Home |Blocks and floors |Reinforced concrete blocks for foundations

Date: December 3, 2018

Comments: 0

In the construction industry, reinforced concrete blocks are used, produced by specialized construction companies. They are widely used in the construction of objects for various purposes, the construction of buildings, the construction of basement walls, and the preparation of reliable foundations for critical objects.

The dimensions and design features of elements made of reinforced concrete are regulated by the current regulatory document. All types of reinforced concrete block elements are made from structural concrete, which is characterized by the use of fine crushed stone with a fraction size of up to 10 mm. This contributes to the homogeneity of the structure of the concrete mass and ensures high performance characteristics of concrete blocks.

Let us consider in detail the structure, purpose of reinforced concrete blocks, markings, their design features, and dimensions.

Foundation reinforced concrete block is a high-strength factory product that is an element of foundations

Device

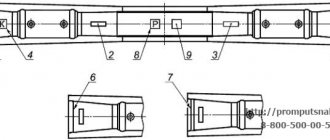

The block has the shape of a rectangular parallelepiped made of concrete. Structurally, to ensure performance characteristics, the product is reinforced with steel reinforcement.

The end planes have vertically placed cavities, allowing for connection when forming masonry. The upper plane provides for the presence of two mounting brackets, which, if desired by the client, may not be installed. This building material is produced at enterprises producing reinforced concrete structures.

What is reinforced concrete

Reinforced concrete is such complex structures formed from concrete and steel rods working together are called reinforced concrete, and steel rods are their reinforcement.

The steel reinforcement of the beam, in addition to the longitudinal rods located in the tensile zone and perceiving normal tensile forces, includes transverse vertical rods that act on the main tensile stresses (closer to the supports), and mounting rods. All rods at intersections are connected by resistance spot welding, forming a welded reinforcement frame.

The required cross-sectional area of the longitudinal and transverse reinforcement bars is determined by calculation, and the method of combining them into welded frames and the number of such frames in the beam section is determined by the convenience of welding and installing the frames, the convenience of laying the concrete mixture and other conditions.

A fundamentally important condition for the joint work of reinforcement with concrete in reinforced concrete structures is their adhesion, which is ensured by:

- in periodic profile reinforcement - protrusions on the surface of the rods,

- in welded reinforcement - due to welded intersections, in each of which a rod in one direction serves as an anchor for a rod in another direction, and, in addition,

- in all cases due to compression of the reinforcement bars by concrete during shrinkage.

Purpose

Reinforced concrete blocks are intended for the construction of building foundations and are capable of withstanding significant forces. The foundation of the building is subject to serious loads and must withstand them, maintaining the strength of the construction site.

The main areas of use of reinforced concrete products of block construction are:

- use at the zero stage of construction of facility foundations;

- formation of prefabricated strip foundations;

- construction of basement walls;

- construction of technical premises.

Capital construction begins with the foundation

When selecting the necessary products, the main emphasis is on the following technical characteristics that determine the area of operation:

- strength parameters;

- homogeneity of the massif, its density;

- resistance to seasonal temperature fluctuations and long freezing cycles.

Regardless of the application, block products are made from heavy concrete, which determines the service life of the entire structure.

Varieties

Depending on the purpose and design features, block-type reinforced concrete products used in construction are divided into the following types:

- Solid products marked with FBS and intended for the use of building foundations and the construction of lintels in basements. Experts call these reinforced concrete wall elements. They are characterized by increased resistance to current loads and have low thermal insulation characteristics. Installation is carried out directly on the soil or pre-prepared sand and crushed stone base.

- Monolithic block-type structures, designated FBV, having a special cutout designed for the installation of concrete lintels and the passage of utilities. Installation of reinforced concrete products is carried out in the ceiling part of basements and underground spaces for technical purposes.

Correctly selected dimensions and modifications of reinforced concrete products create a solid foundation for buildings

- Elements with cavities in the lower part are marked FBP and provide an increased degree of thermal insulation of building structures. The products are heat-insulating and lightweight.

Classification

Precast concrete products are available with and without prestressing. If during the manufacturing process the steel reinforcement located inside is stretched, then the products are usually called prestressed. Such manipulations are carried out in order to increase the reliability of the building.

Depending on what kind of building the material will be used for, reinforced concrete is usually divided into the following groups:

- for public premises, houses;

- for industrial premises.

Marking of reinforced concrete products

Manufacturers of reinforced concrete products, in accordance with the requirements of the current standard, mark the manufactured reinforced concrete products, which allows construction organizations using the products to obtain complete information about the dimensions of the products and their type from the marking. Let's look at the abbreviation used in the notation.

