If you decide to lay a new floor, but probably many people have a logical question regarding what material to choose for the floor screed and how long it will take for it to dry properly. It’s not so easy to get an answer to your question, because the duration of drying a floor screed depends on many factors: the air temperature in the room, the materials used and the thickness of the layer.

In order to accurately determine the required parameter, it is important to think through the progress of repair work during the period of setting and hardening of the solution, and also to eliminate downtime. Only this approach to work will allow you to avoid defects in floor installation.

One of the factors that affects the drying time is the thickness of the layer being laid. It has already been verified that at normal temperatures and humidity levels, a layer whose thickness is 1-4 mm requires 7 days to dry completely, and each subsequent one requires 4 mm - 14 days. What follows from this? When using a cement-sand mortar embedded in 2 cm, 2 weeks x 1 week is required.

When laying a screed with a thickness of 5 mm, 6 weeks are required 4 cm x 1 week/cm x 2 weeks/cm.

In order to understand the excess moisture in the screed, it is worth using one proven method. It is necessary to prepare a plastic film with dimensions of 1mx1m, cover it with the dry outer film and secure it with tape around the perimeter. After a day, check.

If there are droplets of water on the inner surface of the film, this means that there is a large amount of water in the solution. If its color becomes darker, this indicates that the solution used is not dry enough. When the strength indicators have already been achieved by the required setting time, it is necessary to perform forced drying of the floor.

From sand concrete

When a floor is formed using sand concrete, grade 300 cement is used. It is this composition that is considered the most universal. This material is actively used to produce a solution that can serve as a floor leveler.

To accurately determine the readiness of a screed made of M300 sand concrete, it is necessary to focus on the recommendations for cement compositions. All time parameters are almost the same. You can read about floor screed made of sand and cement.

Drying time for cement bases

Cement screeds are especially popular today. These compounds are used to level subfloors in both small-scale and large-scale construction. That is why most craftsmen are concerned with the question of how long it takes for a cement floor screed to dry.

As a rule, the drying time of the mixture is indicated on its packaging, but it should be remembered that this is only approximate information, and you can more accurately calculate the drying time, again, focusing on the layer of solution. As an example, we use an average thickness of 40 mm.

So, for the final drying of 40 mm of cement screed, 7 full days are needed. For every additional centimeter, it is recommended to add another 14 days. It follows from this that it will take 2-3 months for a screed 8 cm thick to gain maximum strength.

Cement

As a rule, the drying time of the cement screed can be determined on the packaging. However, in addition to this, there are many parameters that influence how quickly a floor made of cement will harden. To calculate the time of full readiness, it is necessary to include in the calculation such parameters as the thickness of the coating layer. The duration of readiness is directly dependent on the atmospheric conditions in the room or outside.

The duration of this process can reach up to a month. In addition, the drying time is influenced by the material used. It is impossible to determine the exact drying time of the cement screed. On average, the hardening process can last 2.5 -3 weeks.

After just a few hours, you can walk on the completed screed without causing any harm. However, it is not recommended to carry out cladding measures in this case. The duration of readiness will depend on the temperature, thickness and type of material. The cement screed sets after 10-12 hours.

Two main stages of hardening

To achieve the declared qualities, it is necessary to maintain the correct proportions when mixing the solution. Only in this case will the desired strength be achieved. About an hour after pouring the mixture, the process of changing its structure begins. This stage is called setting. How long does it take for the cement mortar to harden before further work is continued?

After a day, the mass becomes so strong that you can walk on it. But it is still far from the declared brand strength. This was only the first stage, called grasping. Next, the hardening process begins. After two days, the mixture gains about 50% strength in the warm season.

It is recommended to begin full operational load and operations for the further construction of the next floor no earlier than 28 days, when the concrete strength approaches 90% as stated. Particular importance is attached to time during the construction of load-bearing structures. If possible, it is better to pour strong foundations a year before the start of main construction. During this time, almost all processes of structure change occur. There will be no significant changes to the geometry of the structure. It is difficult to determine the exact time for complete hardening of a particular cement mortar. It can last for years, but after 12 months these changes do not affect the quality of the building.

Currently reading: Aerated concrete lintels

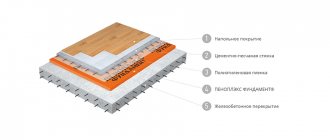

Under laminate

Taking into account all the standards, the surface for installing the laminate should not have differences of more than 3 m by 1 m. If you are performing a wet screed under the laminate, then you must use special mixtures that are capable of self-leveling. Thanks to them, it is possible to facilitate the process of preparing the base. You can also use reinforcing fiberglass mesh for leveling. The floor must be poured in small sections and leveled using a special device.

