The durability and stability of the entire structure depends on the reliability of the foundation. The grade of concrete for the foundation of a private house is selected based on the expected loads, as it guarantees the strength of the building being constructed. Therefore, the answer to the main question, what cement composition is needed for a building, is always relevant. The strength class of a building material that is approved for the construction of a building of 1 or several floors must be at least M200.

Concrete grade

Concrete is classified according to classes and grades. Strength class is the main parameter influencing the choice in various fields of application. It is designated by the Latin letter B and is expressed in MPa. The indicated figure indicates the maximum permissible compression pressure. That is, class B30 concrete can withstand loads of up to 30 MPa. When constructing a strip foundation, the safety margin is always taken into account, because private and any other construction must have guaranteed reliability.

Important! Over time, the strength of concrete changes.

The design of a strip foundation is carried out taking into account the construction period and the specific load at its various stages. On average, strength gain lasts 28 days after pouring concrete, after which the process slows down significantly.

The strength of concrete is also evidenced by its grade, which ranges from 50 to 1000 units. This figure indicates the withstand compression pressure, expressed in kg/cm2. That is, concrete grade M200 is designed for a load within 200 kg/cm2.

GOST 366633-91 contains a table showing the correspondence between the class and grade of concrete. This information must be taken into account when designing a strip foundation:

When studying the topic of what kind of concrete is needed for a strip foundation, in addition to the grade, other indicators are also important:

- Private buildings in cold climates require paying attention to the frost resistance of concrete, that is, the ability to withstand cycles of freezing and thawing. The parameter is denoted by the letter F; the number indicates the number of cycles after which the strip foundation will not lose its performance characteristics declared during the design. The climate of the middle zone allows the use of concrete with frost resistance grade F200.

- Groundwater located close to the surface also has a significant impact on the strength of concrete in a strip foundation. Therefore, it is important to consider its resistance to water pressure, which varies between 2-20 units. The indicator is marked with the letter W.

Characteristics of concrete for the foundation of a private house

The grade means what load the base of the structure can withstand after final hardening, and the class of concrete means the guaranteed strength of the concrete. The brand of cement is indicated above depending on the percentage of the main ingredient. Thus, concrete M400 includes 1 kg of cement, 2.8 kg of sand and 4.8 kg of crushed stone of different fractions. The main parameters of frost resistance and water resistance are achieved by combining the components in certain proportions.

The reliability of the design can be predicted based on the class and grade of the material.

The entire line of markings begins with the designation of the index by the letter M. The numerical value describes the maximum compressive strength of the material (kg/cm2). To decide on the choice of a suitable brand of concrete for building a foundation, you need to know their purpose:

- M100. Suitable for small construction work without the use of special tools and devices; it is used for arranging wooden houses and for fencing.

- M200. Used for the construction of elements with a low degree of load-bearing load.

- M300. Withstands pressure and compressive strength from large private houses up to 5 floors.

- M400, M500. It is recommended to use for the foundations of multi-storey buildings and complexes.

Factors determining the choice of brand

The grade of concrete for the foundation of a private house is selected taking into account several factors that influence the supporting structure. The basic principle is proportionality: the stronger the pressure exerted on the tape, the higher the grade of concrete used to prepare the solution.

So, when choosing a brand you should consider:

- The massiveness of the future private building. Cottages made of timber or gas silicate blocks have significantly less weight than brick buildings. Therefore, the grade of material for the foundation should not be the maximum value.

- Soil properties. This or that type of soil under a private house exerts different pressure on the strip base. If there is hard rocky soil or sandstone, it is enough to take M150 or M 250; loam will require greater strength, so a suitable grade reaches the M350 level.

- In addition to strip foundations, a combined version with piles is also used in private construction. It is especially relevant on soils prone to heaving. The design of the supporting base is taken into account when determining what kind of concrete is needed for it.

- UGV. The water permeability of the foundation is obvious. Information about seasonal fluctuations in groundwater will help you choose the right brand.

