Specific and volumetric gravity

Density, specific and volumetric gravity [p.180]

The difference between specific gravity, density and volumetric gravity is that specific gravity is expressed by the ratio of the weight of the most compacted material to its volume, and volumetric weight by the ratio of the weight of the material to its volume with all pores , gas-air inclusions, cracks, etc. For absolutely dense bodies, the specific and volumetric gravity values coincide. [p.181]

There are several methods for determining specific and volumetric gravity. [p.80]

The requirements for sand used for the production of sand-lime bricks are somewhat different from the requirements for sand used for mortars and concrete. Assessment of the quality of sand and the establishment of its suitability for the production of sand-lime bricks is carried out according to the chemical and mineralogical and grain composition, the color of the sand, the content of clay substances, the specific and volumetric gravity of sand in a loose and compacted state, and the shape and nature of the surface of sand grains. [p.434]

Data on the gas permeability of the surface of the starting material, determined, for example, from adsorption measurements or from the relationship between the specific and volumetric gravities of the material, cannot serve as a reliable means of assessment 8, since its value changes during the reaction process. Measurements made during the reaction are more accurate. response [59, 115]. The value of S is also estimated directly from the kinetics of a given reaction. For a small spherical particle with a radius r, the active penetration depth of the reaction can be taken [p.123]

The density of materials is related to the pore volume expressed as a percentage of the volume of the material, i.e. porosity. The greater the porosity, the lower the density. The porosity of a material can be expressed numerically through the specific and volumetric gravity of a given material. Let's take 100 volume units of some porous material. Let us denote by θ its volumetric weight, by δ the specific gravity of the dense substance that makes up the porous material, and by P the porosity of the material. Then the weight amount of dense substance contained in 100 volume units of porous material can be expressed by the equation [p.24]

Using chemical indicators, the chemical composition of materials and products and their relationship to the action of certain chemical reagents associated with the conditions of use of these materials and products are determined. For example, when evaluating painting pigments and paints, you need to know their chemical composition. in order to correctly judge their purpose - their relationship to the action of alkalis, acids, etc. Using physical indicators, they determine the standards for the above-mentioned physical properties - specific and volumetric gravity, humidity, thermal, optical, mechanical and other properties (see page 23 ). [p.84]

The physical and water properties of soil are often determined by humidity, specific and volumetric gravity, and porosity. These indicators are necessary to calculate the moisture reserve in the soil, its deficiency, and establish irrigation norms. [p.467]

For non-porous materials, the specific and volumetric gravities are the same. [p.174]

Dense materials are those whose specific and volumetric gravities are the same. [p.57]

Weight and volume of products. In refrigeration technology, specific and volumetric gravity and specific volume are important. [p.17]

The physical and water properties of soil are often determined: humidity, specific and volumetric gravity, and porosity. Using these indicators, the reserve of moisture in the soil and its deficiency are calculated, and irrigation norms are established. [p.477]

The main properties of materials used for anti-corrosion work are specific and volumetric gravity, porosity, water absorption, permeability, mechanical strength, fragility, ductility, frost resistance, heat resistance and, which is the most important quality of the material, chemical resistance (acid resistance). [p.23]

Density and porosity. Dense materials are those whose specific and volumetric gravities are the same. These include plastics, glass and diabase tiles and some others. Most chemically resistant materials contain voids to some extent and are therefore called porous materials. For [p.24]

Specific and volumetric gravity and porosity. The volumetric weight of a dry material is the ratio of the weight of the material dried to a constant weight [p.90]

Along with the composition and size of the pieces, when determining the merits of the raw material, its other properties are also important, for example, hardness, specific and volumetric gravity, thermal conductivity, viscosity, etc. All of these properties determine the development of circuits, process technology and design of devices. [p.26]

Specific and volumetric gravity of pesticides used in aviation chemical work [p.183]