When the screed has dried, you can proceed to sanding. The screed under the laminate takes about 2 weeks to dry. But here everything depends on the layer being laid. The process of installing the laminate is carried out after it has gained 50% strength.

What types of cement screeds are there?

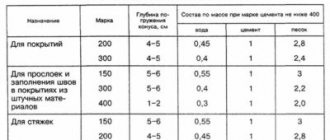

Answer: As a rule, to level the base, a cement-sand screed is used with the addition of water to obtain a moving mixture. Sand and cement are taken in a 3:1 ratio (3 parts sand to 1 part cement), after which a mixture of cement and sand in a 1:1 ratio is mixed with water.

To prepare the mixture, use special construction mixers or a drill with an attachment.

The consistency of the cement mixture should resemble very thick sour cream - it should not disintegrate, but should be quite mobile.

Under tiles

Most often, a cement mixture is used to level the floor under the tiles. You can walk on this floor within the next 24 hours, but here’s what to do with the finishing. Based on the experience of already experienced people, we can say that the process of installing tiles can be carried out the next day. This is completely harmless, although not entirely advisable. If you entrusted the process of performing the work to strangers, then it is very important to check whether reinforcement was done.

The thickness of the screed to be poured must be at least 4.5 cm. If the required thickness cannot be achieved, then the following measures must be taken: lay a plastic mesh with small cells on the screed. It is sold in rolls at any hardware store. After this, be sure to secure it with nails and cover it with a dry adhesive mixture, which will be used when laying the tiles.

The video shows how long it takes for a floor screed to dry:

A screed is a very necessary element to achieve a perfectly flat floor surface. Today there is a wide range of materials from which it can be made. As a result, it is very difficult to accurately determine the drying time of the solution used. In addition, it is worth taking into account factors such as temperature, layer thickness, humidity level and the type of material used. You may also be interested in the disadvantages of dry screed. The link describes it. The advantages of semi-dry floor screed are described. Also read,. To strengthen, they often produce a.

Sand concrete M300 - this mixture, made on the basis of Portland cement, purified river sand and plasticizer additives, provides an excellent base for any floor coverings, good waterproofing and adhesion to the floor slab.

One of the questions that arises among builders after pouring floors is how long it takes M300 sand concrete to dry. In other words, how long after pouring should you not enter the room in which the fresh screed was made?

Rules for pouring floors

First of all, we note that in order to install a high-quality, durable and uniform screed, several important conditions must be met:

- The solution is laid out within 3 hours after diluting the mixture with water onto a base that has been cleared of dust, dirt and foreign objects.

- When diluting, the proportions indicated in the manufacturer’s instructions are observed. It is well known that if there is excess moisture in the solution, this increases the plasticity of the material, but significantly reduces its consumer qualities, including strength and final hardening time.

- Before pouring, the solution is well mixed and brought into a homogeneous state. To do this, on small objects they usually use a drill with a special mixer attachment.

- The room temperature is above +5 degrees Celsius. It is also desirable that the air humidity is not too high. If work is carried out in basements or other damp areas, it is worth adding special water repellents to the solution, which will bind excess moisture.

- When installing and hardening the screed in the room, there are no drafts or significant temperature changes. Window and door openings should be closed during work. You can use a heater or a small heat gun to dry the room without directing a stream of hot air directly to the floor surface.

Why is it necessary to wait for the specified deadlines?

Here are some common mistakes people make when they want to get to their next job faster:

- There is no need to try to artificially speed up the drying process of the screed . For example, you should not artificially significantly increase the air temperature in the room. This will not help, since for the quality of the flooring it is important that the screed hardens on its own and naturally. If you increase the temperature, the screed may crack or break off from the base.

- We have already written about this: there is a difference between the fact that the screed has simply set and you can walk on it and the fact that you can now continue to work and install the finishing floor covering.

It is important! Take your time. if the screed is not completely dry and moisture remains, and you decide to lay laminate flooring, then this will lead to disaster. Then this laminate will pick up moisture from the floor, swell and you will throw everything away.

If you rush, this may lead to the need to re-lay the flooring, such as laminate or carpet, or even knock down partially or completely the screed itself and do everything again. Nobody wants this.

Creating the right indoor microclimate

It is necessary to exclude such unfavorable and harmful factors as:

- sudden changes in temperature;

- screed freezing;

- drafts;

- direct contact of the screed with various types of liquids;

- exposure of the new flooded area to direct sunlight: this is important because it can lead to faster evaporation of moisture in one place. This in turn will lead to cracks and other troubles.

Important! Never pour if the temperature indoors or outdoors is less than 5 degrees Celsius.

Is it worth making drafts?

