Special purpose mortars are often used to repair concrete. They are characterized by high weather resistance and can be used on artificial stone operating in harsh conditions (facades, tunnels, parking lots). One of these solutions is thixotropic mixtures, the characteristics and principles of use of which will be discussed below.

Causes of concrete destruction

Artificial stone can be subject to mechanical loads (vibration, shock, etc.), physical (wear, shrinkage, freezing and thawing, temperature fluctuations, crystallization of salts).

Chemical loads greatly weaken structures. Due to the capillary-porous structure, alkalis and sulfates, salt solutions are able to penetrate into the thickness of concrete and ultimately affect its load-bearing capacity. If the structure cannot withstand the loads and requires repair, the choice of working personnel is based on an assessment of its condition and the causes of damage.

The reasons for the destruction of concrete are very diverse, but they all inevitably lead to the need for repairs

Scope of application

The material is intended for professional and non-professional use.

In professional repairs, thixotropic mixtures are used in the following cases:

- structural repair and restoration of destroyed concrete structures, including those due to corrosion of reinforcement (beams, edges, columns). Elimination of defects made during construction or those that arose during operation;

- repair of the protective layer , filling of hard joints, elimination of surface defects (new filling joints, gravel nests, exposed reinforcement, traces of formwork removal);

- alignment of walls and enclosing structures;

- repair of foundations under strong abrasive loads, reinforced concrete structures of hydraulic structures;

- waterproofing work on the roof, in basements, concrete tanks and trays;

- pouring foundations and monolithic housing construction, embedding prefabricated concrete structures;

- repair of floor coverings of industrial buildings under heavy mechanical loads and under the influence of aggressive environments;

- repair of boiler houses , thermal power plants, chimneys, bridges, viaducts.

In the private sector, thixotropic mixtures are used to repair concrete screeds, floors, paths, wells, stairs, steps, basements, and vegetable pits. The material is successfully used for sealing grooves, cracks, repairing garages, and concrete slabs for various purposes .

In general, the solution is effective in the repair and restoration of any concrete or reinforced concrete structures subject to static and dynamic loads. They are used at civil and transport construction sites, and at hydraulic structures.

Specifications

Repair thixotropic mixture is a ready-to-mix powder with a specially developed recipe. When mixed with water, it turns into a working solution with high thixotropy. This allows it to be used on vertical surfaces without slipping without formwork. The material can be applied in a thick layer.

After curing, the composition is characterized by the following properties:

- waterproof;

- high compressive and bending strength;

- good adhesion to old concrete and reinforcement;

- thermal expansion, vapor permeability, elastic modulus almost completely correspond to the same characteristics of high-quality concrete;

- abrasion resistance.

However, thixotropic mixtures have a number of limitations for use. They do not work on smooth surfaces (roughness must be ensured); if necessary, reinforcement is introduced . The material cannot be used for anchoring or when pouring into formwork.

Application of thixotropic mixtures is carried out only at temperatures above 5 degrees.

The disadvantages of thixotropic solutions include the need for maintenance. The material exhibits all declared characteristics only when used in humid conditions or when water is sprayed. This ensures that all product properties are revealed correctly. This is not easy to achieve on a construction site.

That is why it is recommended to introduce special additives into working mixtures that reduce hydraulic and plastic shrinkage . This will provide all conditions for the solution to work even in windy and dry weather.

Typical technical data

| Consistency and color | Gray powder |

| Volume weight | 1250 kg/cub.m |

| Maximum filler ratio | 2.5 mm |

| Dry residue | 100% |

| Blending Options | 100 parts dry powder to 16-17 parts water |

| Plastic deformation | 70% |

| Density | 2150 kg/cub.m |

| pH | 12.5 |

| Working temperature | +5 +35 degrees |

| Viability | 60 minutes |

| Layer-by-layer exposure | 4 hours |

| Maximum thickness of one layer | 30-35 mm |

| Compressive strength | 60 N/mm2 after 28 days |

| Flexural strength | 8.5 N/mm2 after 28 days |

| Peel strength | 2 N/mm2 after 28 days |

| Elasticity coefficient | 25,000 N/mm2 |

Dry repair mixture BIRSS RSM-1 M450 50kg

One-component repair mixture based on special cements and high-quality natural fillers with a complex of chemical additives, is a fast-hardening, reinforced composition with high dynamics of strength gain. The solution is plastic, easy to prepare, and convenient to use. The material is characterized by high technological parameters (strength, resistance to external loads, crack-resistant). The composition is non-shrinking, moisture- and frost-resistant, has high adhesion to concrete surfaces and steel reinforcement, high fatigue resistance, low capillary porosity, and high impact resistance.