In order to use formula (I, 73), you need to know the average pore diameter h and the number of pores per unit area N. To calculate these two unknown quantities, you can use any two easily experimentally determined and associated quantities. The latter can be taken as either gas permeability and total surface area (determined from adsorption measurements), or gas permeability and porosity (determined from the relationship between specific and volumetric gravity). [p.100]

The value of the total porosity is usually calculated from the ratio of the specific and volumetric gravity of the soil. If we denote the specific gravity of the soil by O and the volumetric gravity of the soil by c1, then the ratio will give the volume occupied by solid particles per unit volume of soil. The difference between the unit and the volume occupied by solid soil particles [p.160]

Dense materials are those whose specific and volumetric gravity are the same. Most chemically resistant materials contain voids, i.e. they are porous. To determine the porosity of a material, first determine its density (volume weight divided by specific weight) and express it as a percentage. The resulting value is subtracted from the absolute density of the material, taken as 100. A denser material has insignificant permeability compared to porous materials. [p.26]

In silicate materials, not all pores are often open. The volume of closed pores cannot be determined experimentally. Therefore, the true porosity of a material (Yist.) is calculated from the values of its specific and volumetric gravity [p.325]

Of course, for technology, not only the composition and size of pieces of raw materials are important, but also other physical properties - hardness, specific and volumetric gravity, viscosity, thermal conductivity, etc. These properties often play a very important role in choosing a technological process scheme and designing the corresponding equipment. [p.93]

Volumetric weight and density

(Slide 1G3_3 )

The volumetric weight of sedimentary rock is the weight of a unit of its volume (1 cm3)

together with pores filled with liquid and gaseous phases.

The volumetric weight of a rock depends on both the mineralogical composition and the porosity of the rock, and therefore can serve as a characteristic of porosity for cemented rocks, especially when their composition is known. The volumetric weight of rocks also depends on the degree of humidity.

The most accurate volumetric weight of a rock is determined by hydrostatic weighing of a sample. The volumetric weight of the rock is calculated using the formula:

where y is the volumetric weight of the rock;

Рс is the weight of the dry sample;

Ркв is the weight of a sample saturated with kerosene in air;

Pk is the weight of the sample in kerosene;

Ak is the specific gravity of kerosene.

The accuracy of the method is ±0.02.

The volumetric weight of a completely dry rock is called the apparent, or volumetric, skeletal weight.

The volumetric weight of a rock has the same dimension and units of measurement as the specific gravity of rocks. It is usually expressed in G/cm3.

The volumetric weight of a rock is generally less than its specific gravity, but greater than the specific gravity of the liquid and gaseous phases contained in the rocks.

Due to their low porosity, the volumetric weight of minerals is almost equal to their specific gravity.

With the depth of rocks, their volumetric weight changes, usually increasing, which is associated with a decrease in rock porosity. This particularly applies to clays and clayey fine-grained sandstones and siltstones. The presence of cements characterized by high specific gravity in rocks influences the increase in bulk density.

The density of the solid (liquid, gaseous) phase is the ratio of the mass of the phase to its volume. Rock density refers to the ratio of the mass of rock with natural moisture and structure to its volume.

Bulk density is the ratio of the mass of dry rock to its volume. Density in the CGS system is expressed in g/cm.

In practice, the density of the rocks corresponds to the volumetric weight.

Porosity

(Slide 1G3_4 )

Between the solid particles that make up rocks, as a result of incomplete contact of their surfaces with each other, gaps of various sizes are formed - pores. The total volume of all pores in a unit volume, regardless of their size and filling, is called rock porosity.

The porosity of a rock is determined by the ratio of the burrow space of the rock to its total volume and is usually expressed as a percentage.

The porous space of rocks is determined not only by the size and configuration of the mineral grains that make up the rock, but also by the presence of cracks, bedding planes and the presence of cementitious substances in the pores.