Using the FBS 24-4-6 T marking as an example, let’s consider the indices given in its designation:

- a group of capital letters characterizes the type of block - FBS and provides information about the features of its design (solid);

- a digital index, consisting of a group of numbers, provides information about the dimensions of a reinforced concrete element, indicated in decimeters, rounded to the nearest whole number. The length of this product is 2380 mm, width – 400 mm, height – 580 mm;

- the capital letter at the end of the marking provides information about the type of concrete from which the product is made. T – denotes heavy concrete, the specific gravity of which is 2.4 t/m³.

Knowing the markings, you can always determine the overall dimensions, obtain information about the material of the block, and calculate the need for the required number of reinforced concrete products to complete the assigned construction tasks.

The strength of reinforced concrete blocks allows them to be used for the construction of large structures

Types of concrete concrete markings

Marking and information inscriptions, as well as installation signs, stand out here:

- Markings - include the brand of the product and its trademark or the shortened name of the manufacturing plant, as well as a stamp indicating that the product has passed technical control and complies with technical specifications or GOST.

- Information inscriptions - include information about the date of production of concrete products and the weight of this product, if it exceeds 500 kg. Such marking is not necessary for products with lighter weight, and in the case of small-piece products, information labels can be placed on only 10% of the building elements in each batch.

- Installation signs - are pictograms that indicate places for installation of reinforced concrete products. This is the place of slinging, places of support, center of gravity (if necessary), risks during installation, designations of the top of the structure, etc.

Marking of reinforced concrete products must necessarily contain the brand of the product. This concept includes alphanumeric symbols, which are divided into three groups:

- Product type.

- Class of reinforcement, type of concrete, load-bearing capacity of reinforced concrete products.

- Special properties of the product.

Often the dimensions of the elements are also indicated - length, height, width or diameter. For example, if a reinforced concrete product bears the following marking: “FBS 20 6 4 TP”, it can be deciphered as Solid Foundation Block, 20 dm long, 6 dm wide, 4 dm high, made of heavy type concrete, special type porous.

As you can see, when marking reinforced concrete products, measures such as decimeters and, in the case of mass or design load, tons are used.

In this case, the rounded value is indicated. The letter P at the end of the marking can also indicate the presence of a mounting loop, which is especially important in the case of reinforced concrete lintels.

Criterias of choice

When deciding on the use of foundation reinforced concrete blocks that take the load from the building structure and are installed on a specially prepared or natural foundation (soil), be guided by the following factors:

- Purpose of the construction site.

- The amount of effort perceived by the block.

- Geological features of the specific region where construction is taking place.

By comprehensively assessing all factors and being guided by the requirements of regulatory documentation, you will be able to make the right choice and guarantee the strength of the structure being built.

Product Parameters

Depending on the tasks facing builders, reinforced concrete blocks of various sizes are used.

For solid products, the dimensions are regulated by the standard. They are:

- length 0.88; 1.18 and 2.38 m;

- width 0.3; 0.4; 0.5 and 0.6 m;

- height 0.28 and 0.58 m.

The reinforced concrete block can be produced in lengths from 20 to 240 cm

For reinforced concrete blocks with special grooves, the dimensions correspond to the following values:

- length 0.88 m;

- width 0.3; 0.4; 0.5 and 0.6 m;

- height 0.58 m;

Products with cavities, according to the standard, with constant length and height equal to 2.38 and 0.58 m, respectively, are characterized by three standard sizes in width, amounting to 0.4, 0.5 and 0.6 meters.

The weight of products made from heavy concrete ranges from 300 kilograms to 2 tons. Carrying out loading and unloading activities related to transportation, as well as installing reinforced concrete blocks directly at the work site, is carried out taking into account special lifting equipment.

Installation should begin from the corners of the building

Properties and composition of reinforced concrete products

Reinforced concrete products are concrete structures with reinforcement struts inside. This type of material has long come into use and is often used for construction. Separately, concrete and reinforcement are no different in durability and endurance than together. Together, they create high-strength structures that are low-cost compared to other materials.

Reinforced concrete and its application

Precast concrete products consist of cement, crushed stone and sand. Water and cement create a tight bond in the form of concrete. Cement does not react with sand and crushed stone, so they are classified as inactive materials. Depending on the filler, for example, stones, crushed stone, limestone or sand, the properties of the material, the degree of connection and the strength of the structure change. Together, these components create a material that is strong, durable and fire-resistant. Houses built from it can withstand seismic loads.

The reinforcement frame of a concrete structure consists of steel rods. Reinforced concrete includes working and installation reinforcing bars. Workers are placed at the bottom of the structure. The mounting ones form the frame, creating a certain stability and strength of the structure.