APPLICATION AREA

The dry mixture solution is intended for repairing elements of reinforced concrete structures of road bridges and tunnels, as well as structural elements of buildings, filling rigid vertical and horizontal joints between prefabricated elements, filling potholes and cavities without the use of formwork in areas where increased requirements for surface quality are imposed. Thanks to the accelerated setting time and high dynamics of strength development, the composition can be used for urgent repair of concrete in various structures and structures, including those subject to dynamic loads. Excellent thixotropy and rheoplasticity allow the composition to be applied in hard-to-reach places.

SPECIFICATIONS

Color gray Application temperature from + 5°C to + 35°C Waterproof grade W8 Solution pot life 20 - 30 minutes Solution density 1950 - 2100 kg/m3 Compressive strength after 1 day no less than 20 MPa Compressive strength after 28 days no less 45 MPa Bending strength after 1 day not less than 5 MPa Bending strength after 28 days not less than 10 MPa Start of setting no earlier than 20 minutes Adhesive strength to the concrete base not less than 2 MPa Frost resistance grade F300c Maximum aggregate size 0.5 mm Made from environmentally friendly raw materials. The class of materials according to the specific effective activity of natural radionuclides is class 1 (Aeff.<370Bq/kg). There is a hygiene certificate.

REQUIREMENTS FOR THE BASE

The repair solution "BIRSS RSM-1 M450" is applied to the damaged concrete surface after it has been cleaned to a solid base using a sandblasting machine or high-pressure water. Remove loose elements and clean the surface from dust and stains of organic origin. The base must have a positive temperature. The cleaned surface of the reinforcement and embedded parts must be treated with an anti-corrosion compound (“BIRSS Germolastik Antikor”). To increase adhesion and quality of repair, moisten the concrete base or treat it with the BIRSS Ground Universal primer.

MODE OF APPLICATION

With constant stirring using an electric drill with an attachment, pour the contents of the bag (25 kg) into a container with 3.4 - 3.75 liters of clean water and mix until a homogeneous, plastic mass is formed (a more accurate amount of water is indicated in the passport for the finished product). Let the solution stand for 2 - 3 minutes, then mix again. The solution is ready for use. To increase the adhesive strength with a concrete base, it is recommended to apply a spray layer to the surface to be repaired with a brush or brush, for which the repair solution is prepared with a more liquid consistency. The main layer should be applied no later than 10 - 15 minutes after applying the spray, with a thickness of no more than 20 mm in one pass. If it is necessary to apply a thicker repair layer, each subsequent layer should be applied after the previous one has set. It is recommended to use BIRSS leveling compounds for subsequent finishing as a covering layer (“BIRSS Betonspachtel”, “BIRSS 37 leveler”). The prepared portion of the solution should be used within 15 – 20 minutes. The surface to be repaired, both during the work and for 1 - 2 days after its completion, must be protected from direct sunlight and precipitation, for which purpose the area should be covered with plastic film or damp burlap.

MATERIAL CONSUMPTION

Depends on the type of surface, and on the volume of potholes and chips - on average 18.5 - 20 kg of dry mixture per 1 m2 with a solution layer thickness of 10 mm.

PACKAGE

Paper bags of 25 kg, 50 kg. STORAGE: The shelf life in a dry place and tightly closed original packaging is 12 months from the date of manufacture. Avoid exposure to moisture; use opened packaging first.

SECURITY MEASURES

Do not allow the dry mixture to get inside your body; use gloves when working, as if the mixture gets on sensitive skin, it can cause irritation. Avoid getting the powder in your eyes and prolonged contact with exposed skin. If this happens, rinse the affected area thoroughly with running water and consult a doctor if necessary. The manufacturer guarantees that the product meets the technical specifications. The manufacturer is not responsible for the incorrect use of the material, as well as for its use for purposes and conditions not provided for in these instructions.