The porosity of rocks can be determined by both sedimentation processes and chemical dissolution processes. In most carbonate reservoirs, which include limestones and dolomites, porosity is a consequence of the dissolution of calcite by formation waters containing dissolved carbon dioxide. The pore spaces of such rocks are usually represented by channels and caverns. Sedimentary (intergranular) porosity is determined by the presence of spaces between individual rock grains.

The porosity value of various rocks varies widely - from fractions of a percent to several tens of percent. For example, the porosity of Baku oil sands ranges from 18 to 52%, Stavropol gas-bearing siltstones and siltstones - from 30 to 40%, Volgograd oil Yasnaya Polyana sandstones - from 20 to 27%. Most often, the porosity of carbonate rocks ranges from 3-30%. The porosity of clays can reach 40-50% and higher.

Reservoir rocks of the sandy-silty type with a porosity of less than 5%, which do not contain cracks, faults and caverns, are usually of no practical importance. A.I. Levorsen (1958) gives the following approximate field estimate of rock porosity:

- negligible 0-5%,

- very good 20-25%.

However, it should be remembered that not all granulometric types of sandy-silty rocks can be assessed on this scale.

(Slide 1G3_51 )

Unlike ideal rock, the clastic grains that make up sedimentary rocks usually come in different shapes. Even well-rounded clastic grains of sandstones rarely have a regular spherical shape. The porosity of a rock consisting of spherical grains of different sizes may be higher or lower than theoretical depending on the sizes of the constituent grains.

The theoretical porosity of aggregates composed of spheres of the same diameter can range from 25.96% (Fig. 1) to 47.6% (Fig. 2). These limits coincide well with the porosity limits of sands, the porosity of which in their natural occurrence is 30-50%.

Slichter (1899) pointed out that theoretical porosity values do not depend on grain size. Thus, the porosity of gravel, consisting exclusively of grains of regular spherical shape with a diameter of 2 mm,

has the same meaning as that of clay, also composed of grains of regular spherical shape, but with a diameter of 0.05

mm.

However, in both cases the porosity is unequal: gravel is a good reservoir, and clay is practically impermeable to oil and gas.

I.M. Gubkin (1932) pointed out that the concept of “high porosity” usually implies an abundance of various holes in the rock, while the concept of “low porosity” indicates not so much the absence or insignificant number of pores, but rather the lack of pores that can accommodate and release oil . For the accumulation of oil or gas in a rock or their extraction from it, not only the relative number of pores is important, but also their absolute sizes.

Real soil grains are not spherical in shape. The presence in the rock of clayey, carbonate and other cementing substances, the grain sizes of which are smaller than the predominant sand fraction, leads to a decrease in the porosity of the sand rock. The larger the contact surface between rock grains, the lower its porosity.

The homogeneity coefficient of clastic grains of various sands in the oil-bearing regions of the USSR ranges from 1 to 20. The higher the heterogeneity coefficient, the less homogeneous the sand, the lower the porosity coefficient.

(Slide 1G3_52 )

Angular, irregularly shaped grains can be packed either more densely or more loosely than spherical ones. In this regard, they can be characterized in one case or another by both the smallest and the greatest porosity compared to ideally spherical grains. At the lowest porosity, irregularly shaped grains should have the same angular shape and, accordingly, should be stacked with offset surfaces, achieving the most dense packing. In natural conditions, a relatively loose arrangement of grains with an irregular, angular shape is quite often observed, which is reflected in the value of porosity.

The contact surface of the grains varies depending on the rock pressure, the geometric arrangement of the grains and their shape. The shape of the pore space of the rocks is more tortuous with less rounded and sorted clastic material.

Cellular and channel-shaped pores are found in limestones.

Pores close to rhomboidal and tetrahedral are often observed in rocks with well-sorted and rounded grains.

Crack-like pores are characteristic of rocks with rigid connections that have experienced tectonic forces, weathering processes, crystallization, etc.