Advice! Waterproofing, which is used for the base and side surfaces of the strip foundation, is designed to protect the foundation of a private house from premature destruction. It comes in different forms - rolls, pasting or coating materials.

Conclusion

To select a material for the foundation of a private one- or two-story house, it is necessary to calculate the weight of the structure, determine the safety margin taking into account possible errors and inaccuracies during construction, find out the depth of groundwater, and take into account the influence of the soil on the foundation being poured.

It is important to accurately calculate the amount of the main components of the concrete mixture, otherwise there may not be enough of them or an excess will form. First, the costs of materials for slabs, foundation strips, pillars and other components are separately calculated. The resulting figures are summed up and multiplied by the shrinkage coefficient of the laid concrete with the corresponding grades. This value can be taken from the passport. When using reinforcement, the volume it occupies in the formwork is taken into account. The resulting volume of concrete is divided by a factor of 1.05, and the resulting value is rounded up.

Composition of the solution

Other components of the solution also influence the question of what brand of concrete to use for a strip foundation. Cement used in frequent construction has several varieties depending on the presence of additives or without them:

- normalized;

- fast-hardening;

- with a high degree of frost resistance;

- having low moisture absorption;

- with protection from aggressive environments.

The strength of the strip foundation is ensured by the presence of reinforcement. In addition to common metal rods, there are also polymer rods that are not subject to corrosion processes. The reliability of the reinforcement cage depends on several factors:

- type of rods;

- brand;

- section;

- quality of material (no rust);

- installation method (welding or knitting);

- material for knitting (polymer or iron).

Comment! The reinforcement structure must be located in the thickness of the strip foundation, not in contact with the walls and bottom, but at the same time exceed the boundaries of the strip belt at the top.

In addition to the required grade of concrete, a high-quality solution is ensured by the correct proportion of other components, which are selected depending on the characteristics of the soil and the planned load on the strip foundation. Possible components:

- sand;

- crushed stone or gravel;

- lime or clay;

- special additives that increase one or another quality of concrete mortar.

Increased soil moisture forces an increase in the proportion of cement. Information from reference books and manufacturers' recommendations will help you calculate the required proportion. The quality of concrete mortar is also influenced by the fractions of accompanying materials (crushed stone, sand or gravel). Cement that is not sold in a timely manner loses strength, as a result, the M500 grade gradually corresponds to the indicators characteristic of the M400 grade, and then is converted into the M300 grade. Therefore, the concrete for a strip foundation must be “fresh”.

When calculating the need for components for pouring a strip foundation, one feature should be taken into account: often the cost of the material is indicated for 1 ton, and a private developer requires the amount of volume in cubic meters. And here we must remember the regularity: there is more material with a fine fraction of 1 m3 in mass than larger fractions.

Common grades of cement may have the following proportions:

Attention! A high-quality solution is obtained when the grade of Portland cement is twice as high as the grade of concrete for the strip foundation. That is, when forming a supporting structure in private construction, durable concrete grade M200 is sufficient; cement grade M400 is used for it.

More durable grades of concrete, starting from M300, require smaller ratios, so the proportion to the cement grade can be reduced to 1.5. For concrete grade M400, cement grade M600 will be sufficient.

What does a concrete foundation consist of?

The composition of the ingredients in concrete for the base in a private house includes water, cement, sand, crushed stone or gravel. The fractional content of sand should consist of particles measuring 1.2-3.5 millimeters, but not smaller. The component must be free of silt and clay. However, impurity content up to 5% is allowed. Otherwise, the strength of concrete will decrease.

The size of gravel or crushed stone varies between 1 and 8 centimeters. The material must also be clean. Cement is selected from the following categories:

- Portland cement, suitable for the construction of any buildings on a monolithic foundation;

- slag Portland cement, characterized by increased moisture resistance, but instability at low temperatures and a low rate of strength gain;

- pozzolanic Portland cement, intended for the construction of foundations with close groundwater or in conditions of high humidity, for the construction of underwater and underground buildings, but in the air it loses its properties and causes severe shrinkage;

- quick-hardening derivatives of the categories of mixtures listed above, which shorten the maturation period of ready-made concrete.