The advantages of reinforced concrete include:

- long service life;

- reliability;

- ability to independently produce foundations;

- fire resistance;

- stability during seismic activity;

- the ability to manufacture beams and ceilings of any shape;

- affordable price.

From which we can conclude that this material is easy to use and good in operation.

Reinforced concrete products made from stressed concrete

Reinforced concrete products can also be made from prestressed concrete. This can be explained in the following way: during operation, the reinforcement is slightly stretched and compressed, after which it is allowed to harden in this form. This is done so that concrete barriers and load-bearing channels do not bend under their own weight.

If you do not use such technology, the structure will constantly be subject to stretching and bending, which will weaken and shorten the service life of the product, and this cannot be allowed. It is for this purpose that the reinforcement is subjected to similar manipulations during the construction process, directing the stress in the opposite direction from the expected load.

These actions are designed in such a way that the real load will be resisted by artificial stress, which will significantly reduce the impact on the structure.

What is made of reinforced concrete:

- floor slabs;

- road slabs;

- electric poles.

Each reinforced concrete structure is built on the basis of an individual drawing of the product; depending on the area, the concrete structure and method of application are selected.

Reinforced concrete parts made in the shape of a cylinder are produced by centrifugation. In this case, a half-mold is used, which is installed on the centrifuge stand, metal rods are placed in it, and they are wrapped with steel rods to create a structure. After this, concrete is poured over the entire length of the mold half and covered with the other half of the mold, and then the centrifuge is turned on. First, the concrete is spread along the outer edges of the form, after which the rotation mode is changed and the prefabricated structure is made more dense.

The properties of such a product are distinguished by density, ability to withstand loads and reliability. Such products are used in various construction fields. The main scope of application is for the construction of residential buildings, industrial buildings and fences.

Benefits of blocks

The use of block-shaped reinforced concrete products during construction work is characterized by the following positive aspects:

- ensuring a high service life of building structures associated with the strength characteristics of reinforced concrete blocks;

- the possibility of constructing buildings in any region, regardless of climatic conditions and soil characteristics;

- expanded scope of use of elements, allowing them to be used as enclosing structures, basement walls, capital supports, partitions.

What is reinforced concrete - Meaning of the word reinforced concrete

Morphological and syntactic properties

| case | units h. | pl. h. | |||

| husband. R. | Wed R. | wives R. | |||

| Them. | reinforced concrete | reinforced concrete | reinforced concrete | reinforced concrete | |

| Rd. | reinforced concrete | reinforced concrete | reinforced concrete | reinforced concrete | |

| Dt. | reinforced concrete | reinforced concrete | reinforced concrete | reinforced concrete | |

| Ext. | shower | reinforced concrete | reinforced concrete | reinforced concrete | reinforced concrete |

| neod. | reinforced concrete | reinforced concrete | |||

| TV | reinforced concrete | reinforced concrete | reinforced concrete reinforced concrete | reinforced concrete | |

| Etc. | reinforced concrete | reinforced concrete | reinforced concrete | reinforced concrete | |

| Brief form | reinforced concrete | reinforced concrete | reinforced concrete | reinforced concrete | |

reinforced concrete

Adjective, relative, type of declension according to A. Zaliznyak’s classification - 1*a.

Root: -iron-

;

interfix: -o-

;

root: -concrete-

;

suffix: ; ending: -y

[Tikhonov, 1996].

Pronunciation

- IPA: [ʐɨˌlʲezəbʲɪˈtonːɨɪ̯]

Semantic properties

Meaning

- connected, correlating in meaning with the noun reinforced concrete ◆ There is no example of use (see recommendations).

- made of reinforced concrete ◆ ― Very simple. From a reinforced concrete products plant. I acted on psychology. )

- transl., colloquial having a strong character; unyielding, stern (about a person, character) ◆ There is no example of use (see recommendations).

Synonyms

Antonyms

Hypernyms

- concrete

Hyponyms

Related words

| Closest relationship | |

| |

| List of all words with the root “iron⁽ʲ⁾-” | ||

| ||

| List of all words with the root “-concrete-” | ||

| ||

Englishen: (attributed) Germande:

| ||

Bibliography

CC © 2011-2018. Copying is prohibited.

Installation activities

Reinforced concrete blocks are installed on different surfaces during installation:

- Tape bases.

- Concrete pillows.

- Sand and gravel bases.

The solidity of the prefabricated structure is ensured by the use of sand-cement composition or concrete during laying. The end grooves provide a reliable concrete connection - a kind of lock.

The installation of the elements is carried out by a construction crane, ensuring a gap of up to 4 cm, which is concreted. After installation of the entire masonry, special compounds are used to waterproof the foundation. A couple of days after the completion of the foundation work, work on the further construction of the building can be resumed.