Typically, as formation depth increases, porosity decreases. This especially applies to clayey rocks, while sandy deposits in the case of pressures that do not lead to shearing of the edges of rock grains (no more than 300 kg/cm2),

found at relatively great depths with fairly high porosity.

Total porosity is divided into macro-porosity and micro-porosity . Microporosity refers to pores less than 1 mm in size,

under macroporosity, pores are more than 1

mm.

What is density

To a first approximation, the definition of density seems simple and understandable: density is a scalar physical quantity (a characteristic of a substance), defined as the ratio of a body’s own mass to the total volume occupied by this body. However, a trained eye will immediately notice a “slippery” place, namely: what specific state of the body are we talking about, how homogeneous is it? Indeed, gas or liquid (with some restrictions) are bodies in the everyday understanding that are essentially isotropic (that is, with characteristics that are the same within the physical volume of interest and do not depend on the chosen direction in this volume), but what about solid bodies?

In the extreme case, this can be demonstrated on a solid bulk material, where in one common volume there are both particles of the material itself and the voids between them (those who studied physics well at school will simultaneously object that approximately the same picture can be obtained with gases/liquids, if you start “break down” them to the molecular/atomic level). Therefore, the above definition implies an average (in other words, averaged) characteristic of a body for a selected characteristic size, and for granular bodies the concepts of “true density” (averaged characteristic, calculated only from the actual volume of the particles themselves) and “bulk density” (calculated characteristic for bulk solids) are separately introduced. material, taking into account all its voids - but without additional compaction).

Density of solids

| This section is missing references to information sources. Information must be verifiable, otherwise it may be questioned and deleted. You may edit this article to include links to authoritative sources. This mark was set on October 6, 2020 . |

In the case of solids with heterogeneous composition or liquids that contain suspended solids, the bulk density

The porosity of the structure and the violation of the molecular and structural integrity of solid materials also have an impact.

Soil density

The main agrophysical property of soil. Determines the resistance to penetration into the soil of both agricultural implements and plant roots. Thus, it indirectly affects the yield. Soil density is important to know not only in agriculture.

Soil density is calculated as the ratio of the mass of the sample to its volume. This is the classic formula for the drilling method for determining soil density. The exception is rocky soils. for them the density is determined by the Seidelman method

What is specific gravity

Specific gravity is understood as a vector physical quantity, defined as the ratio of the weight of a body (the weight of its substance) to the volume occupied by the body . In other words, the specific gravity is numerically equal to the product between the acceleration of gravity and the density of the substance (just in case, let us recall that the weight of a body is the force of the body on the support/suspension or its other fastening in the gravitational field).

Occasionally, a private definition unrelated to the above is also used, where specific gravity is understood as a dimensionless number indicating how many times the substance of interest is heavier than water (at its maximum density, at 4 °C) with an equal volume.

In addition to the usual everyday confusion in the form of identifying mass and weight, in relation to the case under consideration, it is necessary to mention the erroneous identification arising from the use of a similar dimension in the technical system of units of the MKGSS, where specific gravity is given as [kilogram-force / cubic meter] (kgf/m³).

content .. 1 2 3 8 ..SPECIFIC AND VOLUMERIUM GRAVITY

The unit weight of the fibers (y) is the weight of the fiber substance (G) per unit volume (V). Calculate the specific gravity using the formula

y = G/V mg/mm3

The lower the volumetric weight of the fibers, the larger the channel size in the fiber, the more pores filled with air, the lower the thermal conductivity of the fibers and the greater the heat-shielding properties of products made from them. For example, the volumetric weight of cotton is 0.9-1.3 mg/mm3, wool - 1.0-1.3 mg/mm3, viscose fiber - 1.4-1.45 mg/mm3, cotton yarn - 0.8- 0.9 mg/mm3, wool yarn - 0.7-0.8 mg/mm3, viscose staple yarn - 0.8 mg/mm3.