The classic solution for the foundation of a private house consists of 80% fractional filler (sand, crushed stone or gravel) and 30% binder (cement with water).

Areas of use

The grade of concrete for the foundation is determined taking into account the planned load; recommendations from manufacturers will help you make the right choice:

- The M100 grade is optimal for installing curbs along the road; in private construction, concrete of similar strength can only be useful for preparing a cushion under a strip foundation.

- The strength of the M150 grade is not much higher than M100, therefore, in addition to the design of the pillow, in home construction it is used for concreting platforms and forming screeds. If you plan to build a lightweight one-story building, a strip foundation filled with grade 150 concrete will fully withstand the load. Although in this situation it is more practical to turn to a columnar support structure.

- The scope of use of the M200 brand is the formation of stairs, strip and slab foundations. The strength of concrete allows you to make blind areas and support structures from it when terracing the site.

- The more durable grade M300 is suitable for constructing foundations of all types, monolithic walls, ceilings and partitions, stairs and supports for fences.

- The large load-bearing load of the structure forces us to turn to the M 350 brand. The material can withstand even the pressure of an aircraft, so airfield slabs are made using M350.

- The scope of application of M400 concrete bypasses private construction. These are mainly bridges, bank vaults, supporting frames in seismic zones.

Comment! The shrinkage coefficient increases the quality of concrete: the lower the indicator, the higher the strength. The required parameters are achieved by introducing special additives.

Placement options

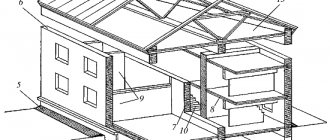

The depth of the structure during capital construction must be higher than the level of soil freezing, which increases labor costs, the cost of work, and the consumption of concrete casting. If we are talking about low-rise construction, you can build a monolithic shallow foundation .

Strip foundation - basic properties of concrete

To understand what brand of concrete is needed for the foundation of a summer house, bathhouse or garage, you need to familiarize yourself with its characteristics.

The arrangement of separate concrete pillar supports will allow you to avoid high financial costs

Strength - the ability to resist compressive loads:

- the minimum value is 100 kg/cm². The upper limit used in private housing construction is 400 kg/cm²;

- strength parameters determine the class, grade and cost of reinforced concrete;

- when selecting material, it is necessary to calculate the load that will be transmitted to the structure under the weight of the structure;

- the maximum level of loads on the support is calculated based on the weight of floors, engineering systems, walls and a number of additional loads, for example, snow;

- the resulting value is divided by the area of the support, so the calculated load is derived.

Nuances of foundation arrangement

Concrete for the foundation plays a key role in the formation of a durable structure. M200 grade material will help achieve the goal, but there are a number of nuances that should be taken into account during private construction:

- The proximity of groundwater obliges us to turn to the M300 brand. This is explained by the ability of high-grade material not to lose strength during prolonged contact with moisture.

- Reinforcement of a strip foundation is an essential condition for creating a solid foundation. Corrugated rods with a cross-section exceeding 12 mm are optimally suited for the frame.

- The bundle of pieces of metal reinforcement is carried out staggered.

- The pouring of the strip foundation is organized in one step. This requirement is especially relevant when using low grade concrete.

- Covering the recently poured concrete with burlap or sawdust will help slow down the evaporation of moisture in hot weather, thereby maintaining the stated strength of the strip base. It is also recommended to regularly water the surface.

Private construction requires a balanced approach at every stage. An informed choice of concrete grade will help create a reliable strip foundation that will preserve the integrity of the entire structure for a long time.

- Screw foundation

- Strip foundation on sand

- Bored foundation for a house

- Foundation for a brick bath

What is a grade of concrete strength, and what are they?

The class determines the maximum load it can bear. This indicator is indicated by the letter B and a number after it, for example, B25 means that the material can withstand pressure up to 25 MPa. There is also a marking with the letter M, indicated in kg/cm2. M100 can withstand up to 100 kg/cm2. The range of brands for the construction of the foundation of a residential building and other buildings starts from M100 and reaches M500.

