Dowel for timber and fastening features

Concrete, due to the fact that it is a material with a high degree of density, is ideal for the construction of walls and ceilings. But it is quite difficult to install a mount in it, fixing a shelf, a chandelier or even hanging interior parts. In a situation where you need to attach any structures to a concrete base, you cannot do without a special fastener product - a concrete dowel.

Purpose and device. By and large, dowels for concrete surfaces are the same self-tapping screws, which are a rod with variable threads and sharp tips.

The fastening product, made of high-quality hardened steel and coated with a protective copper or zinc layer, usually has a countersunk head with internal notches. For installation work where dowels are used, hex bits are also used.

What is a wooden dowel used for?

There is an opinion that the dowels hold the entire structure of the building. In fact, they serve as vertical guides when connecting the beams to each other. Holes for fastening in the timber are drilled in advance at uniform distances. Therefore, assembling the timber on the dowel guarantees even placement of the crowns.

Later, when the wood begins to dry out, deform and crack under the influence of internal stresses, the dowels will hold the beams in their original position and prevent them from moving.

The pins themselves resist deformation. If the load is too strong and the diameter is too small, they may break. You need to select fasteners in accordance with the size of the timber being fastened. For furniture assembly, these can be small cylinders with a diameter of 8-10 mm with a corrugated surface. When building a house from timber, the thickness of the element will be at least 25 mm.

Cost of dowels

The price of fasteners depends on several factors. These include the length of the dowel for the timber and the type of wood. If the product is made of birch and belongs to the first grade, then you will have to pay from 4 to 8 rubles per unit. This is true if the length is 30 cm.

The cost of the same pin 60 cm long can reach 10 rubles. If the length is 120 cm, then the cost can increase to 15 rubles. When the diameter of the dowel for the timber does not exceed 30 mm, and its length is 110 cm, you will have to pay 25 rubles for it. Larch fasteners are more expensive due to the material’s high resistance to moisture. One dowel with a length of 25 mm costs 30 rubles.

Shape, material, types, sizes

Nagel is a German word. Translated it means “nail”. But this nail does not have the usual head and sharp end. The wooden dowel can be round or square. The latter are used mainly when installing window or door units. It is believed that when cutting corners, the fasteners may jam.

Occasionally there is a need for rectangular fasteners with a narrow side.

The material most often used for manufacturing is metal or wood. Steel dowels are used in cases where they want to reduce the cost of construction. They are made by hand from steel rod - homogeneous, or pipes - hollow.

Metal parts are stronger and therefore more durable. But they:

- rust;

- with a significant change in temperature, they change sizes;

- when the temperature drops sharply, condensation settles on them, which is bad for the wood.

Wooden parts do not have the listed disadvantages. In addition, they dry out and change at the same time as the crowns that hold them together. To do this, the moisture content of the dowel should be quite a bit lower than the moisture content of the timber. Over time, the wooden dowel is connected to the beams, and the wall becomes uniform.

To make dowels it is recommended to use:

- conifers;

- beech;

- ash;

- birch;

- oak;

- larch.

But it is better if it is the same material as the one from which the timber is made.

Sometimes plastic is used, but this is rather an exception.

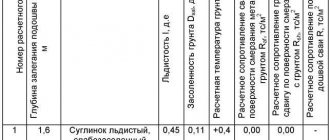

There is no assortment regulating the size of the dowel. The length and diameter depend on the cross-sectional size of the building material and the design loads on the building. Calculations are carried out according to the methods from SP 20.13330.2011 “Loads and impacts”.

Description and sizes of dowels made of different materials

The concept of “dowel” is not simple; it involves not only wooden dowels. These products can be represented by fasteners of different designs and shapes. The most traditional type are cylindrical smooth rods, which can be symmetrical or asymmetrical.

The dimensions of cylindrical products are usually equal to the diameter of the rod to ensure a tight connection. Bolts and nuts are tension bolts that have a high load-bearing capacity due to friction. This effect in practice may be less, and sometimes disappears completely, because during the process of drying and shrinking of wood, there may be no friction at the last stage.

If the screws have a diameter of less than 6 mm, then they are screwed in, but this cuts the fibers, so fastenings of this kind are not always practical and are used in extreme cases.

Metal nails without thread have a diameter of up to 6 mm. Their convenience lies in the ease of driving without the need to drill holes. Such pins are smooth and thin; they do not cut the wood, but push the fibers apart, which does not disturb the structure of the material. Over time, compaction occurs around the nail, sometimes leading to chipping. The metal dowel works worse when bending.

Plate dowels for timber are used to join two or three logs that are stacked in height. The hole for such a pin is cut with a chain mortising machine. The size of the products is determined by the load.

Pros and cons of fastening timber with dowels

The main advantage of fastening with dowels is the similarity of their properties with the properties of timber. They dry together with the walls and grow together with the crowns, preventing them from deforming, sagging, or cracking. This connection is reliable. It absorbs bending loads and prevents the beam from moving horizontally. This means that significant gaps do not form in the walls.

The wooden dowel cannot become a source of condensation and is not subject to corrosion.

The cost of dowels, even those manufactured at the factory, is very low. You can make them yourself from suitable waste.

