РћСЃРѕР±РµРСности заливки S„ундамента

The construction of any building or small structure begins with pouring the foundation.

The integrity and reliability of the entire structure depends on this first stage. An improperly poured foundation can lead to the collapse of a structure within a couple of years after construction. The foundation is the main part of the house

That is why, the purpose of this article is the question of how to pour the foundation of a future building correctly, without fear of further problems during the construction and operation of buildings. We will consider pouring a concrete foundation.

Preparing to pour the foundation

First of all, it is necessary to calculate the required amount of concrete solution. Thanks to this, you can immediately draw up an estimate for construction work. After this, they begin marking the future foundation. Pegs are driven in along its inner and outer perimeters, and then the cord is pulled.

A pit is dug using this marking. How to determine what depth to pour the foundation? It depends on the freezing depth of your soil

How deep to dig the foundation and why. "Important"

If you live in the northern regions, then the depth of the pit can reach one and a half meters. In the middle zone, these indicators are much more modest. They are approximately 50-70 cm. The given data corresponds to a conventional buried foundation.

Trench for the future foundation

A sand cushion with a layer of about 20 cm is poured into the dug pit. The sand should be coarse-grained. The pillow is watered. Waterproofing is laid along the walls of the trench and at its bottom. After this, the pit is reinforced with metal rods. They are tied together with wire.

Formwork is constructed on top of the soil level. For its manufacture, boards, flat slate, metal sheets, chipboard and other materials are used that can hold concrete mortar without deformation. Next, the pit is directly poured with concrete.

Caring for concrete after pouring

After completing the work of pouring the concrete foundation of a residential building, the resulting structure must not be disturbed under any circumstances. It is also desirable to eliminate or minimize work that causes vibration of the earth near the foundation.

The concrete solution acquires its main strength within seven days. Concrete reaches its full strength cycle in 28 days.

To speed up the process, special modifiers are used that double the rate of hardening. They are usually added to the solution during production, but they can be added directly when loading into the concrete pump.

During the first seven days, in addition to vibration, the concrete solution is contraindicated from sunlight and heat, during which the evaporation of water necessary to create a crystal lattice in concrete occurs. Therefore, it is recommended to cover the fresh solution with damp rags and film, first securing it so that it does not blow away with the wind.

In this chapter, we will finish the story about concreting the foundation of a residential building, since when all the recommendations are followed: selecting concrete, treating the soil, strengthening the reinforcement frame, correctly laying the concrete mortar and the further process of its setting, the process was carried out flawlessly. This design will last for centuries.

Methods for pouring a foundation

There are several ways to properly fill the foundation for a house. It all depends on the volume of pouring, the possibility of equipment access to the construction site, the availability of electricity on the site, as well as your financial capabilities.

How to properly mix foundation mortar

Pouring the foundation yourself

This is the most labor-intensive method. At the same time, it allows you to significantly save on the use of construction equipment. All mixing and pouring of the solution is done manually. For this purpose, shovels, hoes, and some containers are used to mix the solution. This kind of work is not very effective, but it is practically free.

Foundation formwork

Using an Electric Concrete Mixer

It is assumed that your site has electricity. Then a small concrete mixer will greatly facilitate manual labor. It is enough to pour all the components of the concrete solution into it and put it into operation. The capacity of the concrete mixer may vary. Of course, a significant capacity will reduce the filling time. After the mixing process is completed, the solution is manually distributed inside the pit. A concrete mixer can significantly speed up the foundation laying process.

Mixing concrete in a concrete mixer

Pouring the foundation using a mixer

Calling a concrete mixer (mixer) will cost you much more. She will bring the ready-made solution to your site. All you have to do is build gutters through which the solution will be fed into the pit. It is recommended to pour the solution not into one place in the pit, but into several points. This will make it easier for you to manually level the solution. The most serious mistakes when pouring a foundation arise precisely because the solution is concentrated in one place. The person leveling the solution simply does not physically have time to move it around the perimeter of the pit.

Another advantage of the mixer is that you can place an order for a different number of cubes of solution. Depending on your needs.

Ready concrete in a mixer

Pouring the foundation with a concrete pump

In cases where it is impossible for the mixer to drive to the site, a concrete pump is used. This is a special machine equipped with equipment for supplying concrete over a considerable distance using a hose. Pouring concrete occurs very quickly, since it is possible to direct the hose socket to various places in the trench. This method is beneficial for filling large pits. For example, equipping a slab foundation.

Is it possible to fill the foundation in parts?

The question often arises - what to do if it is impossible to pour the foundation in one day? Is it possible to divide this stage into parts? Pouring the foundation, if necessary, can be done in parts. It is recommended to fill the foundation layer by layer, preferably in 2 horizontal layers.

The correct order of doing the work is as follows. After pouring the first layer along the entire perimeter of the pit, it is covered with plastic film and left in this condition until the next day. Then the film is removed, the concrete milk is washed off from the solution and the second layer is poured. This method is called "hot joint".

If work is not resumed the next day, it is recommended to use the cold weld method. It involves pouring a second layer onto the already completely hardened first layer. It is prohibited to pour on concrete that has already set but has not yet hardened. The bond between the layers will not be strong, which can lead to displacement of the layers relative to each other. The curing of the foundation after pouring the first layer, in the case of using a cold joint, must be at least 2 days.

Errors in foundation construction

Cost of pouring a foundation

How to calculate the cost of building a foundation? To do this, calculate the amount of building materials required for the work. Take into account the depth of the pit, its width, and the presence of fillers in the solution. Also consider the cost of formwork. The cost of the foundation depends on the choice of pouring method. For example, using a concrete pump or mixer can significantly increase the cost of the job.

