');> //—> Reference data:

Density of water - 1000 kg/m3 Density of steel - 7800 kg/m3 Density of concrete - 1400. 2500 kg/m3 Density of sand = 1400. 1700 kg/m3 Paint density - 900. 1600 kg/m3 Air density - 1.225 kg/m3

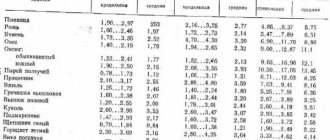

A list of main materials and their densities are presented in this table. The density of materials tends to change depending on the temperature of the environment; see reference books for exact data on density.

You can quickly perform this simple mathematical operation using our online program. To do this, enter the initial value in the appropriate field and click the button.

For complex calculations to convert several units of measurement into the required one (for example, for mathematical, physical or budget analysis of a group of positions), you can use universal unit converters.

This page presents the simplest online converter of units of measurement from tons to cubic meters. With this calculator you can convert tons to cubes and vice versa in one click.

Theoretical calculations

In order to calculate the approximate volume of material using theoretical calculations, you need:

- Find a table with the density coefficient of the corresponding material;

- Applying the formula: V=m/K, where “V” is the required volume, “m” is the known mass, “K” is the density coefficient of the given material.

It must be remembered that the values of the table coefficients are valid under standard conditions: average air temperature (20°C for solid, bulk and liquid substances, 0°C for gases, boiling point for liquefied gases) and normal atmospheric pressure. The mass of hygroscopic materials is affected by air humidity.

- Find a table with the density coefficient of the corresponding material;

- Applying the formula: V=m/K, where “V” is the required volume, “m” is the known mass, “K” is the density coefficient of the given material.

Convert tons to cubic meters using formulas or practical actions

At the first measurement, 16 kg of gravel fit into a 10-liter bucket - the mass-to-volume ratio is 16kg/0.01m3=1600kg/m3=1.6t/m3.

When choosing bulk building materials, you may encounter the problem of converting mass to volume from tons to cubic meters. To calculate the volume, you need to know the density of a given material and its mass (the density of the bulk material takes into account not only the volume of the particles themselves, but also the space between them).

There are two ways to convert tons to cubic meters: theoretical and practical. The result of theoretical calculations will be approximate, and practical ones will be more accurate.

Density of crushed stone - what affects

In fact, there are a lot of such indicators. But you can try to describe at least the main ones:

- Humidity

. Despite the fact that the material does not seem to be wetted at all, it is quite hygroscopic, especially if the pile is constantly stored in the open air. The surface of the crushed stone is actively moistened, and it increases its mass. The frost resistance of the material also depends on this ability. Only one material demonstrates exceptional resistance to splitting from the expansion of water during freezing - basalt, but crushed stone from it has a huge mass and is very expensive. - Compound

. As you know, granite consists of feldspar, mica and quartz. The more of the first component, the heavier the granite. Quartz is also quite heavy, but it greatly affects not so much the density as the strength of the sample. The presence of a large amount of mica is generally undesirable, because it delaminates the stone into fragments at the slightest load. It also conducts cold well, so a house made of such crushed stone will never be warm. If crushed stone has a large amount of quartz in its composition, then it will be lighter, but will have poor thermal conductivity. In some countries, for example in Norway, it is possible to use pure quartz crushed stone. For us, it will be prohibitively expensive. - Fraction size

. The faction can indeed be different. It is only worth mentioning that the lightest stone is considered to be a huge rubble stone, between the fragments of which there are large gaps.

If we talk about crushed limestone, its density is also affected by porosity, and humidity is very strongly influenced. It can almost double its nominal volume when stored in the open air. That is why it is used only in road construction, and even then in heavy traffic it quickly becomes unusable. Therefore, no specialist can accurately answer the question of how many tons of crushed limestone there are in a cube. You just need to weigh it before loading the dump truck.

Only weighing can tell you exactly how many tons of crushed stone there are in a cube. The thing is that most manufacturers have different equipment for crushing. Even the size of the screen tooth significantly affects the shape of the fraction, and this determines how it will be compacted during filling. In Western practice, the so-called vibration compaction is used, but our sellers usually do not use it. Optimizing space comes down to financial gain. In our country, this practice is unacceptable, so we can be content with only approximate indicators, which often vary greatly.

If household construction of low-rise buildings and structures is carried out, then how many tons of crushed stone per cube does not affect the final result at all. This is the basis for engineering surveys during the construction of strategically important and earthquake-resistant facilities. Moreover, this should not be taken into account in road or drainage construction.