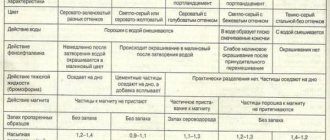

3. FIBER RECOGNITION In the production of knitwear, various chemical and natural fibers are used, both in pure form and in mixtures.

The fibrous composition of knitted fabric determines the nature of its processing in knitting and sewing production, the conditions of storage and operation of products. Therefore, a specialist in knitwear and sewing production must be able to correctly and quickly determine the fibrous composition of knitwear.

Fiber recognition is carried out by two methods: organoleptic and laboratory.

The organoleptic method is the recognition of fibers using the human senses (vision, touch and smell).

Using vision, the shine, color, length, thickness, crimp, and burning nature of the fibers are determined; by touch - softness, hardness, strength, elongation, warmth or coolness to the touch. Using the sense of smell, the smell released during combustion is determined.

The organoleptic method for recognizing fibers consists of the following techniques: 1) identifying the fiber by its appearance; 2) identification of fiber by touch; 3) determination of the fiber by the nature of combustion.

Fiber can be recognized by the combination of all three techniques or, in some cases, by one of them (appearance) or two (appearance and touch).

However, the organoleptic method, characterized by ease of fiber recognition, is characterized by subjectivity.

Below are the distinctive features of recognizing the main types of fibers by the organoleptic method.

Cotton fiber looks like the finest hair with irregular curvature, 18-50 mm long, white or creamy natural color (can be naturally colored - beige, greenish and other colors) or dyed in any color. The fiber has no shine (matte), but mercerized fibers have a significant shine (silky). The fibers are soft, low-strength, and lukewarm to the touch. When introduced into a flame, the fiber ignites with a bright yellow flame with a luminous spark, the formation of gray ash and the spread of a burnt paper smell. If the flame is extinguished, the fiber smolders intensely, releasing smoke.

Wool fiber looks like a thin hair with a fine wavy crimp or a thicker hair with a gentle crimp and without crimp, 3 to 15 cm long, white, red, black and other natural colors or dyed in one color or another. The shine of different types of fibers ranges from weak (fluff) to strong (awn). The fibers are harsh to the touch, with noticeable strength at the spine. When pure fiber is introduced into a flame, it burns, sintering into a dark ball. When the fiber is removed from the flame, combustion stops. When burning, the smell of burnt horn or feather spreads.

Viscose and polynose chemical fibers are thin, of any given length, with a smooth surface, white or dyed, shiny or matte, soft to the touch, low-strength, when wetted their strength noticeably decreases (less noticeable for polynose fiber), when stretched they break off in the wetted plot. When introduced into a flame, these fibers ignite easily and burn like cotton.

Acetate fiber, unlike viscose fiber, is recognized only by the nature of its combustion. When the fiber is introduced into the flame, it first melts and then lights up with a yellow flame with the spread of a specific sour odor, forming a dark influx, which, after cooling, is easily crushed by fingers. If the flame is extinguished, the fiber slowly smolders, releasing a stream of smoke.

Triacetate fiber, unlike acetate fiber, exhibits a greater melting effect before ignition. Other recognition features are similar to those of acetate fiber.

Nylon fiber in appearance resembles artificial fibers, but unlike them, when brought to a flame, it exhibits thermal shrinkage, melts, and then lights up with a weak bluish-yellow flame with the presence of white smoke and the spread of the smell of sealing wax. When the fibers are removed from the flame, the combustion gradually stops and a solid gray ball solidifies at the end. Anide fiber behaves similarly in a flame.

Mylar fiber cannot be distinguished by appearance from other chemical fibers. By the nature of its behavior in a flame, it differs only in that it burns weakly with a yellowish flame with the release of black soot. After attenuation, a solid black ball solidifies at the end of such fibers.

Nitron fiber, unlike polyamide and polyester fibers, burns more intensely, in flashes, with the release of large black soot. After the combustion stops, a dark, irregularly shaped influx remains, easily crushed by fingers.