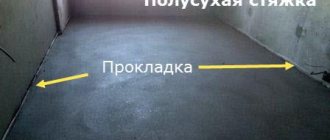

It was written about this above: drafts are strictly contraindicated; on the contrary, for the first few days, or even a week, it is recommended to water even the screed with water or arrange some kind of vapor barrier. The screed must be covered with plastic wrap for a week. This is necessary so that the moisture does not evaporate too quickly, and the entire screed dries evenly and gradually, which will ensure greater strength and durability of the future floor.

It is worth saying that some sources recommend not only this. In the first week, you need to cover the floor with film, and then in the second and third weeks you should periodically water the screed with water as needed. Sometimes, instead, you can simply sprinkle the screed with dry sand or sawdust. They will simply slow down the rate of evaporation so that the intensity of evaporation is lower and the screed dries evenly.

The screed is ready for use - how to determine?

The readiness of the coating is determined by two points:

- the material for the bundle has already set;

- the coating is ready for any job.

The first stages of processing are carried out almost immediately – within a day. It is important that the entire area is uniform in color and has no deviations.

However, avoid placing large objects with enormous weight on the surface.

An experiment to determine whether the treated surface can be loaded can be carried out at least after a week. If you start doing this earlier, the mixture will begin to collapse, and the work will be pointless.

After what time can you walk on the screed?

If you are going to lay tiles on a gypsum screed, then you need to wait at least 3 days; if you are planning to lay other materials, such as parquet, laminate, linoleum, then you will have to wait at least a week. If the composition is based on cement, then the drying speed before laying the floor covering generally increases to 14 days, and sometimes when the layer is thick - up to weeks.

However, such a mixture dries much longer, which is due to the composition and thickness of the layer, as well as the technology of pouring several layers.

Time calculations

Let us consider separately how much time it will take for each type of screed. In particular, we will discuss materials such as:

- sand concrete;

- concrete;

- expanded clay;

- dry screed;

- semi-dry screed;

- laminate;

- tile.

It takes about a week for 4 centimeters to dry, then 15 days are added for each centimeter.

For sand concrete, the drying time is the same. To reduce drying time, use all kinds of additives.

Cement

Thanks to them, the time is reduced significantly. For example, thanks to a proprietary screed, a cement floor can be ready within a few hours.

There are several factors that speed up this process:

- converter. Thanks to it, the drainage function is performed. This helps remove moisture from the inner layer faster;

- accelerator. Thanks to it, there is no need to add a lot of liquid to the solution;

- thinner. The consistency of the solution will become even more plastic. This way, not much liquid melts into the solution - it’s not really needed there.

Thanks to these features, it will take just a few days – 3-7 – for the screed to dry completely.

More information can be found on the manufacturer's packaging.

How to perform a screed correctly?

Question: Are there any rules for pouring screed? Answer: The screed is carried out according to beacons to achieve the best result. The beacons (metal profile) are installed at one mark using a level, after which the prepared solution is poured onto the floor and, using a wide rule placed on the beacons, the mixture is leveled, cutting off the excess. As a rule, in living rooms a screed thickness of 5-7 centimeters is sufficient.

Remember that when screeding, the cement mixture hardens quickly. The prepared solution must be used before it begins to set.

Drying Features

It is worth determining how long it takes for an expanded clay floor screed to dry. This material is used quite often. The reason is that it is different:

- ease;

- strength;

- practicality;

- environmental friendliness;

- high thermal insulation;

- high sound insulation.

It is developed at high temperatures, and therefore it is quite durable.

The use of expanded clay is relevant in cases where the goal is to raise the floor to a greater height. The peculiarity of this material is that it is capable of moving vapors and air through itself.

It will take about 4 weeks to dry. In some cases, 2 weeks is enough.

Drying time for gypsum screed

Very often, gypsum mixtures are used to create a finishing screed. They set very quickly (after 3-5 hours), but final drying occurs no earlier than after a week. Therefore, if you are wondering how long it takes for a gypsum floor screed to dry, take this fact into account.

The chosen facing material has a great influence on the drying time of such a base. Thus, laying laminate, parquet and carpet can begin only after 8 days, but installation of tiles can begin after 3-4 days.

Here you need to remember that these calculations are applicable only for coatings whose thickness does not exceed 40 mm. For every additional centimeter, the master must add another day.

conclusions

As you can see, there are certain features that will directly affect how quickly the screed dries. Including pay attention to the moisture level in the room. Also remember about the temperature. Under no circumstances should you neglect the thickness and number of layers in the solution.

After all, this directly affects time. It is also worth remembering about fillers that affect drying. The waterproofing base can have different levels of quality.

At first, you may be confused about how much time is needed to set and how much time is needed to dry. Interestingly, within 24 hours you can start walking on the flooring without leaving marks. After a week it may seem that the surface is very durable. However, this is deceptive.

