Concrete GOST 7473 2010 refers to interstate standards. In Russia, valid from January 1, 2012 instead of GOST 7473-94. The state standard applies to ready-to-use heavy, light and fine-grained concrete mixtures based on cement. The purpose of the materials is the construction of prefabricated monolithic or monolithic structures, the production of concrete and reinforced concrete products.

GOST 7473 2010 does not apply to structural and special concrete (including concrete with special aggregates).

Concrete produces mixtures in strict accordance with current GOST.

Concrete GOST 7473 2010 technical characteristics

The standard establishes the data that must be contained in the name of the mixture.

For main types of concrete:

- Frost resistance (F) - 9 classes from F25 to F500.

- Water resistance (W) - 10 classes from 2 to 20. Steps of 2 units are used.

- The degree of readiness of the mixture is for a ready-made mixture from the factory - BSG.

- Strength class (B) - 21 class.

- Workability (SZh, Zh, P) - 3 types: flexible (P1-P5), rigid (Zh1-Zh4), super-rigid (SZh1-SZh3).

- Strength grade (concrete M200 GOST 7473 2010), in fairness it should be said that the M marking remained from the Soviet GOST.

Lightweight concretes are also labeled with an average density value.

If the characteristics of the material differ from the standard ones, unique designations are used: high-strength special (HS) or with fine-grained filler (SM). But GOST does not regulate such markings.

Concrete grades GOST 7473 2010 for strength

There are 21 concrete strength classes. Confusion may arise here, since the technical documentation indicates exactly the classes of mixtures, and factories produce grades of concrete. Responsible manufacturers indicate both values - both B and M.

Brands directly influence the scope of use of mixtures:

- M-100, M-150 correspond to classes B7.5 and B12.5. They are used for non-load-bearing and so-called “irresponsible” structures.

- M-200, M-250 correspond to concrete B15 GOST 7473 2010 and concrete B20 GOST 7473 2010. They are used for floor slabs, covering areas with light loads, reinforced concrete belts.

- M-300, M-350 correspond to B22 and B25. They are used for foundations in low-rise construction, for highways and other structures with heavy loads.

- M-400, M-450, M-500 for industrial premises and multi-storey civil construction.

- M600-M1000 for complex industrial and military facilities: bridges, mines, dams, airfield slabs.

produces and delivers all popular grades of concrete produced in accordance with GOST 7473-2010.

Description of material

Concrete M200 is indispensable in private and residential construction. Reinforced concrete structures made from such a building mixture can withstand long-term loads, which allows them to be used for the construction of buildings 5-6 floors high. Today on sale you can find various types of concrete of strength grade M200, which will differ in their strength indicators, moisture and frost resistance and a number of other characteristics.

This material is made from M400 Portland cement and may include fine-grained and coarse-grained fillers. Accordingly, its characteristics, mobility and ability to maintain strength over a certain period of time will differ.

Thanks to the use of various plasticizers and additives, it is possible to significantly change the characteristics of the final mixture, but all production of M200 concrete is carried out exclusively in accordance with GOST in compliance with the recipe of this material.

It is customary to distinguish between the following types of concrete M150 and m200, depending on the characteristics of the material:

- According to the purpose of the mixture: for industrial and domestic construction.

- Type of binding material: gypsum, cement, silicate and with the addition of polymers.

- Fractions of solid fillers used: fine-grained and coarse-grained types of crushed stone.

- Density and elasticity of the composition: porous, dense, special purpose.

- Type of maturation: with natural hardening and autoclave compositions.

- Depending on the volumetric mass indicator: lightweight and heavy.

Provided the correct choice of such material, it will be possible to ensure maximum durability of the erected buildings, their resistance to pressure and other adverse environmental influences.

READ Laying foam blocks for building a house with your own hands

The most popular are cement coarse-grained dense varieties, which are used with equal success for the manufacture of reinforced concrete structures, pouring foundations and erecting structures using monolithic construction technology.

Concrete GOST 7473 2010 - technical characteristics

Concrete mixtures are used in all types of construction. To choose a quality material, you need to understand what it will be used for and what properties it has. Let's consider concrete GOST 7473 2010 and its technical characteristics . This state standard applies to ready-to-use concrete mixtures of fine-grained and lightweight cement-based concrete.

Concrete M200 GOST 7473 2010

Concrete M200 GOST 7473 2010 is one of the most popular building materials. It belongs to the type of lightweight concrete and is used for the manufacture of monolithic structures and reinforced concrete products.

