There are quite a lot of types of autoclaved aerated concrete; before choosing a material for construction, you need to study its properties and characteristics.

Lightweight, precast foam concrete was invented back in the 1920s. Constantly developing, AGB production now offers a very convenient modern building material.

Types and scope of application

Autoclaved aerated concrete has positive qualities: environmental friendliness, thermal insulation and lightness. Thanks to these properties, the material is used in private construction and in the construction of public buildings: schools, hospitals, government agencies.

Smaller blocks are used in the construction of summer houses, country houses, garages and technical buildings.

Due to their low weight, blocks are available in the following sizes (length, width and height in mm):

- 625 / 200 / 100;

- 625 / 250 / 400;

- other slab sizes.

Large blocks are used in the construction of multi-storey buildings, for indoor walls or renovation of ancient buildings.

There are 3 categories of AGB based on their properties:

- Thermal insulating aerated concrete. Density up to 400 kg/m2. Thermal insulation material, which is used in areas with cold climatic conditions.

- Structural aerated concrete. Density 700 kg/m2. Suitable for load-bearing structures of buildings up to 3 floors.

- Structural and thermal insulating aerated concrete. Density 500 kg/m2. Universal qualities of thermal insulation and strength.

If you also reinforce the walls during construction using autoclaved lightweight aerated concrete, the strength of the structure will increase. Architects already indicate the need for this work in the project.

Risks and disadvantages of business

The production of aerated concrete blocks is a profitable business, but it also has its disadvantages:

- high competition. The relative ease of starting production and the small list of required materials have made the market saturated. You should fight your competitors by improving the quality of your own products;

- seasonality. A stable income in this industry is almost impossible. During the period of consumer activity, it is necessary to ensure stable supplies of products. In this case, a missed day can cost a month's earnings;

- lack of a permanent customer base. Most clients place only one order during the period of active construction. Relatively constant demand is observed only among construction companies.

The production of aerated concrete blocks requires technical knowledge and the availability of special equipment. With a competent approach to the implementation of the business, the owner will quickly recoup the invested funds, despite the fact that the amount of the initial investment is quite large.

Composition and characteristics of autoclaved aerated concrete

The following components are used in production:

- Portland cement, without active mineral additives from 35 to 49%;

- quicklime calcium with a CaO content of at least 70%;

- quartz sand with a quartz content of SiO2 of at least 85%, and clay impurities of no more than 3%;

- gypsum stone;

- aluminum powder with active aluminum content of at least 80%;

- fresh water to bring the mass to 100% volume;

- calcium chloride from 0.18 to 0.25%

Necessary technical equipment

To equip both a home workshop and a full-fledged enterprise, you will need to buy a line for the production of aerated concrete blocks. The difference here will lie in the degree of its configuration, and, accordingly, the final price.

The installation for the production of aerated concrete using the non-autoclave method is less functional. In this case, the following machines and devices are used:

- dispenser,

- vibrating sieve,

- mixer,

- cutting complex,

- forms.

Production line for aerated concrete blocks

The price of a line for the production of aerated concrete blocks of this configuration is relatively low - in the range of 600,000-900,000 rubles. But if we start talking about the production of more expensive autoclave products, we will have to spend money on an industrial autoclave. Its cost can reach 800,000 rubles.

Experts recommend that aspiring entrepreneurs initially organize a business producing only non-autoclave blocks. Then you won’t have to spend money on an expensive machine.

But spending on technical equipment does not end with the purchase of the main line. The production of aerated concrete blocks will require loading and unloading equipment and working tools. And this is at least another 150,000 rubles. Capital costs will increase if you create your own fleet of vehicles to deliver finished products to customers.

The costs of technical equipment can be reduced if you buy used machines or order them from China.

Advantages of autoclaved aerated concrete

- Complies with fire safety regulations due to its porous design.

- Easy. Installation is simplified and the load on the foundation of buildings is reduced.

- Does not burn.

- Quick assembly because it is available in various block options and can be easily adjusted to the required dimensions.

- Excellent sound insulation.

- High thermal insulation properties.

- Environmentally friendly production.

- The long service life of aerated concrete is time-tested.

However, there are disadvantages to this type of building material:

- Fragile structure due to porosity.

- Wall mounts made of foam concrete need to be made deeper and with thinner fasteners.

- Low moisture resistance. Not recommended for use in showers.

Autoclaved GB is capable of absorbing and releasing moisture. This may not only be a disadvantage. This quality helps to avoid condensation and mold on the walls.

How to set up the production of aerated concrete blocks?

The current crisis has little impact on enterprises producing building materials.

The level of sales of finished products has decreased slightly, but this should not stop entrepreneurs who have decided to implement a profitable project, since many budget-class building materials are becoming more in demand among consumers today than before.