Sand is usually measured in cubic meters when sold in hardware stores. But there are calculations for various mixtures, which are based on measurements in tons or kilograms. Making a recalculation in practice turns out to be very difficult. As a result, you almost have to weigh the control volume in the form of a bucket, and then make an adjustment for cubic meters. This approach gives a large error, so it is best to find out how the density of sand depends on various factors. There are a lot of them, but everything is predictable if you have certain knowledge.

How many tons of crushed stone in one cube, material properties, calculation formulas

As a result, you almost have to weigh the control volume in the form of a bucket, and then make an adjustment for cubic meters. This approach gives a large error, so it is best to find out how the density of sand depends on various factors.

There are a lot of them, but everything is predictable if you have certain knowledge.

Varieties of sand

Experts in this field count several dozen varieties, but in everyday use the generalized concept of “construction sand” most often applies. For these purposes, the following types of this material are used:

- River sand. Contrary to popular myth, it is taken not from the shore, but from the very bottom of the river bed. This material is extracted by dredging and then either thrown ashore by an earthen shell or stored on barges. Next, it is dried, after which it is used for its intended purpose. This is pure sand, but does not require pre-treatment. The quality is not inferior to the next variety, but costs several times less.

- Alluvial sand. It is formed as a result of artificial washing of quarry sand with a large amount of water under pressure on sieves.

- Silicate sand. It has a dazzling white color. It can be used as a cheap drainage layer, but there is a limitation in its use - it can lime the soil, making it impossible for trees to grow on the site.

- Quarry sand. It is mined in specialized quarries using excavators and does not undergo any additional processing.

- Sea sand. It is completely unsuitable for concrete mixtures for two simple reasons. The first is that it is salted, and to wash off all the salt, you will need to spend too much water. The second is that it is ground by the surf until the grains of sand are rounded, which then negatively affects the overall strength of the concrete.

There are several main factors that determine the mass of sand:

- Humidity. This factor can be considered variable, but it is very relevant when measuring the weight of sand, due to the fact that most construction sand is stored in open areas. Even if he lies under a canopy, it doesn’t matter. Because sand absorbs and retains moisture very well, and this significantly increases the mass of 1m³ of sand.

- Density. A factor such as density has a significant impact on the mass of sand, since it has the ability to compact and loosen when exposed to external factors. For example, during loading and unloading of sand, it loosens and, in turn, its density becomes less and its weight per 1 m³ also decreases. During transportation, sand, on the contrary, is compacted and the mass of 1 m³ of sand will increase and the volume will decrease.

- Presence of third-party inclusions. This can be clay, various roots, leaves, mollusk shells. It should also not be ruled out that these inclusions may be present as fragments, which also needs to be taken into account when measuring mass.

- Formative rock. Typically sand is formed from quartz and quartzite rocks. But the presence of impurities of another rock, even in an amount of 10% of the total volume, can significantly change the density and, in turn, the mass of sand.

- Fraction size. Grain sizes have an impact on the consumption of building material and its water demand.

The most accurate calculation is the dependence of bulk density on humidity, because the more moistened the sand is, the more it depends on the amount of water. It fits more tightly into containers when poured.

Table of dependence of sand density on absolute humidity

| Absolute humidity (%) | 0 | 2 | 5 | 10 | 15 | 18 | 20 |

| Bulk density (kg/m3) | 1510 | 1190 | 1160 | 1230 | 1515 | 1775 | 2100 |

An abnormally low mass per cubic meter for a certain humidity is possible due to clumping and changes in the adhesive characteristics of the mixture. Low humidity levels depend on the permeability of the material. Maximum sand moisture is 20%. If there is more water, it is considered unfit for sale.

In order to convert sand from cubic meters to tons you need:

- First you need to determine the bulk density of the material. Which, as we already know, is measured in kilograms per cubic meter. We can determine the density value of sand from a physical reference book or use the above table. Ideally, the density of natural sand is 1300 kg/m3, but it can increase with increasing humidity.

- Then you can determine the mass of sand using the formula: m = V*P (V – volume (number of cubes), P – density).

- Then convert the result into tons from kilograms, dividing the resulting value by 1000.

m = V*P

m = 15 m3*1500 kg/m3 = 22500 kg

22500/1000 = 22.5 tons.

As a result of the calculations, it turns out that 15 m3 of wet sand weighs 22.5 tons.

