Concrete is the most popular building material. It is used in a variety of areas of construction. With its help, they create foundations for various buildings, make fences, roads, platforms, sidewalks, etc. M250 concrete is one of the best mortars with high performance.

This class of concrete can hardly be called the most popular, but it is used in a large number of works. M250 is intermediate between 200 and 300 brands. Its quality is slightly better than 200, but it is more expensive. At the same time, it loses significantly to 300, and is not much cheaper. Thus, this brand is largely niche. Applies only to certain types of work.

Specifications

Concrete 250 is a cement mortar prepared from standard components in a certain proportion. Subject to the concrete production technology, the mixture demonstrates certain characteristics and properties prescribed in the standards and standard for a given type and class of material.

The main parameter of the mixture, which determines the scope of its use and performance qualities, is strength.

To determine the strength, hardened cement stone (a piece with a side of about 15 centimeters) is subjected to pressure tests. This is how the average force directly applied per square cm of the prototype monolith plane is determined. The material is able to withstand this force under pressure without destruction.

The indicator obtained in this way is close to the standard marking and must be indicated on the packaging of the material, as well as in documents and GOST. Concrete grade M250 demonstrates a compressive strength of 262 kgf/cm2.

Thanks to crushed granite, concrete B20 M250 demonstrates water resistance up to W6; this indicator can be increased by introducing special additives into the composition (plasticizers, water repellents, pozzolans, etc.).

The density of B20 concrete is fixed at 2350 kg/m3, which is why the M250 grade is considered heavy. It is worth noting that the specific gravity of the material is determined directly by the selected proportion of the components taken during mixing. Also, the density indicator is largely influenced by factors such as the presence of seals, the type and fraction of fillers, the method of compaction, etc.

Other characteristics of the M250:

- Concrete class M250 – the considered building mixture corresponds to a value of B 20. This parameter is determined during compression testing of standard test samples. The number 20 is evidence that in 95% of cases a sample made of M250 concrete is capable of withstanding a pressure of 20 MPa (the same compressive strength - 200 kgf/cm2 and up to 262 kgf/m2).

- Frost resistance – F100-F150: that is, B20 concrete can withstand 100-150 freezing/thawing cycles without losing its qualities. The indicator can increase due to the introduction of special additives into the composition.

- Mobility – P2-P4: depends on the specific requirements of casting, the selected components for mixing, affects the ease of working with the solution.

- The weight of concrete is within 2300 kg/m3, but the final figure directly depends on the composition of M250 concrete and the type of aggregate.

- Cost - quite strongly depends on the specific manufacturer, region, exact technical characteristics (compressive strength, hydrophobicity, ability to withstand sub-zero temperatures, mobility are usually determined), within Moscow and the region it is 4250-4400 rubles / m3.

The cost of making the mixture yourself will be significantly lower, since the price of the prepared concrete solution in a factory includes such items as: employee wages, depreciation of buildings, tools and equipment, structures, electricity payments, taxes, contributions to state funds and other production and production costs. non-production type.

The characteristics of B20 concrete make it possible to classify it as heavy - the mixture is most often used in civil engineering.

Basic recipes

The structure of the material and all its technical characteristics, including density and strength, are directly dependent on cement consumption and water-cement ratio. Even a large amount of binder with a W/C ≥ 0.7 - 0.75 will not be able to provide high durability.

For M250 concrete without requirements for frost resistance and water resistance, the cement consumption can be slightly reduced and the amount of mixing water increased. In this case, it is only necessary to ensure the design strength class and the specified mobility of the mixture.

If additional conditions arise in the form of frost resistance grades f150 and water resistance grades w6 and higher, it is necessary to ensure W/C ≤ 0.6, which leads to the use of special chemical additives and an increase in cement consumption.

Basic compositions, depending on the requirements for the material and the quality of the components, can be presented as follows.

| Mixture parameters | Consumption per 1 m3 of concrete, kg | ||||

| Cement | Sand | Crushed stone/gravel | Water | Additive | |

| V20 P3-P4 | 260 – 300 | 600 – 750 | 1080 – 1150 | 140 – 180 | plasticizer |

| B20 P3-P4 W4 F100 | 270 – 310 | 600 – 700 | 1080 – 1150 | 140 – 170 | plasticizer |

| V20 P3-P4 W6 F150 | 285 – 340 | 580 – 700 | 1080 – 1100 | 150 – 180 | plasticizer |

Costs in the indicated ranges depend on the class of cement, as well as the quality of inert materials. M250 concrete, in addition to strength, density, frost resistance and water resistance, has a number of additional properties. The main ones are water absorption of no more than 1.5 - 3%, tensile strength during bending, porosity and elastic modulus.

The content and number of pores, as well as the ability to absorb water, are additional characteristics of durability. Flexural tensile strength and modulus of elasticity demonstrate the ability of B20 concrete to resist shear and bending loads, which is very important for floors and wall elements.

| Concrete | Initial modulus of elasticity of concrete in compression and tension Eb·103[MPa] for compressive strength |

| IN 20 | |

| natural hardening | 27 |

| heat treated at atmospheric pressure | 24 |

| autoclaved | 20 |

Concrete composition

The properties of the components for mixing the mortar are carefully described in GOST R 7473. Preparation of concrete grade M250 requires precise adherence to proportions and selection of the right ingredients.

Composition of concrete M250:

- Cement - as in other building mixtures, here acts as a binder and directly affects the properties of the solution. Usually choose cement grades M400-M500, with the correct release date (maximum 6 months before use) and properly stored.

- Fine aggregate - it is sand of the first/second class. For the M 250 solution, the sand is cleaned of dirt and impurities (especially clay, which significantly worsens the final quality of the mixture). The best choice would be sand of fraction 2-2.5.

