When constructing various structures, one of the main components of obtaining a successful result is laying a high-quality foundation. As is known, concrete solutions used for these purposes have disadvantages, such as uneven shrinkage, the appearance of microcracks and others. These defects can lead to the penetration of moisture, which, in turn, will cause complete destruction of the structure. To prevent such undesirable consequences, reinforced concrete structures are waterproofed. In this case, previously water-repellent materials were used to cover parts of the building or which were laid in layers of several elements.

Now special additives to concrete for waterproofing have been developed, which make it possible to increase the resistance of structures to corrosion and the water resistance of the structure of the composition itself.

Concrete solutions have disadvantages such as uneven shrinkage, the appearance of microcracks and others. To prevent such undesirable consequences, reinforced concrete structures are waterproofed.

Waterproof concrete - what is it?

Moisture-resistant reinforced concrete is a special type of material in which there are no pores and capillaries (voids) that allow the bulk of moisture to pass through. The material is characterized by increased density , which determines its specific properties, but this is not enough to ensure complete waterproofing.

Water resistance classes

The grade of concrete related to the degree of waterproofness is indicated by the letter “W” followed by a numerical value. The number can range from 2 to 20 and determines the maximum permissible fluid pressure.

Concrete with maximum water resistance is labeled W20 and vice versa. In private housing construction, it is enough to use material W4-W8 , but if groundwater is close, this figure can be increased to W12.

When carrying out work, it is necessary to prepare a special concrete solution and seal the joints

Do-it-yourself concrete additives for waterproofing

Special materials increase the density of reinforced concrete and eliminate any penetration of moisture (pressure, capillary).

Additives are classified as follows:

- polymer;

- plasticizing;

- clogging.

Plasticizers

The materials differ in quality, but have the same operating principle:

- Most compositions, entering the solution, form a film coating that envelops the cement particles and determines their characteristics. They become slippery and help improve the mobility of reinforced concrete;

- Some plasticizer systems generate an electrical charge, activating the solution particles, which also improves the fluidity of the mixture.

- Polycarboxylic compounds have been developed with a combined principle of action, simultaneously forming a charge and a film. Ready-made concrete gains strength, frost resistance, water resistance, and density.

Plasticizer C3

The use of the material is permissible on prefabricated and monolithic structures with a high degree of reinforcement. The proportion of the substance is calculated based on the mass of dry cement and is 0.3-0.8% of its weight . The additive is introduced into the mixture after dilution in water, according to the selected technology.

Cooking recommendations:

- the solution is mixed at positive air temperatures;

- the container must be clean;

- during dissolution, constant stirring is performed;

- When working, personal protective equipment is used.

Material advantages:

- saving cement;

- increasing the mobility of concrete and reinforced concrete products without compromising strength;

- the freshly laid mixture does not need to be vibrated;

- the finished composition is characterized by increased density, which improves water resistance;

- high frost resistance;

- reduction of shrinkage.

When work is carried out with your own hands, it is advisable to use special additives that are proportionally introduced into the working mixture

Colmatizing

The principle of operation of the compositions of this brand is revealed as follows:

- reinforced concrete is compacted after the solution hardens;

- a strong chemical reaction occurs between the components of the additive, water and cement particles;

- the substances formed are insoluble high-strength compounds that fill voids in solid concrete;

- The basis of all mixtures with bridging properties is microsilica.

Polymer

Polymer compositions determine the mobility of the concrete mass : a film is formed on the particles of the mixture. Such materials make it possible to ensure high moisture resistance even for those structures that have already become damaged.

Penetrating waterproofing

Additives with penetrating action help to obtain a high effect. They can be applied to hardened concrete or injected directly into the solution. The composition of the mixtures varies depending on the manufacturer.

Systems in which sand and cement predominate form a crust; bases with chemical compounds penetrate deeper into concrete, that is, they fill voids and pores more effectively.

"Penetron"

The main representative of penetrating waterproofing.

Material properties:

- ensuring water resistance of reinforced concrete and concrete structures at the concreting stage;

- application extends to prefabricated and monolithic structures, including those with cracks and pores. These could be swimming pools, tanks, basements, foundations, septic tanks;

- compatibility - additives are used in concrete for strength, which are not difficult to buy;

- radioactive safety, environmental friendliness;

- the composition is represented by chemical additives, granulometric quartz sand and special cement;

- increasing the frost resistance of hydraulic concrete;

- protection of the structure from wastewater, groundwater, alkalis, acids, including sea water.

"Penetron Admix" is dissolved in water and added to the concrete mixture at the mixing stage. To carry out waterproofing of communication inputs, connections, seams, joints, additional waterproofing gaskets are laid

To install waterproofing, it is recommended to follow the following sequence of actions::

- the concrete base is cleared of all materials that could serve as an obstacle to the penetration of active chemicals. For work, you can use a high-pressure water jet or a brush with metal bristles;

- surfaces that have been sanded are moistened with a weak acid solution, which is washed off with water for an hour;

- before applying the system, the concrete surface is moistened;

- the finished solution is applied in two layers to the base using a brush with synthetic bristles;

- the second layer is applied to the set first layer, which is also moistened;

- the surface must be processed evenly, without gaps.

