When laying out a stove, every master must certainly remember that everything in this matter matters, including the quality of the material, as well as the professionalism of the stove maker. If you want the stove to have good draft, and the base products to retain and intensely release heat, then you cannot neglect even the most insignificant nuances; this should also include the choice of brick. Therefore, before creating a furnace, you need to understand which material is best to choose, as well as what dimensions it has in order to make a calculation.

Description of kiln bricks

The stove brick, the dimensions of which are mentioned in the article, can be fireplace or ceramic. In the latter case, we are talking about products for the manufacture of which red clay is used; such blocks are made using firing technology. Among the advantages of this material is full compliance with state standards.

This brick can be used to build the upper part of the chimney, where the heat of the stove will not be so intense. If you are interested in fireplace bricks, then you should know that they are divided into 4 more types:

- quartz;

- basic;

- carbon;

- fireproof fireclay.

Description of species

Quartz is made from quartz chips, sandstone and some clay. The main ones are made of magnesite and lime mixture. If we are talking about carbon bricks, then they are made using the technology of pressing graphite and coke chips.

The most common today is fireclay refractory brick; clay is the basis of this material. When laying fireplaces and stoves, only fireclay and quartz bricks are used. Making a comparison between the former and a ceramic block, it can be noted that stove makers most often give preference to fireclay products.

Reviews

Kiln bricks, the dimensions of which are mentioned in the article, have many advantages and some disadvantages, which you can learn about by reading the reviews. Among the advantages, consumers note the material’s ability to retain heat for a long time.

Heat transfer occurs slowly, which is explained by the long-term heat retention of the fireclay furnace. Users also note disadvantages, which are expressed in the ability to quickly gain and retain moisture within for a long time. Therefore, it is not recommended to store chamotte outdoors in the open air.

Main characteristics

Kiln bricks, the dimensions of which will be mentioned below, have two main characteristics that must be taken into account when choosing products. These include a grade for frost resistance and a grade for density. These features affect the quality of the block. Density grade is not an indicator of low or high quality, but an indicator that allows you to obtain the following information: the higher the density, the slower the brick will heat up.

Kiln brick, the weight of which any craftsman should be interested in, can have the following density indicators: from 100 to 500, with intermediate values being: 150, 200 and 250. You should not assume that the higher the density, the more suitable the material. A certain parameter of a brick block will be suitable for the construction of individual objects. If you need a brick for the stove, then you should opt for a brand of density no greater than M-250. If you prefer products with a higher density, then lighting the stove will be a real challenge.

How and where is it better to buy

Very often, construction stores do not have kiln bricks in their assortment - this is an unpopular position among buyers, and accordingly, few people keep them in stock. Therefore, you will need to order it, or contact the manufacturers. In both cases, the choice and purchase of stove bricks should be taken responsibly. First of all, you need to remember that to buy a brick, it is not enough to simply order it, or simply pay and pick it up. It’s better to go to the warehouse and select a few bricks at random from the batch offered to you for careful study. The surface of the brick must be free of cracks, chips and uniformly colored. All bricks must be the same size, of the correct shape, the edges must be smooth and perpendicular.

It is also worth paying attention to the strength grade of the kiln brick, the value of which can be from M175 to M500. The higher the number, the more durable and durable the product; It goes without saying that the price of M175 brick is significantly lower than M500. However, one should not strive for savings here - replacing one or two bricks that have become unusable can entail significant time and cost for the services of a specialist stove.

Why pay attention to frost resistance?

When choosing a material, it is important to take into account not only the dimensions of the standard stove brick, which will be discussed below, but also the frost resistance grade, which allows you to obtain information about the ability to release and absorb moisture.

This characteristic is important for products that will be used to equip the chimney. To carry out such work, you should choose a brick that has quite impressive frost resistance.

Dimensions and weight

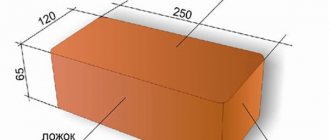

On sale today you can find red stove bricks, which can have different sizes. For example, the parameters of a standard block are limited to the following: 250 x 120 x 65 mm. The end wedge has the same parameters as the side wedge, which, in turn, has the following dimensions: 230 x 114 x 65 x 55 mm.

If you prefer a slab, it can have two sizes, including: 460 x 230 x 75 or 600 x 230 x 90 mm. When choosing the size of stove bricks for the chimney and the stove itself, you should prefer the standard shape. Using the side wedge, you can form a figured masonry, while the end wedge is used for a narrowed butt. You can cover the firebox using a stove.