It is precisely the production of inexpensive, but at the same time high-quality products that beginners should pay attention to. Manufacturing aerated concrete can be a profitable business. If you buy equipment for the production of aerated concrete blocks and develop a recipe for the finished product, you can recoup all costs in the shortest possible time.

The popularity of aerated concrete among private builders and large companies is becoming increasingly popular. This largely explains the benefits of the planned business. By establishing cooperation with wholesale clients, you can ensure an influx of constantly high profits.

Our business assessment:

Starting investments – from 500,000 rubles.

Market saturation is low.

The difficulty of starting a business is 6/10.

This direction is attractive not only due to the popularity of the product, but also due to the fairly low competition in this niche. There are not so many large manufacturing enterprises in our country that they can cover the ever-increasing need for material.

We are talking about the production sector, and therefore, a business plan for the production of aerated concrete plays an important role in this matter, since it will help to clearly plan all further activities - estimate capital investments, variable costs and the final profit from sales. If you do not have any skills in drawing up business projects, it is better to invite a specialist or buy a ready-made business plan for the production of aerated concrete blocks. What awaits an entrepreneur who decides to start his own production?

The “scale” of organizing a business will primarily depend on what investments the entrepreneur is willing to make in the business.

If you are planning to enter the regional market with your products, while receiving high incomes, it is worth launching a full-fledged workshop with a separate room and all the necessary equipment. The costs here can be quite large, but the profits will be considerable. By producing high-quality products, you can easily find wholesale buyers who will not let the equipment stand idle.

But for those who are short on funds, it is better to start a business producing aerated concrete based on their own garage or country plot.

In this case, the mini-workshop will be equipped with semi-automatic or fully manual machines, which do not cost as much as powerful production lines. But in this way you cannot produce large quantities of goods that can be sold to wholesalers.

Therefore, you should not count on high profits. Home production of aerated concrete blocks will only become highly profitable if you hire 1-2 workers to help you.

Both options for organizing a business are quite possible in Russia today. In addition, even home production can be brought to a higher level over time by renting production space and purchasing high-tech equipment.

Diversity of product range

Cellular aerated concrete is presented on the construction market in different variations. And in order to be able to offer potential customers a full range of products, it is important to consider the release of each of the possible product options.

And first of all, the produced material will differ in the technological process.

The technology for producing aerated concrete can be:

- autoclave,

- non-autoclave.

The difference between autoclave and non-autoclave building blocks will lie not only in the raw materials used, but also in the final technological characteristics of the product. For example, autoclaved blocks can be used for any construction work, while non-autoclave material is not recommended for use in monolithic construction.

It will be great if we provide for the production of both types of products within the workshop walls. But the production of autoclaved aerated concrete will require expensive equipment, which not every entrepreneur can handle. That is why, in the case of organizing a home business, only non-autoclave blocks are often produced.

In addition to the fact that the technological scheme and raw materials used may differ, finished products vary in size. And here it is important to take into account consumer demand - it is better to bet on blocks of the geometry that are most in demand among buyers.

A mini plant for the production of aerated concrete can produce products in 2 main forms:

- Rectangular (length – 625 mm, height – 250 mm, width – 100, 150, 200, 240, 300 or 400 mm).

- U-shaped (length – 600 mm, height – 250 mm, width – 200, 240, 300 or 400 mm).

The manufacturer can increase the cost of production, and therefore the profitability of the enterprise, if it begins to fulfill private orders, producing products of other standard sizes. Modern equipment allows you to do this without any additional costs.

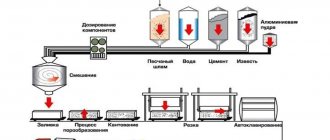

Production cycle of aerated concrete production

The technology for producing aerated concrete blocks will depend on what type of material is planned to be produced.

But in general, the process can be described as follows:

- Accurate dosing of the components required in the recipe.

- Preparation of an aerated concrete mixture in a container with the introduction of a gas-forming agent into the recipe.

- Pouring the mixture into molds of a certain size.

- Cutting off excess material that has “extended” beyond the edges of the mold.

- Keeping the mixture in molds.

Further stages will vary. The production of non-autoclaved aerated concrete will require drying the “semi-finished product” under natural conditions, either in the fresh air or in a warehouse. But autoclave blocks are kept for a certain time in the chambers of a special unit - an autoclave.

Products are considered ready for use only after 30-40 days of aging. This process can be carried out both at the enterprise’s warehouse and directly at the client’s construction site.

Technological scheme for the production of autoclaved aerated concrete

A mini plant for the production of aerated concrete blocks processes within its walls materials available on the market, and most importantly, inexpensive ones. Autoclave blocks are based on lime, while non-autoclave blocks are based on cement. The other components are identical - sand, water, gasifier (aluminum suspension). To save on the purchase of raw materials, it is better to organize the delivery of all materials in bulk.