Concrete grades GOST 7473 2010

Concrete grades in accordance with GOST 7473 2010 have their own technical characteristics. These are strength class, frost resistance, workability, water resistance. In order to choose the right mixture, you need to understand all the indicators.

Waterproof

This indicator indicates the possibility of using concrete in a humid environment. It is designated by the letter “W” with a number from 2 to 20. The higher the number, the better the material resists water. It is especially important to study this characteristic when selecting a mixture for building hydraulic structures or pouring a foundation when groundwater levels are high. Concrete grades higher than M500 are suitable for such work.

Frost resistance

It is designated by the letter “F” with a number from 25 to 500. The number shows how many freezing cycles the concrete structure will withstand. If the building or individual elements will be exposed to aggressive effects of low temperatures, then the indicator should be as high as possible.

Workability

Three types of indicators: super-hard, rigid, plastic. Rigid concrete contains a minimum amount of cement and a high content of filler. The installation method differs from plastic ones.

Concrete strength class

There are only 21 classes and are designated by the letter “B”. When choosing a brand, first of all, you need to be guided by the value of this indicator.

Technical characteristics of concrete M200: density, weight, strength

Share:

17 Jan

| see prices for concrete M-200 order concrete M-200 Call!; |

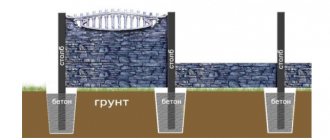

Ready-mix concrete M200 is a sales leader in the individual construction sector and one of the most popular brands for the manufacture of concrete foundations, screeds, paths and blind areas. Brand classification M200 corresponds to strength class B15, and in terms of density, concrete M200 belongs to the lightweight category. The volumetric weight and density of M200 concrete depends on the filler used in the mixture and can range from 500 to 1800 kg/m3. When producing M200 grade materials, the proportions of the components that make up the mixture depend mainly on the grade of cement. If M400 cement is used to make concrete, then the proportion for M200 concrete will be as follows: 1: 2.8: 4.8 (cement/sand/crushed stone). When used in the formulation of M500 cement, the proportions of M200 concrete require the following ratio of ingredients: 1: 3.5: 5.6. Water in the total volume of the solution, as a rule, is no more than 20%, however, the exact proportions of water for M200 concrete are determined from tabular data, taking into account the type of filler and the size of its fraction. Reducing the volume fraction of cement in the mixture turns classic concrete into a so-called “lean” mixture. The consistency characteristic of “lean” concrete is liquidish, sometimes called “wet earth”. Lean mixtures of the M200 brand are used as a base for stabilizing the soil under the foundation. Instead of the mobility indicator, the hardness indicator (W) is used to characterize lean mixtures. Varieties of lean mixtures are also often used in road construction. In some cases, the components also include lime, clay or gypsum. These ingredients act as a binder. The technical characteristics of B200 concrete are primarily determined by its composition. The highest strength indicators are demonstrated by a product that contains granite crushed stone as a filler. Less durable, but at the same time cheaper, are concretes based on crushed limestone and crushed gravel aggregates. The strength characteristics of M200 concrete are quite sufficient to solve any problems within the framework of private individual construction. The product of this brand is ideal for pouring foundations (of any type, including slab and pile-grillage), and for erecting staircase structures, garden paths, and small architectural forms.

produces and sells concrete M200 directly from the plant, providing customers with a number of undeniable advantages:

- Extensive selection of branded products with the required technical characteristics;

- Quality strictly according to GOST;

- Quality certificate for each batch of products;

- Possibility of placing an order of any volume from 7 cubic meters. meters;

- Delivery within 1 to 3 hours to any construction site in Moscow and the region;

- Reasonable prices and a convenient system of discounts for large wholesale buyers.

Make an application in any convenient way: by phone, email, using the feedback form or by coming to our office.

Proportions and composition of the mixture

The manufacturing technology of grade B15 concrete is regulated by GOST requirements, which allows maintaining all the declared characteristics of the material, including its strength and moisture resistance. Production is carried out using standard technology from cement, crushed stone, sand and water.

The composition of concrete m200 per cubic meter includes the following components:

- cement - 265 kg;

- sand - 860 kg;

- crushed stone - 1050 kg;

- water - 180 l;

- plasticizers - 4.8 kg.