Table of mass of 1 m3 of sand of various types

| Type of sand | Number of tons in 1m³ |

| Dry | 1,21 — 1,75 |

| River | 1,5 |

| River compacted | 1,59 |

| River coarse | 1,47 — 1,63 |

| River dry | 1,4 — 1,65 |

| River wet | 1,77 — 1,86 |

| Building | 1,68 |

| Construction dry friable | 1,44 |

| Construction dry compacted | 1,68 |

| Construction wet | 1,92 |

| Construction wet compacted | 2,54 |

| Construction, normal humidity according to GOST | 1,54 — 1,7 |

| Molding, normal humidity according to GOST | 1,7 |

| Career | 1,5 |

| Quarry fine grain | 1,72 — 1,8 |

| Quartz regular | 1,41 — 1,95 |

| Quartz dry | 1,5 |

| Quartz ground | 1,45 |

| Quartz compacted | 1,6 — 1,7 |

| Nautical | 1,62 |

| gravelly | 1,7 — 1,9 |

| Dusty | 1,61 — 1,75 |

| Slag | 0,7 — 1,2 |

| Expanded clay | 0,4 — 1 |

| Pumice | 0,5 — 0,6 |

| Mountain | 1,5 — 1,6 |

| Chamotte | 1,4 |

| Perlite | 0,074 — 0,4 |

| Magnesite | 2 |

| Basaltic | 1,8 |

| Ovrazhny | 1,4 |

| Alluvial | 1,65 |

| Titanium alumina | 1,7 |

| Natural coarse | 1,49 — 1,61 |

| Natural medium grain | 1,53 — 1,64 |

| Medium size | 1,5 — 1,7 |

| Large | 1,53 — 1,6 |

| Small | 1,7 — 1,8 |

| Washed | 1,3 — 1,6 |

| Compacted | 1,68 |

| Wet | 1,92 |

| Wet | 2,08 |

| Water-saturated | 3 — 3,2 |

| Soil sand | 2,66 |

| Sand and crushed stone | 1,5 — 1,8 |

| Sand and cement | 1,1 — 1,7 |

The data presented can be considered generalized indicators. But with this knowledge, calculating the mass of sand is much better than making calculations without knowing the real values.

As practice shows, it is still better to measure bulk materials in cubic meters.

Sand is rarely measured by mass because it varies depending on humidity, and there are no accurate hygrometers to measure this indicator yet.

29.09.2016

How many tons of sand are in a cube?

How to convert cubes to tons? This question often arises among novice builders when they need to buy sand. You measured everything, and you got a certain amount of sand, for example, 8 cubic meters. And sand is sold by weight, i.e. in tons. In this regard, the question arises: how many tons of sand are in a cube?

river sand

In Samara, river sand is the same almost everywhere, because... It is mined in the Volga, so on average its bulk density per cubic meter is 1500 kilograms (plus or minus depending on the moisture content of the sand).

It so happened that in Samara there are 1.5 tons of sand in 1 cubic meter. That is, if according to calculations you need 8 cubic meters of sand, then feel free to order 12 tons and you won’t be mistaken.

Online conversion of cubes to tons

Quarry sand

With quarry sand, when converting cubes into tons, things are a little more complicated, because it is not as uniform as river sand, depending on the location of extraction. Its bulk density characteristics range from 1300 to 1700 kg/m3.

Therefore, 1 cubic meter of quarry sand can contain either 1.3 tons or 1.7 tons.

It can be used as a decorative decoration, as an engraving item for a building, and, undoubtedly, as a material that binds all the components of mortars during the construction of a structure. I would like to dwell on the last point in more detail and generalize, as well as add some information about another type of stone building product - crushed stone.

This type of building element has many functions and properties that it can easily perform during construction:

- Crushed stone in concrete mortar is capable of producing the best results in the grip and strength of the bulk of the concrete. This characteristic contributes to good compaction of the material, due to the fact that when connected with other elements, crushed stone can be used as an additional filler for the solution. When it sets with cement mortar, the crushed stone forms a single whole, making the concrete truly stone-like and indestructible.

- The next characteristic of crushed stone is its thermal insulation in solution. Thanks to this function of this stone cut, it is used directly in casting foundations for the frame of a house, walls, and greenhouses. The fact is that, due to its natural structure, stone is an excellent source of heat storage. But this characteristic passes quickly enough, and at the slightest frost, crushed stone is able to give off heat again.