Tools, equipment and accessories for thixotropic concrete repair

To carry out repair work, you will need professional electrical equipment and hand tools.

The following set of equipment should be present on the site:

- surface preparation equipment : grinders, grinders, construction vacuum cleaners, compressors, high-pressure apparatus, sandblasters, hammer drills, jackhammers;

- tools : trowels, shovels, spatulas, chisels, drills with mixing attachments, brushes, metal brushes;

- measuring instruments : to determine the strength of concrete, the viscosity of working solutions, to search for reinforcement, thermometers;

- P/E film to protect the finished layer;

- special clothing, personal protective equipment.

Preparing the base

Thixotropic mixtures are most often used for structural repair of concrete, that is, to restore its load-bearing capacity.

In view of this, special requirements are imposed on concrete and reinforced concrete surfaces:

- strength, ability to bear a load (bearing capacity);

- absence of peeling, destroyed layers;

- absence of contaminants that negatively affect adhesion (fats, oils, dirt, dust, rust, paint);

- rough texture.

All weak parts of the base are removed down to solid structural concrete. Any compounds remaining from previous work must also be removed. The reinforcing rods and the concrete itself are processed. The work is carried out until the elements are freed from cement laitance, dirt, oils, fats, and paints and varnishes.

The hydraulic cleaning method is unsuitable where an increase in air humidity is unacceptable

Methods for cleaning bases:

- mechanical - for repairing cracks and defects, jackhammers, hammer drills, picks, and pneumatic hammers are used. Cleaning is carried out using sandblasting, shot blasting units, grinding machines and high-pressure apparatus. This is a universal preparation method that is advisable to use in all cases, regardless of how much and how the concrete is damaged. However, the technique is not used where dust is unacceptable;

- thermal - implemented using special burners. For concrete, heating is allowed no higher than 90 degrees. The thermal method is effective for minor damage depths - up to 5 mm. High temperature allows you to remove traces of oils, rubber, and organic compounds. Such treatment is always followed by mechanical or hydraulic;

- hydraulic – hydraulic units and high-pressure apparatuses are used. This is a universal solution for effective and fast concrete cleaning;

- chemical – special chemical compounds are used to prepare concrete. The method can help out where mechanical cleaning is impossible. After etching, the substrates are always washed with water.

If defective concrete is found at the work site, it must be cut out with concrete breakers, breakers or hammer drills. All loose layers with insufficient thickness, structural damage, and peeling coatings must be removed.

Before applying the thixotropic solution, the base is saturated with water . The surface should be damp, but without puddles. If accumulations of liquid are found, they are removed with a sponge or compressed air. In some cases, the working solution is applied to a wet primer layer.

Where and how to use repair mixtures

When numerous cracks ≥ 0.3 mm, chipping and crumbling of the material appear on the concrete surface, it makes sense to use a repair mixture. Operating concrete in a dusty environment also contributes to its accelerated destruction. In addition, a humid environment causes corrosion of reinforcement, which accelerates the appearance of voids, and this is a direct indication of the use of repair and restoration mixtures.

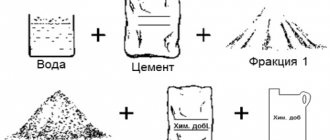

Most often you can see dry mixtures on sale that need to be mixed with water. In addition to the main fillers (sand, Portland cement, gypsum, lime), manufacturers can add special additives - plasticizers, stabilizers, etc.

According to their intended purpose, repair and restoration mixtures are divided into those intended for:

- restoration of structures operating under load;

- restoration of concrete floor;

- protecting reinforced concrete objects from metal corrosion, sealing the surface to protect against moisture.

Casting restoration compositions

Also, the repair composition for concrete can be dry and cast:

- Dry compositions are designed to restore the original parameters of concrete and strengthen monolithic parts and elements of structures. Frost resistance and strength of the composition are recommendations for use for the repair of concrete structures operating in harsh natural conditions. In addition, dry mixtures waterproof the concrete surface, and the environmental friendliness of the material allows it to be used even in the food industry.

