage will most likely only work under orders from private clients and small construction firms. It won’t work any other way, since a small workshop with low-productivity equipment will not be able to provide large retail outlets with high-quality products.

It will be difficult to establish cooperation with large buyers, because they prefer to do business with well-known brands. Therefore, the minimum that an entrepreneur will have to do is to officially register his activities.

Landscape designers and interior finishing firms may be interested in the products. But during the period of business formation, we place our main emphasis on private clients.

And in order to convey information about the products produced in the workshop to a potential audience, it is necessary to launch advertising - in newspapers, on the Internet. An excellent option is to organize your own online store.

But here you cannot avoid investing additional funds.

Glowing decorative stones for landscape design cost 500-2000 rubles/m2 on the market. This “range” in price is due to the different shapes and textures of the material - a variety of products can be offered to customers. And the fairly low cost (250-1000 rubles/m2) of luminescent concrete makes this direction highly profitable.

Total: 3 ( 4.67 out of 5) Loading…

Source: https://vseoip.ru/idei-dlya-biznesa/proizvodstvo-lyumobetona.html

Production of luminous concrete - a unique technology for producing luminous stones

Lumobeton are luminous decorative stones for landscape design, but also used for interior decoration.

The uniqueness of the material lies in the fact that it accumulates solar energy during the day, which it converts into light at night. Lumobeton does not lose its properties and retains its brightness for a fairly long period of time.

The advantage of the material is its resistance to acidic and alkaline environments, which makes it possible to use it indoors and outdoors.

Our business assessment:

Starting investments – from 50,000 rubles.

Market saturation is low.

The difficulty of starting a business is 1/10.

Advantages of a business producing luminescent concrete

The production of glow-in-the-dark stones can become a fairly profitable enterprise due to the uniqueness of the products and the almost complete absence of competition in Russia. To start a business, you do not need to look for large areas for production premises. All equipment can be placed on 30 m2.

The production of luminescent concrete and the subsequent sale of decorative stone is a business that does not require large financial investments and special skills. At the initial stage, an entrepreneur will have to spend no more than 50-60 thousand rubles: purchasing technology, equipment, raw materials.

The production of luminous concrete at home has a number of advantages that provide good profits to the owner and the subsequent development of the enterprise. The main advantages of the business are the following aspects:

- all-season;

- location of the production workshop in any area;

- versatility of products;

- minimum investment at the start;

- high profitability.

The technology for producing luminous concrete is not much different from the manufacturing process of other decorative stones. It is important to follow the order of work, proportions when mixing components, and also monitor the result of the vibration table.

Before you make luminous stones with your own hands, you need to prepare special forms made of wood, reminiscent of boxes in their design.

Next, the two-component polyurethane system Por-A-MOLDA and synthetics are poured. The appearance of the polymerized material, which hardens within 24 hours, resembles elastic rubber.

After the composition has gained the required strength, it can be used to make luminous concrete with your own hands.

The solution for making decorative luminous stone consists of the following elements:

- Quartz sand, fraction from 0.63 -15.

- Dyes are added in a volume of 5% of the total mass of the solution. The best option is pigments with a high content of iron oxide, which have high coloring properties and light fastness.

- Titanium white is used to bleach stone made of gray Portland cement.

- Gypsum or Portland cement.

- Plasticizers increase the strength of products.

- Latex polymers ensure the durability of products.

- Water repellents increase the level of moisture resistance of the material.

- Special chemical fibers added to the mixture reduce the likelihood of cracking and chipping.

- Luminescent pigment TAT 33, added to luminous concrete, is the main element responsible for the unique glow of decorative stone.

The listed components are mixed and the mixture is poured into wooden molds. Then shake on a vibration table for 2-3 minutes. It is important to prevent the appearance of air bubbles in the solution.

After processing on a vibrating table, the boxes with the solution are placed in a drying oven to gain strength. Hardening time is about 7-12 hours, at a temperature of plus 30°C. As soon as the product reaches the required hardness, it is removed from the molds, packaged and transported to the place of sale or storage.

Equipment for making luminous decorative stone

Before making decorative artificial stone with unique properties, it is necessary to purchase and install equipment for the production of luminescent concrete.