READ Features of aerated concrete blocks for building a house

It is recommended to use Portland cement with class M400 and M500. It is possible to use materials with lower strength indicators, but the ratio of expensive components in this case only increases. It is preferable to use river sand; there is no need to sift and wash the material. The optimal fraction size is 1.3−3.5 mm. Additionally, crushed granite or gravel with a fraction of 10–40 mm is used as backfill.

Depending on the volume of the mixture being prepared, you can do it yourself manually or in small concrete mixers; it is also possible to order ready-mixed concrete directly from the plant, which is delivered by concrete mixers directly to the construction site. In the latter case, it is possible to guarantee the excellent quality of the material, as well as its full compliance with the declared characteristics.

Concrete composition

The selection of the nominal composition of concrete is carried out in the laboratories of mortar-concrete units: for cement of a specific type and brand of a specific manufacturer; for crushed stone or gravel of a specific quarry; for sands of a specific quarry; for chemical additives of a specific type...there are so many changing parameters... Therefore, for the manufacture of critical structures: reinforced foundations, floors, flights of stairs and platforms, concrete recommended by the design documentation and delivered to the construction site by automixers should be used. For non-critical structures or if you take the risk yourself, concrete can be produced on the construction site.

Field method for determining the composition of concrete

The most common way to determine the composition of concrete is as follows. Crushed stone or gravel is poured into an empty bucket. The bucket is shaken to distribute the coarse aggregate more evenly. Then water is poured into it using a measuring container, for example a liter jar, until the water is equal to the top of the crushed stone. The volume of water contained by the crushed stone indicates the required volume of sand. The crushed stone is poured out of the bucket and sand is poured into it, in the same volume as indicated by the water and in the same jar. Again, pour water into the bucket until it covers the sand. This time the volume of water contained shows the volume of cement. The last component required to prepare concrete is water. It is taken in a volume equal to 50–60% of the volume of cement.

This “field” method for determining the composition of concrete implies that cement will fill the voids between grains of sand, and sand will fill the voids between crushed stones, i.e. The cement-sand mixture is used as ordinary glue. The strength of concrete will be approximately equal to the strength of crushed stone (depending on its size). The method does not take into account the movement of aggregate grains and some other characteristics, but it is simple and can be used in the manufacture of concrete for non-critical structures.

Tabular method for determining the composition of concrete

A more correct selection of concrete composition is made according to the tables below.

An example of selecting the composition of concrete. Suppose you need to make M300 concrete with a volumetric weight of 2400 kg/m³. From Table 1 we determine that it corresponds to concrete of strength class B22.5. To produce one cubic meter of such concrete (Table 3), 350 kg of M400 Portland cement is required. Let us assume that there is crushed stone with a fraction of up to 20 mm, from which it is necessary to prepare mobile concrete with a cone draft of 2–2.5 cm. According to the table for determining water consumption (Table 5), we see that 190 kg of water will be required. According to Table 6, we determine that sand in concrete should make up 40% of the total mass of the aggregate. Then the mass of sand will be equal to: (2400-350-190)×40/100=744 kg. Next, we calculate the mass of crushed stone, it will be equal to: 2400-350-190-744 = 1116 kg.

Thus, it turns out that to prepare one cubic meter of concrete M300 you will need: portladder cement M400 - 350 kg, crushed stone - 1116 kg, sand - 744 kg, water - 190 liters.

When using cements of other brands and crushed stone (gravel) of other sizes and shapes, correction factors are applied to the tabulated material costs (Table 4). The volumetric mass of one cubic meter of heavy concrete on crushed stone can be taken equal to 2400 kg, on gravel - 2350 kg. Based on this, the required amount of varietal coarse aggregate corresponding to GOST 26633-91, 8267-93 is found.

In the given example of selecting the composition of concrete, the results obtained are very approximate. In real conditions, several batches of different compositions are made and concrete samples are made, which are then tested and only after that the concrete is assigned a nominal strength class.