- Casting mixtures are used to fill small cracks and potholes in concrete. When poured, moistened cracks expand and are glued together with a repair compound, and when the solution hardens, they do not shrink. The casting mixture hermetically seals the repaired area, but for application it is necessary to have a horizontal surface.

The composition of the mixture is:

- monocomponent - these are mixtures consisting of coarse and fine aggregates;

- two-component - based on synthetic substances;

- multicomponent - based on liquid polymers.

Multicomponent repair and restoration compositions

Fast-acting composition

The mixture dries quickly and hardens just as quickly. The standard time for complete readiness for further work is 30 minutes. Typically, such compositions are used in industrial environments where production or other work, such as loading and unloading, cannot be stopped.

Non-shrink mixture

Shrinkage is a surface deformation that occurs when the volume of cement in a concrete solution decreases. Shrinkage can occur when water evaporates from the solution, so the volume of water used to mix dry mixtures must be strictly regulated. Conventional construction and repair restoration mixture can shrink up to 5 mm, which, in turn, provokes the appearance of cracks in concrete.

Thixotropic and frost-resistant composition

The thixotropic mixture is used to restore vertical or inclined surfaces. Because of this, it requires the creation of a frame (sheathing). The mixture has a high viscosity coefficient, so it does not spread within the frame. The frost-resistant mixture is used in winter at sub-zero temperatures.

Thixotropic reducing mixture

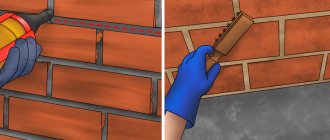

Application of adhesive primer

The material is also applied to a moistened base. If concrete absorbs moisture well, moistening is realized repeatedly. A properly prepared surface should be damp, but not shiny.

Application principle:

- the soil is spread using wet torquetting or medium-hard brushes;

- during work, control the filling of pores and unevenness of the base;

- The thixotropic repair compound is applied to the wet primer. But, if the surface has had time to dry, another fresh layer of soil is applied.

Repair mixtures of the Birss brand

Repair mixtures for restoring concrete are produced, which is located in Russia. These compounds are intended for the restoration of structures and concrete foundations. If there is a need to cope with damage of the first degree, then you can use the mixtures “Birss 28”, “Birss 29”. While the second degree will be handled by the compositions “Birss 30 C1” and “Birss 58 C1”.

This manufacturer has repair mixtures for all degrees of damage. The main advantages include salt resistance, high levels of adhesion, water resistance, frost resistance, density and elasticity, as well as wear resistance and shrinkage resistance. The price of such mixtures is much lower and is equal to 6 dollars per 50 kg.

If protection of fittings from corrosion is required

In accordance with GOST 31384-2008, GOST 32016-2012, it is necessary to ensure long-term anti-corrosion and passivation (inactivity) of steel reinforcement. The first stage of protection involves cleaning the reinforcing bars. According to GOST RISO 8501-1-2014, newly installed or old fittings must be cleaned to a degree of Sa 2 ½. The work is carried out manually or with metal brushes. A mechanized method using sandblasting machines can be used.

Ideally, the depth of jointing should exceed the width of the seam by 3-4 times

If there is damaged concrete on the work site, it is removed along with the reinforcing bar . The use of rotary hammers and jackhammers is unacceptable, as this may lead to a decrease in the adhesion of concrete and reinforcement. Exposed reinforcing bars are completely exposed. The gap between steel and concrete must be at least 20 mm. If the diameter of the rods is small (up to 5 mm), a smaller gap of 10 mm is acceptable.

Application of protection:

- An anti-corrosion compound is applied to the cleaned reinforcement in two approaches. When working, use a medium-hard brush or a (wet) torquetting technique. The thickness of the first layer should be 1 mm. When the first layer begins to set, a second layer of identical thickness is immediately applied;

- edges, reinforcement-concrete transition zones, wire fastenings undergo particularly careful processing;

- If the first layer has completely set before applying the second, apply another fresh layer.

