Specific gravity of sand and methods for its determination

Specific gravity or specific gravity is the weight of sand that is contained in a certain volume. Typically, this value is indicated by the weight of sand, measured in kilograms, contained in a volume equal to one cubic meter. However, in the technical literature there is also another designation for the specific gravity of sand - tons/cubic meter and grams/cubic centimeter. The specific gravity of construction sand in kg/m3 is calculated by the formula:

m=V*p, where the weight of the sand is m; its volume is V and its density is p.

Knowing the weight of the sand and the degree of its density reported by the supplier, the specific gravity can be determined. It is not necessary to do calculations, as you can use reference data or perform the calculation on an online calculator.

Specific gravity of construction sand: how to calculate parameters

m= O*p;

- m—melt mass in kg.

- O - volumes, in cubic meters.

- n is the density of the material in the uncompacted state, in kilograms per cubic meter.

For a cubic meter, weight indicators are equivalent to material density. The parameters of the density of the material in the uncompacted state must be stated by the product sales manager.

On average, moisture accumulation reaches 6−7%.

If the material is wetter, the indicator increases by 15-20 percent. It is important to add this difference to the resulting weight.

Factors influencing the specific gravity of sand

The weight of 1 m3 depends on its density. And the density value is influenced by many factors, of which the following are considered the main ones:

- the amount of impurities contained in the sand;

- composition of minerals;

- size of individual grains of sand (fractions);

- compaction percentage;

- humidity level;

- storage method.

In the regulatory literature (for example, in GOST 8736 of 1993), the average value of the specific gravity of construction sand is equal to 1500 kg/m3. For the same type of sand with other moisture and density indicators, the following standard data are used:

- dry sand - 1440 kg/m3;

- dry and compacted sand (compacted) - 1680 kg/m3;

- wet sand - 1920 kg/m3;

- wet and compacted sand (compacted) - 2545 kg/m3.

How to determine how much a cube of sand weighs: material characteristics

Many owners of country houses try to calculate the weight of sand in one cube. This indicator is especially relevant for suburban construction, which involves such serious amounts of work as the construction of a building or the arrangement of a yard and local area. How much does 1 cubic meter of sand cost with delivery is one of the burning questions of any person who undertakes independent construction or is concerned about purchasing material for hired workers.

Depending on how many kilograms of sand are in a cube, the main proportions of the concrete mixture will be calculated. This point is very important, since an incorrect calculation will lead to disruption of the technology and serious consequences.

Sand is used for a wide range of construction work

Why is it so important to determine how many cubes of sand are in 1 ton

An indicator that reflects how many kilograms are in 1 cubic meter of sand can cause many difficulties if calculated incorrectly:

- violation of the concrete mixture recipe;

- incorrect consistency of the finished solution;

- loss of adhesive properties;

- low quality concrete;

- disturbances in the hardening process;

- reduction in concrete strength;

- premature destruction of a structure made of cement mortar.

For this reason, it is very important to determine not only how much sand is in 1 cube, but also what weight of material is contained in this volume.

When calculating the required number of cubic meters of sand, its specific gravity is taken into account

An indicator that reflects, per 1 cubic meter, how many kg of sand is contained in a specified volume is called specific gravity or specific gravity. This measure, applicable to bulk materials, is in the range of 1500-2800 kg/m?. Accordingly, you can now estimate how many kg of sand are in a cube.

The value of the specific gravity of a material can be influenced by various factors, including:

- composition of minerals;

- grain composition;

- fraction size;

- humidity level;

- compaction percentage;

- impurities.

Compacting paving slabs using wet sand

Sand Density

Today, many are concerned about the cost of a cube of sand, but few people know that the final price is influenced by the characteristics of the material, one of which is density. Sand, like crushed stone, belongs to the category of bulk materials. The level of its density depends on the air layers that form between solid particles.

Sand density is:

- technological;

- real;

- bulk - represents the ratio of the specific gravity of sand to the volume occupied by this material. In this case, the volume includes not only solid sand particles, but also all the pores, as well as voids present in the embankment (taken as the basis for determining how many cubes of sand are in a bag or bucket);

- true or conditional - the value is considered as the limit of the ratio of the specific gravity of the material to the volume it occupies minus all the pores and voids present in the embankment.

