Concrete injection is one of the most modern and effective technologies that allows you to repair defective concrete structures of buildings and structures. Its essence is to fill the voids that appear in the monolith using specially developed polymer compounds injected under pressure.

As a result of this operation, which with proper skill and skill can be carried out with your own hands, there is no need for a major reconstruction of the damaged surface.

Materials used

The mixtures used to fill cracks are made on the basis of:

- epoxy resins;

- polymer cement compositions;

- polyurethane.

Concrete injection should be carried out with a solution that has low viscosity and high penetrating ability, independent of the size of the damage and the ambient temperature.

We list the main properties of injection compositions:

- reduced viscosity;

- possibility of use at very low and high ambient temperatures;

- minimal shrinkage during hardening;

- high level of adhesion to various materials, including metal reinforcement;

- resistance to aging;

- lack of corrosive properties.

Note! The choice of injection material must be made before starting work so that the necessary equipment can be selected.

Epoxy resins

They are used to fill cracks in various concrete foundations, the strength of which is subject to increased demands. Epoxy resins can penetrate microscopic defects that are less than 0.5 mm thick.

In this case, the filling density will be maximum, regardless of the volume of damage. As a result of the measures taken, the concrete structure will restore its load-bearing capacity and structural strength.

Epoxy resins are also indispensable for treating surface cracks and chips.

Polycement materials

Their use is justified in cases where the volume of damage is large enough, which makes the use of epoxy resin too expensive. They make it possible to enhance and strengthen both new concrete structures and elements of old buildings during restoration.

During injection, a special cement mortar is supplied under excess pressure, which allows it to penetrate into all cavities and pores, some of which may be hidden.

This type of treatment is used to strengthen old buildings with columns. In order for the new reinforced concrete structure to be fully integrated into the structure of the building, injection is carried out, with the help of which the support will be connected to other architectural elements.

The described method is also indispensable for restoration, which has not only cracks that appeared as a result of shrinkage and under the influence of the weight of the building, but also fragmentary destruction.

Waterproofing compounds

In order to protect structures from water penetration, polyurethane is used, which has waterproofing properties.

It is often used for the following types of work:

- filling seams and joints between monolithic concrete parts;

- processing wet openings;

- insulation of holes and cracks in water supply and sewer networks.

Stages of work

Surface preparation

The instructions that regulate concrete injection work state that before introducing compacting resins, it is necessary to properly prepare the surface of a wall or other reinforced concrete structure.

To do this you need:

- Using a hammer drill, drill holes along the crack that appears. They should be staggered, directed towards the defect and reach cavities and voids inside the monolith.

- Packers must be inserted into the holes. They are special tubes to which concrete injection equipment is connected using special hoses.

- Using a pump, the cement mixture is supplied through the tubes. If the holes and packers in them were placed correctly, the composition will evenly and tightly fill all voids, restoring the integrity of the monolithic slab.

Note! The pressure of the supplied epoxy or polyurethane resin directly depends on the viscosity of the material and the size of the crack. If too much compound is introduced, it will widen the crack, compromising the strength of the concrete monolith.

Features of crack filling

The simplest option is when the defect in the concrete does not exceed 0.5 mm, and there is no rust on the metal parts of the reinforced concrete structure. In this case, even if manual concrete injectors are used, filling the voids occurs quickly and without additional effort.

When a visual inspection has revealed the presence of traces of corrosion and delamination of the concrete slab, all excess crumbled material should be removed and the reinforcement should be cleaned using a grinding machine.

Do not neglect this stage of work, the cost of a mistake is too high: the injection solution will not harden correctly, and the crack will increase even more.

Depending on the location of the defect, several filling schemes are used:

- Vertical. In this case, injection occurs starting from the lowest point and ending at the upper end.

- Horizontal. Filling with a cementitious composition can be done simultaneously from both sides, from the center to the edges and from left to right.

- Ceiling. The work is carried out similarly to the previous scheme. Epoxy resin, due to its viscosity, will not leak out of the holes.

After filling is completed, the tubes are disconnected and the packers are closed with special plugs. The restoration site is protected with a special film, which is left until the composition hardens. This lasts from 2 days to a week.

The final stage is the application of an insulating and decorative layer, which allows you to hide all traces of the repairs made.

Nuances of waterproofing work

If the purpose of injection is waterproofing, the work is carried out in two stages:

- first, polyurethane is pumped into the cracks

, which blocks the flow of moisture and forms a porous waterproofing structure; - after the polyurethane has hardened, epoxy resin is fed through the packers

, filling the voids and pores of the polyurethane and forming a strong and integral structure.

Materials for work

Concrete injection pumps deliver injection solutions under pressure.

For this method, various materials are used, such as polyurethane and epoxy resins, acrylate gels, microcements and other polymeric materials. Acrylate gels and polyurethane materials are very elastic and do not collapse under changing loads. Microcements create an impenetrable barrier for moisture, similar to waterproofing.

