Solid minerals, building materials, chemical raw materials, abrasive materials, solid secondary raw materials, and some types of plant materials are subjected to crushing. Among all types of raw materials that undergo crushing, ores of ferrous and non-ferrous metals and non-metallic minerals (coal, granites, limestones) dominate. According to a rough estimate, 2.5 - 3 billion tons of solid raw materials are crushed annually in the world.

Obviously, it is necessary to crush solid raw materials to obtain pieces of smaller size from it compared to the original material, since initially this material, for example, ore mined in a quarry, can be very large - with pieces up to 1-1.5 m in size.

Crushing operations, as a rule, are used in conjunction with the processes of classification by size (screening) of solid raw materials.

Crushing operations, like other disintegration methods, are used mainly to solve the following problems:

- To consistently reduce the size of minerals to sizes of 3-15 mm before operations of fine grinding and beneficiation of minerals.

- To obtain raw materials of the size required by direct consumers, for example, in the production of building crushed stone, abrasive materials, as well as in the preparation of solid fuels and metallurgical charge components.

- To prepare solid industrial and household waste for deep processing operations into secondary products.

- The crushing process is carried out using special machines - crushers. Material is destroyed in crushers as a result of the application of compression, shear, impact, or a combination of these forces.

Crushing reinforced concrete: features of construction waste disposal

In this article we will talk about the purpose and how crushing of reinforced concrete is carried out. In addition, we will consider what technologies and what equipment are used to carry out this work.

It’s probably no secret to anyone that at least half of the modern domestic housing stock was built in the 60-70s of the last century.

Like any structures, buildings have their own operational life. As a result, construction sites are demolished and new buildings are erected in their place.

Production of recycled crushed stone directly on the construction site

Important: Each demolished object, to one degree or another, consists of reinforced concrete, which must be effectively recycled.

And, if recycling bricks and ordinary concrete is not difficult, then recycling concrete products requires a special approach.

Features of recycling of reinforced concrete structures and products

Bulky construction waste resulting from the destruction of residential or industrial facilities poses a serious problem for many construction organizations.

Meanwhile, competently organized and effectively carried out recycling of reinforced concrete allows not only to solve this problem, but also to obtain an appropriate amount of secondary building materials.

Recycled building materials can be used as a cheap alternative to new, more expensive materials, and this advantage can significantly reduce the cost of subsequent construction.

Scope of application of recycled concrete

In the photo - cheap building material obtained by crushing reinforced concrete products

As already mentioned, recycling used building materials allows you to obtain fundamentally new materials, the price of which is affordable.

If when processing bricks we obtain a type of construction sand, then as a result of processing reinforced concrete products we can obtain secondary crushed stone that complies with GOST 25137-82.

Crushed stone produced in this way is not much inferior to its natural counterpart, and therefore can be used in the following areas:

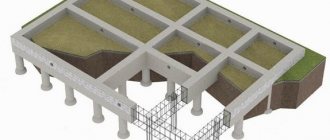

- when arranging the base of the floor and foundation with your own hands;

- in the process of construction and repair of asphalt concrete road surfaces;

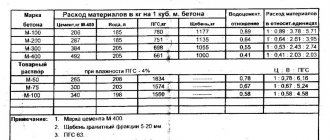

- in the production of mortars as a filler with average strength parameters from 5 to 20 MPa;

- in the manufacture of a wide range of prefabricated concrete products and monolithic structures;

- during the filling of temporary or secondary roads;

- when constructing all types of sidewalk paths;

- during the filling of the base for the construction of asphalt sites;

- during construction as backfill, instead of missing soil;

- when carrying out a wide range of works in landscape architecture.

Equipment for destruction and recycling of concrete products

Technological line using a hydraulic press for recycling concrete products

Dismantling of reinforced concrete and its subsequent recycling is carried out using specialized equipment - crushing and screening complexes or technological lines. Crushing and screening lines are, as a rule, stationary equipment, while complexes can be mobile.

The difference between waste processing on stationary and mobile equipment is significant. In the first case, you will need to load substandard concrete products onto a vehicle and take them to a special plant.

But upon completion of processing, the resulting recycled crushed stone will once again need to be loaded onto a vehicle and now delivered to the construction site where the processed waste will be used as building material.

In the photo - a mobile complex for processing construction waste

It is much more profitable to use a mobile complex, since this installation for recycling reinforced concrete can be used directly on the construction site.

The fact is that where a building has been demolished, there will always be new construction, which will most likely require crushed stone.

As a result, we have a unique opportunity to save money and time by eliminating the transportation of waste and recycled materials.

What is a crusher?

The dismantling of construction waste, its reception and subsequent processing is carried out using a special crushing machine. When reinforced concrete products are processed, the metal frame elements must first be selected from the structures. An excavator with attachments is used for this. Next, a crushing plant is directly used for the primary crushing of concrete debris.

Recycling bricks and plain concrete is not a difficult task. Processing reinforced concrete structures requires the use of special equipment.

Equipment for crushing monolithic products comes in two types:

Lines are usually not transported, but installed permanently.

- Line for crushing and sorting construction waste. A specialized modular enterprise, the main elements of which are a mechanical crusher and a screening line. The production is highly productive and large-sized, it is always located permanently. Therefore, processing scrap concrete using this method is associated with high transportation costs: Waste is loaded from the dismantling site onto vehicles.

