Construction of a concrete ramp

Movement difficulties for people with disabilities are a problem that they face every day, not only at home, but also on the street.

After all, many places are simply not accessible to a person who uses a wheelchair, especially those that can only be reached using stairs. These buildings, along with the degrees, are equipped with ramps. What is a ramp? A ramp is an indispensable structure in our time for access with a slope for strollers, bicycles, wheelchairs and other vehicles. Most often it duplicates stairs. The ramp is installed at the entrance to the room or on a flight of stairs. Its main purpose is that it combines horizontal planes of different heights for technical purposes: for the disabled or for transport.

Purpose

The ramp is installed at the entrance to the room or on a flight of stairs. Its main purpose is that it connects horizontal planes of different heights in cases where a structure that differs from a staircase in technical purpose is needed: for the disabled or for transport.

Primary requirements:

The angle of inclination of the ramp must be minimal so that a disabled person in a non-powered chair can climb it independently. The surface must be non-slippery, straight, and free of any irregularities. Nothing should interfere with movement. Return to contents

Ramp construction - basic requirements:

• The angle of inclination of the ramp should be minimal so that a disabled person in a chair can climb it independently. • The surface must be non-slippery, straight and free from any unevenness. Nothing should interfere with movement.

The design is a concrete flight of stairs, but instead of steps it has a flat plane of descent. Unlike a staircase, its slope should not exceed 10%, and a lifting plane of 9% is already a deviation from the norm, since a person with disabilities will not be able to climb it without anyone’s help.

What types are there? First of all, let's determine what types of ramps there are. Depending on the material used: • metal; • concrete; • wooden.

There are also ramps: • Stationary; • Folding; • Removable.

Stationary ones are installed at the entrance to the building. They don't clean up. Folding ones are used when space is limited and are lowered when necessary. They are fixed to the wall of the passage. They are often installed in houses where the installation of a stationary one will interfere with the free passage of other residents. Removable ones are installed temporarily to overcome an obstacle at a specific moment. They, in turn, also come in different types: 1. Sliding telescopic - two ramps that extend in length and when assembled do not take up much space. 2. Roll ramps are an option for those who have very little space. Thanks to a special frame, they roll up like a carpet. 3. Ramps - a folding model that is used to overcome rapids and other small hills.

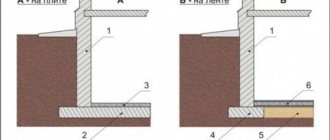

Ramps can also be classified into: • monolithic; • with wall support; • with full support on the ground or bedding.

What it is?

A folding ramp for the disabled is a convenient and fairly versatile device that can be installed on almost any staircase. Its main advantage is that it does not take up much space. The structure can be easily folded into working position and put back together. Even a child or a disabled person can do this.

When the folding ramp at the entrance is in the non-working position, that is, folded against the wall, it does not interfere with the movement of other people or the movement of goods. Similar structures installed in residential buildings are widely used not only by disabled people, but also by residents with strollers.

It is important to know that installing a folding ramp in the entrance does not require any approval. According to the law, no one has the right to protest the presence of such structures in residential buildings.

Ramp construction - how to do it yourself?

Determining design parameters Concrete ramp is one of the most stable types. They can be single-flight (one span) or multi-flight (with intermediate platforms). It depends on the lift height. The maximum length of one strip should not exceed 9 meters, so you cannot make one long plane over a long distance. It is also taken into account that the maximum height of the march is 80 cm. Based on this, when calculating the dimensions of the ramp, you need to take into account the areas at the beginning, at the end of the ramp, as well as intermediate areas. When constructing a ramp, it is important to know that nothing should interfere with the ascent, such as a door. The platforms must be of sufficient size to provide enough space for the stroller to turn around freely.

