Processes occurring in glue

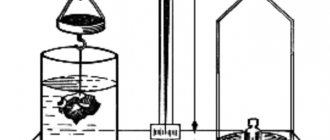

A working solution of tile adhesive is prepared from a dry mixture and water.

Glue powder is added to water in the proportion indicated on the package and mixed. It is also important to follow the mixing instructions given in the instructions for use of the adhesive. Chemical processes in the glue begin immediately after adding water, so the solution should be used within about two hours. After this period, the properties of the glue deteriorate. After the tiles are glued, the adhesive begins to harden and dry. These are different processes. Part of the water contained in the solution chemically binds to the cement, which as a result hardens; some evaporates.

The speed of these processes varies and depends on temperature and humidity. As the temperature rises, the processes accelerate. When air humidity decreases, the glue dries faster. At high temperatures and low humidity, water from the glue can evaporate so quickly that there will not be enough of it for normal hardening - the glue will not gain the required strength and the tile will fall off ahead of time.

It is believed that at normal temperature and humidity, tile adhesive gains nominal strength (the one indicated in the technical specifications) in 14 days.

When can you lay tiles after pouring a heated floor screed?

Those who do the repairs themselves are interested in the question: how many days after installing the screed can the tiles be laid? This interest is due to the desire to quickly lay the tiles and get pleasure from the new floor. But if you lay the tiles on a freshly completed screed, this will lead to the new floor covering gradually deteriorating.

To get a good result, after pouring the screed, you should let it dry completely, and only then start laying tiles and other floor coverings. And if you look in more detail, the hardening time of the mortar for installing tiles depends on a number of factors, which we will talk about below.

Before talking about the hardening time of the screed, you should first find out what materials it is made from. Construction mixtures can be of two types: gypsum and cement. Construction gypsum mixtures have the shortest drying time. But in practice, when calculating the drying time of the floor screed and deciding when to lay tiles on it, professional builders advise resorting to a special formula.

For gypsum and cement-based mixtures, if the layer thickness is up to 40 mm, the drying time is calculated as follows: for each 10 mm layer you need to wait seven days. Therefore, if the layer thickness is 30 mm, then its drying time lasts twenty-one days.

Screed for laying tiles

The drying of floor screed under tiles is influenced by the following factors:

- The degree of moisture content of the laid construction mixture.

- An indicator of indoor air humidity.

- Thickness of the laid mixture. The thicker the screed layer, the longer it will take to dry.

- Presence of chemical additives in the solution.

- Ambient temperature indicator.

In the case when the layer of the laid screed is 40 mm, it will dry for 28 days. If a thicker layer of mortar is laid, then the drying time will increase. With a layer of 60 mm, the tiled floor can only be laid after two months. Such a long period of drying time is required for moisture to come out of the lower layers of the damp solution through the upper ones, which have already dried.

These drying times are valid at average air humidity levels of 60-70% and temperatures within 20-25 degrees. But these indicators are difficult to maintain, because in a room with a large drying surface area of the base, the humidity level will be much higher than usual.

Attention! When drying the building mixture, under no circumstances should you allow drafts in the room, this will negatively affect the quality and lead to cracking. To prevent this from happening, the screed is moistened with water from time to time.

Drafts in the room negatively affect the laid mixture, cracks form on its surface

When the building mixture dries, the top layer hardens first, but moisture remains in the lower ones, which gradually comes out of them, saturating the already dried layers. Many people do not want to wait long for the moisture to evaporate from the screed and create suitable conditions for this, but this step leads to cracking of the surface. And this is additional labor costs, because before laying the tiles, the screed will have to be grouted and sanded. This can be avoided by waiting enough time for the mixture to harden naturally.

Cracking of the surface can also occur if it is exposed to high temperatures. Therefore, from time to time the surface needs to be watered. If this is not done, then even a temperature of 20-23 degrees can lead to cracking of the screed. If you need to reduce the waiting time for the poured mixture to dry, in this case you can expose it to high temperatures, but do not forget to constantly water it.

Water the screed from time to time to prevent cracking.

If you ask the question of how long it takes to lay tiles on a screed, then the opinions of professionals differ. Some argue that it is better to lay the tiles seven days after the base is made, because this time is enough for 80% of the moisture to evaporate from it, and tiling work can take several days. While the tiles are being laid on a semi-dry screed, the remaining moisture will have time to evaporate.