Injection materials are selected based on the purpose of repair, operating conditions and purpose of the object, and type of work. Crack injection is performed using special equipment.

These equipment are one- or two-component injection pumps. When working, many people do not use pumps, but a pneumatic gun, or use gravity feed of the material. These are the simplest methods.

Before injecting cracks, you must first prepare the surface. To do this, use a brush to clean the crack from dust and debris. If it is less than 0.5 mm, then it does not need to be cleaned. Then, under a certain pressure, we pump a polymer solution into the crack, which fills all the voids in the concrete and increases its strength. After the solution hardens, this place is treated with hydroactive resin.

Conclusion

Before choosing one or another injection method, you should be aware of how the structure was and will be used, as well as why the destruction occurred. This will allow you to develop the correct procedure scheme and select the material needed in specific conditions.

The video in this article will help you learn more about various ways to eliminate defects in concrete structures.

Injection is a fairly new and effective method for restoring concrete structures. It consists of filling cracks on the surface, using special equipment, with polymer compounds. Concrete injection allows for the reconstruction of a building without major construction work.

For this, polyester and epoxy resins, as well as their mixture with polyurethane, are most often used. The final product must have low viscosity and be able to penetrate to great depths at different air temperatures.

Injecting cracks with a polyurethane compound is used for waterproofing, filling joints and seams, and when treating wet openings that contain water. Polyurethane resin is suitable for filling holes in drinking water structures, underground, above-ground and utility lines.

Technology of injection of concrete surfaces

Holes are drilled along the crack with a hammer drill. They should be staggered, directed towards the opening and connected to it. Injection of cracks and concrete occurs using special equipment.

Tubes (packers) are inserted into the resulting holes, to which a hose attached to the pump is connected. Using pressure, the device forces liquid into the tubes, from where it enters the crack cavity. If the packers are positioned correctly, the injection material will be evenly distributed in the opening.

The force of pressure directly depends on the viscosity of the resin, as well as the width and depth of the crack. During operation, the pump should not release too much mixture, this will negatively affect the quality of the seam.

Hydro-KS: we sell everything for waterproofing

Leave a request - we will select equipment and consumables, and help with advice

Leave a request

The technology of their design differs significantly from expansion packers. The main difference is that the packer is attached using epoxy glue to the crack itself, which is then opened, sealed with repair compounds and pumped.

Drive packers are secured in a pre-drilled injection channel. Material of manufacture: metal or plastic. A driven plastic packer is used for injecting cement and polymer compositions. The packer is equipped with a check valve to prevent fluid leakage.

The plastic packer operates under pressure up to 100 bar. It is considered to be a one-time device intended for performing operations with small volumes. When choosing a plastic packer, the price of which is significantly lower than its aluminum and steel counterparts, the buyer should evaluate all the advantages and disadvantages of its use.

In addition to the base material, injection packers vary according to the connection type. Collet, coupling or flat grease fitting are all types of locking, each of which has demonstrated its advantages under different conditions.

The injection packer is equipped with a check valve. Such a system prevents the injection substance from escaping from the building structure. Products are assembled on modern, high-tech equipment using innovative technologies.

Stages of work completion

In order for concrete injection (injection) to be carried out efficiently, it is necessary to determine the extent of the damage. If the crack width is no more than 0.5 mm, and there is no rust on the reinforcement, then filling the opening is done quickly.

If concrete delamination is noticeable in the area of the problem area, and the iron elements are covered by erosion, then first remove the damaged areas and clean the rods.

The work is carried out in 2 stages, which makes it possible to fill the voids as much as possible.

Depending on the damage, there are different methods for injecting concrete. A vertical crack is filled from its bottom point upward; resin can be fed into a horizontal crack from different sides, from left to right and, conversely, from the center in one direction and then in the other. The ceiling is injected in a “suspended” position, but due to its good viscosity, the resin does not flow out of the crack.

Upon completion of the procedure, the packers are closed (after which they are removed), if necessary, the supports are reduced, which provide the structure with better strength. After hardening, the protective film is removed. Depending on the composition, setting lasts from 2 to 7 days.

The final stage is finishing the area with a decorative-sealing mixture that protects against moisture penetration and hides traces of repairs.

Waterproofing by injection

Before starting work, fill pores and cracks with polyurethane. The product prevents water seepage and remains elastic after hardening. To waterproof concrete structures under pressure, injection is carried out. The resin penetrates into the voids of the foam, forming a flexible structure inside the structure; thanks to its elasticity, the structure retains its waterproofing properties for a long time.

Price

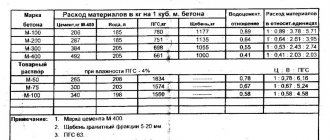

Prices for injection materials depend on many factors: manufacturer, quality of raw materials, and so on, but you can still make a rough calculation.