The minimum width of the ramp plane should be 1 m, if one-way traffic is provided, and, accordingly, 2 m, if two-way traffic is provided. The law also provides for the mandatory installation of sides on the ramp so that the wheels of the stroller do NOT jump from the surface. Their minimum height is 5 cm. For safety and ease of movement with a ramp, it is equipped with railings on both sides. Handrails should be located along the entire length, their height should take into account the needs of children and adults. Therefore, the railings are placed at a height of 50 cm for a child and, accordingly, 70, 90 cm for an adult.

Ramp construction - calculation

Before starting work, you need to prepare, make all the necessary calculations and measurements, that is, draw up a project. According to the standards, the height of the ramp should be related to the length in the calculation of 1:12. This means that to build a structure with a height of 1 meter, you need to make it 12 meters long, and with a height of 1.2 meters - 15 meters. However, according to the standards, it is prohibited to do this, so you need to divide it into 2 flights of the same length - 7.5 meters each, the platform between the flights will be at a height of 0.6 meters (h1 / 2 = 1.2 / 2)

Let's take the size of the area between the flights to be 2 m2. Based on this, you need l1 17 m2 (15 m and 2 m platform). V1 = 1/10 s = 1/10 17 m2 = 1.7 cubic meters. V2 = h1 * l1 = 1, 2 * 15 = 18 m2 * ½ brick thickness (0.125 m) = 2.225 cubic meters. m = 2.25: 0.002 = 1125 pieces.

We also determine the volume of fill used (9 m3) and the required length of the reinforcement bars (243 linear meters): • area - s; • ramp height – h1; • platform height – h2; • slab length – l1; • volume of concrete - v1; • volume of walls - v2; • number of bricks - n.

Ramp construction - sequence of work

• Ramp reinforcement. Step 1. We make markings for construction with cords and pegs. In this case, the internal width of the future structure is taken into account. • Step 2. Pour the foundation under the walls. • Step 3. We stretch and set the slope. • Step 4. We are laying out brick walls. After this we wait about a month. • Step 5. Fill in the distance between the walls. • Step 6. It is necessary to make a protective layer between the backfill and the concrete (polyethylene is often used). • Step 7. We reinforce the structure. • Step 8. We make the flanging. • Step 9. Concreting. It is better to pour concrete grade no lower than M300 from bottom to top. Since the top layer will dry quickly, it is lubricated with water so that everything dries evenly. If cracks appear after it has completely dried, they can be corrected with a cement screed. • Step 9. Install the railings. • Step 10. Cover the structure with bridge or other material.

Algorithm for making a ramp with your own hands

After a drawing of a concrete structure has been drawn up, its construction can begin. The arrangement algorithm is in many ways similar to the production of a shallow strip foundation and consists of several stages.

We carry out preparatory work

- In accordance with the drawing, we make markings using pegs and construction cord.

- We excavate the soil to a depth of about 30 cm.

- In the prepared recess we make a sand cushion 10-15 cm thick and compact it thoroughly, periodically moistening it with water.

We arrange the formwork

Depending on the length of the ramp, the formwork for the future concrete structure can be made in two ways:

- We make two identical wooden panels (from boards, plywood or chipboard). Moreover, the upper parts of the blanks must be beveled in accordance with the angle of inclination of the future ramp. In the future, they will serve as guides when leveling the outer surface. Along the outside of the marking we drive wooden blocks into the ground. Using self-tapping screws, we attach the manufactured shields to them.

On a note! This method of manufacturing formwork is preferable when the length of the ramp is short. If the length of the structure is large, then the wooden blanks will simply be “too heavy to lift.”

- Initially, in accordance with the applied markings along the entire length of the future ramp, we drive wooden blocks into the ground. We attach boards (sheets of plywood or chipboard) to their inner side using self-tapping screws. We draw a slope line on the top of the equipped formwork, and saw off the excess using a hacksaw (or jigsaw).

We carry out reinforcement

After the arrangement of the formwork is completed, we reinforce it using a metal frame. First, over the entire surface of the “pillow” we lay a mesh of rods fastened together with knitting wire.