Elimination of active leaks

At this stage, the task is to waterproof the structure and eliminate active leaks. If pressure leaks are found on the surface, they are eliminated with hydroseals (quick-setting waterproofing compounds). Such materials are capable of hardening under liquid pressure within 1 minute.

Additional surface preparation is required here:

- areas of active leaks are sealed. During operation, the gap is expanded into the structure to a depth of at least 3 cm and a width of 2 cm. The cavity is washed with water;

- the base is cleaned using sandblasting or high-pressure apparatus.

When a leak is eliminated, a hydraulic seal is formed based on a quick-hardening mixture. The material should take the shape of a truncated cone or ball. After this, it is pressed forcefully into the active leak area for 3-5 minutes. If the waterproofing area is large, they work with it in several stages.

If the leak is very intense, a drainage polyethylene tube is inserted into the area being repaired , which will localize the drainage of water. The area around the pipe is treated with a hydraulic seal. When the material has hardened, the tube is removed by caulking the hole with a quick-setting compound.

Features of MBR repair mixtures

In the assortment you can find other types of compositions. For example, the repair mixture for concrete MBR 500 is intended for repairing structures that have defects. This composition can be stored for six months at a fairly wide temperature range, from -50 to +50 degrees. Considering the technical characteristics of this composition, it can be noted that it has different grades within the range of MBR 300 - MBR 700. Each of these mixtures can be laid with a maximum thickness in one approach. For example, MBR 320 is applied at a thickness of 40 millimeters, while MBR 700 is applied at a thickness of 20 millimeters. As an alternative solution in the latter case, a form can be used. After hardening, MBR 700 acquires a density of 2350 kilograms per cubic meter. While MBR 300 demonstrates a density within 2100 grams per cubic meter.

Application of thixotropic solution

If the surface is well prepared, has a rough texture, and does not require a primer, it is pre-moistened. In all other cases, the range of operations discussed above is carried out. In any case, before applying the base solution, the concrete should be damp, but not shiny.

The thickness of the applied solution can vary from 6 to 35 mm

Proper preparation of the solution:

- the required number of bags is opened immediately before mixing;

- A small amount of water is poured into the mixer. For 25 kg of dry mixture, 3.9-4.0 liters of water are required;

- the equipment is turned on, after which dry powder is continuously poured into the mixer;

- the composition is mixed for 1-2 minutes until it becomes homogeneous;

- if required, add a small amount of water, mix the solution again for 2-3 minutes;

- to reduce the risk of shrinkage deformations, it is recommended to use a moisture-retaining additive when mixing;

- To mix a small amount of solution, it is permissible to use not a concrete mixer, but a clean container and a drill with a paddle attachment. With this method, mixing takes 5-6 minutes;

- The viability of the solution, regardless of the preparation method, is 60 minutes. To prepare 1 m3 of working mixture you will need 1800 kg of dry thixotropic powder.

The solution's water requirements are indicated in the table.

| Method of application to concrete | Volume of water per 25 kg thixotropic composition |

| Spatula | Minimum quantity – 3.75, maximum – 4.0 |

| Spray | Minimum quantity – 3.9, maximum – 4.1 |

Manufacturers of repair mixtures

Repair mixture for concrete "Emako" is produced in Russia. It is used to restore concrete structures that have serious or minor damage. This composition is capable of eliminating five different degrees of damage.

The first degree involves the presence of shells, shrinkage cracks, and contamination. The maximum depth of damage is 5 millimeters. To eliminate such errors, you should use a mixture of the Emaco N 5100 brand.

The second degree of damage involves peeling of the surface and the presence of minor chips. In order to get rid of such shortcomings, you should use compositions of the Emaco N 900 and Emaco N 5200 brands.

The third degree involves the occurrence of cracks within 1-2 millimeters and rust. The maximum depth of damage is 40 millimeters. If you choose repair mixtures for restoring concrete with such errors, then it would be best to purchase compositions of the Emaco S 488 PG, Emaco S 5400 and Emaco S 488 brands.

The fourth degree is cracks that are larger than 0.2 millimeters. In this case, exposed reinforcement may appear and carbonization may occur. The maximum depth of damage is 10 cm. It is best to purchase Emaco T1100 TIX, Emaco S560FR or Emaco S 466 mixtures to eliminate such damage.