Chlorine fiber differs from all chemical fibers in its lack of shine. When brought to the flame, it shrinks greatly, chars, but does not burn, and emits a dusty smell. PVC fiber behaves similarly in a flame, spreading the smell of chlorine. Vinol fiber is similar in appearance to most chemical fibers. When introduced into the flame, vinol shrinks and then burns with a yellowish flame with a slight soot. After the combustion stops, a solid brownish influx remains.

Polypropylene fiber can be distinguished from other chemical fibers by the fact that when brought to a flame, it shrinks and melts, burning weakly with a yellow flame. After the combustion stops, a hardened influx of yellow-brown color remains.

Laboratory method - fiber recognition using a microscope and chemical reagents; it is characterized by objectivity.

Knowing the structure of various fibers and examining them under a microscope, you can accurately determine their type. However, some chemical fibers are similar in structure (nylon, anide, enanth, lavsan, copper-ammonia, polynose). In this case, microscopy of fibers should be supplemented by testing their properties in relation to certain chemical reagents.

With the help of chemical reagents, it is possible to determine the type of fibers by their different relationships to solvents, different colors of fibers of different natures, and qualitative (chemical) analysis.

Taking into account the solubility of fibers in certain solvents, it is possible to select solvents that will accurately determine the nature of the fiber. For example, acetate fiber can be easily distinguished from triacetate fiber by the action of methylene chloride: acetate fiber does not dissolve in methylene chloride, but triacetate fiber does; or lavsan can be distinguished from nylon by the action of o-dichlorobenzene or formic acid, in which nylon dissolves, but lavsan does not, etc.

It is known that when cellulose fibers are exposed to zinc chloride, they turn bluish-violet or red-violet, and wool, nylon, natural and acetate silk fibers turn yellow.

Using the express method proposed by F. P. Lobachevskaya, it is easy to recognize nylon, lavsan, and nitron fibers. To do this, prepare a mixture of dyes (rhodamine C and cationic blue K), into which the fibers are immersed for 2-3 minutes at a boil. In this case, nylon is painted in a bright reddish-lilac color, lavsan - in light pink, nitron - in bright blue-blue.

Using the method of qualitative analysis, wool can be determined by the presence of sulfur, and copper-ammonia fiber can be determined by the presence of copper. In addition, there are a number of other methods for recognizing fibers: by melting point, by equilibrium moisture content, by their density, etc. However, in practice, fibers are most often recognized by the organoleptic method and the method of different ratios to solvents.

Differences between specific gravity/density

From the above it is clear that the exclusively imaginary similarity of density and specific gravity is generated by at least two factors: the general similarity in the construction of their definitions and the typical erroneous everyday identification of weight and mass. Density and specific gravity are radically different concepts.

Here are the most important differences you should know (besides the definitions):

- Specific gravity (as, indeed, any force in general) is a vector physical quantity, and density is a scalar physical quantity and characteristic of a substance.

- Density as a characteristic of a substance, ceteris paribus, is unchanged depending on the location of the measurement - and the specific gravity strongly depends even on a change in the location of the measurement location within the Earth (for example, due to variations in the acceleration of gravity between the equatorial and subpolar zones), especially if there is significant external accelerations.

- The units of measurement (in the SI/CGS systems used) are completely different in both cases: for density - [kilogram/cubic meter] or [gram/cubic centimeter], and for specific gravity - [newton/cubic meter] or [dyne/cubic centimeter ].

What is the difference between density and volumetric weight?

⇐ PreviousPage 2 of 11Next ⇒

Density ρ is the mass of a unit volume of liquid (kg/m3): ρ = m / V,

where m – mass, kg; V – volume, m3.