To convert a brand into a class, the following formula is used: B=M*0.787/10. The class varies depending on the composition. The more cement, the higher the strength.

For foundations, M100, M150, M200, M250, M300, M400 and M500 are used. M100 and M150 are selected for the construction of utility buildings, small garages, fences, private houses (no more than one floor) made of foam, aerated concrete or wood. Also as an initial layer for pouring a higher class solution. M200 is used in the construction of the foundations of small buildings made of gas concrete, foam concrete, cinder blocks with light floors. M250 and M300 are suitable for constructing the foundations of two-story houses and buildings with more floors, pouring monolithic structures. Concrete of this brand can withstand significant loads; most often it is chosen for the construction of private houses.

M350, M400 and M500 are suitable for multi-storey buildings. According to building codes, it is not recommended to use a solution below M250.

The type of base affects the class; for example, a house with a basement will require stronger concrete than a conventional building. The grade for strip foundations may be low, but for pile foundations a higher grade is needed. If the groundwater level is high, M350 or more is selected for the pile foundation.

Recommendations and requirements for filling

Only clean sand should be used. Either crushed stone or gravel with a fraction of 2-4 cm is selected as a filler. Broken bricks cannot be used, as this significantly reduces the strength characteristics. Cement is selected grade 400 or 500. The most common proportion of components is 1: 3: 4 (cement/sand/crushed stone). Everything is thoroughly mixed to a homogeneous consistency, there should be no lumps.

The denser the solution, the stronger the foundation will be. Because of the voids, the quality and strength of the entire structure decreases, so after pouring the mixture is treated with a vibration machine. It will evenly distribute the mixture over the entire surface, compact it and remove air.

The monolith should be poured in one go. If you do this in several stages, then the first batch will already have time to set. After pouring the second one, a “cold seam” will appear in the concrete. According to the principle of action, this defect is similar to cracks. As a result, the base will not be monolithic, but will consist of several parts. It may break due to the load.

During pouring, temperature conditions must be observed; the optimal temperature is considered to be +16°C. If construction is carried out during the winter season, then anti-frost components are added to the solution. If without them, then the foundation must be insulated and warmed, for example, with heat guns or electric current, thanks to this the water will not freeze.

In summer, water evaporates too quickly from the top of the solution. As a result, the concrete dries unevenly and cracks appear. To avoid this, it is constantly watered with water and covered with non-transparent material. Or plasticizers are added at the stage of diluting the mixture.

During hardening, all necessary conditions must be met - temperature, humidity, and so on. Concrete gains its greatest strength after 28 days (at optimal temperature and humidity conditions).

For buildings that will be built from aerated concrete, monolithic foundations should be erected, since it has a weak bending property. Even with slight heaving of the soil, cracks appear in the blocks. If the foundation is monolithic, the load will be distributed evenly over the entire surface.

The cost depends entirely on the brand of concrete. The higher it is, the more cement was spent to make it. To determine the required volume of solution, it is better to contact specialists, since if there is a shortage of the mixture, the foundation will be poured more than once, which will lead to a deterioration in its quality, and if there is an excess, there will be an overpayment.

Proportions of components for concrete

In recipes, concrete compositions are given by weight or volume. Moreover, cement is always taken as 1, and all other components are taken in relation to it. The proportions for commonly used brands are shown in the table.

Proportions for concrete grades. For foundations, M200, M250, M300 are most often used

As you can see, the same concrete can be obtained using different brands of cement. Fall asleep as you have, only adhering to the recommended mass (or volume) portions. Mostly when pouring foundations, Portland cement M400 and M500 is used. When composing the mixture, remember that if gravel is used instead of crushed stone, 0.05 more water is added.

How to decipher the table instructions? For example, let’s take concrete grade M250, it will be made from Portland cement M400. We will focus on mass. Then select the corresponding line in the third column: 1/2,1/3,9. This means that for one kilogram of M400 cement, we take 2.1 kg of crushed stone and 3.9 kg of sand. The amount of water can be taken from the table below - it is 0.65 kg for crushed stone backfill.

