Dry mix M200 masonry in big bags (MKR - soft containers made of synthetic (polypropylene) fabric with a bulk weight of the mixture up to 1.5 tons) is a target product of a unique composition for solving construction problems when implementing projects for the construction or reconstruction of houses/buildings by developers, construction contractors and large construction teams.

Depending on the Customer’s preference, dry masonry mixture M200 can be delivered to sites in big bags (BBC) by trucks and covered railway cars, or in bulk by cement/sand trucks and special railway hopper cars. Thanks to the supply of dry masonry mixture M200 in big bags (MBR)/bulk in medium and large wholesale, the logistics of supply and storage of consumables are optimized, estimated costs are reduced and the planning process is simplified when implementing construction projects.

Use of dry masonry mixture M200 in big bags (MBR).

Dry mix M200 for masonry in big bags (MKR) is mainly focused on the masonry of walls and partitions made of piece materials and small wall blocks made of lightweight or cellular concrete, as well as the installation of wall panels, floor panels, and lintels.

At the same time, dry masonry mixture M200 in big bags (MKR) can be used with equal success for preventive repair of surfaces before plastering, making finishing layers or floor screeds with a limited load, blind areas, laying ceramic and artificial/natural stone tiles, driving lightweight foundations of low-rise buildings (when justifying the admissibility of using mortars with a compressive strength (at design age) of 20 MPa in the design documentation for construction.

Reference: Dry mix M200 masonry in big bags (MKR) should be used for the construction of walls from blocks of aerated concrete, foam concrete, gas silicate, foam silicate of categories 2 and 3 according to GOST 21520-89 (as amended on April 19, 2010) with deviations from the linear dimensions according to height ±3 - ±5 mm, length/thickness ±4 - ±6 mm.

For laying small wall blocks made of autoclaved aerated concrete/gas silicate and foam concrete/foam silicate with curing in steam chambers of category 1 according to GOST 21520-89 with deviations from the linear dimensions in height ±1 mm, in length/thickness ±2 mm, you need to use special glue for blocks Professional QUICK BLOCK.

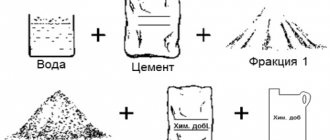

Composition of dry mix of masonry M200 in big bags (MKR).

The composition of the dry mix of masonry M200 in big bags (MKR) is a copyrighted intellectual property that allows you to obtain a construction product with unique properties in strict compliance with the standards of the original recipe and a guaranteed dosage error by weight of binders, water and additives ± 1%, filler ± 2%, and the alkali content in the cement binder is less than 0.6% by weight. The basic requirements of GOST 28013-98 (as amended on April 19, 2010) for masonry mortars in dry mix masonry M200 in big bags (MKR) of the VosCemProduct brand are achieved thanks to strict control over the mass fractions of the components of the composition, the use of high-quality cement M500 D0 ( according to GOST 10178-85 as amended on July 19, 2010) or TsEM I 52.5N (according to GOST 31108-2003 as amended on July 19, 2010), purified fractionated quartz sand with a maximum size of 1.2 mm and modifying additives - plasticizing, water-retaining, air-entraining, increasing the frost resistance of the hardened mortar and the workability of the dry mixture mixed with water.

Main technical and technological characteristics of dry masonry mixture M200 in big bags (MBR).

| Parameter | Meaning |

| Compressive strength at design age 28 days, MPa | 20 |

| Maximum aggregate size, mm | 1.2 |

| Dosing error: Binders, water and additives Fillers | ±1 % ±2 % |

| Bulk density, kg/m3 | 1700-1900 |

| Average density of the hardened solution, kg/m3 | 1500 ± 10% |

| Moisture content of dry mixture | No more than 0.1% by weight |

| Water holding capacity, %, not less | 90 |

| Delamination of the solution, %, no more | 10 |

| Mobility of the mortar mixture | 7-8 cm cone immersion depth (grades Pk2 and Pk3) |

| Strength of adhesion to the coated base, MPa, not less | 0.5 |

| Vapor permeability, mg/(m*h*Pa), no more | 0.2 |

| Frost resistance | F50 (50 freeze/thaw cycles) |

| Temperature range of application, degrees. Celsius | From -20 or less (when using heated solutions) to +35 |

| Layer thickness, mm | 5 — 50 |

| Volume of water for mixing the mixture, l/kg | 0.15-0.17 |

| Maintaining the working properties of the solution (production time), min | 90 |

| Specific effective activity of natural radionuclides Aeff, Bq/kg | Less than 370 |

Preparing surfaces for work with a solution of dry masonry mixture M200 in big bags (MKR).