The density of water at a temperature of +40C is 1000 kg/m3. Other values of water density depending on temperature can be found in the reference data. It is easy to see that the density of water depends only slightly on temperature. In most hydraulic calculations, the properties of compressibility and thermal expansion of liquids are neglected; for example, for water the density is considered constant and equal to 1000 kg/m3.

Specific gravity γ is the weight of a unit volume of liquid (N/m3): γ = G / V; where G is weight (gravity), N; V – volume, m3.

Specific gravity and density are related through the acceleration of gravity g as follows: γ = ρ g.

3.What is the relationship between the volumetric compression ratio and the volumetric modulus of elasticity? Compressibility is the property of a substance to change its volume when external pressure changes (or in other words, when stress in the substance changes). Compressibility is characterized by the volumetric compression ratio

, where V is the volume of the substance, p is the pressure. The minus sign indicates that an increase in pressure corresponds to a decrease in volume.

The above formula is incomplete because the volumetric compression ratio for any system depends on whether the process is adiabatic or isothermal. Accordingly, the isothermal volumetric compression coefficient is determined by the following formula:

, where the subscript T indicates that the partial derivative is taken at a constant temperature.

The adiabatic volumetric compression ratio is determined as follows:

, where S denotes entropy (an adiabatic process occurs at constant entropy). For solids, the differences between these two coefficients can usually be neglected. The reciprocal of the volumetric compression ratio is called volumetric modulus of elasticity , which is denoted by the letter K (in English literature - sometimes B). Sometimes the volumetric compression ratio is simply called “compressibility” .

The compressibility equation relates isothermal compressibility (and indirectly pressure) to the structure of the fluid.

Adiabatic compressibility is always less than isothermal compressibility. Fair ratio

where is the heat capacity at constant volume, is the heat capacity at constant pressure.

What is the coefficient of thermal expansion?

The coefficient of thermal expansion is a value characterizing the relative magnitude of the change in the volume or linear dimensions of a body with an increase in temperature by 1 K at constant pressure. In accordance with this, they distinguish:

⇐ Previous2Next ⇒

Recommended pages:

Determination of specific gravity

The physical quantity, which is the ratio of the weight of a material to the volume it occupies, is called the HC of the material.

Materials science of the 21st century has gone far ahead and technologies that were considered science fiction a hundred years ago have already been mastered. This science can offer modern industry alloys that differ from each other in qualitative parameters, but also in physical and technical properties.

To determine how a certain alloy can be used for production, it is advisable to determine the HC. All objects made with the same volume, but different types of metals were used for their production, will have different masses, it is in a clear connection with volume. That is, the ratio of volume to mass is a certain constant number characteristic of this alloy.

To calculate the density of a material, a special formula is used, which has a direct connection with the HC of the material.

By the way, the HC of cast iron, the main material for creating steel alloys, can be determined by the weight of 1 cm 3, reflected in grams. The more HC the metal, the heavier the finished product will be.

Specific gravity formula

The formula for calculating HC looks like the ratio of weight to volume. To calculate hydrocarbons, it is permissible to use the calculation algorithm, which is set out in a school physics course. To do this, it is necessary to use Archimedes' law, or more precisely, the definition of the force that is buoyant. That is, a load with a certain mass and at the same time it floats on the water. In other words, it is influenced by two forces - gravity and Archimedes.

The formula for calculating the Archimedean force is as follows

F=g×V,

where g is the hydrocarbon liquid. After the substitution, the formula takes the following form: F=y×V, from here we obtain the formula for the shock load y=F/V.

Difference between weight and mass

What is the difference between weight and mass. In fact, in everyday life, it does not play any role. In fact, in the kitchen, we don't make a difference between the weight of a chicken and its mass, but there are serious differences between these terms.