Water-cement ratio for different grades of concrete

If we compose the same concrete based on volume, for example a 10-liter bucket, then we take the proportions from the fourth column: 10/19/34. This means that for 1 bucket of cement, we put 1.9 buckets of sand, 3.4 buckets of crushed stone. The water/cement ratio remains the same: 0.65 buckets.

Sometimes you need to calculate how many components are required for one cube of concrete. These data are shown in the following table.

Proportions of concrete per cubic meter. The mass of the components is indicated in kilograms, parts are given in brackets.

Another table summarizes data on the consumption of M400 and M500 cement per cubic meter of the most popular grades of concrete during foundation construction.

Cement consumption per cubic meter of concrete of different grades

The correct grade of concrete for the foundation is the key to its strength. But high-quality compounds are very expensive. If, according to all the recommendations given, you need to use M300 and higher, it is better to order a foundation calculation that will confirm or refute your assumptions. This service costs about $100-$150, but can save you thousands if you want a lower grade.

The service life of any building is largely determined by the strength of the supporting structure. For private buildings, strip, slab, columnar and pile foundations are used. The first two types are especially in demand during the construction of a residential area. Therefore, the question of what brand of concrete is needed for a strip foundation always sounds relevant. After all, the value of the indicator directly affects the quality of the basic support of a private house.

Concrete grade

Concrete is classified according to classes and grades. Strength class is the main parameter influencing the choice in various fields of application. It is designated by the Latin letter B and is expressed in MPa. The indicated figure indicates the maximum permissible compression pressure. That is, class B30 concrete can withstand loads of up to 30 MPa. When constructing a strip foundation, the safety margin is always taken into account, because private and any other construction must have guaranteed reliability.

Important! Over time, the strength of concrete changes.

The design of a strip foundation is carried out taking into account the construction period and the specific load at its various stages. On average, strength gain lasts 28 days after pouring concrete, after which the process slows down significantly.

The strength of concrete is also evidenced by its grade, which ranges from 50 to 1000 units. This figure indicates the withstand compression pressure, expressed in kg/cm2. That is, concrete grade M200 is designed for a load within 200 kg/cm2.

GOST 366633-91 contains a table showing the correspondence between the class and grade of concrete. This information must be taken into account when designing a strip foundation:

When studying the topic of what kind of concrete is needed for a strip foundation, in addition to the grade, other indicators are also important:

- Private buildings in cold climates require paying attention to the frost resistance of concrete, that is, the ability to withstand cycles of freezing and thawing. The parameter is denoted by the letter F; the number indicates the number of cycles after which the strip foundation will not lose its performance characteristics declared during the design. The climate of the middle zone allows the use of concrete with frost resistance grade F200.

- Groundwater located close to the surface also has a significant impact on the strength of concrete in a strip foundation. Therefore, it is important to consider its resistance to water pressure, which varies between 2-20 units. The indicator is marked with the letter W.

Factors determining the choice of brand

The grade of concrete for the foundation of a private house is selected taking into account several factors that influence the supporting structure. The basic principle is proportionality: the stronger the pressure exerted on the tape, the higher the grade of concrete used to prepare the solution.

So, when choosing a brand you should consider:

- The massiveness of the future private building. Cottages made of timber or gas silicate blocks have significantly less weight than brick buildings. Therefore, the grade of material for the foundation should not be the maximum value.

- Soil properties. This or that type of soil under a private house exerts different pressure on the strip base. If there is hard rocky soil or sandstone, it is enough to take M150 or M 250; loam will require greater strength, so a suitable grade reaches the M350 level.

- In addition to strip foundations, a combined version with piles is also used in private construction. It is especially relevant on soils prone to heaving. The design of the supporting base is taken into account when determining what kind of concrete is needed for it.

- UGV. The water permeability of the foundation is obvious. Information about seasonal fluctuations in groundwater will help you choose the right brand.

Advice! Waterproofing, which is used for the base and side surfaces of the strip foundation, is designed to protect the foundation of a private house from premature destruction. It comes in different forms - rolls, pasting or coating materials.