Then we drive pieces of reinforcement into the ground around the perimeter so that they are slightly below the upper ends of the formwork. We attach the next horizontal reinforcing layer to the vertical pins. If we plan to install handrails, then in certain places we install vertical reinforcing elements above the inclined outer surface. Subsequently, we weld the support posts to them, and then attach the handrails to them.

Fill the solution

If access roads allow, then we order a ready-made solution of the required consistency at the nearest enterprise for its production and fill the entire formwork at once. At the same time, we compact the mixture using a submersible vibrator. We level the outer surface of the laid mortar using a rule (or a vibrating screed) in the direction from bottom to top.

If we make the ramp ourselves, then when preparing the solution (manually or using a concrete mixer), we try to minimize the intervals between batches. This is extremely important so that the future design has better solidity.

Important! To prevent rapid drying of the laid mortar, the concrete structure should be covered with plastic film (periodically removing it and wetting the surface with water).

To prevent cracking of the outer surface of the concrete ramp, do not forget to install expansion joints. For this purpose, wooden slats of small thickness (10÷15 mm) are suitable, which we press into the laid mortar at a distance of 80÷120 cm from each other.

We dismantle the formwork only after the solution has reached its final strength (usually this happens after 25–30 days).

We produce cladding

We decorate the side parts of the constructed concrete ramp in accordance with personal preferences, the overall design of the residential building and available materials. Ceramic tiles, artificial or natural stone are suitable for this. But we cover the external inclined surface (that is, the “roadway” part) only with materials that have anti-slip properties (for example, special rubber-based coatings).

Metal ramp

One of the options for amenities for wheelchair users and young mothers with children is a folding metal ramp, which is installed in multi-story buildings. Even in a house with two floors, this device will be necessary and appropriate. A metal ramp with a folding ramp can be installed not only at the entrance. It is necessary for moving from and to the porch, and not only.

In order to build a folding metal ramp, you will need:

- Two channels, the lengths of which must match the size of the flight of stairs. The thickness of rolled metal must meet two rules. On the one hand, the channels should easily withstand the load from a person in a wheelchair, on the other hand, they should not be too heavy, since the structure will have to be lowered and raised frequently.

- Spacers that will connect 2 channels together and in this case are ramps. The thickness of these parts should be up to 5 mm, width - up to 40 mm. Metal corners or strips of thick sheet steel can be used as spacers.

- Door hinges of sufficient strength, extension plates, fasteners. There should be 3 pieces of each part.

Stages of work

Work on the installation of a ramp is carried out in a certain order.

- Holes are drilled in the channel, which should coincide with similar ones in the hinges. Using bolts, the door hinges are attached to the near channel. Thanks to the chamfered holes in the hinges, the bolt heads should not stick out from the mounted structure. The extension plates must be the same width as the hinges, as they will also need to be bolted together. Extension plates must have cutouts for the railing posts and be of sufficient length to be inserted behind the vertical members and secured with fasteners. The notches in the extension plates should be slightly larger than the cross-sectional dimensions of the railing posts.

- Before installing the channels and connecting them with spacers, you need to determine the distance between the ramps. It must match the dimensions that exist between the wheels of a wheelchair or stroller. Another important detail is that with a folding ramp there should be no gap between the spacers and the steps, otherwise the person walking behind the stroller may trip and be injured.

- The wheelchair ramp is almost ready. It remains to come up with a device with which the folding ramp will be fixed to the top of the staircase railing. To do this, you need to attach a loop to the far channel. A chain is passed through the loop, which closes when the ramp is raised and locked. If the ramp structure is attached to the wall, then a latch can be attached to its surface, which will securely hold the entire system.

Wooden ramp

The design of a folding wooden ramp is not much different from the design of a metal ramp. The whole difference is that making it is a little more difficult, since the working material is wooden and metal elements.