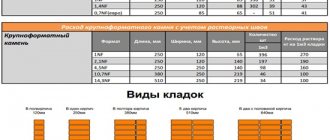

The size of the kiln brick may vary. Thus, the standard material is made a little longer, which allows it to be used despite its impressive weight. There are also one-and-a-half and double sizes of standard bricks. In the second case, we are talking about products whose length is twice as long as a standard brick. If you are interested in the size of a one-and-a-half red stove brick, then you must remember that its length is one and a half times greater than the length of a standard product.

Dimensions of bricks for laying furnaces

Fire bricks have standard dimensions: 250 x 123 x 65 mm, 230 x 113 x 65 mm and 225 x 225 x 70 mm. It is made by mixing and firing fireclay (a powder made from fired and ground clay) and fire clay.

Refractory bricks are necessary for lining fireboxes of furnaces when burning natural gas, coal and liquid fuel. It is characterized by great strength and increased fire resistance. Class “A” fireclay bricks can withstand temperatures up to 1600 °C.

For masonry and lining, it is best to use fire bricks measuring 250 x 123 x 65 mm because they are almost the standard dimensions of ordinary red clay bricks.

Master's advice. Whole one-dimensional brick, which remains after dismantling old buildings, can also be used for laying stoves, provided they are thoroughly cleaned of clay and cement mortar.

Small bricks (mezhigorka), left over from dismantling old furnaces, can be used not only for laying solid wood, but also for lining the firebox. But before laying, it must be sorted to avoid burnt or smoked bricks.

Bricks with soot deposits on the side faces should not be included in the masonry, otherwise black spots will be visible on the outer surfaces of stoves and chimneys.

If there are traces of soot deposits on the surface of a small brick, then it can be used for laying a vault, installing internal partitions and lining a firebox. Burnt out brick is not suitable for masonry, as it is a weak and brittle material.

Dimensions and characteristics of Vitebsk brick

Due to the fact that for laying stoves it is recommended to use only high-quality material that is well fired and can be processed, you should pay attention to Vitebsk brick, which has sufficient strength.

In a wide range you can find several varieties of products from this manufacturer. For example, a ceramic stove ordinary solid single brick, the dimensions of which are 250 x 120 x 65 mm, may have a strength grade of 85 or 200. As for frost resistance, the material may be classified as F15, F25 or F35. The water absorption of this material is 8%, and the thermal conductivity varies within 0.529 W/(m•K). The weight of one product is 3.7 kg.

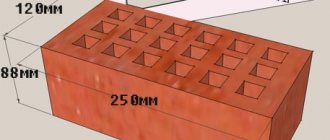

The dimensions of Vitebsk stove bricks vary depending on the type of product. For example, a ceramic ordinary solid thickened brick will have the following dimensions: 250 x 120 x 88 mm. Its water absorption varies from 13 to 14%. The weight reaches 4.8 kg, and the block is manufactured in accordance with GOST 530-2012. On sale you can find ceramic ordinary solid bricks with chamfers. Its dimensions remain the same as in the first mentioned case, as does its mass, as well as thermal conductivity and water absorption. An ordinary solid profile single brick weighs somewhat less - 3.6 kg, but thermal conductivity and water absorption remain the same, as do the dimensions.

Dimensions of red bricks for the stove

If you didn’t succeed in breaking the brick into the required fragments the first time, there is no need to panic. In the process, your hand will quickly become full and the skill will be consolidated. After splitting, the resulting incomplete brick must be trimmed until smooth with light and gentle blows with a pick.

If it is necessary to split the brick not along its shape, as shown in the figure, but across it, the task becomes more complicated. The process itself does not change, except that the furrow should be made a little deeper. But the result is not always satisfactory, even for specialists - it is more difficult to split the material, and the result is often defective parts that do not correspond to the notch. When choosing a building material at the point of sale, you should not be deluded by the appearance of the samples on display and rush to order.

First of all, you need to ask the seller to provide a certificate for the product.

Dimensions of red and fireclay refractory bricks

Then it is advisable to personally visit the warehouse and inspect the pallets of bricks. To check how well the brick is fired, you need to tap it. High-quality material sounds clean and metallic. When fired poorly, brick becomes a water reservoir and loses strength, which is absolutely unacceptable when laying stoves and fireplaces.

Burnt material is immediately visible - it has melted edges, and in a broken state, the black core is also visible. Such substandard goods can only be used when laying the foundation. When buying bricks, you need to remember the main thing: when laying a stove or fireplace, even the slightest defect in this building material is unacceptable. And the time spent when choosing red stove bricks will more than pay off in the process of its long operation and high-quality service.