Find out the features of Lego brick production technology.

Necessary technical equipment

To equip both a home workshop and a full-fledged enterprise, you will need to buy a line for the production of aerated concrete blocks. The difference here will lie in the degree of its configuration, and, accordingly, the final price.

The installation for the production of aerated concrete using the non-autoclave method is less functional. In this case, the following machines and devices are used:

- dispenser,

- vibrating sieve,

- mixer,

- cutting complex,

- forms.

Production line for aerated concrete blocks

The price of a line for the production of aerated concrete blocks of this configuration is relatively low - in the range of 600,000-900,000 rubles. But if we start talking about the production of more expensive autoclave products, we will have to spend money on an industrial autoclave. Its cost can reach 800,000 rubles.

Experts recommend that aspiring entrepreneurs initially organize a business producing only non-autoclave blocks. Then you won’t have to spend money on an expensive machine.

But spending on technical equipment does not end with the purchase of the main line. The production of aerated concrete blocks will require loading and unloading equipment and working tools. And this is at least another 150,000 rubles. Capital costs will increase if you create your own fleet of vehicles to deliver finished products to customers.

The costs of technical equipment can be reduced if you buy used machines or order them from China.

How to organize sales of finished products?

The price of equipment for the production of aerated concrete blocks will pay off faster if you start looking for potential customers for large quantities of products as early as possible - even before the launch of the workshop.

There should not be any problems with having clients, since the material is characterized by many positive qualities:

- strength,

- reliability,

- environmental friendliness,

- good heat and sound insulation,

- low cost.

When planning to establish contacts with potential clients, your main bet should be on wholesale buyers. This is much simpler, because then the goods will not sit in warehouses, thereby bringing consistently high profits from sales.

Even a mini line for the production of aerated concrete will be able to provide high-quality products to the following consumers:

- large construction supermarkets, bases and warehouses

- development companies.

- private builders.

When planning your own business in this area, it is also important to take into account seasonality. An entrepreneur should be prepared for the fact that sales will decrease in the autumn-winter period. And this is another reason to make every effort to attract wholesale customers. After all, large construction companies may need material all year round. If you find these, you can forget about the problem of seasonality.

More to read:

Profitability of a mini plant for the production of expanded clay.

What equipment do you need to buy for sand block production?

What are the criteria for choosing a machine for the production of polystyrene concrete blocks?

How profitable is the planned business?

It’s now clear how to start the production of aerated concrete blocks at home and in a full-fledged workshop; all that remains is to figure out the profitability of the planned enterprise. But it will be quite difficult to talk about specific profitability figures here, since the final revenue depends on several factors - production volumes and sales of finished products, pricing policy in the region.

Let us first imagine the expenses that an entrepreneur will have to incur to start a business:

- Registration of an enterprise.

- Purchase and commissioning of equipment.

- Providing a raw material base.

- Preparing the premises for work.

In the case of a full-fledged workshop producing autoclave blocks, you will have to spend at least 2,500,000 rubles on everything. And the most impressive expense item here is equipment for the production of autoclaved aerated concrete. Costs will be reduced to 1,800,000 rubles if we plan to produce non-autoclave material. A home business can be organized with expenses of at least 500,000 rubles.

To calculate the net profit of an enterprise, let’s take as an example a mini-production of aerated concrete blocks with our own hands with a production volume of 15 m3 of products per shift. If you work 8 hours daily, 22 days a month, you can get up to 350 m3 of finished products monthly.

Aerated concrete can be sold at the average wholesale price established in Russia - 2500-3500 rubles/m3. It turns out that an entrepreneur can earn an average of up to 1,000,000 rubles per month.

From this amount you need to subtract the following variable costs (we do not take wages into account in the absence of employees):

- premises rental,

- purchase of raw materials,

- fare,

- payment for communications and utilities.

Average calculations show that even with small volumes of block production, an entrepreneur can have up to 150,000 rubles. net profit monthly. Accordingly, if you buy equipment for the production of aerated concrete with higher productivity (up to 80 m3 per shift), your profit will increase significantly.

Production and sale of gas silicate blocks as a promising business.

But in order to achieve such attractive figures, it is impossible to do without well-functioning sales channels - profits will constantly flow only if there are orders.

Much is further complicated by the fact that the material must be tracked for a long period before being sold. But this process can also be carried out on the buyer’s territory.

In this way, free space can be freed up for new batches of released products.

Source: https://namillion.com/proizvodstvo-gazobetonnyx-blokov.html

Equipment for the production of autoclaved aerated concrete

This process is fully automated and fine-tuned by equipment suppliers.