The set of devices looks like this:

- mixer for mixing the solution: experts recommend buying the MN 151 model, which has minimal mixing time (about 2 minutes) and works with mobile solutions;

- a vibrating table, equipped with a special adjustable mechanism and consisting of a stable platform secured with shock absorbers, as well as an electric vibrator connected to a transformer;

- molds for pouring the solution.

The cost of a mixer for cement mortar MN 151 varies from 4000 and above. The price of a vibrating table depends on its assembly and ranges from 29,000 and above. You can make your own molds. All equipment is installed on an area of no more than 100 m2.

Financial part

Small financial costs at the start ensure the low cost of luminous concrete, approximately 300 - 500 rubles per 1 sq. m. meter. The cost of the material on the market varies from 700 to 1700 rubles. for 1 sq. meter. The difference in price is determined by different types of tiles and a set of accompanying materials, such as color, lubricants, and finishing coating.

Even if you prudently take away all the required payments (taxes, purchase of raw materials, electricity, etc.), the owner of such a business will have at least 400 rubles in profit from each square meter of decorative stone. Considering that one person during an 8-hour working day can produce from 30 to 50 square meters. meters of stone, then the profitability of the enterprise becomes obvious.

We recommend reading:

Features of organizing the production of 3D paving slabs.

All the secrets of producing flexible stone are here.

How to make marble from concrete with your own hands.

Product advertising

You can interest buyers via the Internet by creating pages on social networks. Over time, you can create your own website and advertise your products through it. The search for potential clients can be continued in print media or by posting flyers with an offer.

When offering luminescent concrete, you should indicate the unique properties of the material and explain the need for its use in interiors of different styles.

Source: https://namillion.com/proizvodstvo-lyumobetona.html

Ultra concrete products

The main area of use of ultraconcrete products is finishing and cladding:

There are several dozen different shapes for tiles and facing stones on the modern market.

- Paving slabs.

- Facing and floor slabs.

- Steps and risers.

- Window slabs.

- Balustrades.

- Countertops.

In addition, prefabricated fences and fences are made from granite.

Can you imagine that this beauty consists mostly of cement?

Do-it-yourself luminescent concrete production technology

Lumobeton is a decorative stone-like tile used for interior and exterior work, as well as in landscape design.

It is created on the basis of ordinary concrete, but has unique characteristics: it accumulates solar energy during the day and glows at night. The material is new and not yet popular.

They can be used to decorate facades, flower beds, fountains, benches, fences, fireplaces, ceilings and walls indoors.

Advantages and disadvantages of the material

Lumobeton differs from other facing materials in its ability to glow in the dark. But it also has other advantages:

- The material is universal. Suitable for finishing premises, facade work and designing a personal plot.

- Robust and durable, resistant to adverse weather conditions.

- Its weight is less than that of natural stone.

- Lumobeton is easy to work with.

- The material is in demand at any time of the year.

- Environmentally friendly, non-flammable.

- It looks aesthetically pleasing both during the day and at night.

- There is a large selection of products.

- The shade of the glow may vary.

- The light is dim and does not irritate the eyes.

- The period of glow in the dark is 6-12 hours. There is an opportunity to save on lighting.

- The pigment remains on the material for up to 200 years with the correct manufacturing technology.

- The production of luminous concrete is a new business that does not have many competitors. It does not require the purchase of expensive equipment and the rental of spacious premises. You can make luminous concrete on your own or invite several partners.

Among the disadvantages, it can be noted that at the initial stage the business requires significant financial investments. This material is new and not known to all buyers, so it is necessary to organize advertising for it. The price for this type of finishing is still high.

Making a glowing stone

Making luminous concrete with your own hands is not difficult; the technology for its production does not require special skills. Several preparations need to be made:

- It is important to study the market in the city and find out whether there are competitors in this production.

- Allocate a heated room for business.

- Purchase minimal equipment (mixer for combining the components of the solution, vibrating table, molds for pouring, drying machine).

- Buy a proven technology (recipe) for preparing the mixture.

- Find a good supplier of mortar materials.

- Find retail outlets where finished products will be sold. You can open them yourself.

- If a large volume of production is planned, it is necessary to allocate space for a warehouse.