The retail price for resin is at least 800 rubles per 1 kg, a metal packer will cost 50 rubles, but the larger its size, the more expensive it is. A roll of protective tape costs about 400 rubles (the cost is also affected by the width and length).

| Articles |

During moving into new houses and during construction work, defects in concrete structures are often identified, which can have different effects on the integrity of the structure and further living in such a house. In order to prevent this phenomenon, it must be prevented. And for this you need to know the minimum standards (for self-construction) and the reasons for what is happening.

The very formation of cracks in concrete is a signal that warns of possible danger and this issue should be approached with all seriousness. Of course, you can contact a construction company or, in case of minor violations of the composition, try to restore everything yourself.

Few people would want to live in a house where a palm-wide gap has formed from the very foundation to the roof. This is an emergency situation that should be immediately reported to the relevant housing and communal services structures serving multi-storey buildings and organizations.

But a slight discrepancy in the structure of 2-3 mm can be “restored” independently, this is especially true for home builders who built a house, and a month later they were surprised that a gap had formed in the wall

Stages of work

The specifics of the injection procedure depend on the current state of the building. If thin, dry cracks appear at the base of the building, it is necessary: 1. Use a grinder or drill to increase the width of the crack to eliminate dust and dirt particles, reaching a solid concrete structure. 2. Packers are placed in the resulting hole - tubes through which the reducing composition is transported. The volume of material used is determined by the degree of destruction of the structure. A special protective film is glued around the packers (this is necessary to prevent the mixture from spilling out). 3. Slots and packers are filled with a mixture with high strength characteristics. 4. The composition is supplied using a manual or electric pump. 5. When the injection is complete, the parkers inserted into the holes are removed. 6. The restored base is cleaned.

Standards

In order to accurately understand the need for repairs or the possibility of doing without additional measures, you should either be an engineer or study the necessary documentation, which clearly states the crack resistance of reinforced concrete structures and acceptable standards.

In ordinary language, the categories of crack resistance of reinforced concrete structures are divided into several main ones:

- When the formation of any kind of cracks is not allowed at all. This applies to all sealed elements and containers. In this case, the tensile strength of concrete should be kept to a minimum, which will prevent any deformation of the composition.

- A small gap formation is acceptable within normal limits (1 mm maximum). This is possible in any buildings during shrinkage of the building and short-term exposure to external atmospheric factors - frost, heat, as well as mechanical influences from the outside - wind, movement of groundwater, etc. Cracks are also possible from improper pouring of the foundation in the cold season and when concrete expands in the summer period.

- And the last, most common category is the formation of cracks limited in width. It is found in almost all reinforced concrete structures. External factors and human activities influence the appearance of cracks here. The reinforcement is not subject to corrosion, and such a situation can only be called critical in rare cases when the width of the cracks becomes too obvious.

Advice: don’t wave your hand and don’t rely on the Russian “maybe”; in any case, if the crack resistance of concrete is damaged, repairs are necessary. You can remove minor defects yourself or invite more experienced specialists. The price for the services of each team is different and it all depends on the complexity of the work performed.

Cause and effect

Before starting any restoration work, it is necessary to identify the cause of the formation of cracks and the further fate of the structure in this regard.

There are several main reasons:

- Structural, which are caused by design errors, insufficient building materials, reloads during operation. This can lead to complete destruction of the entire structure and deformation of the building.

- Fire and flood, which lead to delamination of the concrete layer

. Depending on the complexity of the elements, they are subject to restoration or complete reconstruction. - Non-constructive, most common

. The reason may be premature shrinkage of the building immediately. The opening width of cracks in concrete is insignificant, and the length reaches 75 cm.

The latter reasons may not be noticeable for several weeks after laying the concrete and appear with a sharp increase in air temperature and rapid drying of the concrete. The depth is insignificant and all these deformations are often caused by poor-quality material and non-compliance with building standards.

Shrinkage cracks can occur not only on the foundation, but also on the walls of the structure, and therefore repair work is also different.

Advice: be sure to check the reason for the formation of any type of crack in the wall, foundation or floors, since restoration work directly depends on this.

Repair options

Repairing shrinkage cracks in concrete depends on the complexity of the damage and the main task is to ensure optimal bond strength between the concrete layers. For this, only material with high adhesion to concrete is used.

Injection

One of the most common jobs remains the injection of cracks in concrete with special resins without solvents and with low viscosity. This is necessary in case of further divergence and in this case there will be no cracks, because the resin has astringent properties and will simply stretch, and not tear, like cement mortar.

In this case, there are certain instructions that should be followed:

- Holes are drilled along the cracks at intervals of 0.5 meters to a depth of 2/3 of the masonry and with a diameter of up to 20 mm.

- The holes are cleaned of dust using a special construction vacuum cleaner or suction.