Laying tiles on the screed is done after drying

If you decide to lay tiles on a screed, but do not know how such work is performed, then watch the video presented here, which shows in detail the process of tiling. But if you are not sure that you can do such work yourself, then it is better to immediately seek help from professionals; they will complete all the work competently and quickly. Of course, their services are not cheap, but the result will certainly please you.

When can tiles be laid on a screed? This question interests almost everyone who is independently renovating their home.

The emerging interest can be explained by the desire to quickly complete construction and finishing work and enjoy the created individual solution that the finished premises will accept.

However, if the tiles are laid on a fresh screed, this can lead to a gradual destruction of the integrity of the floors.

Before talking about how many days after pouring the screed you can lay the tiles, you need to know that the period directly depends on the type of base.

Its installation is carried out immediately after the base has been cleaned, the nature of the unevenness has been determined and the beacons have been installed. Only after this work can you decide on the method of leveling the surface on which the tiles are laid.

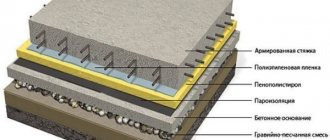

The simplest and fastest method is dry screed. To complete this, you need to waterproof the base; for this, polyethylene is used, the seams of which are glued together with tape.

The overlap of adjacent strips on each other should be at least 20 cm. An overlap of 15 cm is made on the walls, which can be cut off after laying the tiles. The following materials can be used for manufacturing:

However, despite the simplicity and ease of installation, it should be taken into account that tiles can only be laid on such a screed after 1.5 - 2 weeks. Installing tiles before this time will lead to poor adhesion, peeling or cracking of the base along with the top decorative layer.

The classic type of screed pouring using a cement-sand mixture mixed with the addition of a large amount of water has been known for a long time and is considered the classic method of leveling the base.

During installation, it must be taken into account that the thickness of the layer must be at least 4 cm, otherwise there is a possibility that under load the layer may be pressed through along with the tile.

It is advisable to start laying tiles no earlier than after 3 weeks

Despite the fact that many craftsmen lay tiles 2–3 days after pouring, this technology is considered incorrect. Complete drying will require a much longer period of time, so installing tiles on such a base is not allowed even for 10 days.

The optimal drying period for a layer of cement-sand mixture 5 cm thick is considered to be a three-week period. It is after this exposure that the tiles can be laid. Although the composition gains maximum strength only on the 28th day.

The exact amount of time depends on the thickness of the layer and the amount of water added to the solution, so a lot of liquid to facilitate stirring in this situation is not always positive. Especially if you need to do the installation as quickly as possible.

Installing tiles on a base that is not completely hardened, which some people practice, explaining their effect by better adhesion, is erroneous.

In fact, tile adhesive and cement-sand mixture are different in chemical composition, so they practically do not interact with each other. Thus, tiles laid on such a base can be peeled off without much effort. To learn how not to lay tiles, watch this useful video:

The concept of self-leveling flooring appeared in Russia not so long ago. However, the technology has already proven itself on the positive side and is widely used in interior decoration. There are several varieties united by one term. In our case, “self-leveling floor” means pouring screed for laying tiles and tiles.

After complete drying, the base turns into a perfectly flat and durable surface, free from flaws in the form of cracks, chips and potholes. Thus, the use of self-leveling mixtures is the most popular method of preparing floors for tiles.

If we touch upon the main question of interest to us, after how many days can tiles be laid, then everything depends on the characteristics of the chemical composition of the mixture used.

On average, exposure is allowed for 3 days, but exact information can be found on the back of the package, which indicates the proportions of adding water, application conditions and drying period.

The uniqueness of this method is that there is no need to use beacons. The liquid composition itself is distributed over the area in a strictly horizontal position.

It is better not to rush when laying tiles on the screed

The owner decides which base leveling option will be chosen for a particular room. This depends on several factors: the drying period of the composition and the possibility of laying tiles.

In addition, it should be emphasized that the cost of self-leveling mixtures significantly exceeds the price of cement-sand screed. However, the latter wins in terms of characteristics, timing and ease of filling.