- Instead of two channels, 2 boards of a certain thickness and width are taken. The length of the ramps should cover the entire flight of stairs. The distance between the boards should be such that it is convenient for a wheelchair or stroller to pass through. At the entrance of a house, a wooden structure is best suited. In this case, the staircase can be limited either by railings on both sides, or only on one side - the second supporting side can be a wall.

- As in the previous version, 2 wide boards are fastened together with spacers, which are wooden blocks of a suitable size. The structure of the wooden folding ramp is attached to the staircase railing using the same hinges. The dimensions of the structure are dictated by the area and shape of the flight of stairs, as well as the dimensions of the stroller. The spacers must be adjacent to the steps, otherwise the person pushing the stroller may break their legs. In addition, in order for the accompanying person to feel safe, the distance between the boards must be sufficient for comfortable movement.

- Then, when the ramp is not in use, the wooden structure is fixed to the railings with a lock. If you work with the wooden material longer, then the folding ramp can be made from the reverse side in the form of an enclosing structure that will serve as a railing. To make the ramp beautiful, the wooden material can be varnished - it will be practical and attractive. It must be remembered that the ramp can only be treated with a slippery coating on one side. The working surface of the boards must have good adhesion to the rubber wheels.

How to install a ramp in the entrance of a residential building

Today, every person has the right to express the need to install a wheelchair ramp in the entrance of an apartment building. The rights of a citizen with limited mobility must be respected, so he will not be denied. Having chosen a ramp model, the interested person must:

- Submit an application for installation of a ramp to the management organization.

- Wait 30 days. During this period, utility services must review the application and provide a written response.

- If refused, you should file a complaint about violation of rights with supervisory or human rights authorities (society for the protection of consumer rights, prosecutor's office, local government, court).

- If the decision is positive, the utility workers will do their job.

You can contact your local social security authorities to install a ramp.

The application must be accompanied by a document on disability, proof of the need to move in a wheelchair. The regional department is required to send an application to the Ministry of Social Protection. After studying the request, specialists will visit the site to assess the need for work and the cost. Installation will be free of charge for the applicant. Funds are allocated for this from the local budget.

Application for installation

An application must be written addressed to the head of the management organization. According to changes made to the Housing Code in 2013, today there is no need to collect the consent of 2/3 of residents to install ramps in apartment buildings. Only one person can submit an application. If the neighbors support the request, this will add credibility to the statement.

References to legislative documents will emphasize the seriousness of the applicant's intentions. There will be a greater chance of a positive answer if you indicate the dimensions of the room and the model of the ramp (stationary or folding). It is advisable to attach photographs of the entrance.

The application must be sent by registered mail or delivered in person. It is recommended to obtain a registration stamp on a second copy.

- Cause of loss of smell due to coronavirus

- Conditions for refinancing loans at VTB

- Blueberries - beneficial properties

Concrete ramp

It is not surprising that a concrete ramp is a fairly durable and reliable structure. First you need to make a project, and then move on to manual work. Installing a concrete ramp on your own is not very easy. To do this, you need to perform work in a certain sequence.

- First comes the excavation work. Since the concrete base of the ramp at the bottom will be quite thin, there is a possibility that the surface may crack at this point. Therefore, in a certain place you need to select soil for deepening. Due to this, the layer of concrete in the lower part will become thicker. But if you adhere to the technology completely, then a excavation in the ground must be made for the entire concrete base.

- The first step after excavation work is to build curbs. To create them, formwork is made, at the bottom of which a cushion of layers of sand and gravel is placed, after which concrete with preliminary reinforcement is poured. Ultimately, 2 borders with load-bearing characteristics grow. They create the edges of the concrete ramp structure.

Construction of a concrete ramp

Movement difficulties for people with disabilities are a problem that they face every day, not only at home, but also on the street. After all, many places are simply not accessible to a person who uses a wheelchair, especially those that can only be reached using stairs. These buildings, along with the degrees, are equipped with ramps.

What is a ramp? A ramp is an indispensable structure in our time for access with a slope for strollers, bicycles, wheelchairs and other vehicles. Most often it duplicates stairs. The ramp is installed at the entrance to the room or on a flight of stairs. Its main purpose is that it combines horizontal planes of different heights for technical purposes: for the disabled or for transport.

