It is very difficult to feel comfortable in an apartment or house without a quality floor. In most cases, to obtain an excellent result, it is necessary to perform two operations: first level the base, thereby achieving ideal conditions for laying the flooring, and then lay the flooring itself, which is an integral part of the future interior and plays an important role in creating a pleasant atmosphere.

Floor leveling mixtures

As a rule, a dry mixture diluted in water is used to level the floor. To create a high-quality floor, you must follow the instructions that the manufacturer must enclose with the package with the mixture.

Dry mixtures contain different binding elements:

- Mixtures for which gypsum is the binding element;

- Mixtures for which cement is used as a binding element;

Mainly cement mixtures are used. This is due to the fact that cement mixtures are less susceptible to moisture than gypsum mixtures. Therefore, gypsum mixtures are highly not recommended for use in rooms with high humidity. As a rule, the packaging with dry leveling mixture indicates what type of premises the mixture is intended for. Please read the attached instructions carefully!

Popular questions:

Which expanded clay is better for the floor, which fraction to choose? There is an answer from an expert

Which floor is better, concrete or wood? There is an answer from an expert

Which floor is better to make in the garage, which option is cheaper There is an answer from an expert

All questions

Types of mixtures and their features

As for classification, the mixtures in question can be leveling and self-leveling, which in turn are used to apply the initial or finishing layer.

This is what a good result of smoothing out unevenness looks like

The difference between the mixtures lies in the way they are worked with. For example, self-leveling mixtures spread with virtually no human intervention. If the room is of impressive size, the mixtures are poured using pumping devices, that is, pumps. But leveling mixtures require active participation: they must be spread manually with a spatula. This means that self-leveling mixtures have greater fluidity.

If we consider this issue more carefully, we will notice that self-leveling compounds quickly harden and are intended for leveling and leveling bases. Their main purpose is to prepare floors, for example, made of concrete, wood, gypsum for the subsequent installation of carpet, cork, linoleum, ceramic tiles.

After this self-leveling floor dries, a durable, dense layer is formed. It should be understood that this base cannot be used without a floor covering. This is explained by the fact that an unprotected surface tends to absorb oils, water, and it is also dusty.

When the mixture hardens, no significant stress is created, but when applying a thick layer in a room with a large area, experts recommend laying a polypropylene foam cord along the perimeter to the entire thickness of the layer. Many manufacturers take this point into account, so they produce mixtures for finishing and for rough leveling of overly uneven surfaces. But mixtures for applying a thick layer have reduced fluidity, and this does not guarantee the final result of an ideal floor. Therefore, then you will need to apply an additional finishing layer.

Self-leveling polyurethane floor

For residential premises, self-leveling flooring is chosen, the basis of which is polyurethane resin, for non-residential premises - epoxy resin or methyl methacrylic resins and others.

Advice

For the chemical reaction to proceed correctly, working with a self-leveling polyurethane floor (one or two-component) requires special conditions, namely the absolute absence of moisture.

Polyurethane flooring is a finishing coating, and at the same time it is final, and its optimal thickness is 1.5 - 2.5 mm. It hardens completely within a day. While the floor is curing, all factors affecting its integrity are excluded: drafts and sunlight.

The transparent surface of polyurethane floors does not require additional decorative finishing, but at the same time allows you to find new interesting solutions. For example, place a volumetric composition or design under a layer of self-leveling coating. The only thing you need to take into account is that the thickness of the fill depends on the volume of the composition, and the cost depends on the thickness.

Such floors look great in the kitchen, bathroom and restroom areas.

The basis of a two-component polyurethane floor is an aqueous dispersion of the polymer and primary alcohol, which, in combination with the polymer, gives it strength and rigidity. This type of self-leveling flooring is definitely more durable. For a coating 0.1 cm thick, its consumption is 1.5 kg per m2.

Choosing a resin-based self-leveling floor requires special attention - it is better to give preference to a well-known brand with detailed instructions on the manufacturer’s website and with a quality certificate.

Even when buying the most expensive screed, it should be recognized that it alone will not be enough. No matter what words of praise are written regarding their independent fluidity, in order for the screed to fully cover the floor, it should be helped with a rule, a spatula and a needle roller, spreading the creamy mass in different directions .