How long does it take for tile adhesive to dry on a wall?

Work on wall cladding with ceramic tiles can be carried out without special pauses for drying the glue. The strength of the adhesive within a few hours after laying the tiles is sufficient to support its weight. You can perform the work in the following order:

- On the first day, do only laying tiles.

- The next day, you should remove all the “crosses” (distance inserts) and clear the tile seams from any glue that has accidentally come out. At this time, the glue has hardened slightly, so it is easy to remove without damaging the tile. The seams can be grouted on the same day.

- After another day, you can finally wash the tile surface.

- You can drill the tiles after the glue has gained full strength, that is, after 14 days.

Factors affecting the drying rate of concrete

Leveling concrete screeds are decorated with linoleum, tongue and groove boards, cork, PVC tiles, laminate and other cladding using various technologies.

Therefore, if there is a ventilated gap between them and the concrete screed, it is enough to wait for 75% of the strength gain of the structural material. After which, the concrete will dry under them without any problems on its own.

However, for claddings glued to the screed (tiles, linoleum, porcelain stoneware), the moisture content of the base becomes very critical for the service life and adhesion strength of these decors.

The main factors that influence the drying time of the screed are:

- temperature;

- layer thickness;

- screed design;

- concrete composition;

- screed technology.

Before laying cladding in wet rooms, the surface of the screed is covered with a continuous layer of waterproofing material, which also makes it difficult for the concrete to dry out.

Layer thickness

The regulation SP 29.13330 specifies a screed thickness of at least 30 mm. This is due to factors:

- the structure is cut off from the walls by damper tape, from the floor slab by sound insulation, insulation and waterproofing, resulting in a floating type;

- operational loads (weight of furniture, movement of residents) are transmitted through it to the base, so it is possible for the screed to chip in areas thinner than the specified value.

However, with significant differences in the heights of the floor slabs or their uneven surface, the thickness of the screed can increase to 8 - 15 cm. In this case, thin and thick screeds dry differently:

- with a thickness of 3 – 4 cm – the accepted value is 1 cm/week;

- for a layer of 4 – 7 cm – the calculated value must be doubled (1 cm/2 weeks)

| Thickness(cm) | Drying time (days) |

| 3 | 21 |

| 4 | 28 |

| 5 | 56 |

| 6 | 84 |

| 7 | 98 |

| 8 | 112 |

| 9 | 126 |

| 10 | 140 |

In other words, a thin 40 cm layer of sand concrete can be tiled after a month (28 days), a 7 cm layer - no earlier than 84 days, and an 80 mm screed can be decorated with linoleum on the 113th day.

A more accurate method for determining the dryness of a screed is to measure the humidity using available materials:

- a napkin is placed on the surface of the concrete;

- covered with plastic film;

- the edges are sealed with tape.

A day after gluing, the napkin should be dry under the polyethylene (determined visually or by touch).

Screed design

The design must also be taken into account:

- Insulation materials and insulation materials are often placed inside the screed;

- moisture evaporates in all directions, so it can penetrate into these layers.

Therefore, you need to add another week for the water to evaporate from these materials.

The warm water floor circuits embedded in the screed can be turned on for the 15th day at a temperature of +20 degrees. That is, by analogy with the drying time of concrete for facing work.

How long does it take for tile adhesive to dry on the floor?

Modern types of tile adhesive allow you to walk on the tiles the very next day after laying. However, you should start “trampling” (intensive walking) no earlier than 48 hours after installation.

- On the first day, lay the tiles on the floor.

- Let the glue harden for two days and only then continue work: clean the seams, remove any remaining glue from the surface of the tile, fill the gaps between the tiles with grout.

- The next day, you can finally clean the tile surface from any grout residue.

List of factors on which the drying speed of tiles depends

Almost all tile adhesive manufacturers mark their packaging with the recommended drying time for the adhesive solution. Since the time is only recommended, this means that how long it takes for tile adhesive to dry on the floor is relative information, and you can only rely on it if the tiles are laid in ideal conditions.