Types of ramps

Now construction companies offer a large number of types of ramp designs that fully comply with all legal requirements. Let's consider those structures that are installed in entrances and on the porch.

The most common ramp variation is ramps. They are attached to the steps and represent runners or a monolithic surface. In this case, it is necessary to calculate the width of the stairs in a residential building, which remains unused. Most reasons for failure are precisely that the remaining width is too small for passage.

If the flight of stairs is a rather narrow structure, then it is possible to install a folding ramp. For the entrance of a residential building, such a design will be much more convenient, will not take up a lot of space and will not be too expensive.

The folding ramp design has the following advantages:

- Simple installation with a fastening that can be installed both from the wall side and from the railing side.

- The functionality is the same as the stationary version.

- A person with disabilities will be able to independently raise and lower the ramp.

- When folded down, the structure will not interfere with normal movement on the stairs.

- Light weight, usually between 4 and 5 kg, making it easier to use for disabled people.

- Excellent appearance that does not spoil the overall impression.

Most often, folding ramp options are installed in those houses where families with small children live. The material for this version of the ramp is galvanized steel with a thickness of at least 1.5 mm. The design standards for the runners are also taken into account during installation. These dimensions are 40*190*40 cm. This size is suitable for both children's and wheelchairs.

An interesting variation of the ramp is a removable one. But it can only be installed on short stairs, in places where it is not possible to install a conventional model.

You can also highlight a product such as a roll-ramp. It is a roll-up design for overcoming curbs, which you can always take with you.

Ramp construction - basic requirements:

• The angle of inclination of the ramp should be minimal so that a disabled person in a chair can climb it independently. • The surface must be non-slippery, straight and free from any unevenness. Nothing should interfere with movement.

The design is a concrete flight of stairs, but instead of steps it has a flat plane of descent. Unlike a staircase, its slope should not exceed 10%, and a lifting plane of 9% is already a deviation from the norm, since a person with disabilities will not be able to climb it without anyone’s help.

What types are there? First of all, let's determine what types of ramps there are. Depending on the material used: • metal; • concrete; • wooden.

There are also ramps: • Stationary; • Folding; • Removable.

Stationary ones are installed at the entrance to the building. They don't clean up. Folding ones are used when space is limited and are lowered when necessary. They are fixed to the wall of the passage. They are often installed in houses where the installation of a stationary one will interfere with the free passage of other residents. Removable ones are installed temporarily to overcome an obstacle at a specific moment. They, in turn, also come in different types: 1. Sliding telescopic - two ramps that extend in length and when assembled do not take up much space. 2. Roll ramps are an option for those who have very little space. Thanks to a special frame, they roll up like a carpet. 3. Ramps - a folding model that is used to overcome rapids and other small hills.

Ramps can also be classified into: • monolithic; • with wall support; • with full support on the ground or bedding.

Types of ramps

Among the varieties of ramps presented on the modern market, it is easy to choose the appropriate model for a specific entrance. Based on design solutions, stationary and removable (temporary) devices can be distinguished.

Stationary ones are divided into fixed and folding structures.

A permanent concrete ramp is being built on the porch of a public building. Folding ramps for landings are used in entrances and on staircases of small width and length. Such structures are held vertically against the wall by special fasteners. Omitted only when necessary.

Removable structures are used for mobile access anywhere. The following models have found practical distribution:

- telescopic, adjustable in length;

- folding ramps with low weight;

- roll ramps that are easy to roll up.

Ramp construction - how to do it yourself?

Determining design parameters Concrete ramp is one of the most stable types. They can be single-flight (one span) or multi-flight (with intermediate platforms). It depends on the lift height. The maximum length of one strip should not exceed 9 meters, so you cannot make one long plane over a long distance. It is also taken into account that the maximum height of the march is 80 cm. Based on this, when calculating the dimensions of the ramp, you need to take into account the areas at the beginning, at the end of the ramp, as well as intermediate areas. When constructing a ramp, it is important to know that nothing should interfere with the ascent, such as a door. The platforms must be of sufficient size to provide enough space for the stroller to turn around freely.

