The biggest problem with these concrete mixers is the crown. During operation, cement, sand and crushed stone get between the teeth. Because of this, rapid wear of the teeth occurs. On average, with active use of the device, the crown lasts about three years, after which it will have to be replaced. Although it is worth noting that the cost of a crown made of steel or polyamide is relatively low and is approximately 20% of the cost of the mixer.

Who is the concrete mixer suitable for? This is the best option for those who do not plan to use the mixer constantly, and it is necessary for infrequent work. If you are planning to build a private house, then such a mixer will be enough for the entire construction period. For example, you can take Zubr Master BS-120-600 with a volume of 120 liters. For a construction team that works all year round, it is better to take a gear-type device.

Geared

Here, the rotation from the engine is transmitted to the gearbox, which in turn rotates the drum and the ingredients poured into it. The gearbox is covered with a metal casing that protects it from gravel and sand, so it lasts a very long time. The average service life of gearboxes is 7 years (much depends on the manufacturer). However, if the gearbox fails, replacing it will cost approximately 30% of the cost of the mixer.

Geared mixers are capable of operating both by gravitational and forced operating principles. The mixture turns out homogeneous, without lumps. In terms of performance, a gear mixer is much better than a Leo crown mixer (much depends on the specific model).

In the gearbox, the number of transmission links is much smaller than in the crown ones, due to which maximum power balance and energy consumption are achieved. Also, in such models, the handles are located not on the side, like crown ones, but on the back, which makes moving around the construction site more comfortable. Which concrete mixer to choose from geared ones for your home? Among the relatively inexpensive ones for home repairs, we can recommend the Parma B-130R with a power of 850 W.

What operating principle should you use for a stirrer?

How to choose a concrete mixer based on its operating principle? It is worth noting that absolutely all models can work either according to the principle of gravity or in a forced way.

The gravity method of operation consists of mixing the mixture by lifting the solution on the blades and throwing it down. That is, these blades are fixedly fixed in the drum, and the drum itself moves.

Devices with a gravity operating principle are capable of mixing no more than 75% of the total volume of the drum. Accordingly, the drum cannot be lifted vertically.

- Home Appliances

How to pester your neighbor: choosing a hammer drill for your home

The forced principle of operation involves the rotation of the blades inside the drum (as in a food processor). At the same time, the mixture is mixed very efficiently. On average, devices with a forced operating principle are capable of mixing 75 - 90% of the total volume of the mixer. But the cost of such units is much more expensive than gravity ones.

Which is better to take a stirrer, with a gravitational or forced method of operation? For household work, gravity units are quite suitable, since there is no particular need to mix large volumes at once (except for pouring the foundation). Among the domestic ones, you can take the Whirlwind BM-230 , which is capable of mixing up to a maximum of 165 liters of mixture out of 230 liters of total volume. Devices with a forced method of mixing the mixture are best used for construction teams of masons, where a large volume of mortar is needed in a minimum amount of time. It is also worth considering that the price for such models starts from 50,000 rubles.

Operation of concrete mixers

The question of how to use a concrete mixer requires compliance with certain rules and a certain order of work. The quality of concrete is influenced by such parameters as the speed of mixing of materials and the quality of these materials. Also, when producing concrete in a concrete mixer, the proportions of the materials being poured play a decisive role. Proportions are determined according to established SNIPs.

- Before loading the device, you need to make sure that the device is working properly - to do this, start it at idle.

- If everything works fine, download mode is activated. In this mode, the ingredients of the mixture are placed alternately into the drum: first water, then cement. After a couple of minutes of mixing, you can load sand and crushed stone.

- After loading all the materials, the mode for mixing concrete in the concrete mixer is selected (usually the “Start” button).

- When mixing is complete, you need to lower the drum or its neck and pour the mixture into the prepared container.

More on this topic on our website:

- How to choose a concrete mixer for your home Those who have independently mixed concrete for construction work using an ordinary shovel know very well what effort it takes to mix at least 10 buckets of cement mixture...

- How quickly does concrete gain strength after pouring? The strength of the concrete composition is a determining indicator of the quality of this sought-after material. The strength of a concrete mixture depends on how long it takes for the concrete to gain strength under the conditions...