Typically, these conditions include a room temperature of 20 to 24 ° C, with air humidity less than 60%. Not everyone can create such conditions at the time of repair work. In this regard, the ideal glue drying time of 24 hours should often not be taken into account as a benchmark. Moreover, each glue has a different drying time due to its characteristics. Therefore, it is especially important to consider how long it takes for floor tiles to dry, because it is on the floor that they experience the greatest loads and are often subject to mechanical damage. Factors that determine how long it takes for floor tiles to dry should be considered below: Room temperature and time of year. The most important thing when laying tiles is to focus on the temperature in the room; therefore, as the temperature increases, the glue needs less and less time to dry. It should be taken into account that this temperature should be natural; the room should not be heated while laying the tiles. That is, in the summer the drying period will be much shorter than in the winter. In winter, there is a high probability that the glue may not harden due to frost, but freeze. Based on this, drying periods for tiles have been determined: in summer or when it’s warm outside - this is 24-36 hours; in cold weather - at least 12 hours can be added to these values. Floor temperature. Quite often the room warms up under the sun's rays, but the floor still remains cold. In this case, you should not overheat it; you can only slightly reduce the temperature difference, because if the base is frozen, tiles cannot be laid on it. In order to be able to lay tiles without negative consequences, the floor temperature must be at least +5 °C, while +20 °C is optimal. Naturally, the colder the floor, the more time the glue needs to dry completely. Room air humidity. It is considered one of the most important factors influencing how long it takes for floor tiles to dry after installation. In this case, the opposite is true: the higher the humidity, the longer the tile adhesive takes to set. It follows that in the kitchen the glue will harden faster than in the bathroom, and this difference can vary within 12-24 hours depending on the humidity level.

In rooms where excessive humidity is constantly maintained, the maximum strength of the adhesive solution can be achieved only after one week.

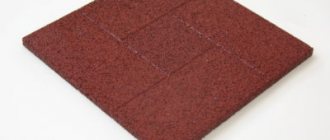

Warm floors lined with ceramic tiles

When a heated floor operates, the tile covering and base (screed) heat up and expand, which causes additional thermal stresses to arise.

When installing a screed under a heated floor, you need to take your time and carefully follow the technology. Any deviation from it leads to a decrease in strength: excess water, contamination (for example, clay admixture in sand), non-compliance with the recommended mixing regime. The cement screed must be done long before installing the heated floor and laying the tiles - it must gain sufficient strength and dry out.

The tiles must be laid with tile adhesive specifically designed for heated floors. The first activation of the heated floor is possible only after the screed and tile adhesive have reached their nominal strength - no earlier than 14 days after laying the tiles.

Why wait until the glue is completely dry?

There is an opinion that even before the glue has completely dried, you can already walk on the tiles and even grout the joints. And many builders do just that. But true repair professionals categorically do not recommend doing this. Firstly, because there is a high probability of moving the “masonry”: even if the mortar has “set”, but has not yet had time to gain maximum strength, the tiles can move under pressure. Secondly, there is a risk of damaging the tile itself, especially in places where the adhesive composition is insufficiently applied (although according to technology, of course, the thickness of the tile adhesive layer should be the same over the entire area).

How long does it take for tiles to dry in rooms with unfavorable conditions?

Unfavorable conditions include low temperature and high humidity. If the room is cold, the tiles take a long time to dry. This process can take forever. In this case, the quality of the connection deteriorates significantly.

At temperatures below 5 degrees, the liquid in the adhesive mixture begins to freeze. This will allow the glue to simply harden but not dry out. With such a deviation from the norm, even quick-drying mixtures will not help.

What to do at low indoor temperatures:

- Even after a day or more, you cannot move on the tiled surface. Otherwise, the tiles will begin to crack and deteriorate. The liquid, which turns into ice, will begin to expand and deform the tile.

- Before installation, the glue must be heated to the required temperature. You should also heat the floor, not the air in the room. Heat guns are provided for this purpose.

- After achieving the desired parameters, it is necessary to strictly maintain the optimal temperature.

If such conditions are provided, the tile will harden after a couple of days. But another important problem is high humidity. If this indicator is elevated, then you can try to lower it by heating the room.

If the floor tiles are completely covered with water, you will have to remove the tiles and lay a new one.

But before the new tiles are installed, the surface must be allowed to dry. It is worth considering that the glue quickly absorbs liquid. Even after drying, it can deform the tiles.