What it includes:

- Warehousing and preparation of raw materials. Cement and lime are pneumatically loaded into supply silos using a compressor unit. Liquids are poured into special containers and brought to the required temperature. The sand is processed in a mill and fed into a slurry basin. Aluminum powder is prepared in a suspender.

- Mixing of components is carried out in a mixing tower with a control panel.

- Filling and forming of blocks is done at the pouring station.

- Cutting autoclaved aerated concrete blocks on a string cutting machine.

- Autoclave ovens for finishing blocks are heated to the required characteristics.

- Transportation of finished blocks is carried out on pallets by forklifts.

- Finished products are sent to the warehouse.

How much to invest in opening

It was determined above that the initial costs of opening a workshop for the production of gas blocks will be 500 thousand rubles. The purposes for which these funds will be used are described in the following table:

| Expense item | Amount of costs, rub. |

| Payment of rent for production premises for six months | 120 000 |

| Repair of the premises and preparation of communications for the launch of production | 50 000 |

| Purchase of equipment for the production line | 200 000 |

| Business registration, paperwork, obtaining permits from the SES, Rospotrebnadzor and the fire service | 10 000 |

| Purchase of the first batch of raw materials for production | 100 000 |

| Costs for training workshop workers | 5 000 |

| Advertising and promotion expenses | 5 000 |

| Other, including unforeseen, expenses | 10 000 |

| TOTAL | 500 000 |

Note: equipment for the production workshop, the cost of which is 200 thousand rubles, will allow the production of up to 10 cubic meters of aerated concrete per shift. Subsequently, the production line can be improved to increase the yield of finished products.

Production technology

- Preparation of components. Some components come to production ready-made, while others undergo preparation. Quartz sand combined with water is ground to form sludge, and then constantly mixed in sludge basins and brought to the desired level. Aluminum powder also undergoes pre-production preparation.

- Dosage and mixing. Dosing and preparation of the mixture is performed automatically. All components, prepared in advance, are accurately weighed and filled into a large mixer. The prepared mixture is poured into metal molds - baths ½ of the volume. As a result, a chemical reaction of the components occurs with the formation of hydrogen and the block fills the entire mold and becomes porous. Hydrogen bubbles can be up to 3 mm. But the main thing is that they are almost uniform. This gives a homogeneous structure. Mixing time for all components is 5 minutes at high speed.

Aluminum powder is an explosive element, so strict adherence to fire safety measures is required in the room where AGB is produced.

Cutting into blocks. The mixture is allowed to harden a little in the mold, according to the technology for 2.5 hours, and when removed, it is still quite soft. Cutting into blocks of the required size occurs on an automated line using a special wire.

- Autoclave processing. Then the prepared AGB panel blocks are left in the autoclave for 12 hours. There, at a temperature of 1900C and a steam pressure of 8 - 12 bar, it becomes especially strong, thanks to the chemical reaction of quartz sand and calcium hydroxide.

- Sorting and packaging. After processing in an autoclave, aerated concrete is immediately ready for its intended use. It is unloaded from the ovens onto pallets and wrapped in film to insulate it from moisture. In this form it is stored in a warehouse. Then it is purchased by construction companies or specialized stores.

Production Features

The described technology, one of the stages of which is autoclaving, makes it possible to obtain a durable and lightweight material with a porous structure, whose properties are significantly superior to materials such as non-autoclaved aerated concrete, wood, brick, foam block, etc.

Autoclaved aerated concrete has a number of undeniable advantages, which we will discuss in detail in a separate article. Now let's look at them based on technological features.

Many people are concerned that the lime and cement contained in aerated concrete are hazardous to health, but these initial components are completely transformed in an autoclave, which means the resulting material is environmentally friendly and will not cause harm to health when a building is built from it.

Safety in the house is guaranteed by the fire resistance of aerated concrete, because it consists of non-combustible materials: sand, cement and aluminum powder. The strength of the blocks is due to many hours of hardening in an autoclave.

A comfortable stay in a room made of aerated concrete blocks is ensured by the porous structure of the material, which can “breathe” almost like wood due to the bubbles formed during the introduction of aluminum powder and then hardened. The presence of pores at a given thickness gives aerated concrete excellent soundproofing properties. Heat and frost resistance are also guaranteed by autoclave technology, which enhances these properties.

As a result, by building your house from autoclaved aerated concrete , you will make it environmentally friendly, warm and safe.

It is also important that the aerated concrete produced at the plant has a relatively low weight (about 25 kg) and does not require special lifting equipment. At the same time, the material, which already has verified dimensions with a minimum error (1-2 mm), is easily processed, which means that you can handle the construction of the building freely and quickly.