- Glass-type foundations for metal columns Let's start with the fact that all buildings are conventionally divided into two types: frame and frameless. Frame buildings include almost all industrial structures. In order to…

- Anchor bolts for the foundation - calculation of foundation bolts for a frame house Anchor bolts for the foundation are a fastener whose main purpose is to hold the structure. With their help, various products and workpieces are secured. Anchor bolts are distinguished…

Concrete mixer volume

The choice of concrete mixer for this parameter directly depends on the intended work, as well as the number of people in the team. The more workers there are, the faster the next portion of the solution will be needed. Below is the ratio of the volume of the mixer to the number of workers in the team:

- Up to 100 l: 1-2 workers,

- 100-150 l: 2-3 workers,

- 150-180 l: 4-5 workers.

These indicators are average, and much depends on specific working conditions. Here we note that size affects the weight of the device. You should not take a stirrer that is too large unless necessary, as it will be difficult to drag around the object.

Purpose of the concrete mixer

A concrete mixer is a construction equipment designed for mixing various building materials: cement, adhesives, water, sand, etc. As a result of mixing concrete in a concrete mixer, concrete is formed - a special building material widely used both in the construction of buildings and during repairs.

Only mechanized mixing of the mixture allows you to obtain truly high-quality material with high performance characteristics, so an important parameter here will be compliance with the rules on how to use a concrete mixer.

Only with the help of a concrete mixer can you prepare a very large amount of concrete, which is completely unthinkable with manual mixing using improvised materials.

In addition, the continuous mixing process allows the composition to be maintained in the required state for a long time, preventing the concrete from hardening prematurely. When producing concrete in a concrete mixer, the proportions of the materials being poured must strictly comply with the standards.

Drum speed

For models with a power from 500 to 1000 W, the rotation speed of the drum is practically irrelevant. But for more powerful devices, the drum rotation speed must be at least 30 rpm so that the mixture is mixed well. In principle, the higher the speed, the faster the solution will be mixed and, accordingly, less electricity will be consumed. Unfortunately, this indicator is rarely written in the characteristics of the product in the product card of online stores, so this parameter should be clarified directly with the seller.

The best crown concrete mixers 2020

Parma B-121E

Budget concrete mixer for home repairs. Its volume is 120 liters, and it can stir up to 65 liters of the finished mixture, that is, about 55% of the tank volume. There is a good quality cast iron crown here. Its service life is on average 3 - 4 years, depending on the frequency of use.

The mixer can be called relatively light, its weight is 53 kg. The power of the device is small, but in principle it corresponds to the volume of the drum. If you need a small, reliable stirrer, then this model is just what you need.

Zitrek Z200 024-0984

This is a more serious and larger unit. The motor power here is 800 W. The total volume of the drum is 200 l. In one pass, the concrete mixer is capable of mixing up to 150 liters of concrete mixture, which is about 75% of the total volume of the tank - this is quite a large figure for crown units.

Users note that even when loading 2/3 of the barrel, the engine practically does not heat up. This device weighs 63 kg, so you will need a second person to move it. Overall, this is a good stirrer for the money for home repairs.

Whirlwind BM-200

This 200-liter concrete mixer from a domestic manufacturer is capable of mixing up to 140 liters of ready-made mortar. Note that even when fully loaded, its rotation speed does not drop and is 29.5 rpm.

The power of the concrete mixer is 900 W. It is also worth noting that a durable cast iron crown is installed here. According to user reviews, the device mixes the mixture well and does not make much noise. The weight of the device is 56 kg.

Rating of geared concrete mixers 2020

Stroymash SBR-132N

This is one of the most inexpensive geared concrete mixers for home use. With a drum volume of 132 liters, it is capable of mixing up to 64 liters of mixture - this is a small figure for a gear mixer, but at such a low price this is normal. The motor power is 600 W.

This model is the younger brother of the SBR-350N device, with the ability to prepare a ready-made mixture up to 175 liters and operate on a voltage of 380 V. If you need it for small home repairs, then take the SBR-132N, and if for a construction crew, it is better to take the SBR-350N.

Profmash B-130R

Many people buy this concrete mixer if it needs to be rolled with mortar from the place of mixing to the place of pouring. Thanks to a well-thought-out balanced design, stable wheels and comfortable handles, it is convenient to roll it at a distance of up to 50 m from the kneading site (rolling over longer distances greatly tires your arms and back). In one go, the unit is capable of mixing up to 70 liters of solution. Moreover, it prepares the maximum volume of solution in just 2 minutes.