The density of sand varies between 1.3-1.8 t/m?, and is equal to 1.3 t/m? for river sand, and 1.4 t/m? - for career.

The density of construction sand is from 1.3 to 1.8 tons per 1 cubic meter

Sand fraction size

How many cubes of material are in a bag of sand can be determined taking into account its grain composition. To do this, it is enough to sift the grains of sand using special sieves. As a result, you will be able to determine the level of gravel particles in the material that have certain dimensional data. Typically, the calculations use the particle size modulus of the material.

Table 1. Sand fineness modulus:

| Material type | Size of material fractions, mm |

| Small | 1,5-2 |

| Average | 2-2,5 |

| Large | more than 2.5 |

If you have fractions larger than 2.5 mm in size, most likely you are dealing with quarry or river sand; how much a cube of material weighs in this case will depend on water demand.

According to particle size, the material is divided into 2 classes:

- I – more than 1.5 mm;

- II – with any dimensional data.

The class of material and the size of its fractions determine how much 1 cubic meter of sand costs for construction work.

There are three sizes of sand fractions - fine, medium and coarse

Volumetric weight of construction sand in kg/m3

In some cases, when it is not possible to weigh the sand, its volumetric weight is determined - how many kilograms of sand are in a predetermined volume. The value of volumetric weight is variable, since its value is influenced by the following parameters:

- humidity;

- specific gravity;

- density.

Therefore, the volumetric weight of sand in 1 m3 is most often determined from tables in reference books or using an online calculator. An incorrectly determined weight of m3 of sand can lead to deterioration in the quality of concrete and cement-sand mortar, to a decrease in their strength and even to premature destruction of manufactured structures.

Volumetric weight of dry quartz sand according to GOST

The volumetric weight of sand in 1 m3 is somewhere between 1500 and 2800 kilograms.

At the stage of use for work purposes, specialists should be interested in:

- specific gravity and volumetric weight of construction sand kg m3;

- particle strength;

- characteristics of its surface;

- grain size or particle shape;

- possible durability of the material, the mineral composition is also taken into account;

- expansion coefficient of volumetric as well as linear type;

- strength;

- how much the particles are worn;

- filtration coefficient;

- compaction coefficient.

When designing the composition of a building mixture, it is worth knowing:

- specific gravity of sand and volumetric bulk parameters of sand;

- the presence of voids and the ability to accumulate moisture.

The specific gravity of sand kg m3 or specific mass indicators is an indicator that can be placed on a volumetric scale.

It is determined by the ratio of the material mass in dry form and the volumes that are handled.

In almost all calculations for sand, only volumes of 1 cubic meter are used.

Buy sand from our company

All technical characteristics meet the requirements of GOST 8736 of 2014 and upon sale are accompanied by a certificate of conformity, which must indicate the specific gravity of sand. Call and pick up high-quality construction sand.

Without sand, any modern construction will be incomplete.

It is used to mix mortar, to create bars from baked clay, building mixture, to create thick lime mortar, and also glass. This material is extracted in several ways: by washing and sifting. It is characterized by its physical and chemical parameters. For example, few people know that the basis of the bulk density of the building material in question is even its uncompacted mass in kg during transportation in bags. It can be different (the material was transported in bulk in the back of a dump truck or in bags).

Distinctive features of dry construction sand

Sand mixture can be divided into several types:

- the one that was mined in ;

- the one that was mined from the river bottom

.

A distinctive indicator of excellent quality is the degree of density of construction sand kg m3. An important role for density is played by the material’s ability to accumulate moisture and its porosity. The density of sand will differ from the density of construction sand.

If a person is interested in the one-time construction of a house, which may not be calculated separately, it is necessary to pay attention to the average figure, which is accepted as the norm. At the same time, during professional construction, the strength of the constructed structure depends on this number.

Density determines the total amount of sand. The density of construction sand is 1.3-1.8 t/m3. This indicator varies so much due to the addition of clay impurities (the more there are, the higher the number will be).