The most recent damage is grade five. In this case, the reinforcement may be exposed, and there may be deep cracks on the surface. The depth of the damage exceeds 20 cm. The Emaco Nanocrete AP mixture will help protect the reinforcement from the effects of corrosion. If you decide to use the above-mentioned brands of repair compounds, then you will have to pay from 13 to 26 dollars per 25 kg.

Manufacturing jobs

The solution is spread on horizontal and vertical surfaces manually using a spatula, trowel or trowel, or using the wet torquetting method. In this case, the layer is smoothed.

If the working conditions are such that it is necessary to create a layer over 35 mm in thickness, the thixotropic solution is applied in two approaches. The second and all subsequent layers are realized when the previous one has set, but has not completely hardened .

When applying a layer thicker than 50 mm, reinforcement is necessary.

The grid is set up like this:

- the gap between the reinforcement and the base should be 10 mm;

- the thickness of the protective layer above the mesh cannot be less than 10 mm.

If a mechanized method (spraying) is used, special equipment is used. After completion of work, both equipment and tools are washed with water.

Features of Ceresit repair mixtures

Repair mixture for concrete "Ceresit" is perhaps the most widespread on the building materials market. It has excellent restoration properties for all kinds of concrete surfaces and bases. After application, the composition forms a non-shrinking plug that is resistant to frost and water. It will reliably seal all cracks and leaks. You can purchase this composition at a higher price compared to other mixtures; the price varies between $41 per 25 kg. However, this mixture will be compensated by superior quality.

Quality control

Control is realized by external inspection

Three days after the repair, the quality of the work performed is checked. There should be no visible peeling or cracks on the surface. If such defects are found, this indicates errors in the use of the material. It is necessary to carry out repeated repair work.

If a more in-depth test is required, a method is used to assess adhesion strength, compressive strength, and the waterproof grade of concrete is also determined.

Tips for choosing a concrete repair mixture

The repair mixture for concrete should be selected depending on the type of defect, the expected load during operation, and the size of the damage. If there is a need to strengthen the base, then the most suitable option is the use of a deep-penetrating primer mixture. If you are choosing a concrete repair mixture that should help strengthen a vertical surface or concrete structure, you should prefer thixotropic compounds. Such mixtures have a thick consistency and excellent adhesive properties. This means that they adhere quite well to the surface of the walls.

Safety precautions

Dry thixotropic compounds contain cement. The material may cause irritation to mucous membranes and skin. Avoid contact of the mixture with eyes and skin. If this happens, the affected areas are thoroughly washed with water, then consult a doctor.

Persons at least 18 years of age are allowed to work . All personnel must undergo medical examination, training, and TB instruction. If work is expected to be done at height, ladders and scaffolding are used.

conclusions

Modern thixotropic mixtures can be confidently used for repairing and leveling concrete structures. The material is easy to use, available at an affordable price, and can be easily applied even to vertical surfaces. The only limitation that you may encounter is that work can be carried out at temperatures above +5 degrees . If you need to eliminate a defect in winter, it is better to turn to polymer compositions.

Details of concrete repair using the thixotropic composition Profscreen are shown in the video:

review, characteristics, application. Repair mixture "Emako"

Speaking about concrete foundations, you can’t help but think that these surfaces are durable and strong, but even such structures do not last forever. During operation, exceeding technical capabilities and simply wearing out parts, surfaces, structures, cracks, chips, and other defects appear on them, which lead to partial or complete destruction. Fortunately, at the present stage of construction and the development of technological progress, there is no need to carry out major replacements or repairs. It is enough to carry out restoration work, armed with a special system, and seal/blow out the cracks with a non-shrinking mixture.

Let's talk in more detail about what it is and how to use it.

Features of repair mixtures for concrete

Reliable adhesion of the composition and the concrete base is ensured by a specially selected component composition. Restoring mixtures differ in the following characteristics:

- are not afraid of frost;

- resistant to sudden and unpredictable temperature changes;

- vapor permeable;

- durable;

- high strength;

- with an increased level of grip;

- have antiseptic properties;

- water-repellent properties are increased.