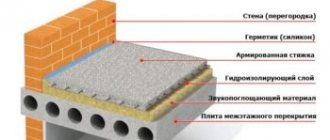

After all, for example, cement has pores that contain water. It takes enough time to let it come out. Due to the fact that waterproofing has been laid under the bond layer, it is important to allow water to escape to the top. Otherwise, damage may occur - the coating will begin to become damp and deform.

Therefore, even when a week or two has passed, there is no need to rush, because there is enough moisture inside that needs to come out.

If you add a little filler to a solution that takes a long time to dry, you can greatly reduce the drying time.

For this you can use:

- expanded clay;

- expanded polystyrene granules;

- basalt fibers;

- fiber fiber.

This method is called semi-dry screed. After all, in this case there is very little water in it. And it will take about a week for it to dry. But if you need to lay parquet or parquet boards, then you should allow about 3 weeks for drying.

It is also worth first familiarizing yourself with the methods of how to determine what the moisture content of the screed is. There are special devices for this. You can find out about them from specialists. In addition, there are methods that allow you to make such determinations without additional tools.

Taking into account the above points, you can achieve noticeable success in your repair.

If construction companies promise a finished floor in 2-3 weeks, you should think about whether this is an advertising gimmick. It is important to know how long it takes for the screed to dry in order to understand how much time you really need to expect before the completion of the repair and subsequent occupancy.

Rushing in this matter can lead to cracks, subsidence and, ultimately, damage to the coating. And who is interested in experiencing such inconveniences after a major renovation and investing money again?

At the same time, some types of floors can actually be done in the shortest possible time and it is useful to know when delaying construction work is unjustified.

What determines the curing time of the screed?

Do not confuse the setting period of the solution and the stage of its drying. In the first case, you can already walk on the surface without bending it or leaving marks. This often happens quite quickly - from several hours to a week, depending on the type of screed. Hardening involves the complete removal of moisture from the mixture. Only at this stage do they most often begin to lay the covering or install a warm floor.

Drying time depends on:

- materials included in the batch;

- thickness of layers and their quantity;

- climatic and other conditions;

- type of coating.

Traditionally, the technology of use and complete drying time are indicated on the packaging. If not, it is appropriate to use the following recommendations.

Thickness

The recommended layer height is usually 40-50 mm. Under these conditions, every 10 mm dries in about a week (depending on the material). At the same time, thickening the layer by 2 times doubles the hardening time. Based on this, you can calculate how many days a screed 10 cm thick should dry: the first 50 mm will take a month, multiply by 2 - you get 60 days and add the same amount for the second 50 mm. That's a total of about 17 weeks!

By the way, if you really need such a wide screed, it is possible to reduce its maturation time if you lay it in 2 stages. Thus, it will take half as much time to harden. The use of lighter components, such as gypsum, also significantly speeds up the process.

Considering how long it takes for a 4-5 cm thick cement screed to dry, it is not difficult to calculate that further work can begin no earlier than in a month.

A Brief Overview of Substrate and Coating Types

- Plaster. It is in great demand due to its ease of use and drying speed. It sets in just 4 hours, and after 7-10 days it gains density and is completely ready for laying the coating. This is provided that its width does not exceed 4 cm.

- Cement strainer. This is the simplest type. By type it is divided into semi-dry, dry, bulk. Pour the solution in thin layers of about 10 mm, waiting for each previous level to set a little. The larger the final width of the screed, the longer it takes to dry. A thickness of 40 mm under optimal conditions requires the ability to settle for 28 days.

- Sand concrete screed m 300. The special composition sets a little faster than cement - after 3-4 days. The final coating is applied after 4 weeks.

- Under the tiles. Place without waiting for the screed to completely lose moisture. Then the glue connects the surfaces better and the blocks are easier to lay perfectly flat. Therefore, it usually takes 1-2 days for the screed to dry under the tiles, depending, again, on the type of mortar. Most often, cement is used for these purposes.

- Under laminate. This coating is universal, so any type of sole can be used under it, without waiting for complete hardening. True, the humidity of the base should not exceed 5%. Typically, a self-leveling concrete screed on a laminate floor takes 4 weeks to dry. Sometimes, to speed things up, without waiting for the moisture to completely evaporate, waterproofing and a cork backing are laid under the coating.

- Screed for linoleum. This material remains the most affordable and practical floor covering. It can be placed on absolutely any surface, as long as it is level, because it is plastic, flexible and takes the shape on which it lies. Linoleum is easy to install and dismantle. It is even placed on parquet, tiles, and plank floors for the purpose of surface repairs. For a thorough finishing, it is better to lay it on a fully established and dry screed, otherwise mold may grow under it. Usually the floor is covered with linoleum 1.5 - 2 months after laying the mortar.

Humidity measurement