Composition of the solution

Other components of the solution also influence the question of what brand of concrete to use for a strip foundation. Cement used in frequent construction has several varieties depending on the presence of additives or without them:

- normalized;

- fast-hardening;

- with a high degree of frost resistance;

- having low moisture absorption;

- with protection from aggressive environments.

The strength of the strip foundation is ensured by the presence of reinforcement. In addition to common metal rods, there are also polymer rods that are not subject to corrosion processes. The reliability of the reinforcement cage depends on several factors:

- type of rods;

- brand;

- section;

- quality of material (no rust);

- installation method (welding or knitting);

- material for knitting (polymer or iron).

In addition to the required grade of concrete, a high-quality solution is ensured by the correct proportion of other components, which are selected depending on the characteristics of the soil and the planned load on the strip foundation. Possible components:

- sand;

- crushed stone or gravel;

- lime or clay;

- special additives that increase one or another quality of concrete mortar.

Increased soil moisture forces an increase in the proportion of cement. Information from reference books and manufacturers' recommendations will help you calculate the required proportion. The quality of concrete mortar is also influenced by the fractions of accompanying materials (crushed stone, sand or gravel). Cement that is not sold in a timely manner loses strength, as a result, the M500 grade gradually corresponds to the indicators characteristic of the M400 grade, and then is converted into the M300 grade. Therefore, the concrete for a strip foundation must be “fresh”.

When calculating the need for components for pouring a strip foundation, one feature should be taken into account: often the cost of the material is indicated for 1 ton, and a private developer requires the amount of volume in cubic meters. And here we must remember the regularity: there is more material with a fine fraction of 1 m3 in mass than larger fractions.

Common grades of cement may have the following proportions:

Attention! A high-quality solution is obtained when the grade of Portland cement is twice as high as the grade of concrete for the strip foundation. That is, when forming a supporting structure in private construction, durable concrete grade M200 is sufficient; cement grade M400 is used for it.

More durable grades of concrete, starting from M300, require smaller ratios, so the proportion to the cement grade can be reduced to 1.5. For concrete grade M400, cement grade M600 will be sufficient.

Areas of use

The grade of concrete for the foundation is determined taking into account the planned load; recommendations from manufacturers will help you make the right choice:

- The M100 grade is optimal for installing curbs along the road; in private construction, concrete of similar strength can only be useful for preparing a cushion under a strip foundation.

- The strength of the M150 grade is not much higher than M100, therefore, in addition to the design of the pillow, in home construction it is used for concreting platforms and forming screeds. If you plan to build a lightweight one-story building, a strip foundation filled with grade 150 concrete will fully withstand the load. Although in this situation it is more practical to turn to a columnar support structure.

- The scope of use of the M200 brand is the formation of stairs, strip and slab foundations. The strength of concrete allows you to make blind areas and support structures from it when terracing the site.

- The more durable grade M300 is suitable for constructing foundations of all types, monolithic walls, ceilings and partitions, stairs and supports for fences.

- The large load-bearing load of the structure forces us to turn to the M 350 brand. The material can withstand even the pressure of an aircraft, so airfield slabs are made using M350.

- The scope of application of M400 concrete bypasses private construction. These are mainly bridges, bank vaults, supporting frames in seismic zones.

Nuances of foundation arrangement

Concrete for the foundation plays a key role in the formation of a durable structure. M200 grade material will help achieve the goal, but there are a number of nuances that should be taken into account during private construction:

- The proximity of groundwater obliges us to turn to the M300 brand. This is explained by the ability of high-grade material not to lose strength during prolonged contact with moisture.

- Reinforcement of a strip foundation is an essential condition for creating a solid foundation. Corrugated rods with a cross-section exceeding 12 mm are optimally suited for the frame.

- The bundle of pieces of metal reinforcement is carried out staggered.

- The pouring of the strip foundation is organized in one step. This requirement is especially relevant when using low grade concrete.

- Covering the recently poured concrete with burlap or sawdust will help slow down the evaporation of moisture in hot weather, thereby maintaining the stated strength of the strip base. It is also recommended to regularly water the surface.