- Bushings are inserted inside through which the solution is poured, as shown in the photo.

- On the outside, everything is compacted and sealed with putty.

- After the composition has dried and hardened, the putty is removed and the packers are removed from the holes.

- Everything is sealed again with a non-shrink mortar.

Advice: if injecting cracks in concrete is also necessary to enhance waterproofing, then the work is carried out somewhat differently, which is better to check with professional craftsmen. It is difficult to carry out the entire range of restoration work on your own.

A simple way to reconstruct

If further separation of the seams is not expected, and you are sure that the shrinkage has ended, then you can repair cracks in concrete walls in a simple and uncomplicated way:

- The entire surface is washed and treated.

- After everything has dried, the cement-sand mortar is diluted in a ratio of 1:3 or 1:2.

- If necessary, epoxy resin is added to the solution for better screeding.

- Everything is puttied and rubbed as described below.

Dust and remaining dirt are removed with a special brush, and the surface is covered with reinforced mesh and puttied.

Advice: if you do not want further cracks, then to prevent their appearance, you can lay serpyanka on the surface in several layers or a special mesh, and then carefully putty everything.

Waterproofing and seam sealing

If at the same time during repair work it is necessary to improve the waterproofing, then the following work should be carried out:

- Armed with a grinder, cut a 20 by 20 mm groove along the entire fault (crack).

- In the slots themselves, drill holes at an angle at a distance of 2 cm.

- Purchase or prepare a highly fluid cement mortar and pour it through the wells using the injection method.

- Seal the seams with the same compound.

Tip: The simplest methods for sealing shrinkage cracks are given, but in some cases bitumen coatings, brackets, latex mortar and asphalt mastics may be needed. If in doubt, consult experienced builders or craftsmen about everything.

Cracks and their grouting

Well, during work you will definitely have to deal with filling shrinkage cracks before starting pouring.

You will need:

- Grinder or drill.

- Brush with metal bristles.

- Putty knife.

- A container and mixer for mixing the solution or a special concrete mixer.

- Bit.

In order to most accurately eliminate the effects of shrinkage, it is necessary to most accurately determine the location of shrinkage cracks in the foundation, since they can be hidden.

To do this, some craftsmen tap the surface, identifying voids by sound. If the crack is small, but the voids are audible, then it is tapped to the maximum size and the size of the crack and the entire internal void are fully revealed.

Advice: to prevent concrete shrinkage, it is better to add polypropylene fiber fiber to the solution at the initial stage of construction, which will protect it from ruptures later.

Measures to save the concrete surface from cracking

If defects are found, you should:

- Inspect the entire building structure to identify problems.

- Determine the nature of the defects (surface, through, microscopic, massive), the width of the opening, the degree of exposure of the reinforcing elements.

- Select the repair composition in accordance with the survey data.

- Open up a crack in concrete by removing loose particles with a brush and vacuum cleaner before repairing the defect.

- If the defect has exposed the reinforcement, then it is necessary to clean it from corrosion products with a metal brush and treat it with an anti-corrosion compound.

- Open small cracks to a state in which they can be filled with a repair compound. Large cracks in concrete with an opening width of more than 4 mm - prepare for strengthening. To do this, grooves are made across the gap in the concrete element for laying reinforcing wire in them.

- Treat the surface to be repaired with a primer, which increases the adhesion of the repair composition to the base.

- Seal the cracks. Most often, cement-sand mixtures with factory-prepared expanding cement are used for this purpose. When deciding how to fill a crack in concrete - in the screed and seams between floor slabs - you can choose a mixture consisting of liquid glass (20% of the total mass), cement (20%), sand (60%).

If the defects are large, they are eliminated step by step. After pouring, the repaired crack in concrete is rubbed down and the surface is leveled. To improve the quality of the repair, a protective coating, such as a plaster layer, is applied to the concrete element.

Injection technology involves injecting special compounds into the cracks under strong pressure. It is used to repair the surfaces of basements, tunnels, and foundations. This technique is especially relevant for restoring the characteristics of block foundations. Injection technology is the most effective and reliable.

Three types of compounds are used to inject cracks in concrete:

- Resins – epoxy and polyurethane. Used to eliminate small cracks. Polyurethane resins not only fill cracks, but also significantly increase the waterproofing characteristics of the structure. With their help, you can treat defects that are in a wet state and cope with leaks. Epoxy compounds can be used to seal cracks in concrete if the structure is operated in contact with chemically active media. These mixtures set quickly, forming an almost solid structure with concrete or brick.

- Polycement materials (microcements). Such compositions, which are based on particularly finely ground Portland cement, are used in cases of significant damage. Carbonate-quartz filler, lime and other additives are used as auxiliary components.

- Waterproofing solutions. Polyurethane materials cope well with defects that occur in wet areas. They can be used in sewer and water supply lines. Acrylic gels are characterized by good fluidity and the ability to increase in volume several times upon contact with a humid environment. Acrylic compounds not only fill defects, but also dry out nearby areas.