- The moisture resistance of crushed stone is also an advantage of this material. Very often, due to this characteristic of crushed stone, it is used as a material for backfilling cliffs and channels. Moreover, in a concrete solution, crushed stone does not allow moisture to penetrate inside the object being poured, be it a concrete foundation or a small country path made of concrete solution.

- The bulk density of crushed stone certainly makes it one of the popular building materials of its stone type. Unlike other light stones, for example expanded clay, crushed stone has a higher density, and therefore the quality of the solution made with the addition of this material is distinguished by its richness and density. In addition, the relatively heavy weight of crushed stone makes it possible to make concrete sufficiently hard and suitable for the heaviest loads per centimeter of its area.

Despite its similarity, crushed stone is also divided into types and subtypes, depending on the following characteristics and factors:

- Grain composition and its shape.

- Fractions of crushed stone.

- Chemical impurities.

Paying attention to all three factors that crushed stone of one category or another has, experts divide it into:

- Crushed granite.

- Crushed gravel.

- Crushed limestone.

Crushed granite is obtained by extracting it from a mine or natural, artificial quarries. Deposited over thousands of years, the layer of granite at a certain depth is very thick. Therefore, to go deeper into the mine, it is necessary to undermine this layer of granite.

The blasted blocks are sent for further crushing and division into fractions, from which crushed stone is subsequently obtained. It is noteworthy that the smaller the fraction of granite crushed stone, the more expensive it will be, since the crushing process takes longer in this case.

Properties of crushed stone

The key property of crushed stone - its strength - directly depends on the rock it was obtained from, as well as on the crushing method. According to this parameter there are:

- high-strength material (M1200−1400);

- durable (M800−1200);

- medium (M600−800);

- weak (M300−600);

- very weak (strength M200).

The most popular is granite crushed stone with a strength of M1200, as well as high-strength basalt, which is used in the production of concrete structures, bridge foundations, etc.

Flakiness is a very important parameter, showing how many needle-shaped and lamellar grains are in the finished material. The less flakiness, the fewer impurities contained in the crushed stone, the better quality it is. Based on how many lamellar and needle grains it contains, they distinguish between ordinary (grain content 25−35%), improved (15 to 25% grains) and cuboid, the number of needle and flakier grains in which does not exceed 15% of the total mass of the material.

Frost resistance is a parameter showing how many complete cycles of freezing and subsequent thawing of the material there were. The following types are distinguished: F15, F25, F50 F100, F150, F200, F300, F400. The most commonly used crushed stone types are F200-F400.

Radioactivity must be taken into account when used in construction. It depends on the specific activity of the radionuclides. In the construction of residential buildings, class I material is used (with activity less than 370 Bq/kg), in the construction of road and industrial facilities - class II (radionuclide activity is in the range of 370−740 Bq/kg). When constructing buildings located far from residential areas, it is possible to use Class III crushed stone, with radioactivity from 740 to 1350 Bq/kg.

The concept of solid waste density, how to convert cubic meters to tons and vice versa

Multi-colored stones are used to decorate paintings to achieve the most colorful effect. However, despite such popularity, a fairly large number of people do not understand which building material is better to purchase, or even do not distinguish crushed stone from gravel and other types of bulk materials at all.

Most of the crushed stone is systematically brought to construction sites for repair work. However, the problem is that the saturation of this material used is quite diverse.

Typically, density is measured in cubic meters (m³). The strength of the stones has a noticeable effect on the weight, which is important for construction calculations.

It can be concluded that the amount of 1 m³ tons of sand affects the final calculation of the strength of the device, but also affects the properties of the base of the structure. According to this circumstance, the pressure area is increased to 10% to eliminate a number of problems.

Crushed gravel is a compacted and durable source that can withstand approximately 200 freeze-thaw cycles while retaining its properties.

Gravel

Contains a small background radiation. Used in the manufacture of concrete buildings.

Limestone

Limestone crushed stone is one of the more commonly used ones.

It differs from other types of crushed stone in its environmental friendliness, which is why it is also in demand.

For production, sedimentary rocks are required, the structure of which contains the mineral.

Limestone

Due to fission, the released raw materials undergo a special chemical process. processing. It has a number of tones: brown, reddish, snow-white, yellowish, grayish.

Granite

The main advantages are considered to be greater stability to frost, and also a low degree of humidity.

Granite

Granite crushed stone is taken out from the rock, and the next procedure is the operation of crushing the material.