The manufacturer claims that the service life of the concrete mixer is about 20,000 cycles (meaning on/off for one batch). In this case, the device can (more precisely, it is recommended by the manufacturer) to mix crushed stone with a size of no more than 40 mm (although at a construction site it was necessary to mix crushed stone of a larger fraction). The power of the device is 850 W, and its weight is 48 kg.

Caiman M134

Professional concrete mixer for home and commercial construction. It has the best power/solution volume ratio: with its 300 W, it is capable of making up to 100 liters of concrete in one go. Electricity consumption is almost half that of competitors with the same tank volume.

The engine speed is 2750 rpm. In this case, the mixer itself rotates at a speed of 21 rpm. The tank has good steel up to 1.5 mm thick, which, even with intensive use, does not corrode for a long time (although, of course, it will rust over the years). For ease of filling, the tank can be rotated around its axis. The cost of the device is certainly quite high, but the build quality and performance compensate for all costs.

What else do you need for home renovation:

- Doing repairs while at home: the best cordless screwdrivers 2020

- Retirement brushes: which electric spray gun is best to buy for your home?

How to make a concrete mixer

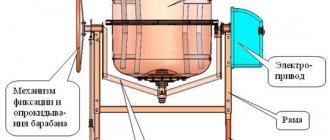

After I started the grandiose construction of a country house, as expected, the need arose to make a concrete mixer for the dacha.

There was no money for a factory-produced device, so the idea arose to try to assemble it yourself from what was at hand.

The design turned out to be reliable: our little concrete mixer has already worked for two seasons and is flying normally. According to my subjective feelings, you can only break it if you hit it with a sledgehammer or throw it off the roof of a nine-story building.

The engine starts easily even at full load, I checked it several times, loading it with the heaviest concrete and crushed stone. The engine does not overheat even after kneading and laying a cubic meter of screed.

The engine was taken from an old Soviet washing machine, with a power of 220 W, 1350 rpm. Such engines are very reliable, they are capable of threshing all day long at maximum power without even giving a damn.

The gear ratio is 48, it is designed in such a way as to obtain rotation of the container with concrete at a frequency of 25-30 rpm. This speed is recommended in most smart books about gravity-type concrete mixers (i.e. without an activator for forced mixing), which I had to read before starting my own production.

The V-belt and pulley from the same washing machine came in handy. I welded the tub itself from steel sheets 1.5 mm thick.

To improve the mixing properties of the tub, three low screw blades are welded on the inner surface of its walls.

A ring gear, which is part of the gearbox, is welded to the bottom. The crown from the ZIL-130 engine was ideal for it. The counter gear (the one that is tiny) is a Bendix from the same place.

As you can see from the photos, the entire structure is welded from 50-gauge angle and profile.

The concrete mixer is designed for a volume of 0.2 m3 (200 l).

To remove the finished mixture, you must manually turn the container over using a rotating device - a large hexagonal steering wheel.

To do this, you need to apply some force, since the center of gravity of the entire volume of mixed concrete is below the axis of inclination of the barrel (this is what prevents it from tipping over on its own).

This feature must be taken into account at the design stage, otherwise it will be somewhat difficult to use your concrete mixer.

In order to increase operational safety, it was decided to equip the concrete mixer with a grounding device - a metal stake connected to the frame of my structure using a conductor with a cross-section of 6 mm².

Perhaps it would be a very good idea to protect the wires going to the engine with a metal hose. At the time of assembly it was not there, but in the future I will definitely take this point into account.

And the future, by the way, has already arrived: a neighbor in the dacha, having seen this whole miracle mechanism in action, ordered himself and another friend the exact same product. Therefore, in the photo, in addition to the almost finished concrete mixer, you can see another one - recently started.

True, the neighbor wanted an even more powerful engine - 380 W, 1100 rpm, so he ordered a smaller diameter pulley from the turner in order to maintain the required gear ratio.

So, if you want to buy an inexpensive electric concrete mixer somewhere near Volgograd, I am at your service. The asking price is 20 thousand rubles.