For injection you need specialized equipment:

- Injection pumps. Manufacturers offer various models designed for the use of certain injection formulations. For a small amount of work, you can choose a budget manual pump.

- Packers for injection. These are special tubes with which solutions are injected deep into the concrete element.

This method is suitable for repairing defects that occur on the surface of swimming pool bowls, for restoring external walls and monolithic foundations. Stages of repair work:

- Cutting a crack, removing weak elements and dust.

- Measuring the width and depth of the crack.

- Selecting a suitable self-expanding cord or tape.

- Laying the cord or tape into the prepared cavity.

- Fill the remaining space with polyurethane sealant using a mounting gun.

A significant advantage of this method is the ability to carry out work at subzero temperatures.

This is a method of applying a dense and durable cement-sand mixture under high pressure. The material fills all cracks, cavities, and chips. The protective coating strengthens the surface, protects it from negative influences, and extends the service life. Shotcrete is used to repair foundations, underground structures, and external surfaces of buildings.

Work can be carried out according to two schemes - dry and wet.

- Dry method. The cement-based dry mixture and water are supplied to the surface to be repaired through different flexible hoses. Pressure is created by compressed air produced by the compressor. The components are mixed in a nozzle and delivered to the surface to be repaired at a speed of 170 m/s. The advantages of this technology are the high density and strength of the resulting protective layer, the thickness of which can reach 60 mm, good performance, and the ability to process hard-to-reach areas from a long distance. Disadvantages - severe contamination of the work site, the need for additional coating of the repaired surface, high requirements for the operator’s qualifications.

- Wet technology. In this case, the ready-made repair mixture is supplied by a concrete pump. Pros: uniform composition, uniform distribution of layers, economical solution consumption. Finishing can be done immediately after shotcrete. The material that rebounds from the surface is suitable for other construction purposes. This method can be used even indoors, since the solution is supplied from a close distance.

When operating concrete and reinforced concrete structures, it is necessary to periodically inspect the surfaces, since eliminating small cracks is much easier, faster and cheaper than carrying out large-scale repairs involving specialists and complex construction equipment.

The photo shows a repaired crack in concrete.

In newly laid concrete (two hours old), cracks can be eliminated by compacting the compound a second time.

We invite you to familiarize yourself with Installation of beacons for pouring a concrete floor

Other methods are used to eliminate cracks in hardened concrete:

- Injection – repair mixture is injected into the opening under pressure. There are mixtures for sealing cracks in concrete, which make it possible to remove moisture from the cracks. Suitable for use in water.

Injection method

- Sealing. For the walls, materials are used to seal cracks in concrete with the addition of a polymer, which increases the adhesion of the base and repair composition.

Sealing method

- Torquetting or spraying concrete mortar onto the surface. This is an effective and global repair process. It is produced using specialized equipment. As a result, you will get a new layer of concrete that protects the structure from corrosion and further destruction.

Restoring the pier using torquetting

To repair cracks, a concrete mixture is used to seal cracks in concrete; after jointing and cleaning the cracks, it is filled with a new composition.

How to repair a crack in a concrete wall using this method? A concrete mixture is used. It consists of fractional sand, water, cement and an organic additive, which can be resin, bitumen, latex. This method is not always convenient to use, since it causes an increase in the weight of the structure, and, consequently, an increase in the load.

Repaired cracks in concrete - grouting with ordinary cement-sand mortar

Let's take a closer look at what it means to seal cracks in a concrete wall using various technologies.

Injection

Schematic illustration of the concrete wall injection process

A common method is injection. In order to inject cracks in concrete and repair cracks in concrete walls, polymer materials are added to them using “injections.” This type of repair makes it possible to do without fragmentary replacement of the concrete structure.

To carry out such an operation you will need specialized equipment and materials. Therefore, you can’t hope to independently reproduce the work. If you are interested in how injections are carried out by specialists, watch the video below.

Sealing

Sealing grout for cracks in concrete

Sealing is the application of a solution to a deformed surface to seal cracks in concrete, consisting of a polymer component and a cement-sand mortar. After the mixture dries and hardens, an additional thin layer of polyurethane sealant is applied to it.

This method is indispensable for reinforced concrete structures, which are often exposed to moisture and atmospheric influences. If you have experience in carrying out such work and the necessary material, then you can carry out the sealing yourself. The video in this article below will tell you how to seal cracks in concrete using the sealing method.

The above methods apply to production repairs. If you need to repair small cracks at home, then watery cement “dough” and proprietary repair mixtures are used for this.

Epoxy resin is also effective for cracks in concrete. Liquid “dough” is used for defects no more than 3 mm, and for larger ones a proprietary solution or a special mixture is used, which consists of 1 part Portland cement, 3 parts each of water and sand, as well as PVA.