When is it necessary to treat a concrete structure with a non-shrinking mixture?

Long-term use of concrete structures, active use of concrete foundations, or violation of construction technology sometimes leads to the formation of defects on the surface and inside the concrete. Today there is an excellent opportunity to correct them by purchasing a special composition. This mixture will be needed for concrete reconstruction if you notice:

- presence of potholes in the concrete base;

- open cracks from 0.3 mm;

- dust formation exceeding permissible standards;

- the presence of voids in the concrete structure;

- pockets of deep or surface corrosion of concrete;

- chipped structures with exposed reinforcement elements;

- presence of defects from 0.2 mm.

At least one of these “flaws” signals that it is worth restoring it using a special non-shrinking mixture.

Variety of mixtures for concrete reconstruction

Depending on the purpose and scope of repair work, such compositions are divided into:

- Special mixtures that restore concrete structures (for columns, beams, slabs).

- Compositions used mainly for repairing road and floor coverings.

- Special non-shrinking mixtures for concrete repair, characterized by protective anti-corrosion properties.

Brief description of each type

The former are ideal for leveling or sealing cracks in load-bearing concrete structures.

The latter are characterized by distinctive frost resistance, increased protective and water-repellent properties, and excellent adhesion.

The third and last ones are used when it is necessary to prevent mold, fungus and corrosion formations on concrete.

Repair mixtures for vertical and horizontal surfaces: what is the difference

Another classification that should not be forgotten is whether the compositions belong to:

- mixtures used for work on vertical surfaces;

- mixtures suitable for use on horizontal planes.

The former are characterized by such qualities as increased reliability and strength, since horizontal surfaces are susceptible to the influence of extreme loads, which is not difficult to assume.

The second - for vertical surfaces, have an increased level of adhesion, ensuring reliable adhesion.

Shrinkable and without

Assuming that if we are talking about non-shrinking mixtures, then there are also those that shrink.

Those that shrink require more painstaking work, since in this case it is necessary to calculate the required thickness of the layer, which shrinks after a certain time. This results in the need for reprocessing for higher reliability. But the use of shrinkage mixtures also takes place in the construction industry, moreover, one cannot say anything bad about them.

In turn, non-shrink dry concrete mixtures are distinguished by the following positive characteristics:

- increasing the speed of completion of all stages of repair and restoration work;

- high level of productivity;

- ease of use;

- excellent strength;

- durability.

Review of popular domestic repair mixture

What kind of composition is this that has received many positive reviews from customers? Let’s open the curtain and present to the reader the sensational repair mixture “Emako” on the market.

The composition is used for the restoration of concrete structures, regardless of the type of complexity of the defect, which makes it universal in use, and, therefore, promotes it among competitors.

The manufacturer made sure that the product line was as useful, diverse and accessible as possible. Therefore, to restore concrete, the company produces products suitable for five categories of concrete damage:

- First: dirt, small shrinkage cracks and cavities not exceeding 5 mm. Best choice: mixture brand N 5100.

- Second: crumbling or peeling of surfaces, the presence of not too large chips. The best option: composition grade N 900, N 5200.

- Third: destruction accompanied by rusty smudges and cracks up to 0.2 mm and a maximum depth of damage of no more than 40 mm. Best product: composition brand S 488 PG, S 488, S 5400.

- Fourth: the presence of cracks from 0.2 mm, bare areas of reinforcing compounds, strong carbonization. Observation of damage with a depth of 10 cm. The best recommended brand of composition: T1100 TIX, S 466, S560FR.

- Fifth: characterized by severe damage due to exposure of fillers and reinforcement, the presence of deeper chips with a damage depth exceeding 20 cm. Best choice: Nanocrete AP - protection of metal elements from corrosion processes, repair mixture "Emako" A 640.

Please note that the price for all concrete mixtures from the stated manufacturer ranges from 13 to 26 dollars per 25 kg.

As you can see, a non-shrinking concrete mixture of poured type or dry composition can solve a lot of problems associated with the need to restore or repair a structure. Therefore, before you destroy and destroy something, despairing of finding a solution, seek help from a construction company, where they will help you by advising on the appropriate mixture option.

fb.ru