The material for manufacturing must be chosen carefully. It should not have any flaws. When undertaking the independent installation of a log house, you must remember that installing dowels in timber is a rather labor-intensive process. The elements must be installed exactly vertically. Determining the diameter and quantity also needs to be taken responsibly. Otherwise, they lose their positive design qualities.

Advantages and disadvantages

The advantages include:

- easy installation;

- reliable and tight fastening;

- uniform shrinkage of the object;

- You can make dowels for timber with your own hands.

Despite all the advantages, experts highlight the key disadvantages of using dowels:

- to install dowels, at least minimal construction experience is required;

- the quality of the dowels must be very high, without knots or irregularities;

- If you drive the dowels with great force, cracks may appear in the timber and it will become unusable.

Make your own wooden dowel

The easiest way to make a dowel from scrap material is on a lathe. To do this, a workpiece is selected, installed in the machine and gradually ground down to a cylinder of the required diameter. Then the cylinder is cut to a certain length, and the ends are chamfered.

If you don’t have a machine, then an ax will do as a tool. Masters recommend taking a birch edged board or log of suitable length and cutting it into chips. Then the resulting square-section blanks are hewn to a round shape.

The easiest way is to cut a cutting from a garden tool that has become unnecessary. It has been experimentally established that a dowel with a diameter of 25 mm is suitable for fastening timber with a side length of up to 200 mm. Larger sizes will require 30mm thickness or more frequent installation. It is recommended to calculate the length as one and a half width of the section of the beam being fastened.

Application

The use of dowels for timber is very limited. With its help, wooden buildings are built. That is why installation features are associated with laying timber or logs. Holes for fastening are drilled through the top of the log, and only halfway from the bottom. The nest is made vertically.

The beam must slide along the rod during the shrinkage process. The holes should be centrally located. The dowel for the timber is usually installed at a distance of 50 cm from the corner. The remaining holes are made in a checkerboard pattern. The minimum distance between them should be 150 cm.

Fastening technology

To build a high-quality, cozy house that will last for decades, you need to strictly follow the construction rules.

How to position a wooden dowel

First of all, you need to calculate how many dowels will need to be installed for a beam of a certain width. Determine their location, the distance between them. Based on this, make the required number of fasteners. It is better to do the preparatory work so that you are not distracted during the installation process if there are suddenly not enough fasteners.

Each dowel holds two beams together. Experts recommend following these tips:

- To mark the first hole, 300-700 mm are retreated from the edge of the beam.

- Depending on the diameter of the dowel, the step is measured at 1.5 - 2 m.

- It is better to arrange the elements in a checkerboard pattern.

Drilling

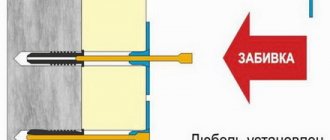

You need to drill holes exactly in the center of the beam. The worker’s position must be stable so that it is strictly vertical. The diameter is chosen equal to the thickness of the fastener, so that it can later be hammered in with a mallet. This helps to avoid sagging of the structure due to a small vertical load.

The depth is defined as the length of the pin plus 2-3 cm. This compensates for the load when the wall shrinks. A drill for drilling timber for dowels is chosen with a power of at least one and a half kilowatts with a large set of drills.

Clogging

The dowels should fit into the holes easily, with little tension. If you have to apply force to drive, instead of relieving stress, the part will add it. Wood may crack during the construction stage.

Soap solution reduces friction well when clogging.

The next crown is put on the fastenings hammered into the holes.

Sometimes during construction, for various reasons, you have to make extraordinary decisions. This enriches the experience of a novice master.

What is a dowel

A dowel is a wooden or metal pin that holds a beam together. When exposed to moisture, the wood swells, and the dowel holds the two logs or beams together more tightly. They are also used in the construction of boats: sea water corrodes the boards, and the nails do not provide proper fastening.

The main purpose of the timber dowel is to prevent the boards from deforming. However, it does not interfere with natural longitudinal deformation. Both boards and logs tend to settle a little after construction is completed.

The result is smooth and smooth walls.

By following the technology of constructing wooden houses using dowels, you can completely avoid problems such as the occurrence of gaps between the crowns and torsion of wood. A wooden house, in the construction of which wood dowels were used, will delight its owners for decades with even and smooth walls.

Video - Installation of a dowel when assembling a timber house

Recommended viewing:

- Inheriting a house: types of inheritance, paperwork - 07/29/2014 06:49

- Transfer of land category - procedure for changing the purpose of land plots - 07/16/2014 05:00

- How to build a wooden house - 11/13/2013 09:54

Related topics:

- Properties of laminated veneer lumber - 08/14/2013 11:44

- Smart home - automation of solving problems in the house - 01/08/2013 11:33

- Requirements for the roof of a country house - 07/25/2013 05:41

Birch dowels - advantages

The dowels should be made of a harder type of wood than the beams. They are made from hard wood - most often oak, beech or birch.

The most popular in construction are birch dowels, which are manufactured at an industrial enterprise. This is due to the availability of the material and the large number of enterprises involved in their production. Birch is an inexpensive and high-quality building material with a dense structure, low natural humidity, which provides sufficient strength to connect the wall elements to each other. Birch dowels can also be used at the joints of doors, windows and frames.

Oak dowels, of course, are distinguished by their strength and durability. But due to their high price, they are used extremely rarely. There are dowels made from pine and spruce on the market, but these are soft wood species that are not recommended for use in construction as dowels.