The minimum width of the ramp plane should be 1 m, if one-way traffic is provided, and, accordingly, 2 m, if two-way traffic is provided. The law also provides for the mandatory installation of sides on the ramp so that the wheels of the stroller do NOT jump from the surface. Their minimum height is 5 cm. For safety and ease of movement with a ramp, it is equipped with railings on both sides. Handrails should be located along the entire length, their height should take into account the needs of children and adults. Therefore, the railings are placed at a height of 50 cm for a child and, accordingly, 70, 90 cm for an adult.

Ramp construction - calculation

Before starting work, you need to prepare, make all the necessary calculations and measurements, that is, draw up a project. According to the standards, the height of the ramp should be related to the length in the calculation of 1:12. This means that to build a structure with a height of 1 meter, you need to make it 12 meters long, and with a height of 1.2 meters - 15 meters. However, according to the standards, it is prohibited to do this, so you need to divide it into 2 flights of the same length - 7.5 meters each, the platform between the flights will be at a height of 0.6 meters (h1 / 2 = 1.2 / 2)

Let's take the size of the area between the flights to be 2 m2. Based on this, you need l1 17 m2 (15 m and 2 m platform). V1 = 1/10 s = 1/10 17 m2 = 1.7 cubic meters. V2 = h1 * l1 = 1, 2 * 15 = 18 m2 * ½ brick thickness (0.125 m) = 2.225 cubic meters. m = 2.25: 0.002 = 1125 pieces.

We also determine the volume of fill used (9 m3) and the required length of the reinforcement bars (243 linear meters): • area - s; • ramp height – h1; • platform height – h2; • slab length – l1; • volume of concrete - v1; • volume of walls - v2; • number of bricks - n.

Installing a ramp for disabled people on the porch: 3 ways to do it yourself

There are too many restrictions in the lives of wheelchair users. But some of them can be easily eliminated if you pay attention to the needs of such people.

For example, equip stairs, curbs and other obstacles that are insurmountable for wheels with flat inclined surfaces - ramps. The installation of a ramp for disabled people on the porch is the topic of this article.

Types of ramps and requirements for their design

According to their type and purpose, ramp designs can be different. But the requirements for them are generally the same.

Ramps designs

Depending on the purpose of the building, the ramp on the porch is made permanent, removable or folding.

- Stationary devices are designed for constant use and long-term operation. They are installed at the entrance to medical institutions, office buildings, shops, pharmacies, etc. And also in parks, underground passages and other public places where there are stairs and high curbs. Ideally, they are provided for before construction begins, at the design stage. This is a concrete or metal inclined plane, or two wide guides with a non-slip coating, often with turntables and handrails.

In the photo - a stationary metal ramp on the city square

- Removable ramps are designed for moving over minor and unexpected obstacles. They are light and mobile. As a rule, such devices are folded or disassembled for transportation and installation in the desired location. They are made from durable but lightweight materials, such as duralumin.

- Folding structures perform the same functions as stationary ones, and they look similar. But they can be folded to the side and attached to a wall or handrails. This ramp design allows you to use it only when necessary. The rest of the time the staircase is free for pedestrian traffic along its entire width. This is very convenient for a narrow porch, as well as for flights of stairs in entrances.

For reference. Folding platforms or rails will make life much easier for mothers with baby strollers. Especially in houses without an elevator.

Legal regulation

Today the “Accessible Environment” program is operating in Russia. Begun in 2009, it mandates that by 2020 the creation of free access for people with disabilities to infrastructure throughout the country. The legal framework also includes other documents regulating the free movement of wheelchair users. Here are some of them:

- Article 7 of the Constitution of the Russian Federation: on the creation by the state of conditions for a decent life and development of Russians.