Secondary

Recycled crushed stone is used to build roads. It is supposed to be a placeholder.

Secondary

Slag

Crushed slag is produced by dividing blast furnace slag.

Slag

Unlike other materials, it contains the usual characteristics of strength and resistance to cold weather. Generally used in track construction.

Decorative

Decorative crushed stone is a key source when decorating “alpine slides”, flower beds, and fountains.

There are three groups of different tint varieties:

- ruby;

- yellowish;

- snow-white.

Peculiarities

What affects volume? It is necessary to focus interest on the characteristic features in order to establish the application of the material:

- frost resistance - assessment of stability to freezing and thawing. At the same time, the material must retain its quality. Typically denoted by the letter “F”;

- reliability – stability of crushed stone to the grinding process, as well as to compression. Indicated by the letter “M”;

- flakiness is an assessment of a physical property that determines the planar dimensions of each individual grain, which is determined by the correspondence to length/thickness. High-quality crushed stone must have the lowest indicator;

Flakiness

- adhesion is a rating responsible for the connection of crushed stone with other elements.

When selecting crushed stone, you need to concentrate your interest on the information received about the characteristics and select the optimal type of crushed stone. The size of the material is important. The larger it is, the less m3.

Moisture absorption is considered an equally important condition when determining weight. Ignoring the conditions of further calculations, the result will not be a good result.

Different types of rocks are mined by grinding, the list of which you can familiarize yourself with in order to further distinguish the concepts:

- granite - harder, more compact, containing mica crystals and quartz;

- gravel - loose, mined from sedimentary rocks;

- marble - has a high compaction coefficient;

Marble

- limestone - unlike marble, it is significantly inferior in strength;

- slag - quite heavy (the characteristic depends on the alloys);

- Volcanic tuff is hygroscopic.

Volcanic tuff

Mass also refers to the concept of volumetric weight. It is necessary to take into account that the correct information for the calculation will be at the time of loading or unloading the material, and then without compacting or spilling crushed stone. Use a universal calculator to calculate weight and volume.

Mass = Volume * Coefficient. For example, 2.5 m³ measuring 5 by 10 (2.5 * 1.38) = 3.4 tons.

Indicators are presented exclusively for granite material (gray). The calculation results are approximate. The following factors influence the value.

Name: gravel, granite, marble, limestone, slag.

Weight 1 m³/kg 1400 1470 1500 1300 1500

You need to measure with a convenient container (bucket), but you will have to spend quite a lot of time. If you want to know the exact weight of 1 m³ of crushed stone, take the mass indicator of 1 m³. Its average value is 1.4 tons and is quite often used in calculations. Choose the payment method at your personal discretion.

The main thing is to get a 100% result after calculating the materials, which is so necessary for carrying out repair and construction work.

For convenient waste disposal, you need to know how much space this or that type of waste will occupy. Human practice has already shown how much solid waste can be located on the territory without harm to the environment. This parameter is the density of municipal waste.

Solid waste density is the volume of waste located in a certain area. It is measured in kilograms for solid substances and liters for liquid substances per cubic meter, which changes the criteria for calculating the norm for the maximum concentration of waste materials. However, the most commonly used indicator is kg per cubic meter, since most municipal waste is solid.

The concentration of solid waste during transportation differs significantly depending on the form of processing, because waste can be transported in bulk, as well as compacted in different ways (for example, in a press or during packaging).

Thus, the density of solid waste without compaction averages from 60 to 120 kg/m3, and when using a press - from 470 to 700, which helps save both money and time during transportation.

The weight is considered by weighing the recyclables or, if garbage trucks with containers are used, then the weight of the unloaded and loaded vehicle is measured. The degree of filling of the container is checked by the height between the garbage and the remaining free space of the tank.

Knowing such a parameter as waste density helps to obtain up-to-date information about the volume of waste accumulation in a populated area. This allows for a planned policy for the collection, transportation and disposal of recyclable materials. To obtain such information, you should pay attention to several points:

- morphological and elemental composition of waste;

- weather conditions in the locality;

- specifics of population consumption of various products;

- technical equipment of residential premises (is there a garbage disposal, gas, running water, etc.).

In addition, it is more rational to sort waste for transportation during collection rather than at a landfill. This is facilitated by separate waste collection, which is widely used in Western countries. In addition to the environmental benefits, this helps in the handling and recycling, evaluation of the density of raw materials.

The approximate density of solid waste was calculated by the Ministry of Natural Resources and Environment of the Russian Federation.