To increase adhesion, you will need a primer impregnation. It is better to buy it according to the manufacturer's recommendations to ensure the best result.

What to start from when choosing the optimal composition?

When choosing a specific composition, several evaluation criteria must be taken into account.

- Where will the floor be poured?

— In the living areas of a house or apartment, any mineral mixtures are suitable, taking into account the level of humidity in the room. Epoxy or polyurethane coatings, “self-sufficient”, that is, without subsequent finishing, are quite suitable. If a “warm floor” is planned, then this must be specified by the manufacturer.

Self-leveling polymer 3D floors have become widely used in residential premises. True, you need to carefully consider whether such a finish will soon become boring and whether it will become an irritating factor.

— In the bathroom, toilet, if you plan to cover it with tiles, then cement-based compositions (the use of combined cement-gypsum ones is allowed). Polymer compositions are also excellent - as an independent coating.

— In the kitchen, it is better to use mineral-based compositions if you plan to finish the flooring with laminate, linoleum, or tiles. Seamless polymer coatings, which can be given the necessary decorative effect, are also suitable.

— Bathhouse - the requirements are similar to the bathroom, but it is better to exclude the use of cement-gypsum mixtures.

— Porch, balcony, pedestrian area in front of the house, etc.: the characteristics of the mixture must necessarily indicate that it is frost-resistant. Naturally, compositions with a gypsum component are completely excluded. Polymer or polymer-cement compositions that are resistant to abrasion and have a rough surface are welcome.

— Garage – the optimal choice would be a polyurethane coating. As an option, leveling is done with a cement composition, and then a thin, up to 5 mm wear-resistant polyurethane layer is poured.

- What thickness of fill is expected?

Everything is simple here - the manufacturer must indicate the range of acceptable thicknesses. And violating these recommendations means risking the strength and durability of the floor.

The range of permissible thicknesses for pouring the self-leveling compound must be indicated by the manufacturer

In addition, the initial conditions and the cost of the material should be taken into account. Filling expensive finishing compounds with a layer of more than 5 mm is extremely wasteful. Therefore, for rough leveling of the surface, you can select “simpler” self-leveling compounds, and then, after such a base has hardened, perform the finishing fill. And it’s better if these mixtures are from the same manufacturer - they are maximally adapted.

- On what basis will the pouring be carried out?

— Any composition can be poured onto a concrete base (floor slab) after appropriate preparation.

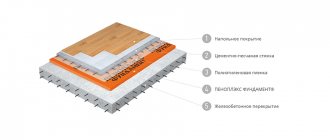

- On a wooden base or on insulation (penoplex and the like) - preliminary pouring of a floating (not connected to either the base or the walls) cement-sand reinforced screed 40 mm thick is required. After this, a thin-layer finishing composition is applied. True, the manufacturer of the mixtures may stipulate other conditions - this must be clarified in the instructions for use of the compositions.

Special self-leveling mixtures are available for sale specifically for complex bases - wooden, bitumen, hardboard, etc.

— For waterproofing (bitumen), for old tiles, preliminary pouring of a reinforced floating screed is also required. For screed, by the way, a self-leveling mixture can also be used - compositions are produced specifically for such purposes.

- What kind of external floor finish is expected?

Any mineral compositions are suitable for tiles, but must take into account the degree of humidity in the room, as discussed above.

Under other coverings (laminate, parquet boards, linoleum, carpet, etc.) any, including polymer ones. The only question is how cost-effective it will be to use expensive polymer bases in such a case.

Laminate prices

laminate

- How quickly will the coating harden?

It should be correctly understood that the terms specified by the manufacturer usually only indicate the possibility of people moving along the poured surface without the risk of deformation. But this is still far from complete maturation of the coating. It will gain final strength and readiness for full operation much later - the period can be from one to four weeks.

The fact that you can move on the floor after just a few hours does not mean it is ready. For information on the timing of full ripening, see the detailed instructions on the packaging.

Be sure to pay attention to another time indicator - the viability of the prepared solution. That is, the time during which it is necessary to distribute the mixture over the surface before it begins to set. If you plan to work alone, and even with insufficient experience, it is better to choose compositions with the highest possible indicator - 40÷60 minutes, otherwise you can simply ruin all the results.