Characteristics of non-shrinking material

Modern construction even includes objects whose operating conditions require the construction and location of objects in a humid environment (or completely in water). For example, dams, dikes, bridges, lining of river canals, and so on. Naturally, the material used in the construction or finishing of such objects must meet the requirements of water resistance.

This is precisely why types of waterproof material have been developed. One of them is waterproof non-shrink cement or WBC.

This composition is based on aluminous cement, which meets the characteristics of a fast-hardening binder using aluminum oxide.

Scheme of cement production.

As for the raw materials for the production of this composition, these are limestone and bauxite, the extraction of which is carried out on Russian territory.

- The principle of operation of VBC provides for the crystallization of calcium aluminates during the hardening of the solution in compliance with the conditions of counteracting free expansion, which in turn contribute to a strong degree of compaction of the stone. It is in this regard that concrete acquires the properties of water resistance and high waterproofing;

- Factory-produced VBC is made by grinding cement (alumina) together with components such as gypsum and calcined lime;

- the basic requirement for the amount of cement is 85%, but the proportions of gypsum and lime may vary. Sometimes asbestos is used in an amount of 5%.

The waterproof properties of such cement are achieved an hour after preparing the solution, and final hardening and acquisition of all qualities by the solution occurs after 28 days.

Liquid glass - modern waterproofing

A type of silicate adhesive improves the performance characteristics of reinforced concrete products without significantly affecting their cost.

The material allows you to provide:

- waterproof;

- moisture resistance;

- heat resistance;

- resistance to fungal and mold attacks.

Liquid glass for concrete is used in the construction of foundations, including for hydraulic engineering, fireplaces, boilers, furnaces, and various underground reinforced concrete structures.

Self-construction involves using the following principles:

- at least 10% silicate glue is introduced into the concrete solution, which ensures optimal technical characteristics;

- silicates are not added to the finished solution. First, the dry components are combined, then glue is introduced, which is previously diluted with water;

- It is recommended to prepare solutions in small portions, since the additive accelerates hardening. Laying and pouring reinforced concrete should be carried out quickly.

For work, it is advisable to use concrete grades M400/M200. Failure to comply with the proportions will result in the finished structure falling apart the next day.

Sequencing:

- a glass of liquid glass is diluted in a bucket of purified water;

- the solution is thoroughly mixed;

- the additive is poured into a more convenient container, for example, a trough, and the dry mixture is introduced there;

- the mass is processed with a construction mixer;

- Do-it-yourself waterproof concrete is ready and can be poured into the formwork.

Waterproofing of finished reinforced concrete products is carried out using a primer with silicate glue. In private construction, a mixture of water, cement and liquid glass (1 liter of water/400 g of glue) is used for such purposes.

Proportions for concrete mixture

To make the desired concrete mixture, it is necessary to strictly adhere to the proportions, because deviation to the side will worsen the properties. This will prevent unnecessary translation of material. You can prepare it either with your own hands or using a special mixer.

The main focus is on the proportion between water and cement. The cement must be taken fresh, marked M300-M400, less often M200 (b15). Class B15 is a good average option. Before use, it is imperative to sift B15 through a sieve. The hydrophobic effect can be achieved by varying the amount of sand and gravel. So, there should be 2 times less sand than gravel.

Possible proportions of gravel, cement, sand are as follows: 4:1:1, 3:1:2, 5:1:2.5. The mass of water should be somewhere around 0.5-0.7. Thanks to these proportions, the mixture hardens well. Various additives are also used to achieve waterproofness.

Waterproofing the basement from the inside from groundwater

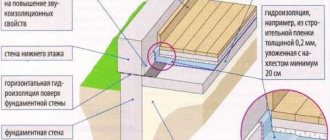

Vertical waterproofing is carried out along the basement part of the structure in cases where the walls of the structure are located at the groundwater level and in the absence of a drainage system. Horizontal is implemented on the floor - when the base is placed at the groundwater level.

The choice of work method is made based on the following parameters:

- foundation material, insulation quality;

- precipitation level and groundwater occurrence;

- purpose of the premises;

- presence of drainage systems.

General principles of work:

- if the basement is flooded, the water is pumped out or you need to wait until it goes away on its own;

- the surface is cleaned down to the concrete base.

- cracks must be grooved and cleaned for deeper penetration of waterproofing systems;

- reinforcement fabric secured to the base with dowels will enhance moisture resistance;

- when strengthening the horizontal plane, it is filled with crushed stone and cemented, the insulation extends onto the walls up to 300 mm.

Seamless waterproofing

This technique is also called liquid film. In this case, materials are used that are suitable for treating all surfaces in bathrooms, kitchens, toilets and rooms where treatment of areas with high humidity is required. The product can be applied with a spatula, roller or brush.

Initially, the joints between the walls and floor slabs are processed, after which the mixture is applied to the floor surface, and you will need a waterproofing tape, which is pressed into the mixture using a roller or manually. In those places where drains are located, it is necessary to install waterproofing cuffs. Then the product is reapplied. The layer should be uniform, it is important to eliminate gaps. The composition should extend 35 cm onto the wall. It should be left for 2 hours under natural drying conditions. Then the surface is re-treated and dried for 12 hours. If the work is carried out according to the rules, then problems with fungus and dampness should not arise.