Here are some calculations in kilograms per cubic meter:

- wood remains – 600;

- cardboard – 680;

- paper products – from 700 to 1150;

- glass remains – 2500;

- polyethylene waste –950;

- acrylic recyclables – 1180;

- glass containers – 2500;

- steel waste - 7700.

More detailed information can be found on the Ministry’s website, as well as in the passport of the substances you need.

Often organizations and individuals have difficulty converting a known amount of waste into kilograms or tons. This is necessary to correctly calculate the conditions for transporting waste materials or accepting them for storage or sale.

Adding to the complexity is the fact that there is no single parameter for the density of solid waste to convert into tons. Each type of recyclable material has a certain density (conversion coefficient), which we discussed above.

To illustrate how mass is calculated, let's give an example.

We have 10 cubic meters of bricks at the landfill, but we do not know how much mass will have to be transported for processing in tons. We know that the density of brick products is 1500 kg/m3 (you need to look at the website of the Ministry of Nature or on other Internet pages).

Since more than one type of waste material is most often considered, it would be better to use a calculator and a computer or paper media for recording.

However, not all garbage is clearly sorted by composition, since not all areas practice separate waste collection (for example, Russia is just moving to this method).

For such cases, an average density indicator of 250 kg/m3 is taken, and if the solid waste is large, then it must be taken into account that the coefficient will be less. It is impossible to achieve absolute accuracy using such a calculation, so it is taken into account that there may be either more or less waste.

Moreover, each populated area, due to different living conditions, can create its own table of the density of recycled substances.

This video shows how the process of sorting waste materials by composition and density occurs, as well as its further processing.

Transporting and sorting waste is not an easy process, so you need to understand what the density indicator for waste means, where it can be useful, what it reflects and how to calculate it if necessary. Calculating this important indicator helps to better understand environmental issues.

At the second measurement, 15.5 kg fit, and the bulk density coefficient was 1.55 t/m3. The average coefficient is 1.575. The volume of seven tons of gravel with the resulting density coefficient will be approximately 4.44 m3.

What affects the volume of crushed stone?

The only characteristic that affects the volume of crushed stone is its fraction. If there is only one faction, then it will not settle tightly even with strong shaking. Due to this, a large number of voids are obtained, and the larger the fraction, the less the cubic meter will weigh. The densest is the so-called granite screening, which is more reminiscent of fine gravel. It weighs so much that you need to be careful when filling trucks so as not to tear the frame and springs.

The volume also greatly depends on the nature of the rock and on the equipment installed at the mining and processing plant. The fact is that only cuboid and prismatic fragments demonstrate the best compaction.

The flakiness of crushed stone greatly reduces its density, which will also then affect its density. Crushed stone can also be limestone. Not only is the density of this rock quite low, but also the curved fragments that form the fraction fit very poorly with each other. That is why this material is only suitable for road construction. It should only be used as a concrete filler as a last resort. You can use it to build a one-story building - a house, garage or barn. The second floor on concrete made of crushed limestone will be unpredictable.

Water absorption is an equally important factor in determining the weight of a cubic meter of crushed stone. Neglecting this factor in calculations will result in inaccurate results. Water absorption is also influenced by different rock porosities and different fraction sizes, and if they are not taken into account, the calculations will be incorrect.

How many tons of sand are in a cube: tables, calculation examples

During the construction process, compliance with proportions and technical standards for the preparation of cement mortar is a fundamental task. All types of construction must begin with an estimate, which is calculated based on the required ingredients.

Crushed stone is the main bulk material that is used as filler or to form a cushion for the foundation.

It is obtained as a secondary raw material from building materials or as a primary one by crushing rocks. How many tons in 1 cubic meter of crushed stone will help you make correct calculations of the cost of materials.

Types of crushed stone

How many types of crushed stone are there? Based on the type of rock from which it was obtained, it is divided into 4 main types:

Gravel is the result of crushing large quarry rocks into small pieces and then sifting. Its distinctive feature is its low radioactive background and low cost.

Granite is the most durable type, consisting of quartz, spar and mica crystals. During its production, rocks are blasted, the resulting granite is crushed and sifted, and then sorted into fractions.

Recycled is the result of recycling concrete and bricks. The price of such crushed stone is almost 2 times less than the cost of granite, which is associated with lower costs for its production.

Slag is obtained by processing slag melts with a special solution, as well as from industrial slag. It is much cheaper than natural material, but its use is possible only in specific conditions.