Private construction requires a balanced approach at every stage. An informed choice of concrete grade will help create a reliable strip foundation that will preserve the integrity of the entire structure for a long time.

- Screw foundation

- Strip foundation on sand

- Bored foundation for a house

- Foundation for a brick bath

Question from our reader Dmitry: Please tell me what brand of concrete is needed for the foundation of a private house? The building will be made of brick, 2 floors, ceilings - concrete slabs. The type of soil in our area is clayey, the freezing depth is 1.4 m, the level of groundwater is 2.6 m. The fact is that I do not have the funds for a reputable contractor, and the competence of the private owner whom I want to hire to carry out the work is limited. It's best to check before starting construction.

The question is posted in the sections: questions , construction, foundations, concrete, brand irindom

Irina Nerekhta October 18, 2020, 10:05 pm

Other posts about foundations

I want to build a house. I have a strip foundation 120 cm deep, size 7x8 m, I want to build a house 10x10 m. Is it possible to increase the area of the house using a pile-screw foundation, will different types of foundation coexist peacefully or not? If not,…

We want to make a second floor in the attic, but we don’t know whether the foundation will hold it. The foundation is old, about 40 years old, strip, about half a meter wide and a meter high. Is there any way to find out how much load the foundation can support?

Hello! A country house 6x9 m sank at one corner by about 5 cm into the ground. There are no cracks. They say that it sat down a long time ago, almost immediately after construction (the house is about 20 years old). The house is built something like this: there are blocks dug into the ground, they look like the ones that...

Construction of foundations and houses from old tires. Clay pot technology.

The frame house is built on blocks. Is it possible to place a foundation under it or install piles?

Question from our subscriber Lyubov: There is a lot of rubble stone on the site (the remains of the destroyed house of the previous owners; the walls were made of stone from the Volga, mixed with clay). We want to build a new house, dimensions approximately 7x8. Is it possible...

See all materials

about foundations :

See all

What grade of concrete is needed for the foundation of a house?

The reliability of the foundation of any structure is the key to its durability. Various types of concrete are used in construction, but if we are talking about the foundation of a house, then only heavy ones are used to load it into the formwork - this is an axiom. We will talk about how to choose the right brand for artificial stone.

Heavy concrete is called concrete in which the filler is fractions of rocks (mainly crushed stone of various types). The sizes of granules for the foundation of a private house are selected from 6 mm. Such solutions are designated by brand from M100 to M500.

What should you focus on?

There is no clear advice on choosing a solution. When deciding what kind of concrete is needed for the foundation of a house, you have to take into account a whole range of factors and, as a rule, look for a compromise option. In this case, the cost of production is not of paramount importance. Even the most expensive brand is characterized by certain restrictions in its use, so all further recommendations are only of a general plan.

1. Expected load.

When calculating it, the following components are taken into account:

- the material from which the house is built - brick, wood, aerated concrete or others. It is clear that the weight of the frame structure will be significantly lower than, for example, from reinforced concrete;

- number of floors of a private building;

- “filling” of the house - engineering equipment, household appliances, furniture, personal belongings. You also need to consider the prospect of purchasing something else.

When determining the grade of concrete for the foundation, it is necessary to ensure a certain margin of safety. Possible errors in calculations, errors and various force majeure circumstances cannot be ruled out.

- M100. As for a private house - if it is made of wood or aerated concrete on the 1st floor - this brand (with some restrictions) can be used. Although most often it is used only at the stage of preparation for laying the foundation. If grade 100 is chosen for a house (for example, aerated concrete), then a “cushion” of the same solution, at least 100 mm, must be installed.

- M150. For small light buildings. For example, if the house is being built from aerated concrete, cinder blocks and similar materials.

- M200. This brand is suitable for the foundation of a two-story house with a light ceiling. On such a foundation, prefabricated panel structures and buildings made of cellular concrete are often erected.

- M250. For the foundations of houses made of aerated concrete or wood, if they have no more than 3 floors.