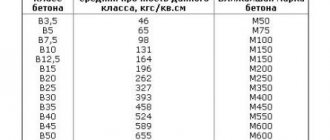

Selecting a concrete strength grade for pouring (concreting) the foundation of a private house

To fill the foundation of a private house, a concrete solution of at least grade M200 is used (see the article “types of concrete”), and when building stone or block buildings, grade M250-M300 is used. However, when using these grades for the foundation, waterproofing is necessary because these types of concrete solutions are not waterproof.

Many experts recommend immediately using special hydraulic concrete mixtures of grades M400 and higher. However, there may be dangers here: it is very difficult for a non-specialist to determine the brand of concrete by sight, and they can bring you anything, so first of all, upon delivery, ask for a certificate confirming the authenticity of the concrete brand and its compliance with TU and GOST.

The poor quality of the concrete mixture can be determined only after 28 days, when obvious defects appear on the hardened foundation, however, the quality of fresh concrete can be determined by appearance.

An obvious defect is the consistency of the solution, that is, the ratio of cement and filler: the formation of voids during pouring, which must be filled with dry filler, indicates poor quality of the concrete mixture.

Crushed stone husks are also considered defective: when mixed in a mixer, crushed stone peels off - this is a defect. Suppliers may try to explain to you that this is an intended screening, but it is not included in the formulation of medium fraction concrete.

Of course, it is necessary to check the delivered concrete mixture for radioactivity. According to the first class of radioactivity, the solution should not exceed 370 bq/kg; higher values mean that the unscrupulous supplier contains crushed stone in the concrete that is not intended for residential construction; such crushed stone can only be used for railway construction.

Keep in mind that standard background radiation dosimeters have readings in microroentgen/hour, and not in bq/kg, so you need to prepare in advance and be able to translate the readings.

Pouring the foundation with a concrete pump

Preliminary work

The construction of any structure begins with laying the foundation. But before pouring the foundation, it is necessary to carry out some preparatory work:

- Layout of the area. This is the transfer of a plan for future construction onto a plot of land.

- Excavation. This includes digging a foundation pit, creating a sand bed and laying waterproofing materials.

- Preparation of formwork. Installation of wooden panels to give the desired shape to the poured concrete.

- Laying reinforcing mesh. It is used when a large load on the foundation is expected to provide additional strength.

- Pouring the concrete mixture is the final stage in which the previously prepared space for the foundation is filled with concrete.

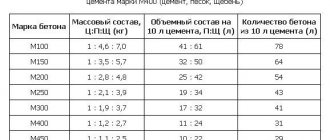

Concrete mix

The concrete that is sold is a mobile mixture of four components: water, crushed stone, sand, cement. The stability and durability of a concrete foundation depends not only on the curing time and the quality of the materials, but also on the selected composition of the concrete. The correct ratio of components is approximately this: 1 part cement, 4 parts crushed stone, 2 parts sand, 0.5 parts water. It is best to transport the selected ready-mix concrete in concrete mixer trucks to avoid exposure to precipitation and direct sunlight, and to avoid loss of concrete milk. If you mix the concrete mixture yourself, then the dosage of materials will be “by eye” - therefore, the mobility of the mixture cannot be controlled, and if there is an excess of water, the strength of the materials will generally be lost.

Cases of soil during concreting

Troubles can also await you at the most crucial moment of pouring the foundation: imagine, the work schedules have been approved, the first concrete pump or concrete mixer truck has already arrived and is preparing to unload when the pit collapses. A more unpleasant situation cannot be imagined. But this is not an accident - this is the simplest non-compliance with building codes. The fact is that, firstly, the pit needs to be stable, and if there is groundwater, or if it is possible to increase it in the spring, an artificial drainage system should be located along the entire perimeter of the formwork, which we will definitely talk about later.

The best option is to dig a pit in the fall, and pour concrete in late spring, then you can be completely sure that the walls of the trench are completely dry, seasonal groundwater has gone, and there is no need to use artificial measures to strengthen the pit, such as bituminization or cementization, which, By the way, they have a negative effect on the rock and poison the soil.

It is also possible for a pit to collapse if there is a large load on the ground directly when pouring concrete, the worst thing is the collapse of a concrete mixer truck along with a team of concrete workers, since unloading creates strong vibration and impacts from the falling solution. It is necessary to use additional chutes, which are included in the special transport kit, and, given that the maximum height of the fall of the concrete mixture during unloading is 2 meters, use an additional concrete pump or design a special chute in advance.

Instructions on how to properly fill the foundation

When building a house, it is of great importance how the work on laying the foundation for the house will be carried out. The foundation is the part of the building that is underground. The entire load produced by the structure is transferred to the base and transferred to the surface of the earth.

The main thing is to correctly calculate the amount of material needed and calculate the load on the foundation when building a house. The project plan is a guarantee that everything will be done in accordance with all construction rules and regulations.

- Pouring the foundation for a house is one of the important stages. When pouring the base, formwork is used, which is subsequently removed;

- pouring the foundation for a house with a basement - in this case, they dig an additional “circle of trench”, which will be the basement. A foundation with a basement refers to deeply buried foundations;

- pouring a foundation for a garage - some experts argue that you can pour a foundation for a garage yourself, the main thing is to complete all the work within one day, otherwise there will be many joints and seams that adversely affect the strength and load-bearing force of the structure;

- pouring a foundation for a bathhouse is one of the simplest ways to construct a foundation, the main thing is to perform good waterproofing;

- pouring a foundation for a fence - this type of foundation includes a strip-type foundation, which does not need to be buried deeply;

- pouring the foundation without formwork - this type of foundation is poured directly into soil trenches;

- pouring the foundation in layers is often used, but according to many experts, the structure is not the strongest;

- pouring a monolithic foundation slab - performed after the reinforcement is tied;