This difference is clearly visible when solving problems related to the movement of bodies in interstellar space and neither those having relations with our planet, and under these conditions these terms differ significantly from each other. We can say the following, the term weight has meaning only in the zone of gravity, i.e. if a certain object is located next to a planet, star, etc. Weight can be called the force with which a body presses on the obstacle between it and the source of attraction. This force is measured in newtons. As an example, we can imagine the following picture: next to a paid education there is a stove with a certain object located on its surface. The force with which an object presses on the surface of the slab will be the weight.

Difference Between Specific Gravity and Density

UV - what is it?

Specific gravity is the ratio of the weight of matter to its volume. In the SI international system of measurements it is measured as newton per cubic meter. To solve certain problems in physics, hydrocarbons are determined as follows - how much heavier the substance being examined is than water at a temperature of 4 degrees, provided that the substance and water have equal volumes.

For the most part, this definition is used in geological and biological studies. Sometimes, the HC calculated using this method is called relative density.

What are the differences

As already noted, these two terms are often confused, but since weight directly depends on the distance between the object and the gravitational source, and mass does not depend on this, therefore the terms shock wave and density differ from each other. But it is necessary to take into account that under certain conditions mass and weight may coincide. It is almost impossible to measure HC at home. But even at the school laboratory level, such an operation is quite easy to perform. The main thing is that the laboratory is equipped with scales with deep bowls.

The item must be weighed under normal conditions. The resulting value can be designated as X1, after which the bowl with the load is placed in water. In this case, in accordance with Archimedes' law, the load will lose part of its weight. In this case, the balance beam will warp. To achieve balance, a weight must be added to the other bowl. Its value can be designated as X2. As a result of these manipulations, a shock wave will be obtained, which will be expressed as the ratio of X1 and X2. In addition to substances in the solid state, specific values can also be measured for liquids and gases. In this case, measurements can be performed under different conditions, for example, at elevated ambient temperatures or low temperatures. To obtain the required data, instruments such as a pycnometer or hydrometer are used.

Volumetric charge density. Definition

Volume charge density is a scalar quantity that characterizes the charge per unit volume of a body. All bodies are divided into positively charged, negatively charged and electrically neutral, depending on the ratio of positively and negatively charged particles in it. Since charges can be both positive and negative, their volumetric charge density values can be expressed in positive and negative quantities. It is denoted by the Greek letter ρ (pronounced rho) and is calculated using the formula:

ρ = Q/V

where Q is the charge of the object, V is the volume of the object

The dimension of volumetric charge density in the International System of Units (SI) is expressed in coulombs per cubic meter (C/m³).

In addition to the basic unit of volumetric charge density, a multiple unit (C/cm³) is used. Another measurement system, SGSM, uses the unit abcoulon per cubic meter (abC/m³) and a multiple of the unit abcoulon per cubic centimeter (abC/cm³). 1 abcoulomb is equal to 10 coulombs.

In countries that do not use metric units of volume, volumetric charge density is measured in coulombs per cubic inch (C/in3) and abcoulombs per cubic inch (abC/in3).

Piezoelectric spark element of gas lighter

Metals with the highest and lowest specific gravity

In addition to the concept of specific gravity used in mathematics and physics, there are also quite interesting facts, for example, about the specific gravities of metals from the periodic table. If we talk about non-ferrous metals, then the heaviest ones include gold and platinum.

These materials exceed in specific gravity such metals as silver, lead and many others. “Light” materials include magnesium with a weight lower than that of vanadium. We must not forget about radioactive materials, for example, the weight of uranium is 19.05 grams per cubic cm. That is, 1 cubic meter weighs 19 tons.

Specific gravity of other materials

It is difficult to imagine our world without many materials used in production and everyday life. For example, without iron and its compounds (steel alloys). The HC of these materials fluctuates in the range of one to two units and these are not the best results. Aluminum, for example, has low density and low specific gravity. These indicators allowed it to be used in the aviation and space industries.

Specific gravity of metals

Copper and its alloys have a specific gravity comparable to lead. But its compounds - brass and bronze are lighter than other materials, due to the fact that they use substances with a lower specific gravity.