When building a furnace, it is important to ensure such parameters as long service life, high heat transfer rates, and optimal furnace dimensions. To achieve them, it is recommended to use special oven bricks. When choosing it, it is important to consider not only the size, but also the physical properties. When the blocks have the correct shape, size, do not have any deviations in appearance, and also provide good traction, then be sure that the constructed stove will serve you well and for a long time.

Which brick is best to use for the stove? For the construction of a furnace, a suitable material is ceramic. Here we describe the pros and cons of ceramic brick, grade M. But it is much better when the masonry of the structure is made from materials from several manufacturers. Single refractory bricks can come in several varieties.

Each species has its own size, weight and physical properties.

This product is based on alumina materials. When purchasing such a product, you must follow the following recommendations:. Red brick is also used for other purposes. The link describes the dimensions of the red plinth brick. For the first type, compliance with geometry is very important. This material is always sold in a wide variety of shades and colors. As for double sand-lime brick, when choosing it it is important to take into account the degree of heating of the future structure.

This material is one of the most versatile.

It is allowed to be used for laying the stove both inside and outside the house. It has the following advantages:. The process of making refractory in Russia began to be introduced back in the 19th century. At that time, steel was actively smelted. But the melting process must take place at high temperatures. To solve the problem, it was necessary to use a material that could withstand this temperature regime.

The production of refractory bricks is based on refractory grades of refractory clay.

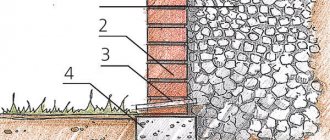

Chimney dimensions

When laying a chimney, you must remember that its vertical dimensions will have the greatest impact on draft. A proper chimney should not have a height of less than 5 m. Among other things, the height difference between the roof surface and the cap is decisive. Thus, the top point of the pipe should be at the level of the ridge or be slightly higher at a distance of no more than 3 m. If we are talking about a flat roof, then the elevation above it should be 1 m or more. When installing chimneys, brick dimensions must be taken into account. Thus, the wall thickness should be 10 cm for residential buildings.

The brick must be laid along its entire length in such a way that the area of the inside of the pipe is constant. The dimensions of the chimney also depend on the dimensions of the building. So, if the pipe is large, and you install it on a small house, then it will look comical. The lowest brick consumption can be achieved when the pipe has internal dimensions of 260 x 130 mm. This design will work if you lay out each row of 5 bricks.

You can find pipes of more impressive sizes, this applies to Russian stoves with a large portal. In this case, it is recommended to choose a stove brick, the dimensions of which will allow you to form a channel cross-section of 260 x 260 mm.

Recommendations for the selection and use of oven bricks

One of the disadvantages of fireclay bricks is that it is capable of absorbing moisture and then releasing it for a long time. Therefore, it is not recommended to store it outside. To lay out the main parts of the stove structure, you need to choose only red brick, and not burnt or unburned, since in this case its quality properties are lost. The brick must have an even shape with sharp edges and dimensions stated according to GOST.

The surface of the fireclay should be matte, without any film, which may indicate that the adobe may collapse due to possible temperature changes.

When you hit the surface of a brick block with a hammer, a clear, ringing sound should be produced. A dull sound indicates the presence of voids, as well as poor hardening and drying. There should be no traces left at the impact site.

When you split fireclay in half, you can judge its quality: the structure should be dense and homogeneous. It should not contain any foreign inclusions, including small pieces of clay - this indicates a violation of technology in the manufacture of brick material.

To build a furnace, it is enough to use the M250 brand of fireclay; the denser structure will take a very long time to warm up.

When choosing a material, you should pay attention not only to the size of the red brick for the stove, but also to the grade of its frost resistance, since it indicates the ability of moisture absorption and moisture separation, which is especially important when installing a chimney.

To build a stove foundation, it is recommended to choose a brick with the lowest hygroscopicity, i.e. water absorption.

Hyper-pressed adobe can be used when laying outdoor barbecue stoves, but it is not recommended for use in home stoves, since the limestone included in its composition is unstable to high temperatures and begins to collapse under the influence of the carbon dioxide released.

Brick for the stove

Red brick with a density of M200 cannot be used for laying the combustion chamber and chimney, as well as the street part of the pipe, since it can collapse within one to two years.

You can use old fireclay left over after the dismantling of buildings and structures, provided that its structure is not destroyed and the surface is intact. In this case, the old brickwork used had to be clay or cement. If the old masonry was on a limestone base, such adobe can only be used as a base for a fireplace or pipe heads. Old fireclay used when laying out stoves can also be used, provided that its surface is well cleaned of soot, otherwise, with new laying, black spots will appear on the outer surface of the pipes and the front part of the stove elements.