Instructions for reproducing independent restoration work:

- Before starting work on sealing with cement-lime mortar, preliminary preparation is necessary. First you need to check the crack itself to see if there are any chips nearby, since in the future they can become shallow pits.

- Next, using a chisel and hammer, we go over the entire surface to make it wider. You can also use a grinder. If during this work a hidden chip appears, then this piece of concrete must be removed immediately.

- Then you need to clean the surface using water, a brush and a special product. In order to remove dust and dirt, you can also take a vacuum cleaner. Using a sponge, remove the remaining water.

Expanding cracks using an angle grinder

- To ensure that the solution for sealing cracks in concrete fills the entire area and holds strong and durable, we make the cracks deeper using a spatula up to 5 mm. The solution is diluted from 3 parts sand and 1 part cement. Be sure to add PVA glue. In this case, the solution is not liquid, but of normal thickness.

- You need to fill the cracks with the solution using a trowel, and then you need to wet the repair areas. Such actions with water are not necessary if you are using a polymer composition rather than a solution.

Freshly repaired crack in the floor

- If the opening width of cracks in concrete is larger and reinforcement is visible in it, it must be cleaned and treated with a solution that protects against corrosion. To secure it into the grooves, you need to lower pieces of wire of the same length, the diameter of which is approximately 4 mm. Then we apply the adhesive composition with a brush and spread it over the surface of our uneven surfaces. The layer thickness is about 3 mm. Then everything is filled with the solution; we don’t wait for the composition to dry. It is necessary to pour it in stages so that the solution fits tightly.

- Using a wooden lath, we level the surface, pushing it towards us and from side to side. When the hole is very deep and large, the solution must be poured in several layers, with the next layers softened with a little water. You can perfectly level the surface using a metal trowel or a regular trowel.

Repairing cracks in concrete - smoothing

- Afterwards, the excess solution is removed with a spatula.

- It should be noted that the layer of mortar should be approximately 0.5 mm higher than the floor surface, since the mortar will shrink after drying.

Elastic sealant

- Repair options

- Technology Methods of reconstruction work

We suggest you read How to start crocheting a washcloth

Bottom line

This material covers only the main points regarding cracks and their reconstruction in concrete buildings. There is some useful information in the video in this article. Repair correctly and build efficiently.

Concrete injection is one of the most effective methods of repairing, strengthening and waterproofing reinforced concrete structures.

Types of repair compounds:

injection

water resistance.

. Calculation of work estimates.

We guarantee: high professionalism, optimal technical solutions, work at the level of world standards. y.

Injection equipment

To competently perform concrete injection work, it is necessary to use specialized equipment. Pressure is created using injection pumps (the power of the equipment is selected separately for specific types of materials). Devices for polycement compositions must have high performance, and therefore have a higher price. Manual methods of work are more accessible, but such injectors are only suitable for carrying out a small amount of work (for example, solving private construction problems).

| hand pump | electric pump | injection packer |

Another necessary component of the procedure is injection packers (special tubes with tips through which mixtures are injected into the cracks of concrete elements). Parts can be of different lengths, and can withstand the pressure of the composition pumped over it.

How is concrete injection performed?

Through holes in the concrete surface, which can be located outside or inside the wall of the building, the repair composition is supplied under high pressure by special pumps. The holes are drilled at a distance of up to 60 cm from each other, the diameter of the holes is up to 2 cm. The location of the holes, their frequency, depth and diameter are determined by a specialist. The repair composition, getting inside the concrete slab, fills all, even the smallest cavities (diameter 0.1 mm). Before drilling wells, damaged areas are examined. The assessment criteria that influence the further location of the holes and the choice of injection method are: the appearance of the damaged area, the size of the defect, the cause of its occurrence, the mobility of the area, the presence of leaks, the volume and speed of water inflow. To begin sealing and strengthening the structure, all cavities, cavities, and defects must be cleaned of substances that affect adhesion: dirt, oily substances, and other separating compounds. Before starting concrete injection work, it is necessary to install tubes for injecting the repair mixture - packers - into the prepared holes.

What repair compounds are used for concrete injection?

Depending on the injection conditions, the compositions of the mixtures may vary; they may consist of several components and be pumped into the holes with one or two-component pumps. In this case, the mixture may contain more than two components. For example, two components may be the basis of the first element of the mixture in the pump, and three components may be the basis of the second element. There are completely ready-to-use compositions used for preparing mixtures, the properties of which depend on the proportions of the powder component and solvent. In addition, it is necessary to take into account the temperature at which work is carried out.