The resulting value will help you find out the quality of the grain composition, for example:

- the material that was extracted from the river bottom will have a moderate density of 1.3 t/m3; Its mineral composition is based on geographical location. In any case, this material is considered to be of very high quality; as a rule, it does not contain any impurities;

- for material mined in quarries, this figure reaches 1.4 t/m3; it contains some clay impurities;

- This is the reason that the material is rarely used to prepare high-quality mortar; but it is used to make the solution more affordable.

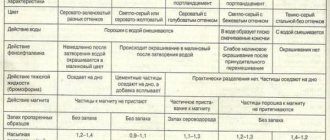

Bulk density values for different types of sand

Sand mined in different places has different structure, composition and particle size. In order to correctly calculate the number of components in different mixtures or concrete, it is necessary to take into account the bulk density of sand of one type or another.

| View | Extraction method | Dry density (bulk) | |

| g/cm 3 | kg/m 3 | ||

| River | Mined from the bottom of the river | 1,5–1,52 | 1500–1520 |

| River with grain size 1.6–1.8 | 1,5 | 1500 | |

| River compacted | Washed, without clay fractions | 1,59 | 1590 |

| River alluvium | Extracted from the river bottom using the alluvial method | 1,65 | 1650 |

| Career | From quarries, alluvial | 1,50 | 1500 |

| Quarry, fine grain | Seeded, dry | 1,7–1,8 | 1700–1800 |

| Building | Complies with GOST 8736-93. Mined during mining | 1,68 | 1680 |

| Loose | 1,44 | 1440 | |

| Quartz | Obtained by crushing white quartz | 1,4–1,9 | 1400–1900 |

| Nautical | Drawn from the bottom of the sea | 1,62 | 1,62 |

| Ovrazhny | Open-pit mined may contain many impurities | 1,4 | 1400 |

| gravelly | Mixed with gravel | 1,7–1,9 | 1700–1900 |

| Perlite | Obtained from expanded rocks | 0,075–0,4 | 75–400 |

| Slag | Obtained as a result of crushing sieving metallurgical waste | 0,7–1,2 | 700–1200 |

The indicated values are valid for dry raw materials, so when calculating, you will need to take into account the actual condition and use compaction factors. If they are neglected, excessive consumption will occur, and the composition of the mortar or concrete will be changed, which can reduce the strength of the pouring or connection of building structures.

Density is a physical quantity characterized by a certain amount of substance, expressed in grams or kilograms, per unit volume. This indicator, characteristic of bulk substances, including sand, cannot be determined unambiguously. This is due to the fact that the volume in which the same amount can fit may be different. The indicator is influenced by several factors, including:

- degree of compaction;

- humidity percentage;

- faction structure;

- porosity;

- the presence of all kinds of inclusions.

How to calculate the amount of sand in kg using the density of sand GOST 8736

This method is quite simple, but only provides preliminary calculations, so always check the results mathematically.

The radiometric method is also no less popular. It is based on the use of radioactive radiation.

Based on how a material can absorb and scatter radiation, this parameter is assessed.

Average additional sand indicators

, which is extracted from quarries:

- first class radioactivity;

- density in uncompacted state – 1.4 t/m3;

- mass of particles per unit volume – 2.6 g/cm3

; - crushed rock content – 1.9%;

Average additional features

, which is mined from the river bottom:

- the ability of atoms of some isotopes to spontaneously decay, emitting radiation A (47 BC/kg);

- density in an uncompacted state – 1.4±0.1 t/m3;

- the amount of chemical elements

transferred into the composition of the alloy during its production as a technological additive is 0.1%.

The number of voids should be determined by the density of the material in the uncompacted state. On your own, this value can be measured in this way: a little sample material is poured into a measuring liter container and weighed.

If the material has accumulated moisture very strongly, then the sample can be placed in a ten-liter container, then the values are converted to the required value.

If there are clay impurities, this negatively affects the quality of the material.

From sand, which contains a high percentage of clay, it is prohibited to make high-quality building mixtures, various for construction.

All this is due to low frost resistance and strength.

