One of the features of building materials is related to the presence of porous areas. They complicate the measurement of specific gravity because it is necessary to weigh an element of ideal density to obtain accurate information. This means that the concrete sample would have to be crushed. It is technically difficult to perform this, and it is necessary during serious examinations. And yet, what is the specific gravity of concrete m200?

Classification of concrete by weight

It is the main component in many construction works and has a high strength index. First of all, it is determined how much 1 m3 of m200 concrete weighs, because based on this characteristic the application features are determined.

Concrete mass is used for almost any work. For this reason, composition characteristics include its distribution by class and brand. This allows you to accurately select concrete for a particular purpose.

Based on weight categories, concrete is divided into the following groups:

- Thermal insulation - concrete is made of cement material and filler. After kneading, a structure is formed that has up to eighty-five percent voids. It is used in the manufacture of structures that have increased requirements for heat conductivity. This category includes mixtures weighing up to five hundred kilograms per cubic meter. Sometimes, to increase the level of strength, plasticizer additives are used.

- Light - the mass of this solution is 500 - 1,800 kg. Special blocks are made from it, having pores in their structure, formed by adding foaming agents or fillers with a cellular structure.

- Heavy is the most common group in the construction industry. This concrete is considered an ideal option for the construction of structures that have load-bearing functions. A cubic meter of mass weighs from 1,800 to 2,500 kg, and this figure fully depends on the proportions of sand and filler.

- Super heavy - metal fillers are used in manufacturing, increasing the weight to the maximum level - more than 3,000 kg per cubic meter.

It should be remembered that porous structures do not withstand frost well. During installation, you will have to take care of waterproofing protection.

Quality indicators of concrete

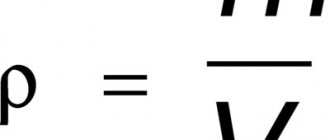

The specific gravity or density of concrete is quantitatively defined as the ratio of the mass of the product to its volume. It directly affects the quality characteristics of the final concrete product. And the following factors influence the density:

- The composition of a batch for preparing concrete, where crushed stone, gravel or expanded clay can be used as filler. More dense crushed stone will ultimately determine the greater specific gravity of the final solution compared to concrete with expanded clay aggregate.

- Quality and brand of cement used.

- Sand grain size and type.

- Use of plasticizers.

- Composition of water used to dilute the solution.

The main quality indicators of concrete include:

- Strength, which determines the durability and service life of the final product.

- Homogeneity, depending on the diffusion and adhesion properties of its components.

- Elasticity, reflecting the ability of the solution to completely fill the formwork shape.

- Porosity, which provides the “breathing” properties of the material.

Porosity is the reciprocal of concrete density. It also affects the strength of the concrete product, only in inverse proportion, i.e. The higher this indicator of concrete, the lower the strength of the product. The porosity of a concrete material arises due to the presence of microscopic voids of various volumes inside it. Its value shows the ratio of the total volume of all internal voids to the volume of the material.

Pores are formed during the hardening process of the material due to the evaporation of liquid; their volume depends on many factors, including the proportions of the constituent components, the granularity of the filler, and the humidity of the finished solution. When preparing the mixture, you should follow the instructions and remember: the thinner the solution, the more porous the concrete will be after hardening. Experienced builders, in practice, “get their eyes on” the optimal proportion of water and fillers necessary to obtain the desired result and the porosity of concrete.

Video: Testing concrete for strength

Specific and volumetric weight of concrete

The most commonly used characteristic is the volumetric weight of concrete grade M200. This indicator is determined by measuring the mass of the finished concrete composition in a specific volume. The value may vary and depends on the fillers used, the presence of pores, air or gas bubbles.

The weight of concrete m200 in 1 m3 ranges from 2,300 to 2,500 and above. This group includes mixtures in which crushed stone is used as a filler. For medium-sized concrete, perlite, expanded clay or aramzit are used, which lightens the weight to 1,200 - 1,800 kg.

You need to know that pores appear in every type of concrete due to evaporating water included in the composition. And to clarify the weight of 1 m3 of M200 concrete, there is no need to contact search engines by entering the appropriate queries. It is enough to use volumetric weight indicators, as in the case of sand, crushed stone, brick and other materials.

Some people make the mistake of believing that its weight depends on the strength of concrete. The strength of the mixture is influenced by the brand of cement composition, and the mass depends on the type of filling component, its quantity and fractions.

If it is necessary to clarify the specific gravity of concrete m200 in 1 m3, then this can be done approximately by adding up the mass of sand, cement composition, fillers and water.

How is the specific gravity of concrete determined?

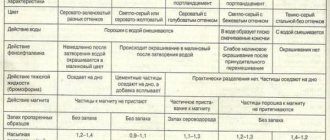

The specific gravity of BSG depends on several features: the quantity and quality of components, the physical properties of cement and aggregate, the chemical composition of water, etc. In accordance with the standard, for each brand of concrete mortar the average mass coefficient of 1 cubic meter of concrete is calculated:

- for brand M100 – approximately 2494 kg;

- for the M200 brand - about 2432 kg;

- for the M250 brand - approximately 2348 kg;

- for the M300 brand – approximately 2389 kg;

- for the M350 brand - approximately 2502 kg;

- for the M400 brand - around 2376 kg;

- for the M500 brand - within 2980 kg.

However, these figures are approximate. Please note that 1 cubic meter of concrete solution can weigh differently, depending on the initial weight of the components used. However, even knowing the exact data from the table, it is not possible to calculate the exact mass of the concrete solution, since this indicator is influenced by the size of the aggregate granules, the amount of water, the presence of voids in the mixture, as well as the quality of the batch.