Types of repair compounds: . Acrylate and methacrylate gels. Used as a sealant. Gels do not require solvents, have low viscosity, penetrate into the smallest and deepest cracks (less than 0.1 mm), can be worked with at low temperatures, the controlled reaction time of the compositions is minimal, elasticity, degree of swelling, frost resistance and chemical resistance are high. The compositions are used in the construction and repair of underground tunnels, basements and other parts of structures located below ground level or in need of additional waterproofing measures. The pressure during concrete injection is determined by the design features of the part of the structure. . Compositions containing epoxy resins. The mixtures are suitable for sealing cracks from 0.5 mm; the composition does not penetrate into cracks of smaller diameter. The mixtures have high adhesion, strength and low viscosity. Injecting structural elements with such mixtures makes it possible to strengthen the structure, restore its load-bearing capacity, and restore damaged areas. Along with resin injection, the structure is often strengthened by other methods, or reinforced concrete elements are restored or replaced. . Polymer cement mixtures. They are used to correct large defects, are used in restoration work, and strengthen the structure of the structure, restoring its strength. The polymer-cement composition has a high penetrating ability and fills the cavities of the repaired part of the structure throughout the entire volume. The technique is used to adapt old buildings to new, higher loads, through the introduction of additional load-bearing elements (columns).

Question: the instructions indicate that to inject Dehydrol Lux brand 3, the crack opening must be 1 mm or more. Will Dehydrol Lux grade 3 not fit into cracks with an opening of less than 1 mm?

Answer: Before considering the relationship between any injection material and the magnitude of crack opening, you need to understand what the final goal is? There is no single “cure”; in each case it is necessary to proceed from expediency.

Repair of concrete in areas operating primarily in compression

For example, there is a concrete column with cracks . Mechanical filling of a crack in a column without waterproofing is required.

Then it's simple. Dehydrol luxury brand 3 has a maximum grain size of 0.2 mm. Accordingly, it is difficult for a large component of the dispersed part of the solution to penetrate into cracks with an opening of less than 0.2 mm. The largest component of the dispersed part will be “filtered” at the entrance to the crack and interfere with the small part that previously did not have time to get into the crack. Moreover, taking into account the inevitable agglomeration (sticking together) of particles, the size of agglomerates can be 2-5 times larger than the size of individual large grains. As a result, the size of these “sticking together” formations can approach 1 mm. Hence, the diagram shows an approximate figure of 1 mm. That is, this is the amount of crack opening when the solution can still be pumped into an empty crack with a relatively small excess pressure, characteristic of conventional mortar pumps.

At the same time, if higher pressure is applied, the agglomerates are destroyed, and the dispersed part of the solution can penetrate into smaller cracks: with an opening of 0.2 mm. This is acceptable for the case when concrete with a crack is subject to compression.

Repair of concrete in areas operating primarily in tension

If concrete works in its most difficult form - tensile, then simply pumping in repair material cannot be done . For example, there is a loaded concrete beam with a through transverse crack in the middle. In this case, the concrete on the upper part of the crack in the beam works in compression, and on the lower part - in tension. Here, regardless of the material used for injection into the crack, it is impossible to do without an additional solution that strengthens the structure and removes the critical load from the problem area .

Since the vast majority of cementitious materials (starting with concrete) do not work well in tension, it would seem that polymer resins can be used as an alternative. But this is only in theory.

Of course, some resins may have an order of magnitude higher tensile strength than cement materials, but in fact, the “fastening platform” of the resin will still be the same concrete in the crack. Moreover, it will already be weakened concrete (it has been stretched so much that a crack has formed nearby, and there are microcracks in it). Therefore, if you do not eliminate the problem that caused the crack, i.e. If you do not remove the excess load, then in the future the resin in the crack may not break, but will tear off the concrete crust from the wall along with the resin (the crack will go nearby). And this is still ideal.

In reality, the walls of the crack are covered with dust and loose concrete, and the resin in the crack, regardless of its viscosity, “does not reach” the strong concrete of the walls, but sticks to the dust and weakened concrete! It is extremely difficult to prepare a substrate made of pure durable concrete as in laboratory tests for adhesion to concrete inside a crack, and in fact no one prepares it! As a result, a resin with excellent adhesion to clean, specially prepared concrete and with remarkable tensile strength does not work. Not because the resin is bad, but because there are no conditions for it to work properly, because... when loaded, it falls off along with dust and loose concrete from the walls. This is why surface preparation is extremely important during repairs!

Consolidation of concrete in areas where waterproofing is required

If it is necessary to waterproof concrete, the situation is different..

In addition to the dispersed part, the Dehydrol solution also contains water-soluble bridging additives. They penetrate into any cracks where water can get in (or where there is already water), incl. into cracks with an opening of less than 0.2 mm. Read more about this here “The mechanism of penetration of water-soluble bridging additives into concrete.”