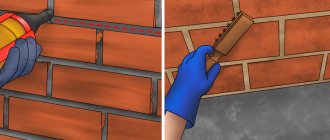

When laying with a mortar from a dry mixture of masonry M200 in big bags (MKR), the surface of each row of wall materials (or the base of the foundation when laying the first row) is cleaned of dirt/dust, layers, grease stains, paint and varnish materials, etc., At high ambient temperatures, brick is desirable, and blocks of cellular concrete must be moistened. Installation of panels, ceilings, lintels is carried out with preventive cleaning of the base from dirt and debris.

When performing facing work with a solution from a dry mixture of masonry M200 in big bags (MKR), the base surface is cleaned of dirt and stains, large defects are repaired with the solution, crumbling areas are primed, smooth surfaces are treated using a sandblasting machine, a hammer, coarse sandpaper, etc. During operation in dry, hot weather, porous ceramic tiles are moistened before use, and the structural base of cellular/lightweight concrete is moistened abundantly until a stable color change occurs.

Where are grade 200 dry mixes most often used?

Sand concrete masonry mixture M200 Rusean, as well as other compositions that can be classified as this class of building materials, are most often used during plastering, construction of walls, including for painting, concreting surfaces, for example, pouring floor screed, etc. If you want to efficiently and reliably install brickwork, both a small partition and a permanent structure, then using M200 Rusean sand concrete will be the best option for you, since the sand fraction used, as well as the composition of the mixture, is optimally balanced for this task.

Preparation and use of mortar from dry masonry mixture M200 in big bags (MBR).

When preparing:

- small batches of mortar are poured into a container with a measured volume of clean water in a uniform flow, with a construction mixer or a powerful drill with a spiral attachment until a homogeneous mortar mixture without lumps is obtained. After 10 minutes of maturation, the mortar mixture is mixed again and used for no more than 90 minutes, depending on the temperature and humidity of the surrounding air;

— for large batches of mortar, the dry mixture of masonry M200 and water for mixing in measured weight and volume fractions are placed in the hopper of a mortar mixer in accordance with the requirements of the mixing equipment manufacturer’s instructions. To prepare mortars from dry masonry mixture M200 in big bags (MKR), he recommends using targeted mortar mixers with a shaft speed of 65 rpm, designed for working with dry building mixtures.

Masonry, cladding, installation of large-format wall elements, screeding and repair of surfaces with mortars from a dry mixture of masonry M200 in big bags (MKR) are carried out using standard construction technologies by qualified workers.

Important: When laying or installation work with mortars from the dry mixture of masonry M200 in big bags (MKR) at subzero temperatures, you should use the recommendations of GOST 28013-98, summarized in the table below.

Table. Minimum temperature of mortars from dry mix of masonry M200 in big bags (MBR) for masonry and installation work at subzero temperatures and different wind speeds.

| Air temperature, °C | Minimum temperature of solutions from dry mix of masonry M200 in big bags (MKR), °C | |||||

| Bricklaying | Block/stone laying | Installation work | ||||

| Wind speed, m/s | ||||||

| Until 6 | More than 6 | Until 6 | More than 6 | Until 6 | More than 6 | |

| 0 — — 10 | 10 | 10 | 10 | 15 | 20 | 25 |

| — 10 — — 20 | 10 | 15 | 15 | 20 | 25 | 30 |

| Less - 20 | 15 | 20 | 20 | 25 | 30 | 35 |

Facing with glazed tiles, artificial/natural stone, etc. must be carried out at an ambient temperature above 5 °C with solutions from a dry mixture of masonry M200 in big bags (MKR) with a temperature of at least 15 °C.