Table 1

Correlation between concrete classes for compressive strength and grades

| Concrete class by compressive strength | Average strength of concrete of this class, kg/cm² | The closest concrete grade in terms of strength | Deviation of the nearest grade of concrete from the average strength class, % |

| AT 2 | 26,2 | M25 | -4,6 |

| B2.5 | 32,7 | M35 | +7,0 |

| B3.5 | 45,8 | M50 | +9,1 |

| AT 5 | 65,5 | M75 | +14,5 |

| B7.5 | 98,2 | M100 | +1,8 |

| AT 10 | 131,0 | M150 | +14,5 |

| B12.5 | 163,7 | M150 | — 8,4 |

| B15 | 196,5 | M200 | +1,8 |

| IN 20 | 261,9 | M250 | -4,5 |

| B22.5 | 294,4 | M300 | +1,9 |

| B25 | 327,4 | M350 | +6,9 |

| B30 | 392,9 | M400 | +1,8 |

| B35 | 458,4 | M450 | -1,8 |

| B40 | 523,9 | M500 | -4,8 |

| B45 | 589,4 | M600 | +1,8 |

| B50 | 654,8 | M700 | +6,9 |

| B55 | 720,3 | M700 | -2,8 |

| B60 | 785,8 | M800 | +1,8 |

Don't miss: Characteristics of thermal insulation materials

Table 2

Recommended grades of concrete for concreting structures of one- and two-story buildings

| Place of concreting | Consistency | Concrete class |

| Massive concrete foundations: in dry soils (crushed brick can be used as a filler) | Tough | B7.5 |

| Massive concrete foundations: in wet soils | Tough | AT 10 |

| Massive concrete foundations: in water-saturated soils | Tough | B15 |

| Preparatory layer for floors | Tough | B12.5 |

| External staircase and basement staircase | Easily flexible | B7.5 |

| Toilet cesspool, septic tank, etc. | Easily flexible | B15 |

| Beams and floor slabs with large spacing between reinforcing bars | Easily flexible | IN 20 |

| Beams and floor slabs with dense reinforcement, as well as thin-walled structures | Very flexible | B22.5 |

Table 3

Cement consumption for concrete of monolithic concrete and reinforced concrete structures

| Concrete class by compressive strength | Basic consumption rates of cement grade 400 for monolithic structures, kg/m³ |

| B7.5 | 180 |

| AT 10 | 200 |

| B12.5 | 225 |

| B15 | 260 |

| IN 20 | 320 |

| B22.5 | 350 |

| B25 | 380 |

| B30 | 440 |

SNiP 82-02-95 Federal (standard) elemental standards for cement consumption in the manufacture of concrete and reinforced concrete products and structures (download the entire document, PDF 251 KV)

Basic rates of cement consumption are given for concrete made with Portland cement grade 400 and its varieties. When using cement grade 500, the basic norms should be multiplied by a factor of 0.88, when using cement grade 300 - by a factor of 1.13. When using Portland slag cement and sulfate-resistant Portland slag cement, the base values are multiplied by a factor of 1.1. When using pozzolanic Portland cement, the basic rates of cement consumption are multiplied by coefficients: for concrete of design class up to B22.5 inclusive - 1.08 and for concrete of design class B25–B30 - 1.15.

The standards provide for the use of crushed stone with the largest grain size of 40 mm, meeting the requirements of GOST 8267, 10260, 23254 and sand with a particle size modulus of 2.1–3.25 corresponding to GOST 8736. When using crushed stone with a different grain size, the tabulated cement consumption rates should be multiplied by coefficients , shown in table 4.

Table 4

Correction factors for consumption rates

| Largest grain size of filler, mm | Coefficient for concrete classes | |

| up to B25 inclusive | B30 and above | |

| 20 | 1,08 | 1,05 |

| 70 | 0,97 | 0,97 |

When using crushed stone with the inclusion of flaky (flat) and/or needle-shaped stones, or when using gravel, as well as fine and very fine sand, download SNiP 82-02-95 and apply the appropriate coefficients to cement consumption rates.

Table 5

Approximate water consumption in concrete mixture, l/m³

| Characteristics of concrete mixture | Largest size mm | ||||||

| cone draft, cm | hardness, sec | gravel | crushed stone | ||||

| 10 | 20 | 40 | 10 | 20 | 40 | ||

| — | 150–200 | 145 | 130 | 120 | 155 | 145 | 130 |

| — | 90–120 | 150 | 135 | 125 | 160 | 150 | 135 |

| — | 60–80 | 160 | 145 | 130 | 170 | 160 | 145 |

| — | 30–50 | 165 | 150 | 135 | 175 | 165 | 150 |

| — | 20–30 | 175 | 160 | 145 | 185 | 175 | 160 |

| 1 | 15–20 | 185 | 170 | 155 | 195 | 185 | 170 |

| 2–2,5 | — | 190 | 175 | 160 | 200 | 190 | 175 |

| 3–4 | — | 195 | 180 | 165 | 205 | 195 | 180 |

| 5 | — | 200 | 185 | 170 | 210 | 200 | 185 |

| 7 | — | 205 | 190 | 175 | 215 | 205 | 190 |

| 8 | — | 210 | 195 | 180 | 220 | 210 | 195 |

| 10–12 | — | 215 | 200 | 190 | 225 | 215 | 200 |

The table is taken from the book by A.I. Konoplenko. “Concrete Technology” p. 222.