- Recycled material is delivered to the enterprise and processed into recycled concrete.

- The finished product is shipped and transported back to the construction site for use.

Crusher for dimensional concrete products | Crushing and screening complex | MPR

The basis of the product line for processing reinforced concrete products (RCP) and large construction waste is the MPR-1500 press-destructive machine.

MPR-1500 is a primary crushing device.

The technical parameters of the installation are such that it is capable of crushing large pieces without primary cutting. The MPR-1500 feeds large-sized concrete products up to 12 meters in length and up to 1.5 meters in width for crushing.

The machine crushes concrete and removes iron reinforcement at the same time.

Technical characteristics of MPR-1500

- Productivity: - 35 m3/hour (when processing fragments of brick buildings) - 20 m3/hour (when processing reinforced concrete products).

- The maximum dimensions of the processed material are up to 12000 mm * 1500 mm * 600 mm;

- At the request of the customer, special a product with increased dimensions of the processed material;

- Overall dimensions of the machine 17925 mm * 6325 mm * 4370 mm;

- Electric motor power 32 kW;

- Weight 34 tons.

- Hydraulic press power 1600 kN;

processing of reinforced concrete piles using a press-destructive machine MPR-1500

Multifunctional crushing and screening complexes

On the basis of the MPR-1500 installation, automated crushing and screening complexes of various configurations are formed.

Having large reinforced concrete products and large brickwork elements at the input, the output can be:

- secondary crushed stone, fractions 5-10, 10-20, 20-40, 40-70 mm

- secondary fractional sand: 0.16-5 mm

- stone flour: Ssp = 2800-3500 cm2/g.

The productivity of such crushing and screening complexes, depending on the configuration and nature of the processed raw materials, will be 40-120 tons/hour.

Processing stages

with a multifunctional complex and a process for processing concrete products in Angarsk

The stages of processing substandard reinforced concrete scrap, reinforced concrete products and other large construction waste do not depend on the configuration of crushing and screening complexes (CSC).

During the processing process the following occurs:

- Loading bulky material

- Crushing the loaded material in the MPR-1500 press-destructive machine up to 100-200 mm

- Extraction and separation of components. Reinforcement and metal are removed and stored. Stone - transported for crushing into a crusher (the choice depends on the technical specifications)

- Grinding concrete and stone to the required size

- Separation of secondary crushed stone into fractions on a unit with a screen

Equipment for processing reinforced concrete

Construction waste is processed using mobile crushing and screening complexes, which are located on the construction site. This process involves grinding construction waste and separating the secondary crushed stone and metal contained in it. Thanks to the production of crushed stone of various fractions, the range of its reuse is huge.

To use mobile crushing and screening plants, a company must have:

- equipment;

- highly qualified personnel;

- appropriate permit and license to carry out work;

- certificates, conclusions of SES and permits from environmental inspections for recycled crushed stone and related materials.

Large construction companies are provided with all this. The use of mobile crushers increases the speed and efficiency of work. Allows you to reduce the customer's transportation costs for the transportation and disposal of concrete products.

The complexes are mobile due to a diesel engine and a magnetic separator. It separates the metal from the concrete. As a result, mechanical processing of reinforced concrete slabs is: 87% recycled crushed stone, 10% screenings and about 3-4% iron.

Industrial crushers: for crushed stone, concrete, film

The technologies of many industries, especially construction and processing, require the use of materials in the form of particles of a certain size.

An industrial crusher allows you to obtain the desired fraction from any raw material (stone, concrete, coal, wood, rubber, plastic, etc.) in large volumes.

Any crusher is a grinder, the operation of which is based on various principles of force (destructive) influence on the processed material.

Variety of crushers

All crushers are divided according to the size class of the fraction obtained at the output. The main sizes of standard particles include the following parameters:

- from 300 to 100 mm;

- from 100 to 25 mm;

- from 25 to 5 mm.

Industrial stationary crusher

Most industrial devices can produce a full range of output. For this purpose, it is possible to reconfigure the equipment to ultimately obtain a fraction of a specific size.

Crushers can be either stationary or mobile.

Stationary crushers are used in enterprises that constantly work with large quantities of processed raw materials.

Mobile (mobile) only in conditions of processing small stocks in a specific location, followed by relocation to another source.

For the most part, mobile devices have a jaw or cone type of crushing action, since it allows you to change (adjust) the particle size at the outlet.

Therefore, such equipment is considered universal. But, unlike stationary models, the productivity of such mobile systems is much less.

The main purpose of each chopper can be determined by its name:

Industrial roller crusher

In order to crush this or that material to the desired fraction, various types of crushers are used:

- cheek;

- conical;

- rotary;

- roller

For example, crushed stone has a compressive strength of 300 MPa and in order to successfully crush it, you need a powerful machine with exceptionally strong parts.

But there are rocks used in construction whose strength index is from 600 to 1200 MPa, and in such cases not only the power and strength of the device is important, but also the principle of its operation.

Industrial wood chipper (video)

They are universal grinders that can process material of almost any strength.

The principle of operation is based on grinding material between two massive plates, one of which is firmly fixed, and the second is in motion during operation.

The gap between them can be adjusted both at the inlet (up to 1.5 m) and at the outlet (up to 5 mm). Thus, a gradation occurs according to the division of the source material into a fraction of a given size.