As a result, the possibilities for monolithication and waterproofing of cracks in concrete for Dehydrol 3 are not limited by the size of the crack opening . The main thing is that there are colmatation conditions. And, moreover, in the concrete where Dehydrol 3 is pumped, there may be no obvious cracks at all ! For example, when it is necessary to increase the water resistance of massive concrete monoliths (dams, foundation slabs...) from the inside. Here the material works with capillary porosity as a penetrating waterproofing. Read more about this here “Repair and waterproofing of concrete monoliths from the inside.” Moreover, even on those concrete structures where waterproofing is not required (for example, on concrete columns in buildings), such a monolithic mechanism will be activated if the concrete is saturated with water .

The feasibility of injection itself

As shown above, in addition to the size of crack opening, in order to develop an optimal solution for their repair and monolithation, you initially need to clearly understand the actual conditions and nuances at the site. On this basis, it is possible to determine the range of tasks at hand and develop optimal practical solutions, based primarily on expediency.

It often turns out that injection into a crack itself is not advisable at all. It is enough to open it and monolith the prepared fine with Dehydrol 5. Unlike the injection method, this method ensures continuous (and not point) covering of the crack. And the bridging additives Dehydrol Lux grade 5 work further into the concrete. As a result, the rest of the crack, after the water stops, is monolithic with sediments and redeposition products from the cement stone. So, for example, cracks inside concrete in reinforced concrete structures of hydraulic structures are sealed. Therefore, we use crack injection itself extremely rarely, but use the most reliable method of repairing and sealing deep cracks: injecting Dehydrol Lux grade 3 into cracks and cavities and continuous jointing with sealing the crack with Dehydrol Lux grade 5:

Thus , in the matter of repairing and sealing cracks, it is initially necessary to determine the ultimate goal. It’s one thing if, for example, the final goal is to use any material: injectable or otherwise. In this case, the purpose is exhausted by the very fact of using the specified material. The contractor does not have the search for an optimal solution for the object in question as a category on his “agenda”: you just need to take a material from a limited list (for example, only injection material) and apply it. The result of such limited decisions does not always coincide with the final goal of the owner of the object and satisfies him, but with this approach, a conflict between the goals of the work contractor and the owner of the object is almost inevitable.

Another thing is if the ultimate goal is to repair and seal cracks, then you need to clearly understand the actual conditions and nuances at the site. And already on their basis, it is possible to objectively determine the range of tasks and optimal practical solutions, not limited to the list or type of any materials, but based primarily on expediency.

Summary

- When it comes to repairing and sealing cracks, you initially need to decide on the ultimate goal. If the ultimate goal is repair and sealing of cracks , then you need to clearly understand the actual conditions and nuances at the site. And already on their basis, it is possible to objectively determine the range of tasks and optimal practical solutions, not limited to the list or type of any materials, including injection materials , but based primarily on expediency.

- The injection method is one of the ways to repair and seal cracks. In itself, we use injection into a crack extremely rarely, but we use the most reliable method of repairing and sealing deep cracks: injecting Dehydrol Lux grade 3 into cracks and cavities and continuous jointing with sealing the crack with Dehydrol Lux grade 5.

- The possibilities for monolithization and waterproofing of cracks in concrete for Dehydrol 3 are not limited by the size of the crack opening. The main thing is that there are colmatation conditions. Moreover, there may be no obvious cracks in the concrete into which Dehydrol 3 is pumped.

In which parts of buildings is concrete injection most often performed?

. It is not uncommon for injection to solve the issue of waterproofing a room (basement floor) in conditions where the structure has already leaked. In this case, acrylate gels are used. The method is used both on the walls and floor of the room. . Injection is used to restore the foundation of a building erected as a monolith with “cold seams”. In this case, if small construction debris, soil or any other contaminants that affect adhesion remain between adjacent parts of the foundation, then over time the seams lose their water resistance. . The method is used in places of deformation or possible deformation of seams, most often in tunnels, passages, and underground parking lots. . On a foundation made of blocks for strengthening and additional waterproofing of the structure. . For filling microcracks in any parts of reinforced concrete and concrete structures. Advantages of using injection technology: . Maintaining the integrity of the design of the structure. . Instant sealing and waterproofing. . The work is carried out in a short time. . Restoration and strengthening of hard-to-reach areas of the building. . Possibility to carry out work almost all year round. . There is no need to carry out excavation work to strengthen the load-bearing structures. . Work is carried out in any plane: on the foundation, walls, ceiling, etc.

Concrete injection services

Our company has all the technical means and highly qualified personnel to carry out high-quality concrete injection work. We work closely with design and technical institutes and are ready to provide advice on restoring the strength and load-bearing characteristics of buildings of any structural complexity and age. Carry out both restoration and restoration work. The experience of our specialists will help you save a lot of money. We will find the best way to restore the building’s load-bearing strength, carry out waterproofing, restoration, and restoration work. We use innovative technologies, the latest equipment, and the most modern repair compounds from the best manufacturers. We guarantee: high professionalism, optimal technical solutions, work at the level of world standards.