- Coarse aggregate - you can take crushed limestone, granite, but most often gravel (this material is usually chosen because it offers the best price-quality ratio).

- Water – experts advise using purified water to be sure of the quality of the concrete mixture.

- Additives – antiseptic, hydrophobic, sealing, etc. All of them are designed to improve certain performance characteristics of class concrete

The optimal proportions of M250 concrete are: part cement, 2.1 parts sand, 3.9 parts crushed stone. If this ratio is observed, from 10 liters of cement you can get 43 liters of ready-made concrete mortar.

Making the solution

The components are mixed in the following proportions: cement - 1, crushed stone - 4.6, sand - 2.6. If the composition is followed, 10 liters of cement powder are required to produce 43 liters of concrete.

To obtain 1 m³ are used:

- 330 kg of cement;

- 140 l of water;

- 1100 kg of crushed stone;

- 740 kg of sand.

The amount of additives and impurities should not exceed 5% of the solution volume. To increase the resistance of the composition to frost, the volume of water is reduced, but the amount of cement and plasticizers is increased.

All components must be thoroughly mixed. At home, the composition can be made only using a gravity concrete mixer. It is impossible to do this without the use of technology - the resulting material will be of poor quality.

The strength of the composition depends on the quality of its components. Cement that has passed its expiration date or has been stored openly is not suitable for use. It absorbs moisture from the environment and clumps, which impairs its strength.

When purchasing cement powder, you need to carefully inspect the bag. It must be intact, without any sealed areas or damage. You should pay attention to the storage conditions of cement. It is best to buy components for making mortar in large construction stores, where the rules for storing materials are followed.

Proportions

Calculating the proportions of grade 250 concrete is easy. In this example, the components will be taken in standard volumes, based on the following conditions: cement corresponds to grade M500, purified water, granite crushed stone of fractions from 5 to 20 acts as a coarse aggregate, and river sand without any impurities or clay as a fine aggregate.

Ideal proportions:

- By weight (in kilograms, for example): 1 kilogram of cement, 2.6 kilograms of sand, 4.5 kilograms of crushed stone, multiplied by the desired final result.

- By volume: 1 part cement, 2.4 parts sand, 3.9 parts crushed stone.

In order for the concrete to harden perfectly and then not have to find out during the research process what grade it turned out to be, you need to add about 30% of the weight of the cement with water. True, such a solution will be difficult to install due to dryness, so usually concrete B20 (M250) assumes a water-cement ratio within 0.62 (provided that M500 grade cement is used).

Areas of use

Concrete grade B20 is used in both residential and commercial construction. Structures and buildings that may experience serious loads in the future are not erected from such a solution, but class B20 concrete is quite suitable for various purposes in private households.

The main areas of use of concrete M250:

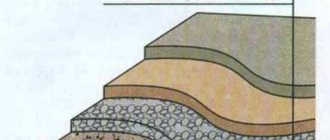

- Pouring foundations - for multi-storey buildings, subject to proper reinforcement. Ideal for bathhouses, garages, one-story buildings, sheds. Concrete B 20, due to its properties, allows you to pour foundations on objects with complex terrain.

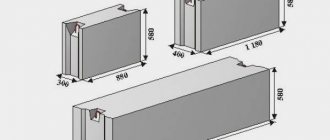

- Pouring floor slabs, various types of staircases.

- Formation of paths, platforms, blind areas in personal areas. This concrete (class B20) is able to withstand the negative impact of external factors, not deform under loads from transport, etc.

- Creation of supports, pipelines, various reinforced concrete structures.

- Construction of internal load-bearing walls and ceilings in low-rise buildings.

- Subject to serious reinforcement (which significantly increases the technical characteristics and parameters), heavy concrete M250 can be used where significant mechanical and weight loads are noted: subway and tunnel columns, rings of technical wells, foundations, etc.

- Production of various reinforced concrete products in a factory environment.

- Filling cellars, basements and other structures.

- In certain cases, the use of M250 concrete is relevant for the construction of highways, even sometimes airfield runways, arrangement of concrete pads, etc.

Concrete grade M250 is a high-quality and durable solution, suitable for a wide variety of tasks and easy to work with. Compliance with concrete mixing technology and the correct choice of components or ordering the mixture from a trusted manufacturer will guarantee the reliability and durability of any poured element or object.

Production and use of the material

In industrial and civil construction, materials of medium strength classes are widely used, including concrete B 20. Most often, a mixture is used, the mobility grade of which is designated as P3 and P4. This solution can be easily placed in formwork or fed through a concrete pump.

Concrete M250 is used for the manufacture of internal wall partitions, pouring staircases and floors. The composition is perfect for making foundations in low-rise construction, and can also be used in the construction of a basement or basement.

Thanks to its high technical characteristics, the durability of structures made from B20 concrete is very high, which guarantees a long service life without loss of basic properties.

Making concrete mixture

In factory conditions, the concrete mixture is produced in forced mixers, the dosage of components into which is carried out automatically. This approach makes it possible to obtain a high-quality solution that is homogeneous in structure and properties.

You can prepare the mixture yourself in a gravity mixer. In this case, the consumption of components per loading volume is calculated, they are weighed and loaded into the mixer drum (you can find the proportions and composition per 1 m3 in the table above).

It is best to first fill in inert aggregates and introduce part of the water, then add cement and the rest of the mixing water. This scheme allows you to reduce dust during the preparation of the mixture. The mixing time should be at least 3 – 5 minutes.

Compliance with the recipe, as well as caring for the freshly laid mortar, guarantees the durability and reliability of the future structure.