- M300, 350. These grades are used for pouring foundations for heavy buildings. For example, when building a private house made of brick.

Addition:

- In some cases (on problematic soils and in other situations), concrete M400 and 450 is used. It is not advisable to use a grade higher than those indicated in the private sector. Such expenses can hardly be considered justified, given the high cost of the product.

- For a private brick building, the concrete grade M250 is selected for a strip foundation, provided that it is one-story.

There is an opinion that mortars of grades 200 and below are not used for arranging the foundation of a residential building of any type. However, opponents point out that factors such as soil properties, reinforcement density, and design features of the house should be taken into account. It is acceptable to use grades M100 – 200, but this is not a rule, but special cases. The choice of cheap brands should be made based on accurate calculations, since M350 is considered optimal for the construction of the foundation of a residential building (both in terms of the strength of the artificial stone and in price).

Under no circumstances are aerated concrete and its cellular analogues used for foundation construction!

2. Soil characteristics.

- Sandstone, rock - such soils are homogeneous in composition, so the entire load on the base is distributed evenly. For lightweight houses, grades 150–250 are suitable, for more massive buildings: 300–400.

- Heaving soils (for example, clay, loam) - they are considered problematic in construction. The peculiarity is increased soil displacements during sudden temperature changes. In such conditions, it is not recommended to use a grade below 350 for the foundation.

The configuration of underground aquifers also matters. Taking into account the specifics of their location, you need to focus on such a characteristic as water resistance. It is relevant for houses with a basement floor.

The base can be protected from contact with liquids by using better waterproofing, installing a reliable drainage system, and introducing hydrophobic additives. If you focus only on the brand, then you should know that the higher it is, the better the moisture resistance. This indicator is designated by the letter “W”. The grade of concrete for water resistance is expressed as a value from 2 (weak) to 8 (high).

When choosing a solution based on this characteristic, you need to calculate what is more profitable: purchase more expensive concrete (W7 - or spend money on materials and carry out additional treatment of the foundation of the house.

or spend money on materials and carry out additional treatment of the foundation of the house.

3. Climate features.

Here frost resistance comes to the fore. It shows how many freeze/thaw cycles the concrete does not change its performance properties. In the marking it is indicated by the letter “F”. The result of an incorrect choice in this parameter is the appearance of cracks on the base and walls of the basement of a private house. In combination with other mistakes made (for example, during technological operations), this may appear after the first winter.

For our latitudes, it is advisable to purchase concrete with an index of at least F75 for the construction of the foundation, regardless of the brand.

What else can you clarify?

1. Size of filler granules.

For a slab foundation, this is not so important, since it is rarely installed for private buildings. But for the tape type, and especially the columnar type, this is relevant. Why? For the first, concrete is poured into a horizontally oriented formwork, for the second - into a vertical form. But in any case, the base is strengthened, regardless of its type. After loading the solution, the mass must be compacted to remove excess water and air.

The quality of compaction and, as a consequence, the uniformity of the structure and the strength of the foundation depend on how tightly the reinforcement is made (cell parameters). If pipes are used for a columnar foundation, then you need to purchase concrete with fractions of no more than 4-6 mm.

2. Type of filler.

Concrete containing granite crushed stone is considered the most reliable. On this basis, the house will stand for a very long time.

3. Mobility of the solution.

Another characteristic (indicated by the letter “P”), which does not depend on the brand. We can say that it shows how convenient it will be to work. Numerical values are from 1 to 5 (the most liquid composition). If it is loaded manually, then an indicator within 2-3 is sufficient. When using a feed pump, you should focus on concrete not lower than P4.

It is prohibited to dilute the solution to increase its fluidity. Adding water simplifies the work, but at the same time changes the proportion of components, reduces the grade and, as a result, the reliability of the foundation.

There is often confusion with the concepts of brand and class. Without going into details, suffice it to say that the latter term is just a derivative of the first. Class (B) is a more accurate parameter, while brand is an average indicator. In any case, the higher their numerical values, the stronger and more durable the base will be.

stroitel-list.ru