Dry mix M300 (sand concrete)

Sand concrete is considered one of the varieties of dry building mixtures today - it is a building material that is used for the primary leveling of floors and horizontal concrete bases. Sand concrete is a material that is most often made on construction sites from a dry mixture M300 by adding the required amount of water to the dry substance to obtain a homogeneous mass. Dry sand concrete mix Fingers is usually used for pouring and leveling floors in rooms with moderate mechanical loads and not subject to constant exposure to moisture, therefore M300 is considered an ideal mixture for its use in residential premises, civil and industrial construction.

To prepare sand concrete for application, cold (15 to 20 degrees) water is added to the mixture, and it is extremely important to observe the recommended proportions, since the final mechanical strength and resistance of the coating to various types of aggressive environmental influences depends on the dosage and ratio of the mixture and water. .

| Cement brand | Packing | Price from 20 tons |

| M300 sand concrete (Fingers) | 50 kg | 120 rub. |

| M300 sand concrete (Mixed) | 50 kg | 120 rub. |

| M300 sand concrete (Stone flower) | 50 kg | 125 rub. |

Prices include VAT. Discounts and delivery conditions are discussed with sales managers. Tel.

A mixture of this type is today considered one of the most common and popular materials for leveling horizontal surfaces, which is due not only to its performance characteristics, but also to such factors as price. Sand concrete M300 , the price of which is low, is consumed quite quickly, so cost plays an important role when choosing a repair material.

When starting repair work, the finished mixture is poured onto the base of the floor and leveled using special mechanical tools such as a squeegee, a trowel or a spatula, but automatic equipment can also be used. The optimal layer of sand concrete is 1-5 centimeters, but in some cases it is possible to lay a layer up to 10 centimeters thick. In this case, of course, the material consumption increases and therefore the M300 dry mixture , the price of which is low, is considered the best option.

Thus, dry mix M 300 has a number of advantages compared to similar dry mixes, that is, it demonstrates high strength, versatility, and also has a fairly low price, which determines its wide distribution when performing repair work on leveling concrete and cement-based concrete. sand surfaces.

Advantages of dry mix of masonry M200 in big bags (MBR).

Dry mix M200 masonry in big bags (MKR) of a patented composition has indicative technological, technical properties and performance qualities that fully comply with the requirements of GOST 28013-98 and modern construction technologies. Supply of dry masonry mix M200 in big bags (MKR) or in bulk in medium and large wholesale significantly reduces the estimated costs for the purchase/delivery of material, simplifies warehousing/storage of the mixture, increases the efficiency of construction planning and significantly eliminates the risks of dependence of the construction process on the work of the department developer/construction contractor supplies and weather conditions.

Sand concrete M200 P2, BSG m V15

I hereby freely, by my own will and in my own interest, give my consent to IP Tsurikov Alexander Evgenievich, located at 627750, Tyumen region, Ishimsky district, Plodopitomnik village, st. Svetlaya, 2, 1 (hereinafter referred to as the Operator) for automated and non-automated processing of their personal data in accordance with the following list:

- name, telephone number, email address and other individual means of communication specified when filling out all forms on the website https://beton-138.ru (hereinafter referred to as the Site), namely: Calculate the cost of the order

- writing reviews;

- using feedback services with the Site Administration;

for the purposes of providing information services and ordering concrete, providing relevant advertising information and optimizing advertising.

I also give my consent to the Operator providing my personal data to third parties and to carrying out cross-border transfer of personal data to achieve the stated purposes of processing personal data.

In order to ensure the implementation of legal requirements in the field of personal data processing, the Operator can:

- carry out the processing of personal data by collecting, storing, systematizing, accumulating, changing, clarifying, using, distributing, depersonalizing, blocking, destroying personal data;

- use an automated method of processing personal data via the Internet;

This consent comes into force from the moment of confirmation and is valid for 5 years, unless otherwise provided by the current legislation of the Russian Federation.

Withdrawal of consent to the processing of personal data is carried out by sending a written application to the legal address of the Operator.

I confirm that I am aware of the right to withdraw my consent by drawing up an appropriate written document that can be sent by me to the Operator. In the event of my withdrawal of consent to the processing of personal data, the Operator has the right to continue processing personal data without my consent if there are grounds specified in paragraphs 2-11 of part 1 of article 6, part 2 of article 10 and part 2 of article 11 of the Federal Law of July 27, 2006. No. 152-FZ “On Personal Data”.