Find out when it is necessary to repair cracks in a self-leveling floor and how to carry it out from our new article on our portal.

- Mixture consumption.

A parameter showing how much material is consumed on average to fill 1 m² with a layer thickness of 1 mm (or 10 mm - different manufacturers may have their own “standards”, but converting one to another is not difficult). On average, this figure varies from 0.8 to 2 kg/m² with a layer of 1 mm.

The maximum consumption is observed for self-leveling cement-based compounds. But this is “smoothed out” by lower cost. Knowing the “certificate” consumption rate and the parameters of the room (its area, difference in floor level, planned minimum thickness of the poured layer), you can calculate the amount of material that will need to be purchased for the work.

Our online calculator below will help you with your calculations. It provides the ability to calculate both by the known area of the room (the area for filling) and by size (for rectangular rooms). The calculation result is shown taking into account the 5% reserve.

Calculator for calculating the required amount of mixture for pouring a self-leveling floor

Go to calculations

Popular brands

Those who choose floor levels today are unlikely to get confused among the huge variety of products.

And yet, there are a number of offers on the market that have won the love of consumers:

- for example, “Knauf” - self-leveling floor mixtures. Several similar offers are presented in the company’s assortment. Of all the products, the Knauf-Boden series especially stands out. All products from this line are based on high-strength gypsum. This also includes quartz sand and modifying additives. Such screeds are suitable for use in rooms with normal humidity levels. The result will be a smooth base suitable for installing any finishing coating. Since gypsum is used in the composition, the screed is stronger than cement screed.

- Self-leveling material will also be much better than a standard cement screed. The main difference here is the amount of water required to obtain the solution and the speed of hardening. All compositions have one thing in common - they cannot be used instead of a topcoat or painted.

- Now let's talk about mixtures. Using the material from this manufacturer, you can create a thin and very smooth self-leveling coating. They are suitable for use in both public and residential areas. Any finishing material can be laid on such a base. It is important for you to remember that self-leveling mixtures can be used in both wet and dry rooms, and even in rooms with a heated floor system. The thickness of the layer usually varies from one to ten millimeters. In just six hours it will be possible to move on the newly poured screed. By the way, floors can be treated with varnishes and paints to improve the appearance of the coating.

- The “Ceserit” brand is also intended for leveling cement-sand, concrete and anhydrite bases. But for repairs, the Ceresit CN-83 brand is more suitable. You can run on this floor in just six hours. The surface can even be coated with concrete paint. Please note that Moment brand mixtures also belong to Cezerit.

- Mixtures can be used in all rooms without exception. The exception is for rooms in direct contact with water. The Volma-Nivelir-Express composition can be applied either manually or by machine. The result will be a screed of five to one hundred millimeters. The company also offers coarse levelers that can be used to repair old screed.

- The Bolars brand is also popular. By giving it preference, you can easily eliminate defects on the old screed and get an even and durable coating. Bolars surfaces are also distinguished by a high level of noise and heat insulation. If the room temperature is eighteen to twenty degrees, the mixture will harden in a few hours.

- Sika Repair 30 putty is ideal for leveling concrete surfaces. It is a one-component PCC/SPCC mortar. Mix it with cement. Modified polymers and microsilica are also used in production. This putty can be applied either manually (sliming or putty) or by spraying. It is particularly suitable for reinforced concrete/concrete structures that are exposed to water and atmospheric pressure. The finished screed can even be painted.

- Basic gypsum putty “Unis Blik” is suitable for leveling ceilings and walls made of concrete, plaster, brick inside a room with any humidity. This putty can also be used if you want to mask depressions, cracks and potholes.

- “Blik” putty has gypsum at its base – the most environmentally friendly material. A microporous structure is formed during hardening. She is able to “breathe”. Thanks to this, a favorable microclimate is created in the room. This mixture is easy to apply to the base, has excellent adhesion and is sufficiently plastic.

- If you want to level a concrete or cement-sand base, then the EK FT01 BASE mixture is the ideal option for you. Perfectly masks differences of eight centimeters. This material is most often used when installing polymer coatings, ceramic tiles, artificial stone slabs and porcelain stoneware. The mixture is compatible with underfloor heating systems.

Drafts and temperature changes negatively affect the quality of the screed