- Federal Law No. 181 “On the social protection of people with disabilities in the Russian Federation”, adopted on November 24, 1995, approved the rights of people with disabilities to unhindered access to public places. On 01/01/16, amendments were made to it regarding the creation of comfortable living conditions for people with disabilities.

- The UN Convention on the Rights of Persons with Disabilities was adopted by Russia in 2012. According to this document, people with disabilities should be given access to urban and rural infrastructure, transport, and apartments in residential buildings.

- Regulatory acts of Russian regions, thanks to which freedom of movement for wheelchair users is provided.

- GOST standards that establish standards for the creation and construction of devices that ensure accessibility to infrastructure facilities for disabled people and mothers with baby strollers.

- What temperature is detrimental to coronavirus?

- Stomach hurts after eating

- 8 amendments that can be made to the Constitution of the Russian Federation

Design requirements

To make the movement of sedentary people and those accompanying them comfortable and safe, instructions have been developed with clear requirements for the design of the ramp.

Here are its main points:

- The slope of the lifting plane should not exceed 8 degrees. In exceptional cases, it is allowed to increase it to 10 degrees. The most comfortable slope is considered to be 5 degrees.

- The length of the ramp is determined based on the first point - but taking into account the fact that the vertical height of the rise above the ground level or lower platform cannot be more than 80 cm. If this parameter is greater, then the design provides for intermediate or turning platforms.

- The width of the inclined surface or the distance between the guides must correspond to the standard width of the stroller wheel mounting. The width of the guides themselves should be such that the wheels move freely between the sides and do not get stuck.

- Sides are a mandatory element of any design, preventing wheels from sliding sideways.

- A porch with a ramp for the disabled must be equipped with platforms on both sides. Their width is not less than the width of the ramp, and their length is not less than 130 cm.

Note. The length of the platform can be increased upward if this is required to freely open the door in front of the stroller.

- The material must be non-slip, with a corrugated surface. Or it is lined with rubber pads.

- If the lift height is more than 15 cm or if the length of the ramp exceeds 180 cm, it is equipped with handrails on both sides.

- The handrails should be 30 cm longer than the inclined plane and located in two rows at a height of 60 and 80 cm. If the structure is also intended for the movement of children with disabilities, then a third handrail is installed at a height of 50 cm.

- The handrails must be solid along the entire length, round in shape with a cross-sectional diameter of 3-5 cm.

Failure to do so may result in falls and injury.

Requirements for folding and folding ramps

To really make it easier to move around in a wheelchair or wheelchair, it is necessary to develop a product drawing that actually complies with the standards.

- Angle of inclination - the requirements are categorical. With a march height of up to 80 cm, this is the maximum permissible height; the slope cannot exceed 2.9 degrees. With a height of 50 cm, 4.8 is allowed. If the height of the march is 20 cm, then the angle of inclination can be made steeper - up to 5.7 degrees.

- The length of the descent is determined by the angle of inclination. The value is calculated using the triangle rule. If such a length turns out to be impossible, a screw version can be constructed.

- The width of the structure is determined by the mode of movement. For one-way movement, at least 0.9 m will be required, for two-way movement – 1.8 m.

- The metal or wooden structure must include guides for a child's stroller or wheelchair. The width of the latter should be equal to or slightly greater than the thickness of the tire.

- The entrance to the entrance must have a fence - the only exception is a march with a height of 15 cm and a length of no more than 80 cm. In addition, bumpers are required on the sides of the march to prevent slipping.

How to make a ramp

While such devices are found almost everywhere at the entrance to public buildings and shops, they are almost never found on the entrance porch. Although management companies, if there are disabled people living in the house, should take care of this.

Not everyone is ready to butt heads with officials or wait a long time, so they take matters into their own hands. And if a person with limited mobility lives in a private house, then relatives should take care of his comfortable movement.

You can watch the video in this article to better understand all the nuances.