True Sand Density

The concept of this term differs significantly from the previous one.

The true density of sand is the density of the monolith that crumbled into sand over time, or that was crushed into grains of sand in a crushing plant. Sometimes true density is called without taking into account the air gaps between grains of sand.

The true density is always higher than the bulk density. If the average bulk density of sand is considered to be 1500-1600 kg/m³, then the true density of this material will be between 2000 kg/m³ and 3000 kg/m³. The average value in the industry is conventionally considered to be the true density of sand at 2500 kg/m³.

True sand density values are used in the design of critical hydraulic structures, skyscrapers and other complex concrete structures. In many cases, the functional characteristics of strength, thermal conductivity, sound insulation, and deformability of buildings depend on it.

The determination of sand density - bulk and true - is carried out by laboratory methods in accordance with GOST 8735. At sites, balloon density meters are used for these purposes.

Sand density is an important technical characteristic of the material that must be well understood in order to be used skillfully.

If you plan to build a house, then after creating the project, the issue of purchasing materials comes to the fore. To calculate how much sand to buy to mix the required volume of masonry mortar or concrete mixture, you need to know the density of the bulk component. This indicator significantly affects the strength parameters of structures and buildings. The conversion of mass to volume (and vice versa) is also carried out because the price of the material is indicated differently: per weight or volume unit.

What is density and what does it depend on?

This is a physical characteristic of a substance, showing the mass of its unit volume and expressed in g/cm3, kg/m3, t/m3. Sand, like all bulk materials, has this peculiarity: depending on conditions, the same amount of it can occupy a different volume. The density of construction sand is influenced by the following factors.

1. Grain size (fineness modulus). Sand is a mixture of particles ranging in size from 0.14 to 5 mm, formed naturally during the destruction of rocks. The smaller the grain size and the more uniform the composition, the denser the sand. Coarse- and medium-grained material is used for the production of concrete, fine-grained - for cement mortars, fine-grained (pulverized) - for fine construction mixtures.

2. Porosity and level of compaction. They characterize the number of voids in the granular substance. In a loose state, construction sand has a porosity of about 47%, in a dense state - no more than 37%. Looseness is reduced due to saturation with moisture, vibration, and dynamic influences. Porosity is assessed using a special coefficient e: for fine-grained sands of dense composition it is about 0.75, for coarse and medium-grained sands it is 0.55. The compacted sand mass takes on fairly high loads and well distributes the stress that occurs in the foundations.

3. Humidity. Typically, reference books provide density at normal humidity levels, regulated by GOST. When purchasing, you should take into account that the weight of a cubic unit of raw material differs significantly from the theoretical indicator. When humidity increases from 3 to 10%, sand grains are enveloped in water - due to this, the volume increases and the density, accordingly, decreases. With further moisture saturation (up to 20%), water displaces air and fills the voids between the grains - while the weight of the cubic meter increases.

4. Presence of impurities. Sometimes they contain particles of clay, dust, salt, mica, gypsum, humus, crushed stone, and stone chips. They affect the quality characteristics of the building material: if for clean sand it averages 1,300 kg/m3, then for clay sand it is 1,800 kg/m3. Sand can be cleaned by washing with water, but its cost increases.

Types of density

Construction sand can be characterized using different indicators of its volumetric weight: theoretical and actual.

1. True (formerly called specific gravity). This is the mass of a cubic meter in an absolutely compacted state, without taking into account the air spaces between the particles. The true indicator is determined in a complex laboratory way; its value corresponds to the weight of a cubic meter of solid non-metallic sand rock - approximately 2500 kg/m3.

2. Medium (bulk). When determining it, it is taken into account that the calculated volume includes not only grains, but pores and voids that fill the spaces between them. The average is usually lower than the true value.

To independently determine the average density, use a 10 liter bucket. Sand is poured into it from a height of 10 meters until a slide is formed - it is carefully cut horizontally at the level of the top edge of the bucket. The material placed in the container is weighed, and then its density in kg/m3 is calculated: divide the mass in kg by 0.01 (the volume of the bucket in cubic meters).