Rigid concrete mixtures are characterized by a low content of cement paste. In flexible mixtures, the layers of dough between the filler grains have a value of more than 30 microns, and in rigid mixtures it can be only 2–3 microns, which determines some features of the properties of mixtures and hardened concrete. Rigid mixtures have poor workability and require increased costs for compaction by vibration. Rigid mixtures should be used when rapid demoulding of the structure is required to continue work. For structures with dense reinforcement, plasticizers should be added to rigid concrete. Movable and slow-moving concrete mixtures are used more widely due to the relative ease of preparation and placement, which ensures the production of dense, freshly laid concrete.

Don't miss: Consumption of materials for walls made of ceramic and silicate stones with and without lining

Table 6

Percentage ratio of fine aggregate (sand) to the mass of total aggregate

| Approximate cement consumption in kg/m³ | Largest grain size of gravel (crushed stone), mm | |||

| 10-20 | 40 | 60 | 80 or more | |

| Sand content in aggregate mixture in % by weight | ||||

| 200 | 46/40 | 42/38 | 39/36 | 37/35 |

| 250 | 44/38 | 40/36 | 37/34 | 35/33 |

| 300 | 42/36 | 38/34 | 34/32 | 33/30 |

| 350 | 40/35 | 36/32 | 33/30 | 31/28 |

| 400 | 38/34 | 35/31 | 32/29 | 30/27 |

| 500 | 34/32 | 32/28 | 30/27 | 28/2 |

Note. The numerator indicates the % of sand assigned when using crushed stone, the denominator - when using gravel. Sand must comply with GOST 8736.

The table is taken from the “Builder’s Handbook” by G.A. Kazachek.

Computer method for determining the composition of concrete

To facilitate the selection of concrete compositions, there are computer programs Ksybs6.3_rus (402 KB) and concrete (3.91 MV). It must be said right away that these programs differ slightly in calculation methods and show different concrete compositions. They, like the calculation example given above, are designed to calculate the components of concrete for the creation and subsequent testing of samples. One should not think that these calculations give the final verdict, although for the amateur construction of a practitioner, safety margins many times greater than the required values will be sufficient. However, let us repeat once again and remind you that the guaranteed required strength of concrete can be obtained by pouring concrete brought from mortar-concrete units. Or you need to select the composition and test the samples yourself. The books will help with this, as well as in understanding the work of computer programs: “Introduction to Concrete Technology” by G.I. Cherkasov. and “Concrete Technology” Konoplenko A.I.

True, here it is necessary to make a reservation: the authors of the books show a calculation method aimed at saving cement, and the above calculation example is based on the cement consumption recommended by SNiP 82-02-95. Which directly states: “Unlike previously existing norms for cement consumption (SNiP 5.01.23-83 and other regulatory documents), in which the only optimization parameter was reducing cement consumption by saving it, these norms provide technologically and statistically sound coefficients, the use of which makes it possible to evaluate and take into account the influence of variations in basic production conditions on cement consumption while unconditionally ensuring all standardized indicators of concrete quality.”

Time for concrete to gain grade strength

When hardening concrete and reinforced concrete products without heat treatment, it is provided that it occurs at a positive temperature of 15–20 ° C to prevent moisture loss from the concrete. At the same time, concrete strength of 60% in products made with Portland cements and their varieties and quick-hardening Portland slag cements is achieved within 3–5 days; equal to 70% - within 6–10 days; and in all cases, at the age of 28 days, the design strength class of concrete is ensured. Building structures made of monolithic concrete can be loaded once it reaches 50% strength. For example, making brickwork on a monolithic foundation can begin after 3 days (at an air temperature of 15–20°C), since the construction of brick walls is a long process and the loading of the foundation to the design value will not happen simultaneously. It is also better to strip monolithic structures after 3 days. The longer the structure stands, the harder it is to remove the formwork, provided that the formwork is not separated from the concrete by waterproofing.