The technology for producing luminescent concrete begins with preparing the mixture. It is better to purchase it, since it will be difficult to calculate the required proportions on your own. The type of components and their quantity depend on the specific technology:

- Portland cement or gypsum.

- Fine quartz sand.

- Persistent high-quality dyes based on iron oxide (no more than 5% of the total mass).

- Whitewash for lightening parts made of gray cement.

- Various plasticizers that improve the characteristics of the material and increase its strength.

- Latex polymers.

- Hydrophobizers, which add moisture protection to the composition.

- Chemical fibers that protect the material from cracks and chips.

- Luminescent pigment TAT 33. It allows luminescent concrete to glow in the dark.

All components are mixed, the required amount of water is added to them. The mixture should be homogeneous, smooth without lumps.

The elements are formed as follows: the solution is poured into pre-prepared molds and placed on a vibrating table for 2-3 minutes to remove voids and air. Then the forms are placed in a drying cabinet at a temperature of +30 ° C for 7-12 hours. After hardening, the tiles are pulled out and allowed to rest for a while. Next, the material is packaged and transported to the point of sale or warehouse.

Application of decorative tiles

The material is universal, it can be attached to any surface. Decorative elements can be made not only in the form of facing tiles, but also in the form of colored pebbles. This modern decor can be used for interior decoration. Tiles can be used to cover a fireplace , part of a wall, arches, openings and floor fragments.

Stones are also used to decorate facades, gazebos, verandas, and fences. Lumobeton is suitable for use in landscape design. It will help you design a fountain, flower beds, benches, a pond, garden paths, borders, stairs and other garden buildings. Installation process:

- It is necessary to remove dust, dirt, and old finishes from the surface.

- Apply a rough sketch and markings.

- Prepare a cement-based adhesive.

- The surface of the wall and the inside of the tile are moistened with water.

- The adhesive mixture is applied with a notched trowel.

- The seams between the fragments are filled with mortar.

With the help of luminous finishing elements, you can create a unique decor and a fabulous, calming atmosphere indoors and on your garden plot. Its versatility and aesthetic appearance have made luminous concrete a popular finishing material among lovers of unusual design.

Source: https://TvoiDvor.com/beton/tehnologiya-proizvodstva-lyumobetona-svoimi-rukami/

Business idea: production of glowing stones

Starting investments – from 50,000 rubles.

Market saturation is low.

Lumobeton

Lumobeton are luminous decorative stones for landscape design, but also used for interior decoration.

The uniqueness of the material lies in the fact that it accumulates solar energy during the day, which it converts into light at night. Lumobeton does not lose its properties and retains its brightness for a fairly long period of time.

The advantage of the material is its resistance to acidic and alkaline environments, which makes it possible to use it indoors and outdoors.

How to organize a business using glowing laces?

The prospects of a seemingly simple business largely depend on the quality of the products produced and the ability to sell the goods. First, you need to decide what is more profitable, resell finished products or set up your own production.

The first option is simpler. It is enough to find a reliable supplier and take advantage of the advantages of a wholesale buyer. By purchasing goods in batches, it is possible to mark up and sell products at retail. The risk of this way of making money is that a large markup may scare off a potential buyer. Today, glow-in-the-dark shoe laces can be found and purchased in many online stores. The only difference is the price, and if your product does not attract profitability, it will remain unclaimed.

If you make small markups, you will have to compensate for the costs by increasing turnover. Considering the specifics of youth fashion, this is also a risky step. It will no longer be possible to respond flexibly to requests. Another risk is related to information accessibility. Active Internet users know perfectly well how to make glowing shoelaces at home, but not everyone is interested in doing this. Despite all the disadvantages of reselling goods, you can try yourself in this business. Many novice entrepreneurs are successfully doing this, taking advantage of the consistently high demand for luminous laces.

Own production will require investments, but this way of earning money is considered more reliable. If small volumes are planned, when purchasing components in bulk, you will need no more than 20-30 thousand rubles. To begin with, you can organize production in a small room with several assistants, this way you can reduce the level of operating costs. If things go well and the business begins to make a profit, it makes sense to think about expanding production. The main thing is to find your buyer, attract him with impeccable quality of products and competitive prices.