The true value is a constant value and has an auxiliary value. In order to competently conduct construction, make practical calculations and evaluate the quality of the purchased material, it is more important to know the average indicator. For example, if a cubic meter weighs less than 1300 kg, this indicates a large number of voids and requires filling them with a binder. The cost of materials increases, making construction more expensive.

Density of different types

The approximate bulk (average) density values indicated in the table will help you purchase sand with the required parameters, quickly move from weight to volume, and calculate the weight fractions of the mortar.

Without sand, the construction industry will simply stop. It is required for mixing mortar, installing drainage, making bricks, concrete, plaster, and glass. It is mined in three ways: washing, sifting, and the open method. It has physical parameters. For example, the bulk density of construction sand affects the amount of sand that is not compacted during delivery in bags or in bulk in the back of a dump truck.

How to determine density - true and bulk

It is necessary to understand that the true density of construction sand differs from bulk sand.

The first value consists of the indicators of the material in dry form, the density being based on the specific sand that is used during construction work.

These are extremely necessary indicators, for example, to dose building material before mixing concrete.

Density, as previously written, is based on the moisture content of the building material. So, if the sand has accumulated ten percent moisture, lumps appear in it, which causes voids to appear.

Despite the visual increase in the material (its volumes seem larger), the density becomes lower, that is, to knead, you need to take more material. With higher humidity, water will begin to displace air bubbles between the grains, as a result the sand will become denser.

When the density of a material in an uncompacted state is calculated, this makes it possible to understand and imagine its future volumes in cubic meters, which will depend on the mass.

By making accurate calculations, you can find out exactly how much material you need to order for a specific construction. And this indicator does not depend on how the cost of the product is determined: per cubic meter or per tonnage.

For more information on determining density, watch the video:

Density of the material in an uncompacted state - significance from the technological and commercial side

Mass in construction practice is the ratio of mass to volume that a material occupies in a compacted or non-compacted state. This number is especially significant from the economic and technological side.

To make a concrete mixture or mortar to create a sand cushion, it is necessary to use a material with known characteristics.

From an economic point of view, it is advisable to calculate several basic criteria - weight per volume unit and density under individual conditions.

Determining the density of sand is important from the point of view of the ratio of its mass and the actual volume occupied. From an economic point of view, density affects the money that the customer is willing to spend - he must purchase usable material of sufficient volume.

To do this, it is advisable to establish the number of particles in a volumetric unit without compactions and take into account humidity indicators, which significantly affect the weight.

Determination of the density of a material in an uncompacted state in accordance with GOST should be carried out according to a standard procedure.

The required amount of material is taken, the specified ability to accumulate moisture is taken into account, sent to a measuring container and weighed repeatedly.

The value of measuring the density of river sand in an uncompacted state

Why is it so important to determine this indicator before future construction of real estate? It is he who is able to display the real amount of materials in a single volume - a cubic meter. Thanks to it, it is possible to use the material in terms of the ratio of resources expended and functionality.

The building material discussed in the article is subject to the standards of a separate GOST 8735-88

, and this indicates:

- material with such indicators is fully compliant with construction technologies;

- the properties of the material

during work and after the construction of the house are quite predictable; - the method for determining the mass of a material per unit volume has been tested and approved as a reference, allowing one to obtain a long-awaited and truthful result;

- During the material verification stage, only approved methods and technical recommendations were used.

You must remember that when purchasing sand, its bulk density will be 1600 kg/m3, which fully meets construction standards. In addition, this material can be stored for a long time, it does not accumulate moisture, and lumps and voids do not form in it over time.

Excessive indicators of the mass of sand per unit volume at high humidity indicate a decrease in its characteristics; it can only be used in limited areas. An increase in humidity causes a decrease in the percentage of quality.

This indicator is critically important for many non-metallic elements. To clarify this indicator in a specific batch of material, the manufacturer uses correction values. Such numbers make it possible to determine values from the technological and economic side.

When purchasing a large batch, the coefficient allows you to level out deviations

, which is caused by the dispersion of indicators. For example, at the stage of purchasing ten tons of material, the amendment will allow you to determine the amount of material up to 2 tons per batch.