Concrete grade m200

This type is considered more common. Such concrete is used for pouring stairs and foundations, when constructing paths and floors. The number “200” means that this concrete grade can withstand loads of up to two hundred kilograms of force per square centimeter.

M200 – category of lightweight concrete. The density of the material is quite small, and this is explained by hollow additives. The specific gravity depends on the volume of water in the solution and on the density values of sand and crushed stone. As a rule, this figure is within 1,500 kg per cubic meter.

To prepare M200 concrete use:

- cement M400 – M500 (one part);

- water at the rate of 42 liters per 10 liters of cement;

- sand (2.8 shares);

- crushed stone granite or lime (up to 4.8 parts).

Various additives can be used to improve certain characteristics.

The main performance indicators of M200 concrete are:

- specific gravity 1,500 – 2,500;

- strength index B15. Concrete can withstand loads up to 196 kg;

- frost resistance. If a good filler is used, the concrete will withstand at least one hundred freezing and thawing cycles;

- waterproof grade – W4, maximum pressure that concrete will withstand and not allow moisture to pass through – 4 atm;

- if water and the weight of cement in 1 m3 of m200 concrete are taken in standard quantities, then the cone settlement will be 5 - 20 cm. This parameter may change due to the introduced plasticizers. As the amount of water increases, the strength of the material decreases;

- You can work with such a concrete solution at temperatures ranging from five to thirty degrees Celsius.

The value of the specific gravity of a cubic meter of concrete

Weight is the force with which the body presses on the support. The specific gravity of a substance is its ratio to volume (N/m3). This physical quantity is often confused with density, which is considered the ratio of mass to volume (kg/m3), since they are numerically the same. The reason for the confusion is the combination of the concepts of weight and mass (amount of substance). Combining the definitions of these quantities is either a mistake or everyday usage when scientific accuracy is not required.

For a rough calculation, take an approximate figure - 2400 kg/m3. If we are talking about the specific gravity of a composite material made of concrete and steel, then add up to 10%. However, many different types are used in construction; their density differs significantly and ranges from 300-3000 kg per cubic meter.

Application of concrete m200

The material is universal; its main characteristics make it possible to use concrete in the construction of various structures that are planned for operation under standard load conditions. The scope of application of concrete is as follows:

- arrangement of floor screeds, foundations, retaining walls, stairs and other monolithic elements;

- arrangement of light-loaded structures;

- production of curbs, paving slabs, floor slabs, blocks and other reinforced concrete products;

- performance of reinforcement works;

- during road construction it is used for arranging cushions;

- during restoration activities.

How does specific gravity affect the quality of concrete?

This parameter determines the type of solution suitable for a particular job. More dense compositions are used for load-bearing structures; secondary problems are solved with the help of lightweight concrete. The density indicator is influenced by the size of the aggregate grains and a decrease in the amount of water. If it is necessary to increase weight, then plasticizers can be used.

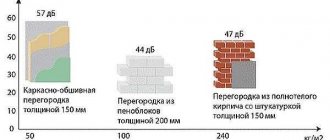

In addition to the strength indicator, water resistance and frost resistance depend on the volumetric weight. Lightweight and porous concrete compositions are distinguished by another important characteristic - sound insulation. In this case, there is a feedback - the denser the concrete, the worse it insulates and protects against noise. In addition, the concrete grade determines the level of porosity - the higher it is, the less air the concrete contains.

The weight of concrete grade 200 1 m3 can be clarified in special tables.

Features of preparation and laying of concrete

Mixing the concrete solution can be done manually or using concrete mixers. Moreover, it should be carried out until a homogeneous creamy consistency is obtained. To check the readiness of the solution by density, you can use the following practice-tested method. Let the solution sit for a while until air bubbles form on the surface. Then you need to take a little solution on the shovel, shake it and turn the shovel over. If the solution sticks and does not fall off immediately, you need to add water or sand. The main component that affects the density of the material is the filler, because... proportionally, it occupies the largest volume in the mixture. When using gravel and crushed stone, their density should be double or triple the calculated density of the resulting concrete, since concrete has the ability to increase its strength over time. At the same time, fine aggregate fractions reduce the porosity of concrete.

The technology for laying the mortar also affects the density of concrete after it hardens. An important procedure in this regard is tamping the poured concrete, which is aimed at squeezing air bubbles from inside the solution onto its surface. More dense grades of concrete require more careful compaction, for which various manual and mechanized devices can be used, for example, electric or pneumatic vibrators.

The compaction procedure should be carried out until characteristic foam or milk appears on the surface of the solution. This is the result of the displacement of excess moisture and air from inside the solution. This ensures high density and strength of the material. To displace air from inside the concrete solution to the outside, other methods can be used in the form of sticking iron pins into the concrete or vacuuming.

The latter method is one of the most progressive methods and is widely practiced in road construction to increase the density of asphalt concrete road surfaces. Vacuuming is effective when using cement grades based on slag silicate components. All grades of concrete, in accordance with the accepted density classification, are usually designated by the Latin letter D with the addition of numbers indicating its specific gravity in kg/m3. In this case, the range of grades lies within D200-D5000, for example, light grades of concrete include D500 - D1800, etc.

Some confusion for uninformed users may be caused by the division of concrete by class, denoted by the letter “B”, and by compressive strength, denoted by the letter “M” and measured kg/cm2. By increasing the density of concrete, the consumer achieves an improvement in its physical and mechanical characteristics, as well as such performance qualities as water resistance, frost resistance, durability, strength and corrosion resistance.